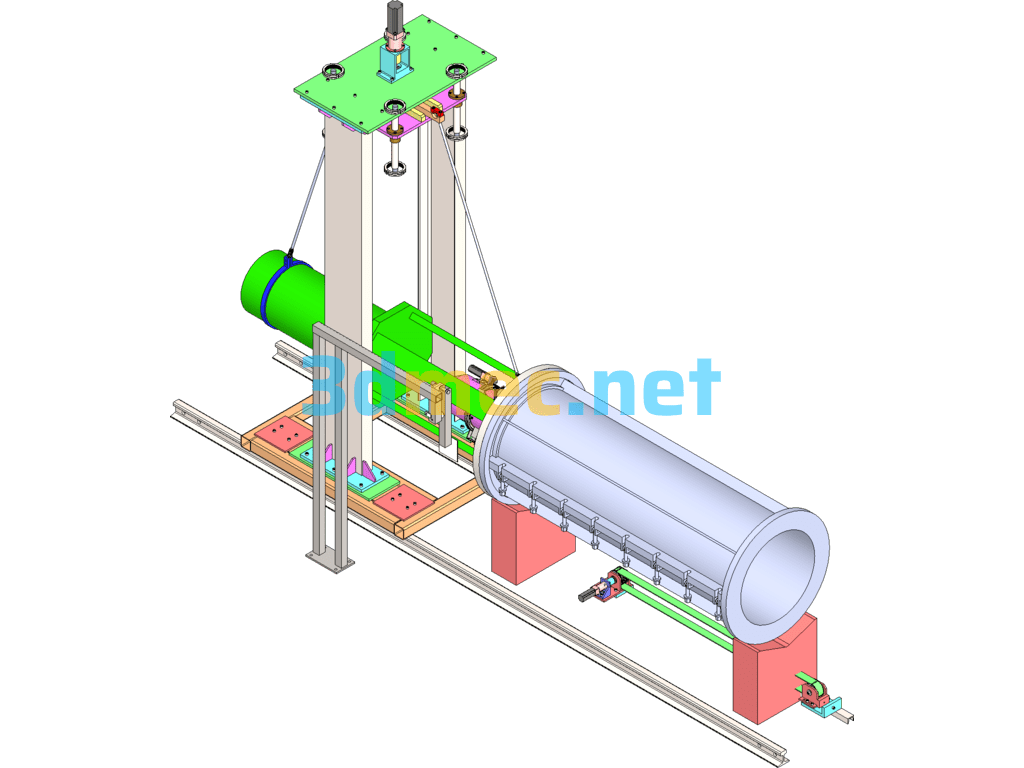

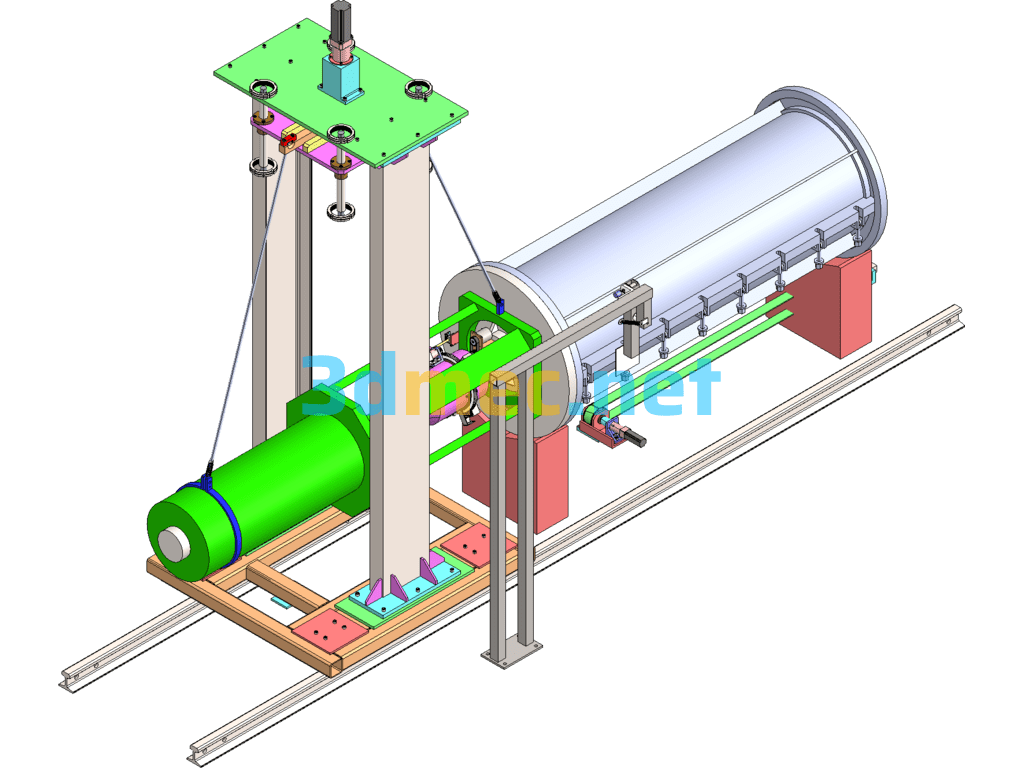

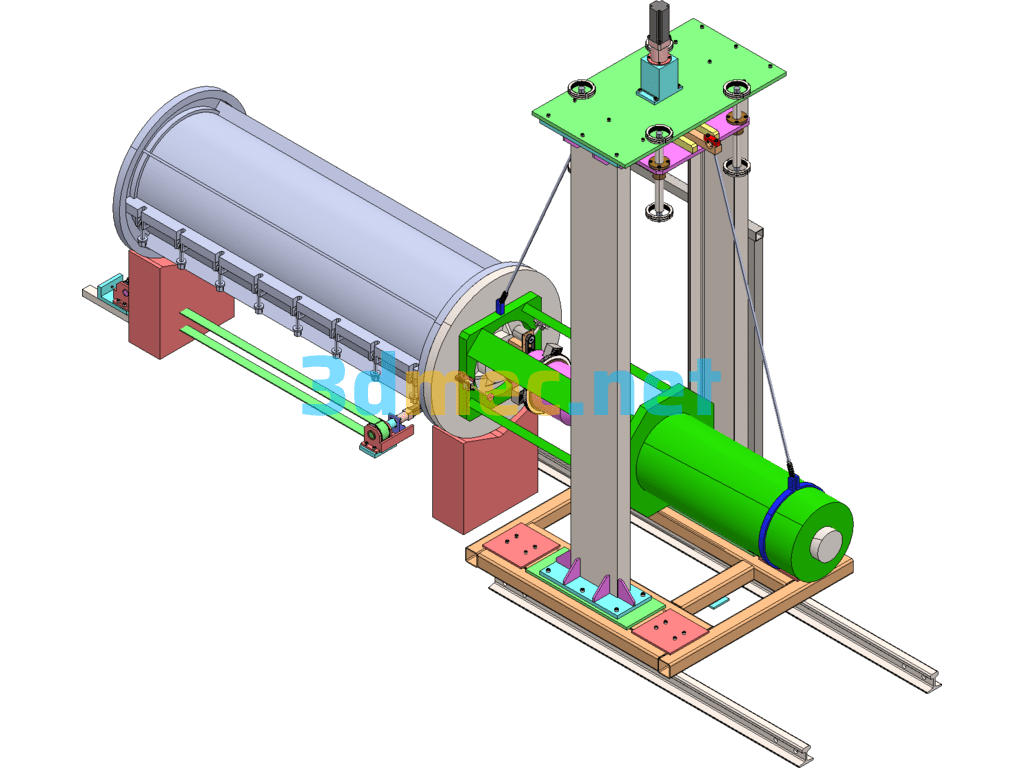

