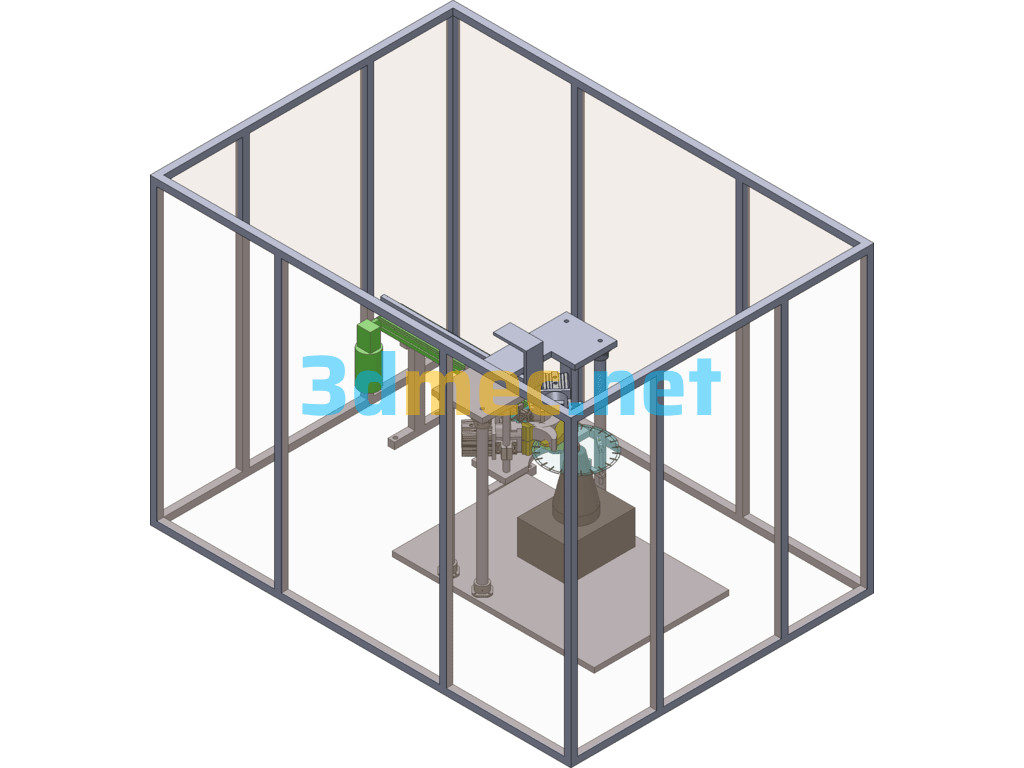

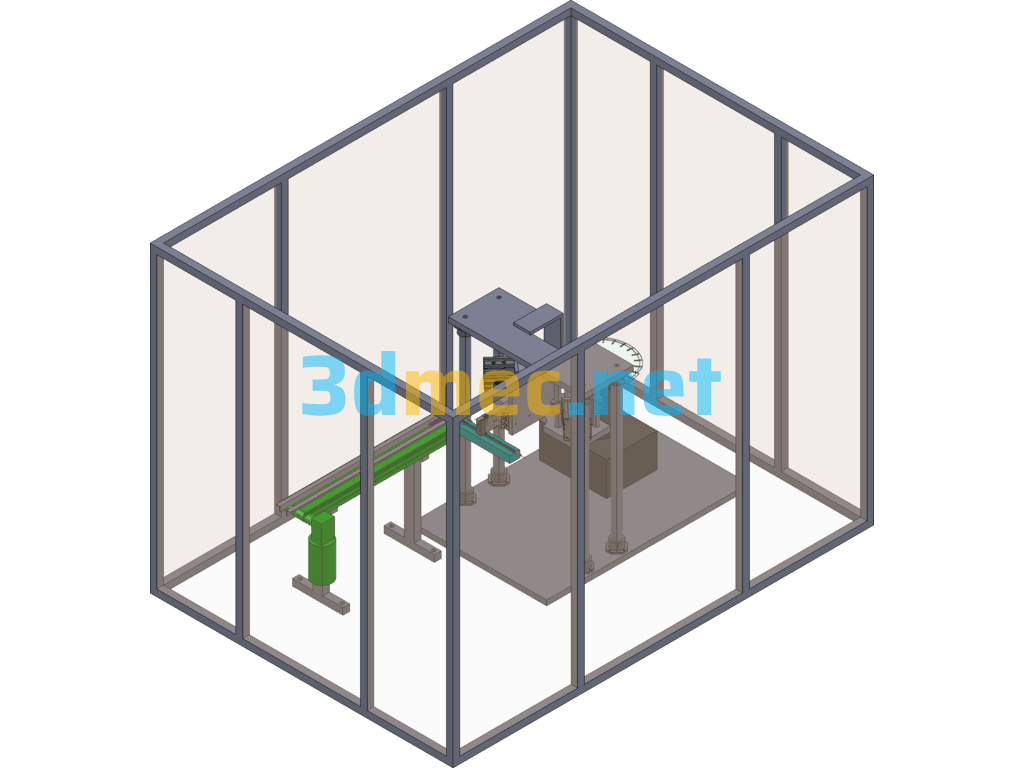

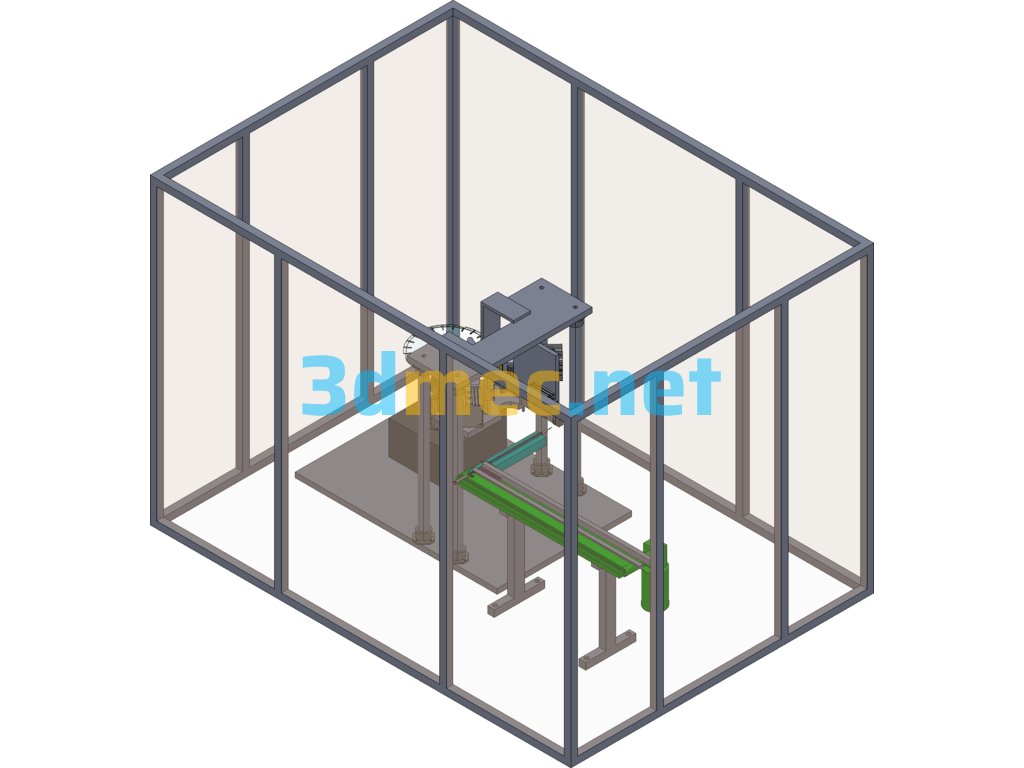

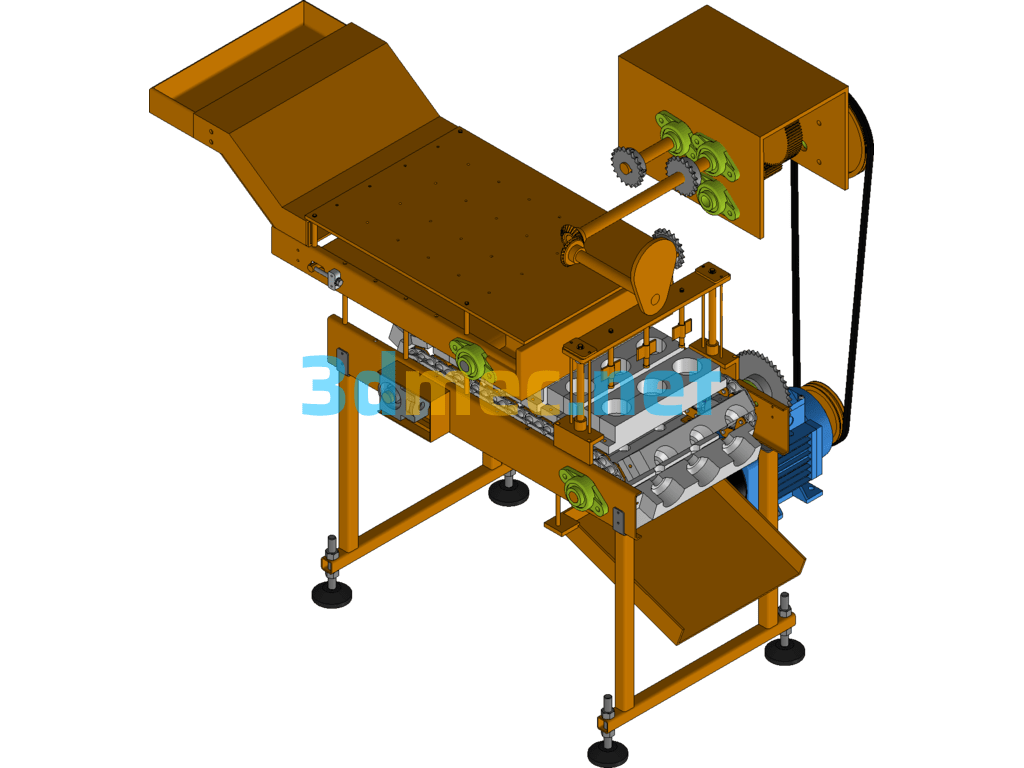

After the line conveying module grabs the feeding clamp and sends the cutter head to the