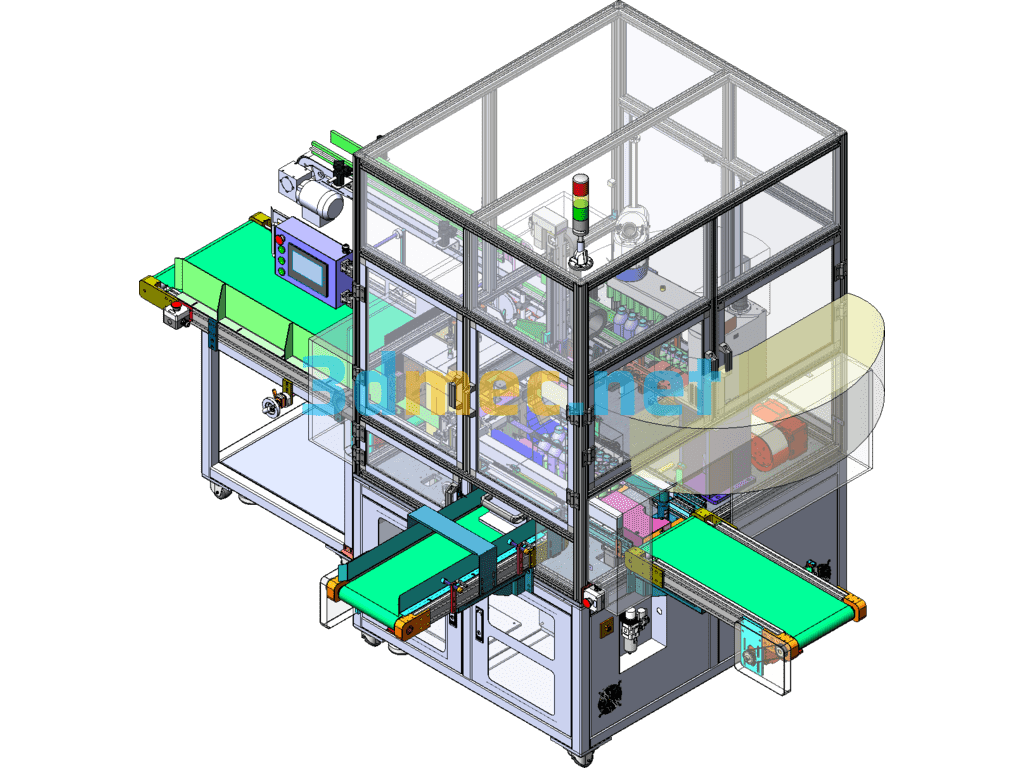

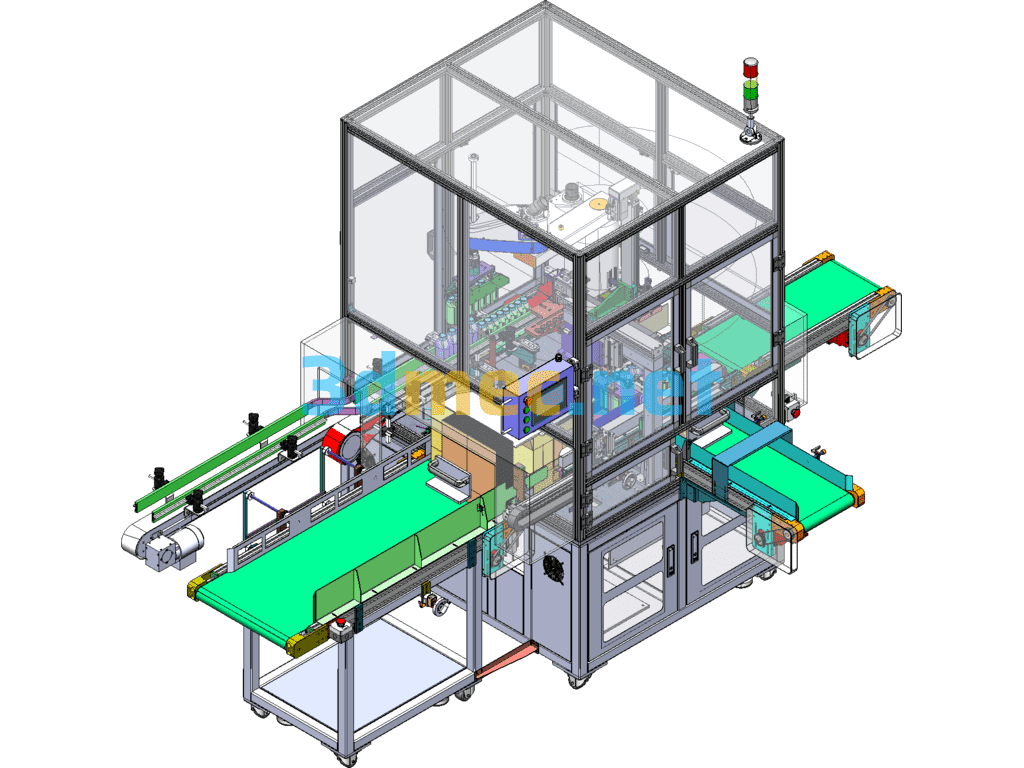