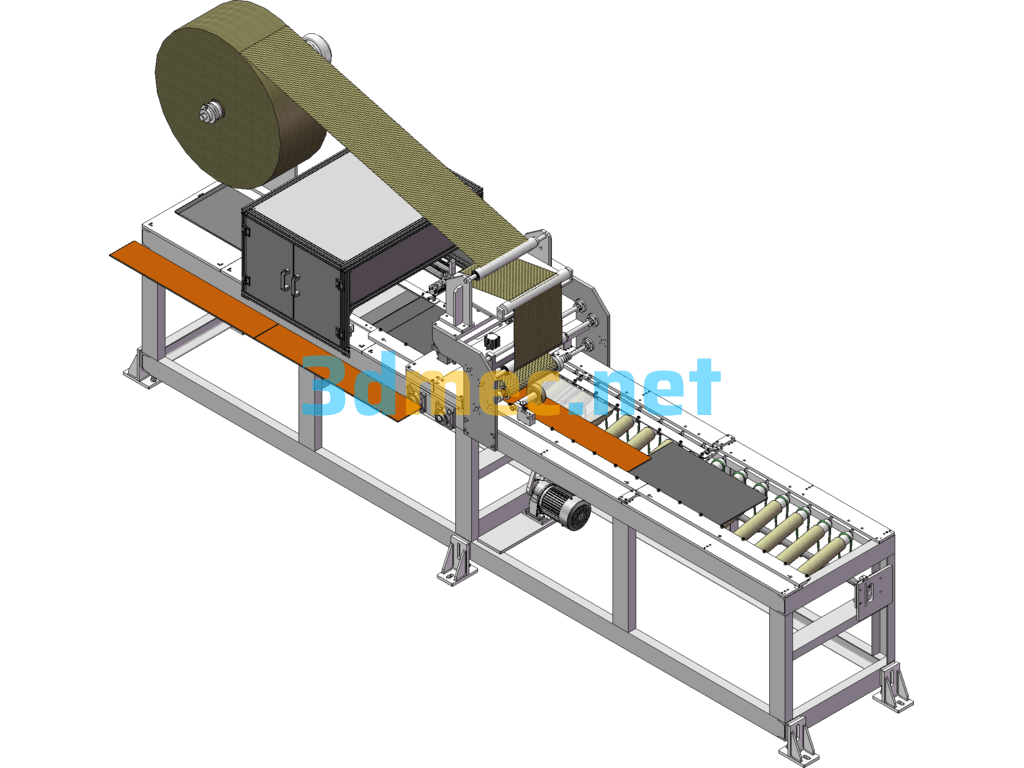

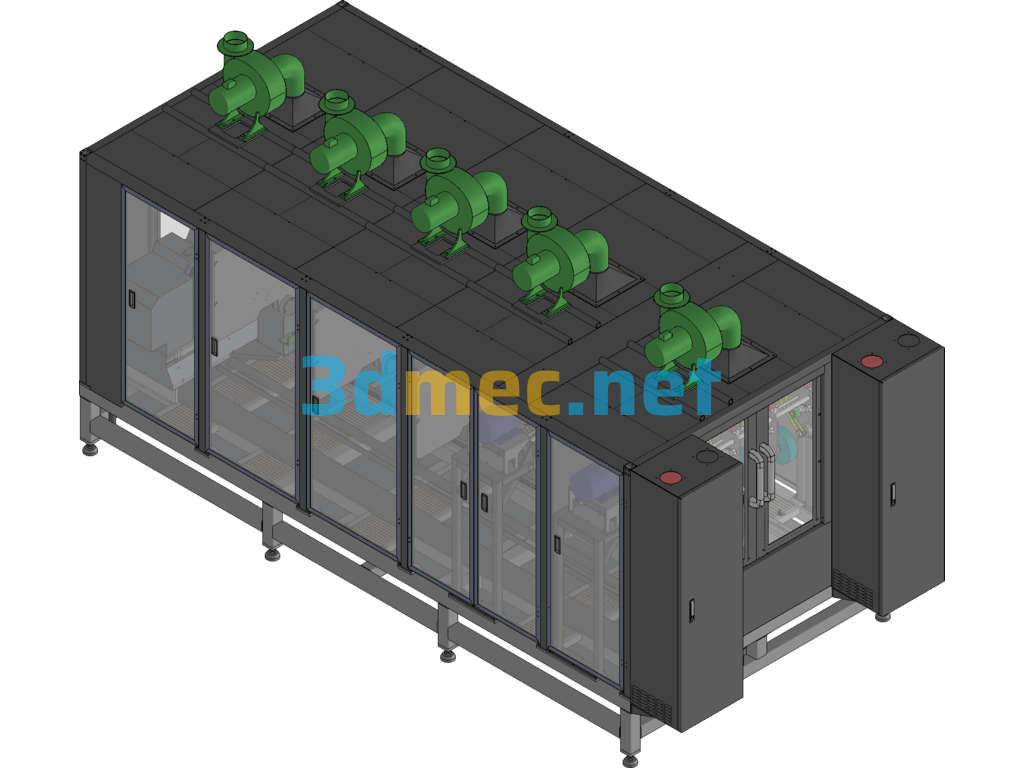

Automatic Tensioning Machine For Prestressed Pipe Piles Of Various Specifications – 3D Model SolidWorks

