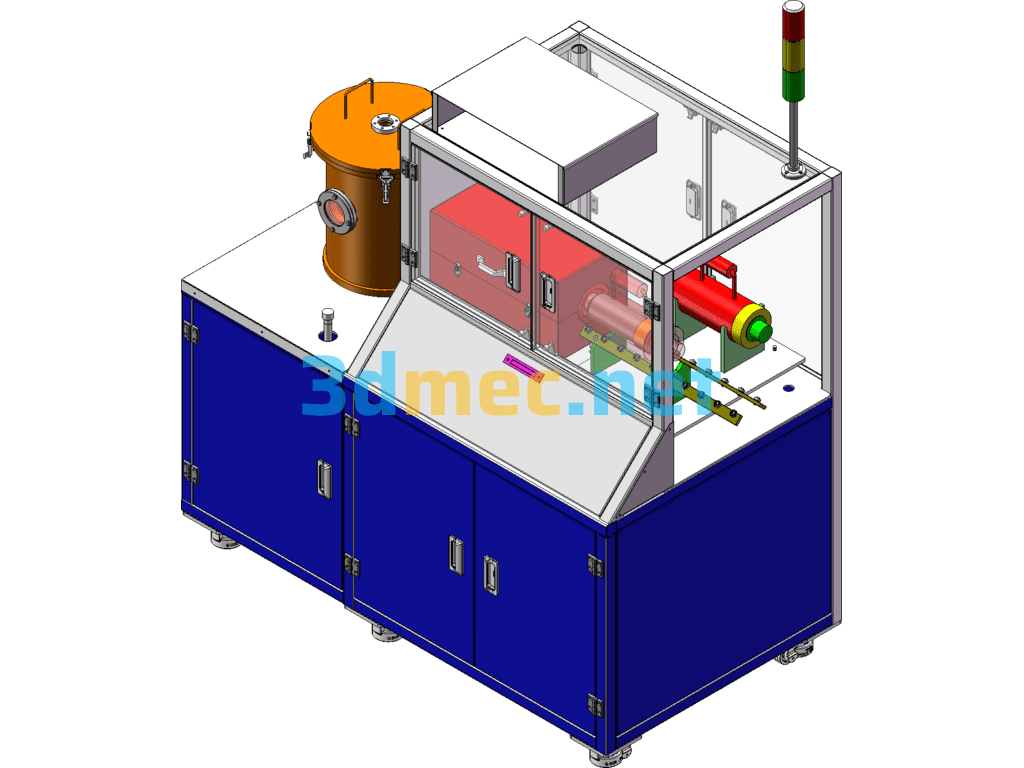

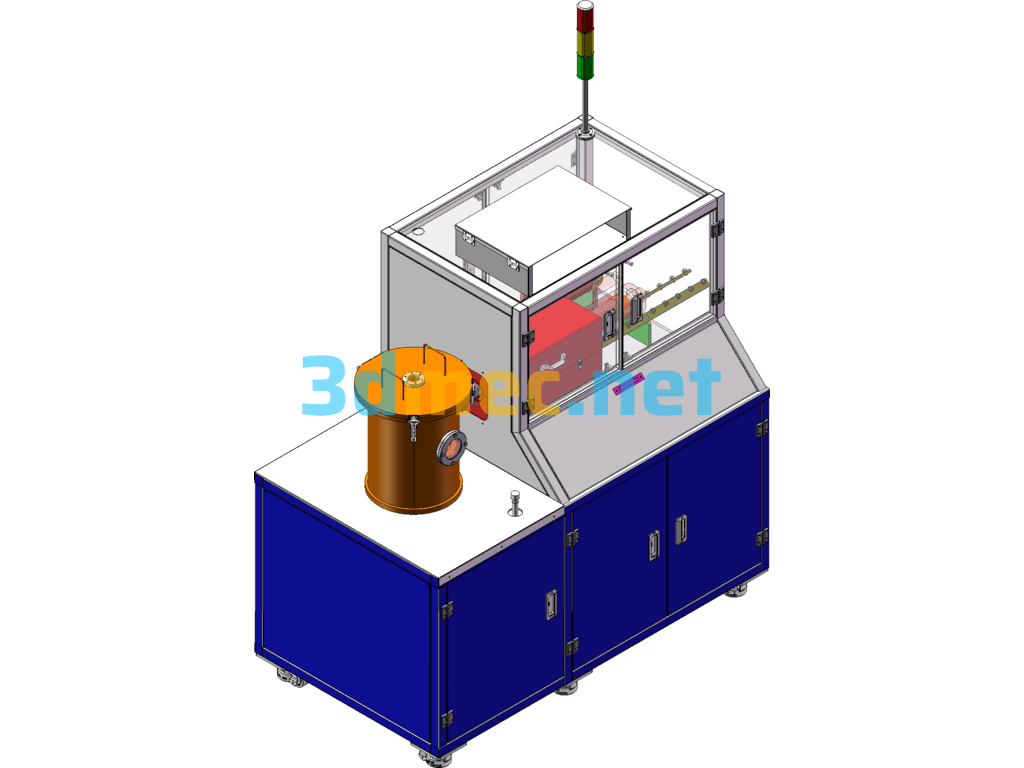

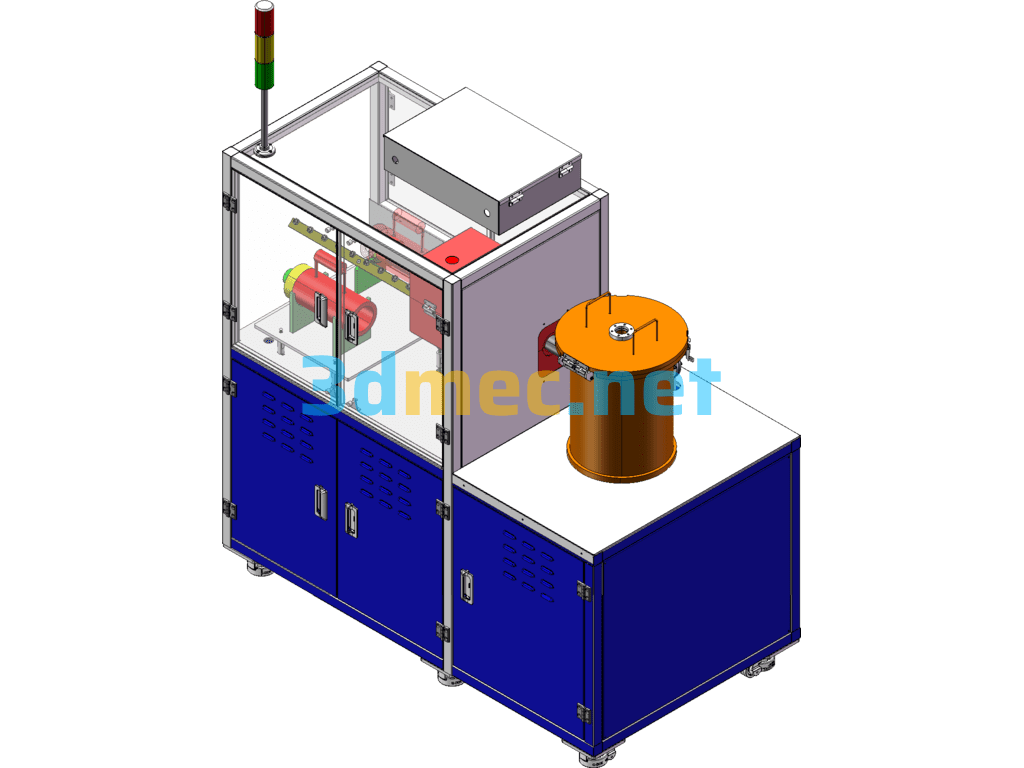

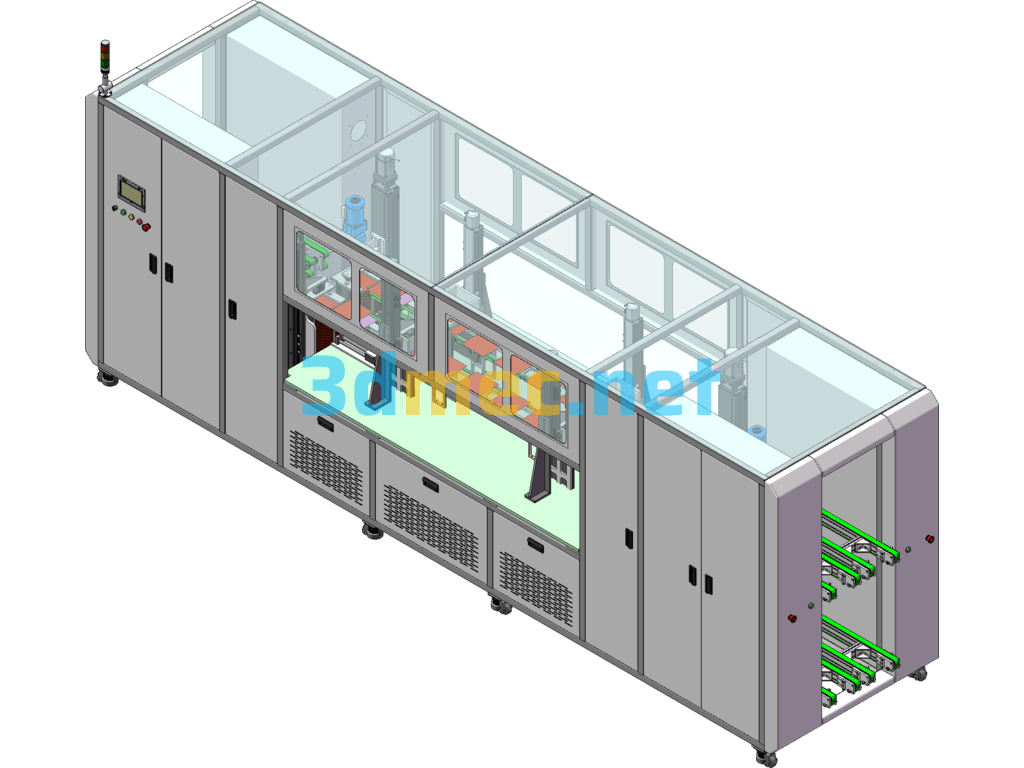

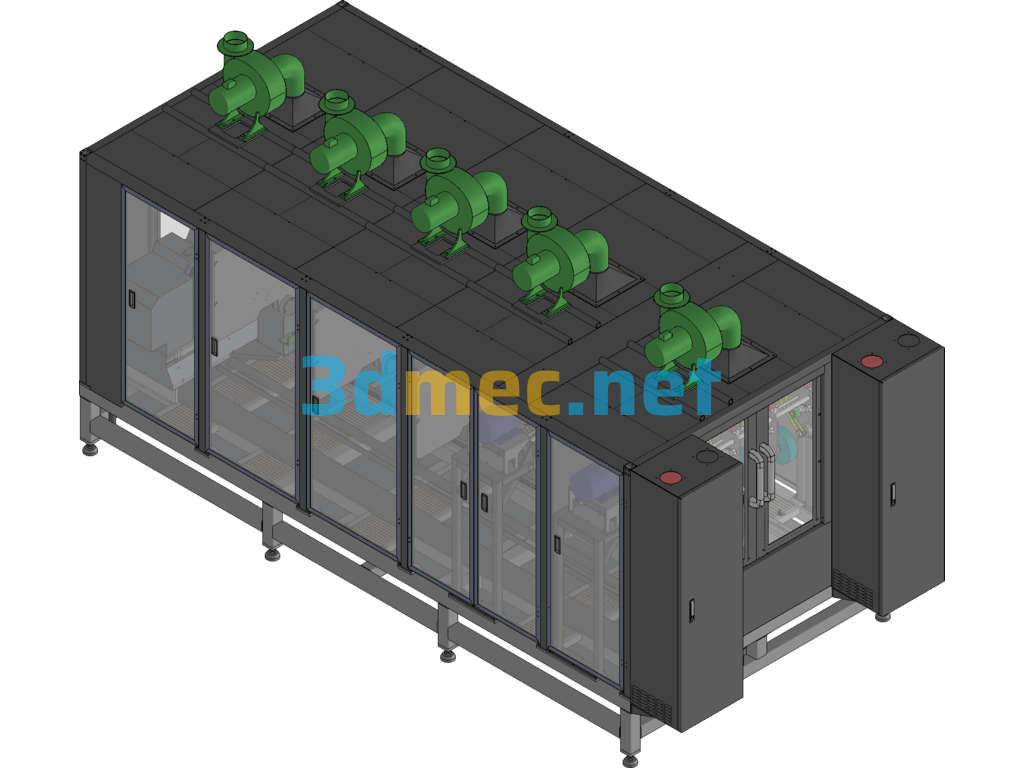

Automatic Vacuum Coating Machine – 3D Model SolidWorks

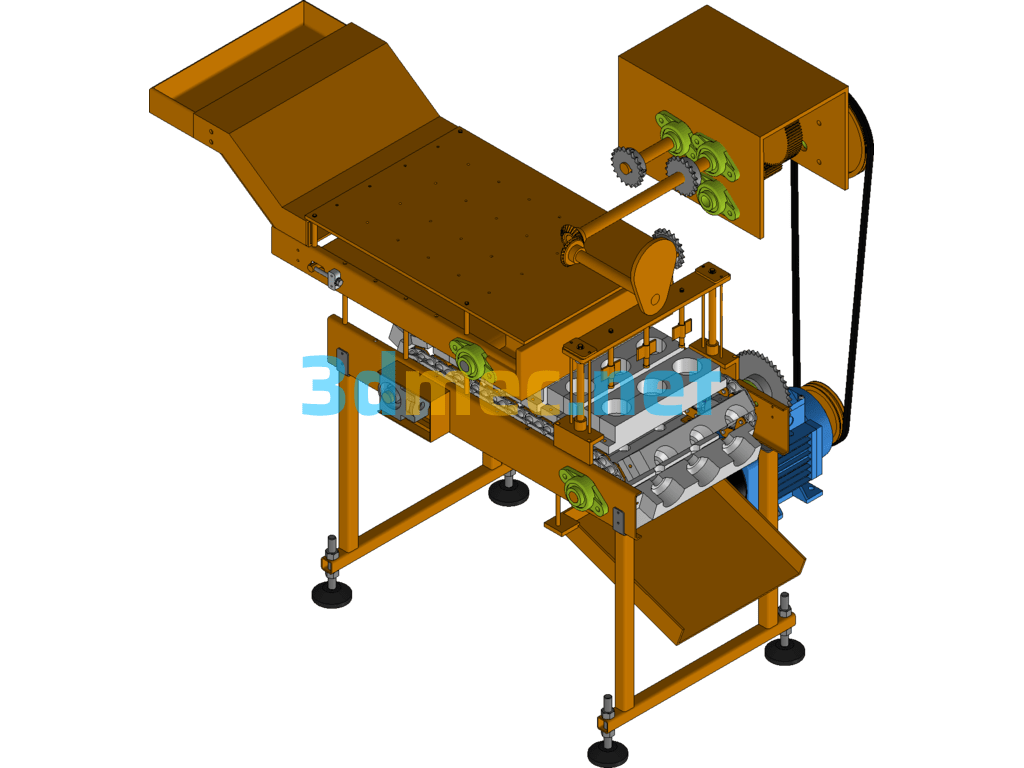

Small coating machines are mainly composed of coating tanks and sublimation heaters

Vacuum coating machines mainly refer to a type of coating that needs to be carried out under a higher vacuum degree. There are many types, including vacuum ion evaporation, magnetron sputtering, MBE molecular beam epitaxy, PLD laser sputtering deposition and many other types. The main idea is to divide it into two types: evaporation and sputtering.

The substrate to be coated is called the substrate, and the material to be coated is called the target. The substrate and the target are in the vacuum chamber.

Evaporation coating generally heats the target material to evaporate the surface components in the form of atomic groups or ions. And it settles on the surface of the substrate, and forms a thin film through the film forming process (scattered points-island structure-vagal structure-layered growth). For sputtering coating, it can be simply understood as bombarding the target material with electrons or high-energy lasers, and sputtering the surface components in the form of atomic groups or ions, and finally depositing on the surface of the substrate, undergoing a film forming process, and finally forming a thin film.

Specification: Automatic Vacuum Coating Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Vacuum Coating Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.