clamping claw, it is clamped and maintained in position by the clamping claw and moved to the welding section. The two sets of clamps are used for positioning and preventing certain welding deformation

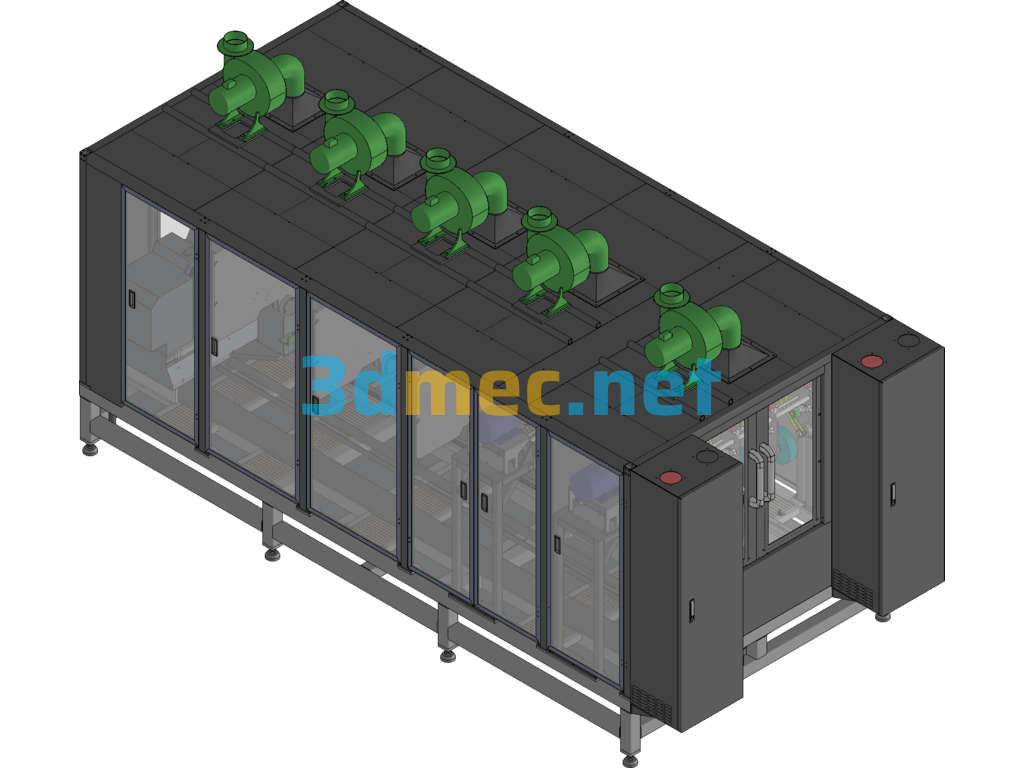

Welding is carried out in two times, one with low energy and fast speed, and the second time is welded firmly (single-sided welding and two-sided forming)

After welding, it is manually taken out and the equipment has been put into production and stable operation.

