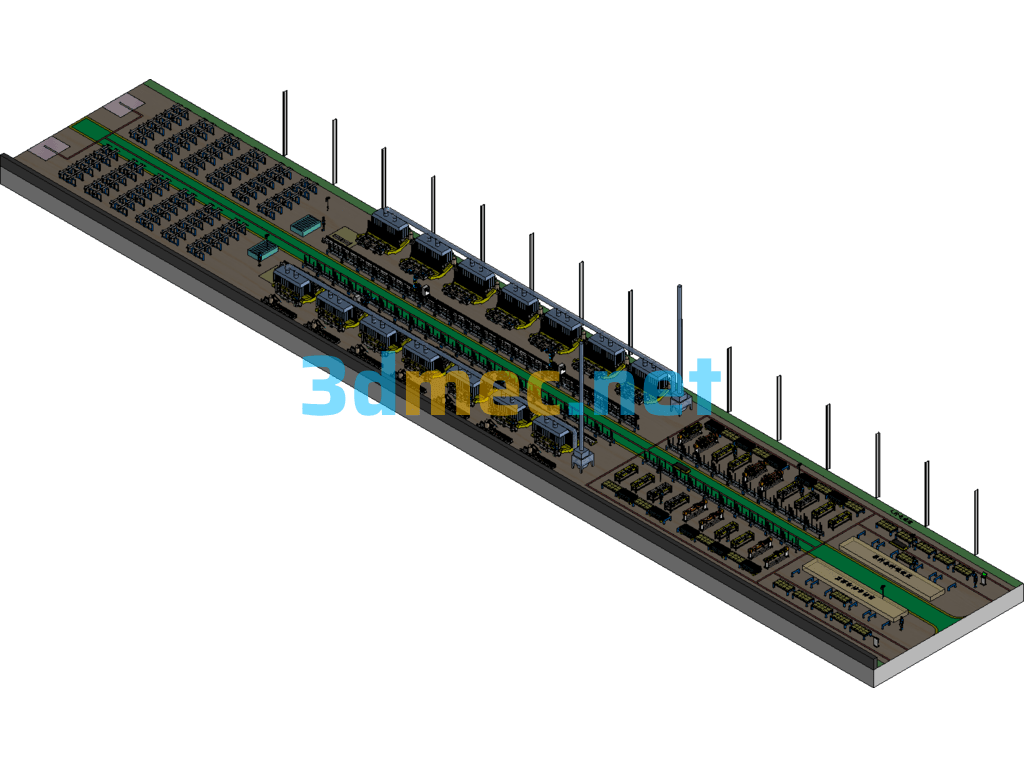

Automatic Unpacking, Loading, Conveying And Assembly (Including Detailed PPT Instructions) – 3D Model SolidWorks

