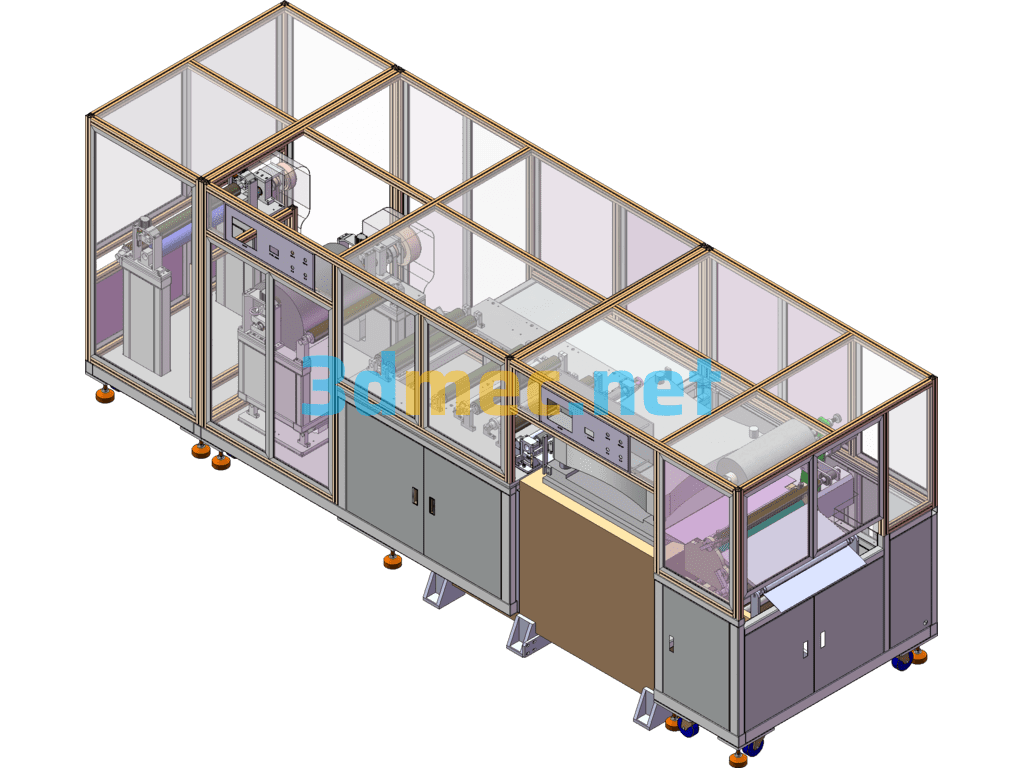

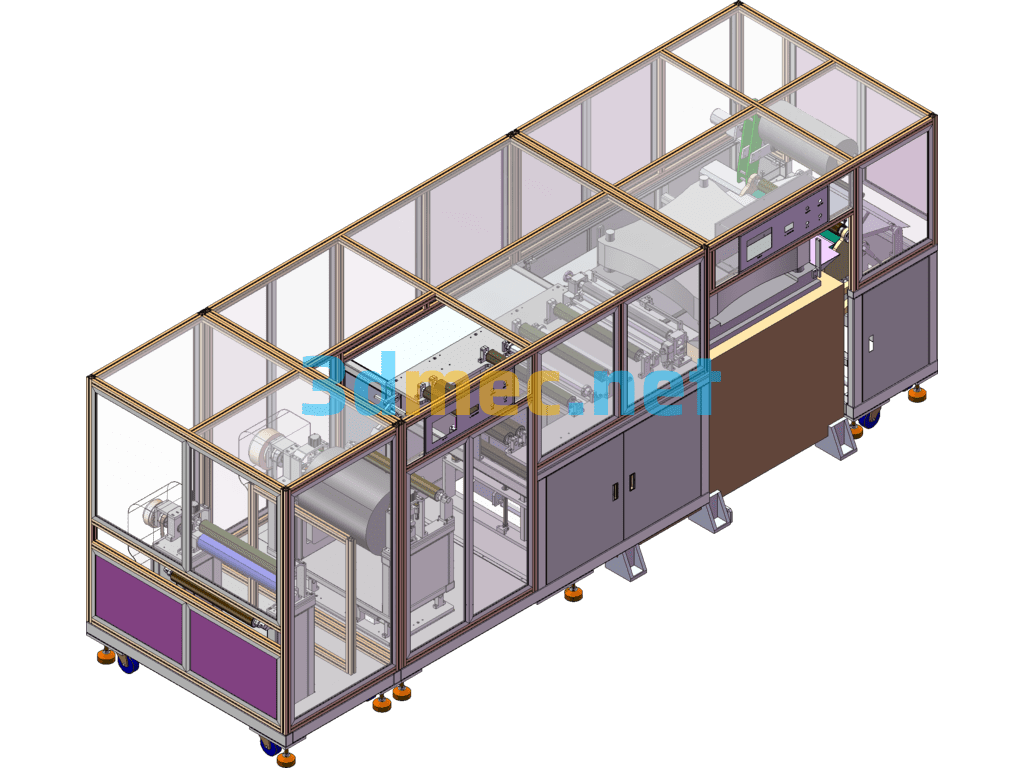