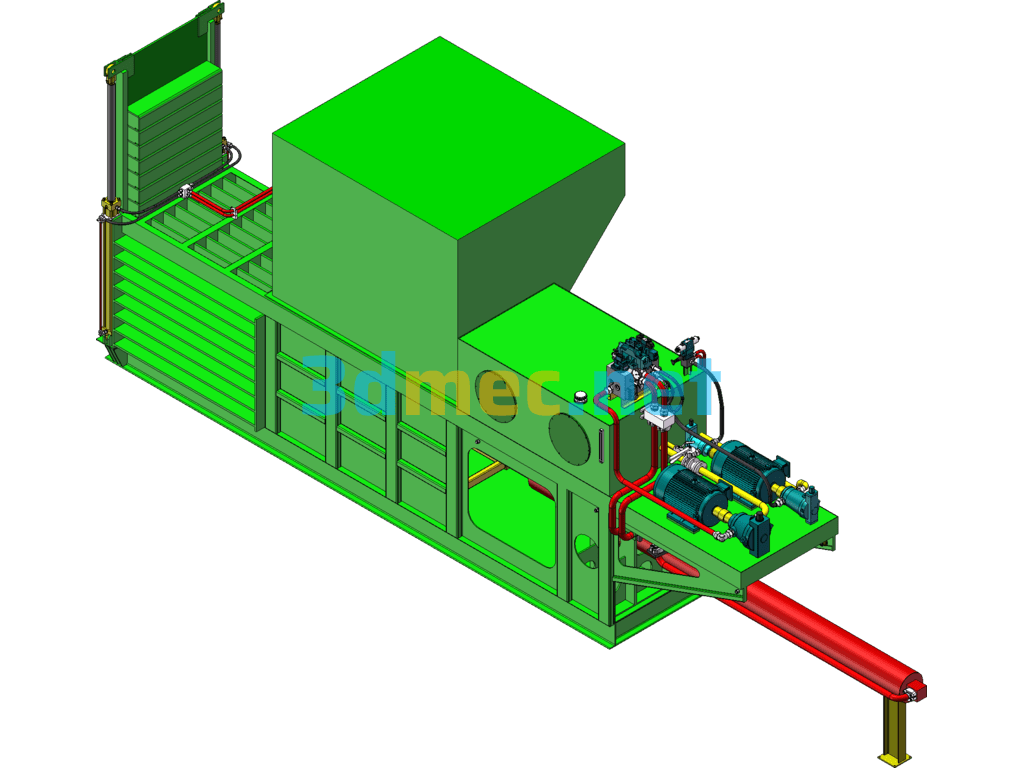

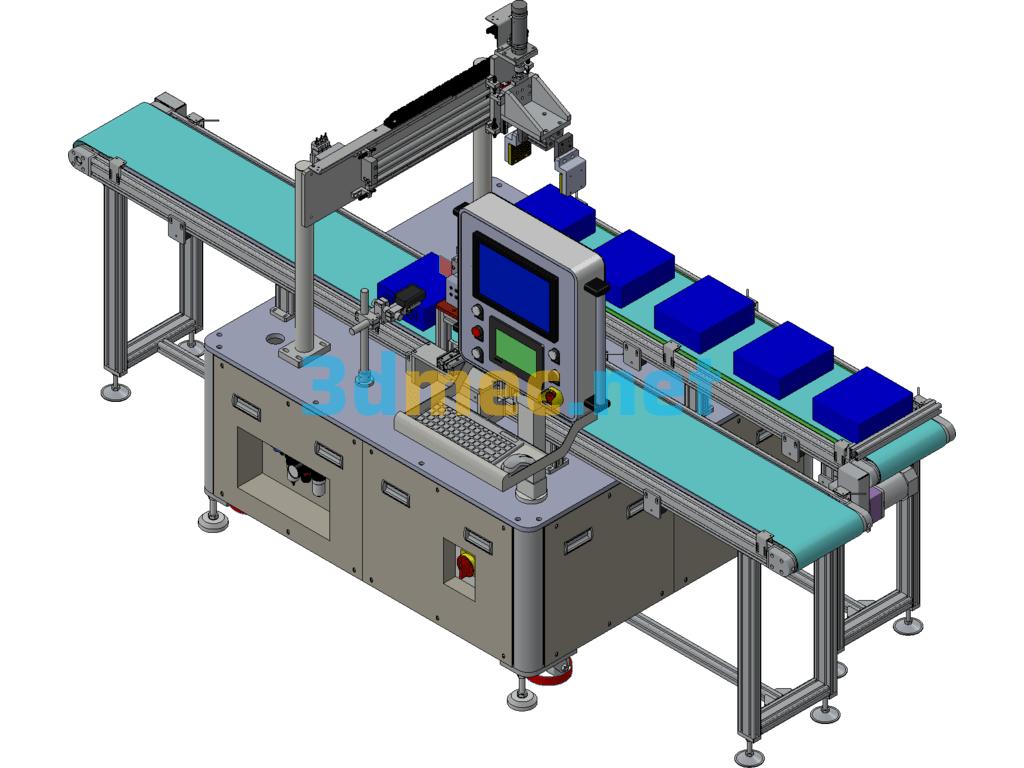

Specification: Automatic Saw Blade Feeding And Welding (Production Equipment Including Video) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Saw Blade Feeding And Welding (Production Equipment Including Video) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.