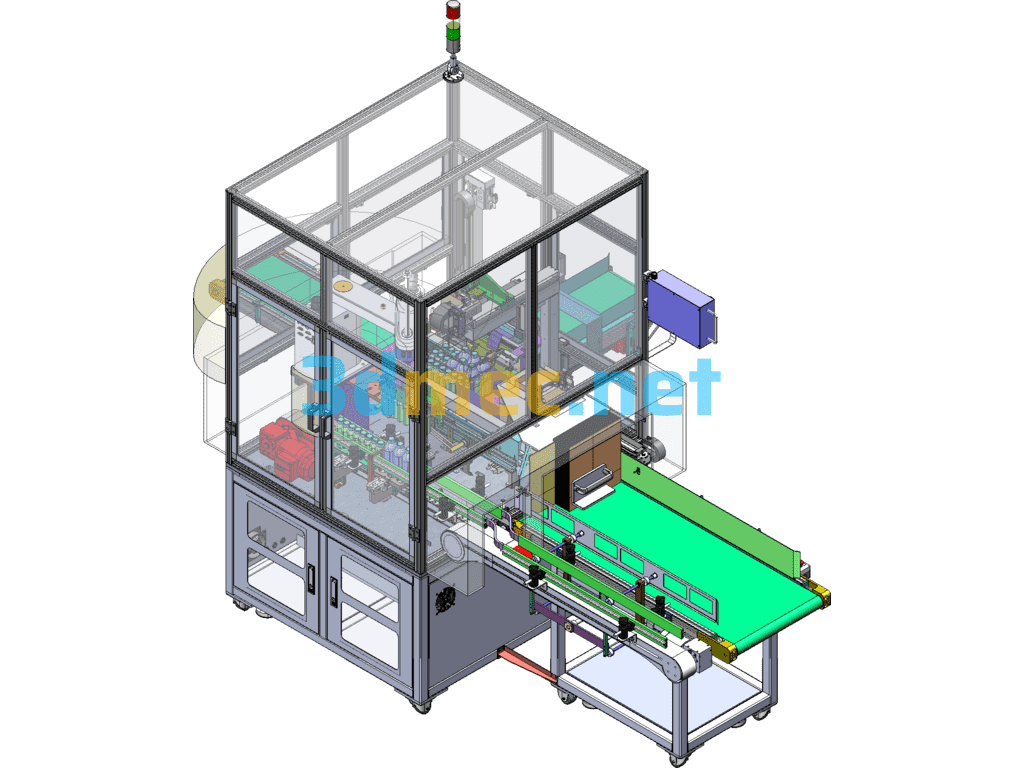

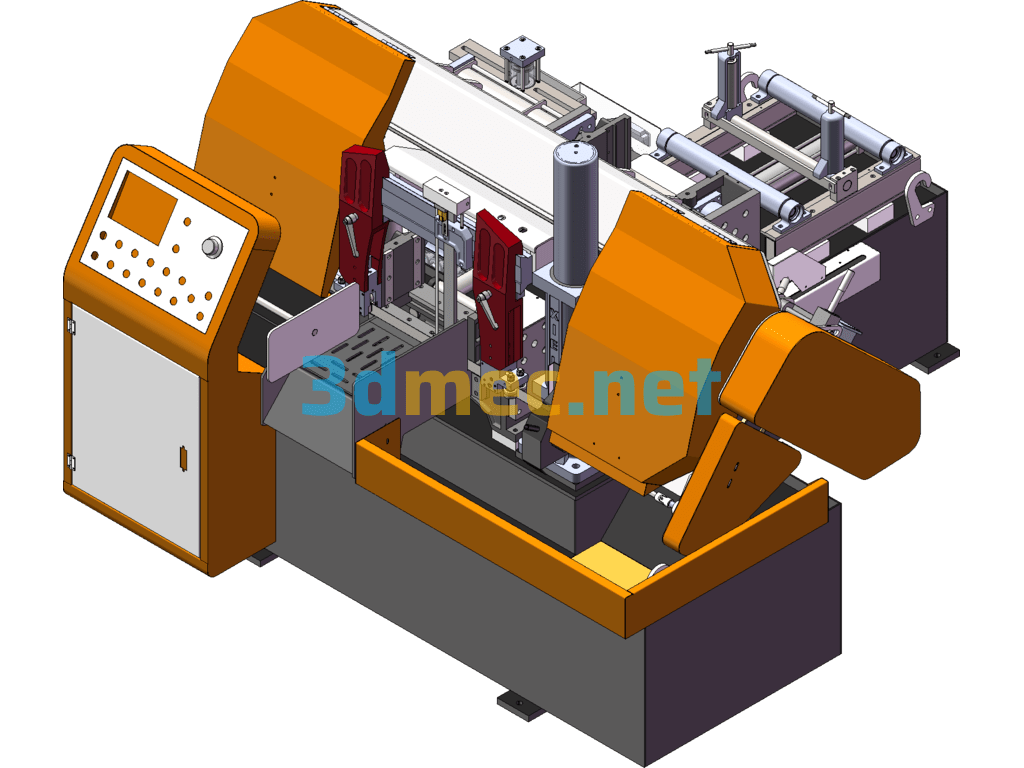

Automatic Unpacking And Packing Equipment For Medicine Bottles (With Generated DFM And BOM) – 3D Model SolidWorks