Automatic unpacking, loading, conveying and assembly – DFM

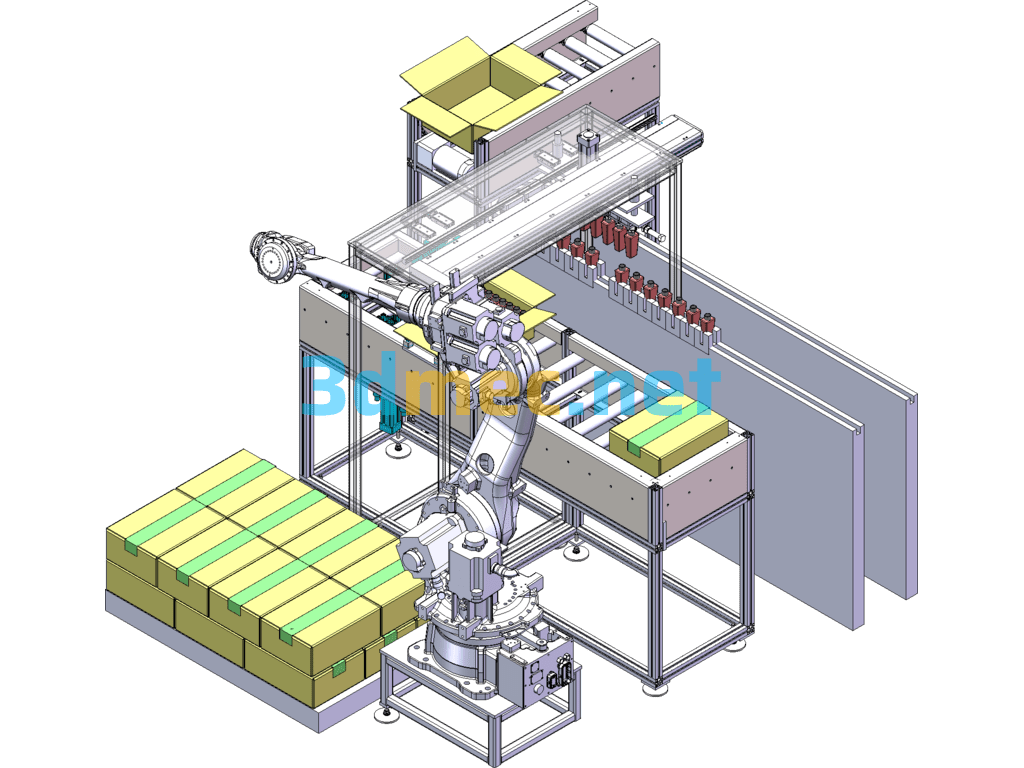

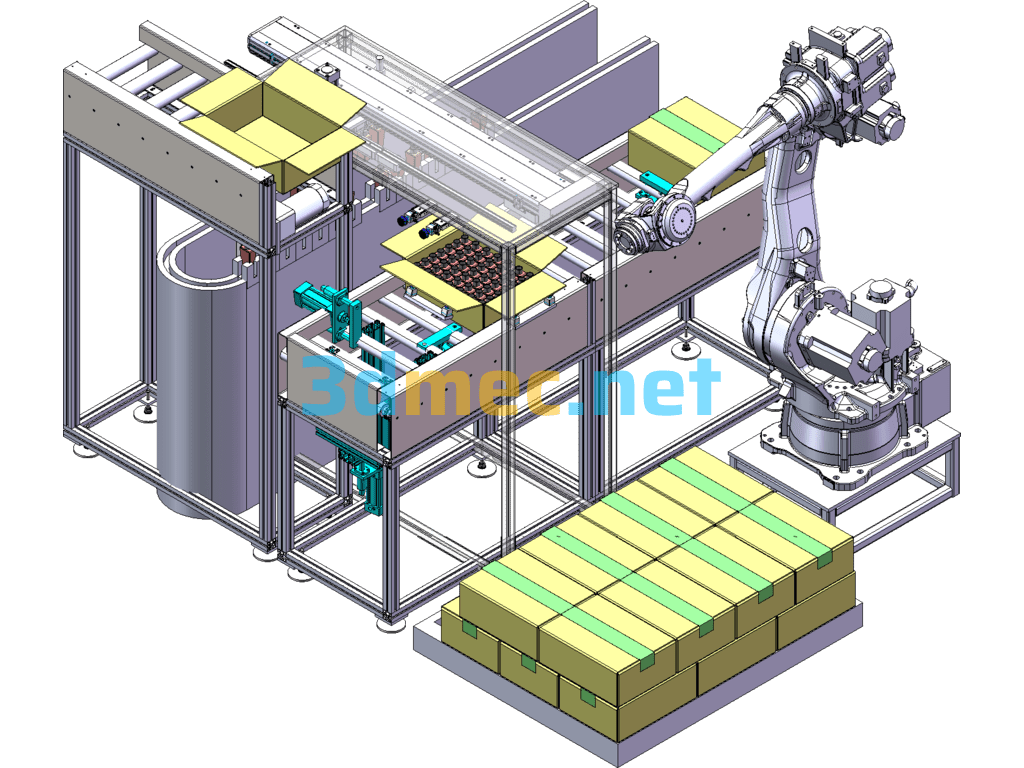

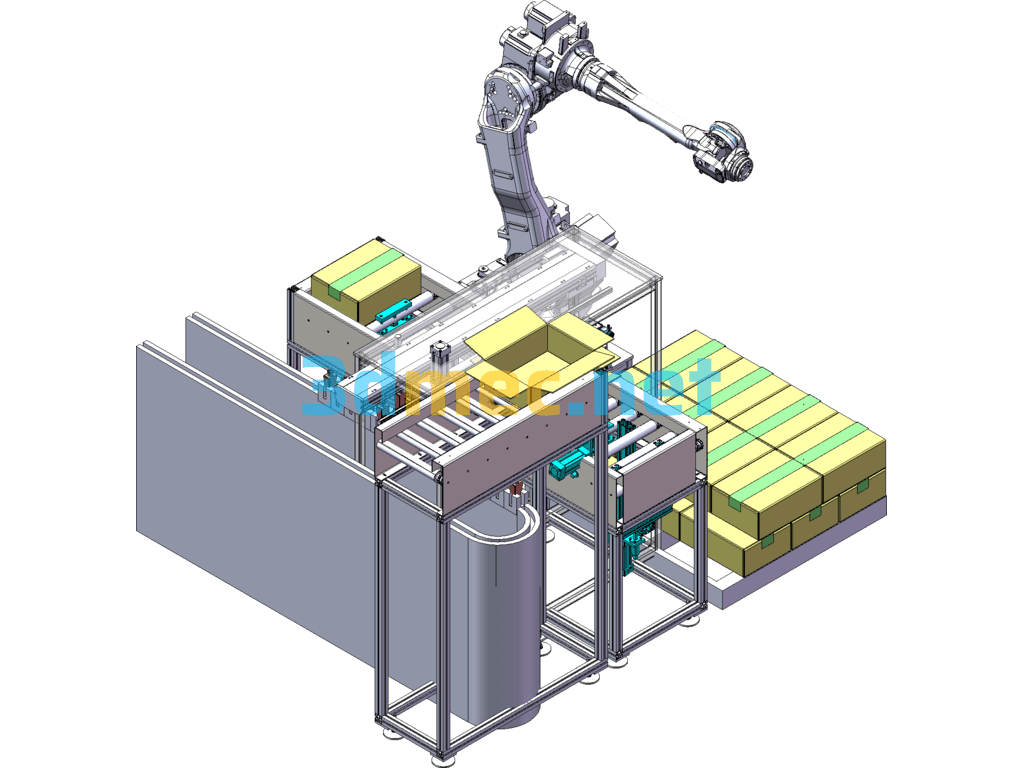

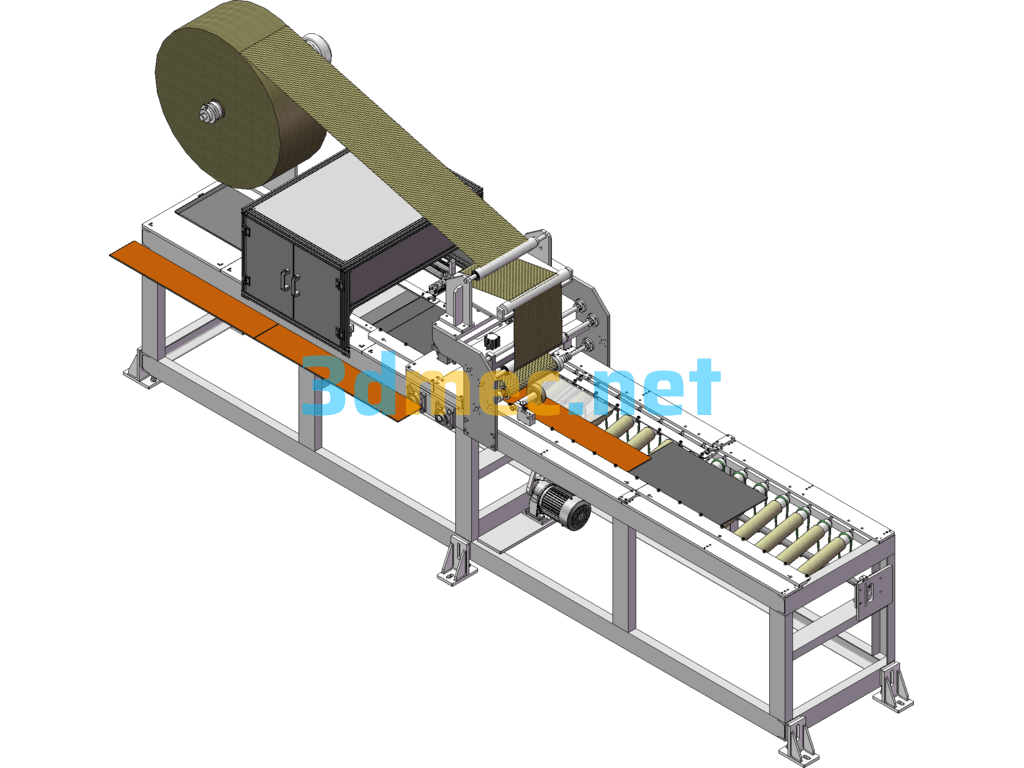

Automatic unpacking, loading and conveying. The robot locates, grabs the box and unpacks it. The module bottles go to the conveyor line and enter the main station

The camera on the robot takes a picture of the carton on the pallet to identify the opening direction of the carton. The suction cup sucks the carton and places it on the roller conveyor line. The blade cuts the tape on the carton. When the box is transferred to the loading point, the positioning mechanism positions the box, the suction cup opens the flange of the carton, and the servo picking robot takes the glass bottle and places it on the fixture assembly line. After taking it, the empty box flows out.

Requirements: Automatically pick and place incoming cartons, glass bottles, and automatically collect empty boxes

Process: Photo recognition of carton direction, positioning, automatic glass bottle pick and place, empty box discharge, incoming materials are 7×7 evenly distributed, 7×1 each time

Sample: Pallet size is 1200*1000, carton size is 390*290*143mm, glass bottle size is 50*126*20

Specification: Automatic Unpacking, Loading, Conveying And Assembly (Including Detailed PPT Instructions) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Unpacking, Loading, Conveying And Assembly (Including Detailed PPT Instructions) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.