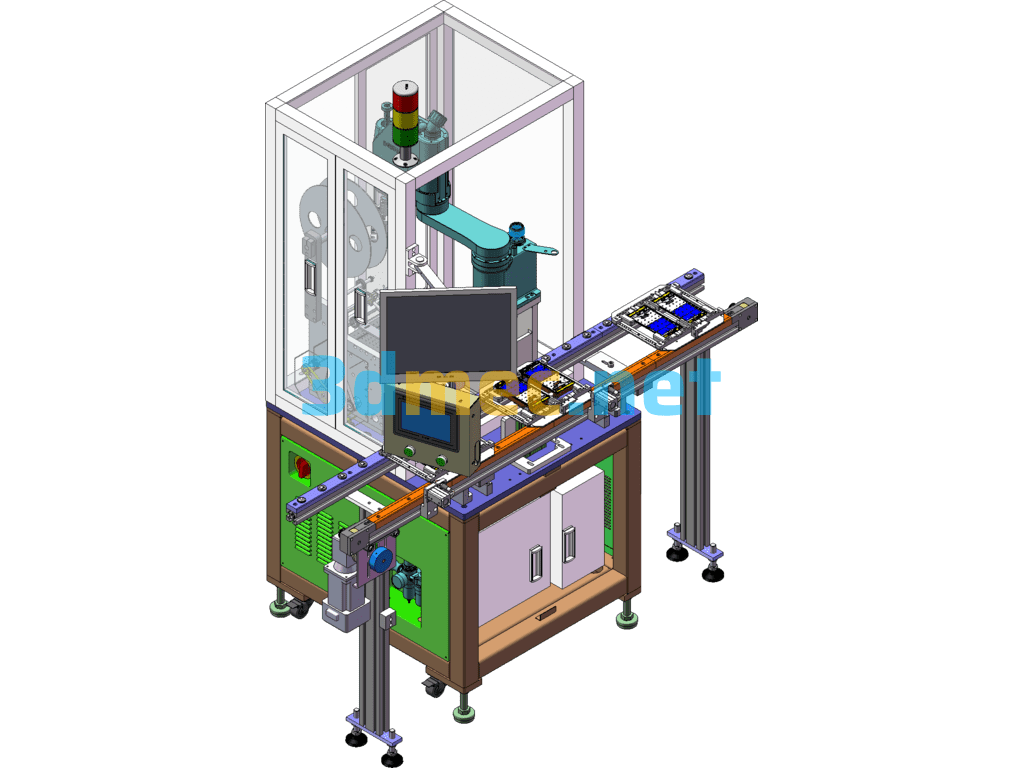

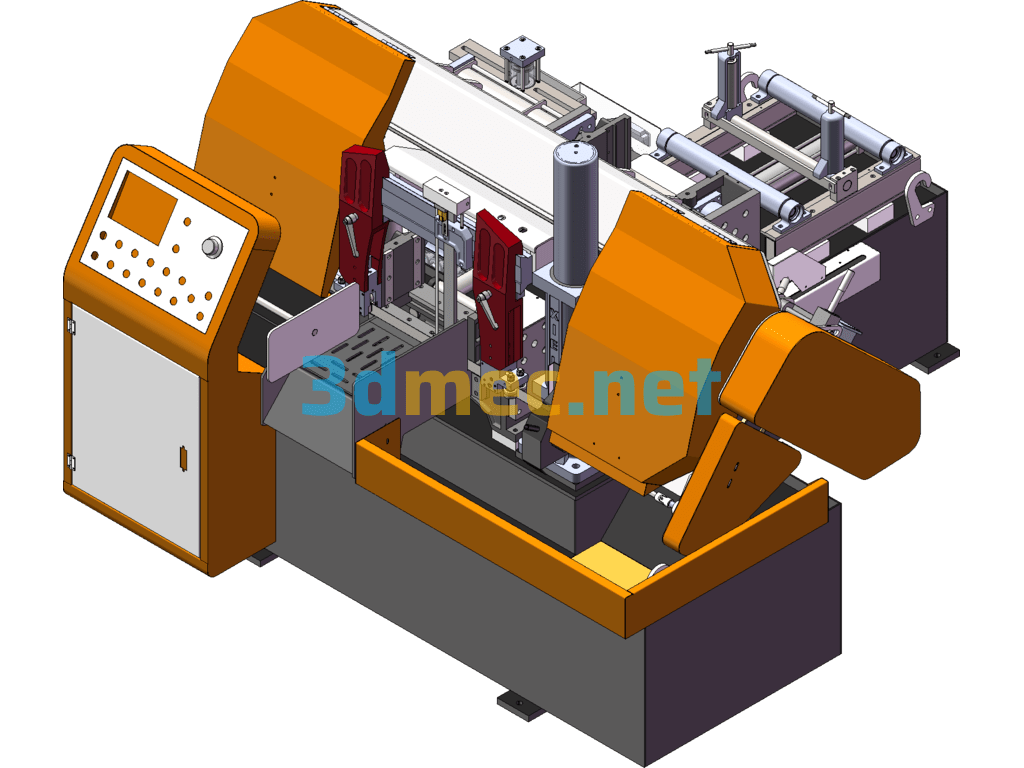

The automatic tensioning machine for prestressed pipe piles of various specifications includes a pipe pile mold assembly, a tensioning device, a lifting platform, a lifting platform horizontal displacement device, a pipe diameter detection device, and a connection locking device for connecting the tensioning device with the plate head pull rod. The tensioning device is driven by the lifting platform to adjust the height, and the lifting platform is driven by the lifting platform horizontal displacement device to adjust the distance between the pipe pile mold assembly and the lifting device. The connection locking device includes a conical connector fixedly connected to the plate head pull rod and a locking sleeve device fixedly connected to the tensioning rod of the tensioning device. The inner side of the conical connector is necked to form a tensioning step. The locking sleeve device includes a locking sleeve and multiple locking pins. The locking pins cooperate with the tensioning step to conveniently and accurately connect the tensioning device with the pipe pile membrane assembly. The tensioning machine can adapt to the tensioning of pipe piles of various specifications. It can be fully automated, liberate manual labor, and greatly improve production efficiency.

Automatic tensioning machine for prestressed pipe piles of various specifications, including

1 Pipe pile mold assembly

2 Pipe diameter detection device

3 Tensioning device

4 Locking nut device

5 Locking sleeve device

6 Guide rod sensor assembly

7 Lifting platform

8 Lifting platform horizontal displacement device

Pre-tensioning prestressed concrete pipe piles Precast concrete foundation piles, interpreted separately as; 1. “Pre-tensioning prestressing” is to tension the prestressed tendons before pouring concrete, and temporarily anchor the tensioned prestressed tendons on the pedestal or steel mold, and then pour concrete. When the concrete curing reaches no less than 75% of the concrete design strength value to ensure that the prestressed tendons and concrete have sufficient bonding, relax the prestressed tendons, and use the bonding between concrete and prestressed tendons to apply prestress to the concrete. 2. “Concrete pipe piles” are round pipe piles with concrete as structural strength.

Specification: Automatic Tensioning Machine For Prestressed Pipe Piles Of Various Specifications – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Tensioning Machine For Prestressed Pipe Piles Of Various Specifications – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.