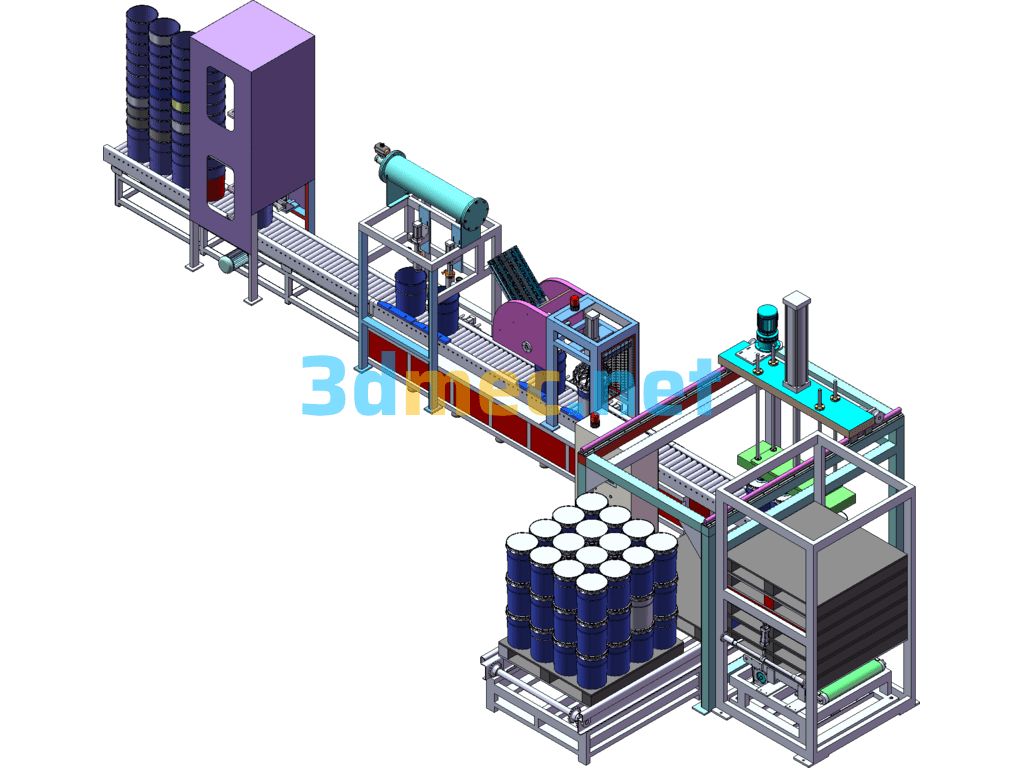

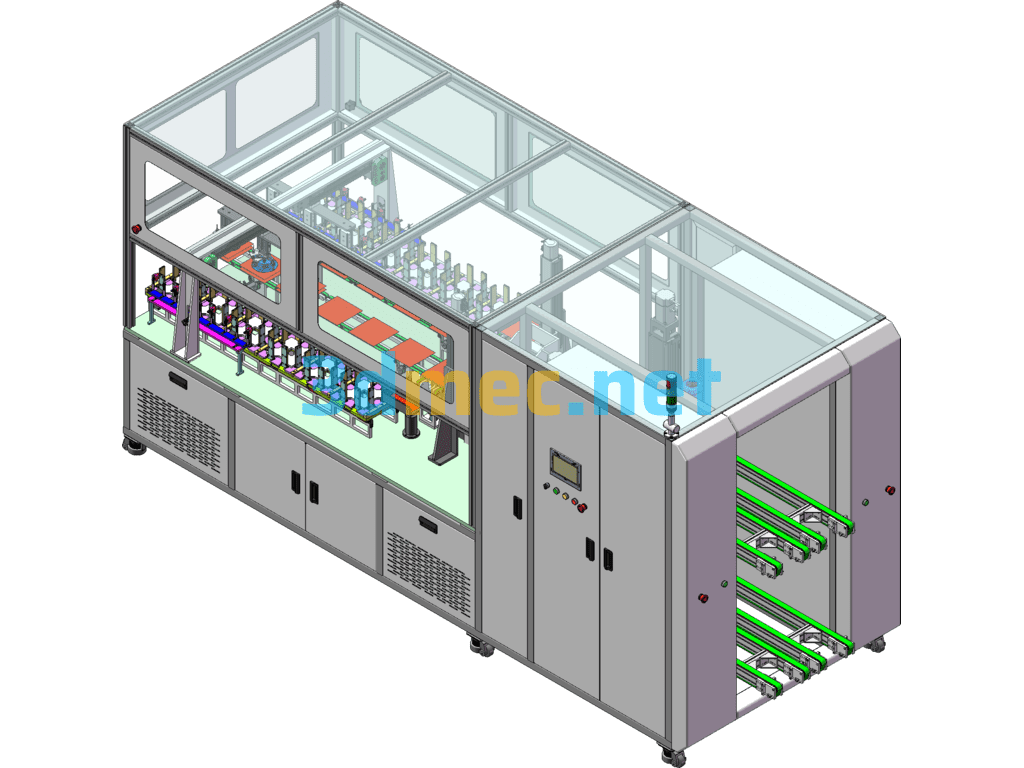

Brief introduction of the operation of the automatic unpacking and packing machine for medicine bottles:

1. The first row is loaded into the box on the left, and the first partition is inserted, and the partition module remains stationary;

2. The robot grabs the second row for packing, and the partition module is moved out;

3. After the partition module is moved out, the robot moves horizontally to the left to ensure that it is completely flush with the partition;

4. The partition module grabs the second piece and rotates it to put it into the box below the shoulder of the second row of bottles;

5. The robot grabs the third row of bottles on the right side of the box wall and puts it into the box;

6. The bottom of the third row of bottles forms a tangent angle with the shoulder of the second row of bottles to ensure the relative position of the partition, the partition module is loosened and moved out, and the robot moves downward to make the partition vertical, and assists in pressing down the partition and loading the bottles into the box at the same time (or the partition module presses down the partition for the second time).

Specification: Automatic Unpacking And Packing Equipment For Medicine Bottles (With Generated DFM And BOM) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Unpacking And Packing Equipment For Medicine Bottles (With Generated DFM And BOM) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.