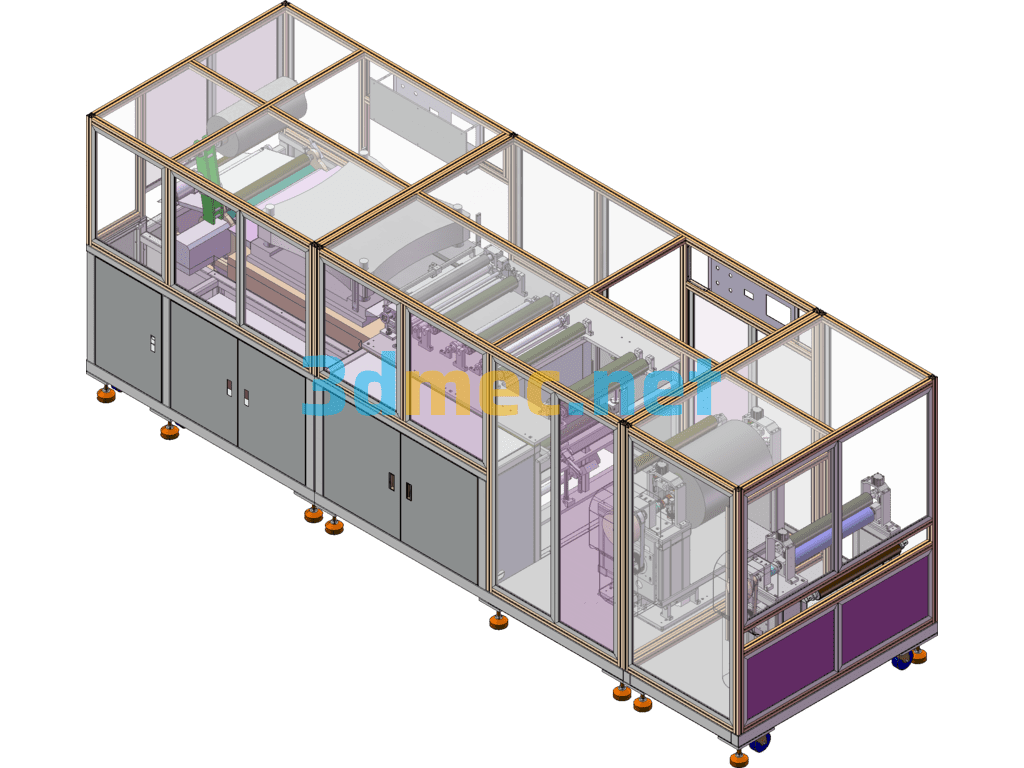

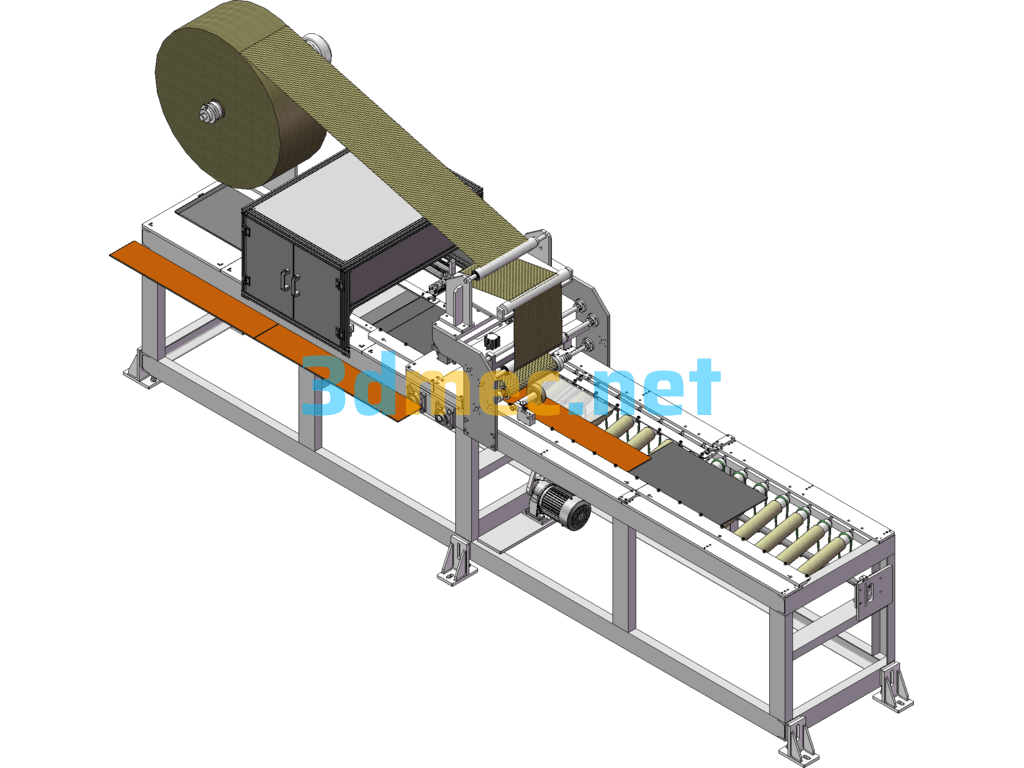

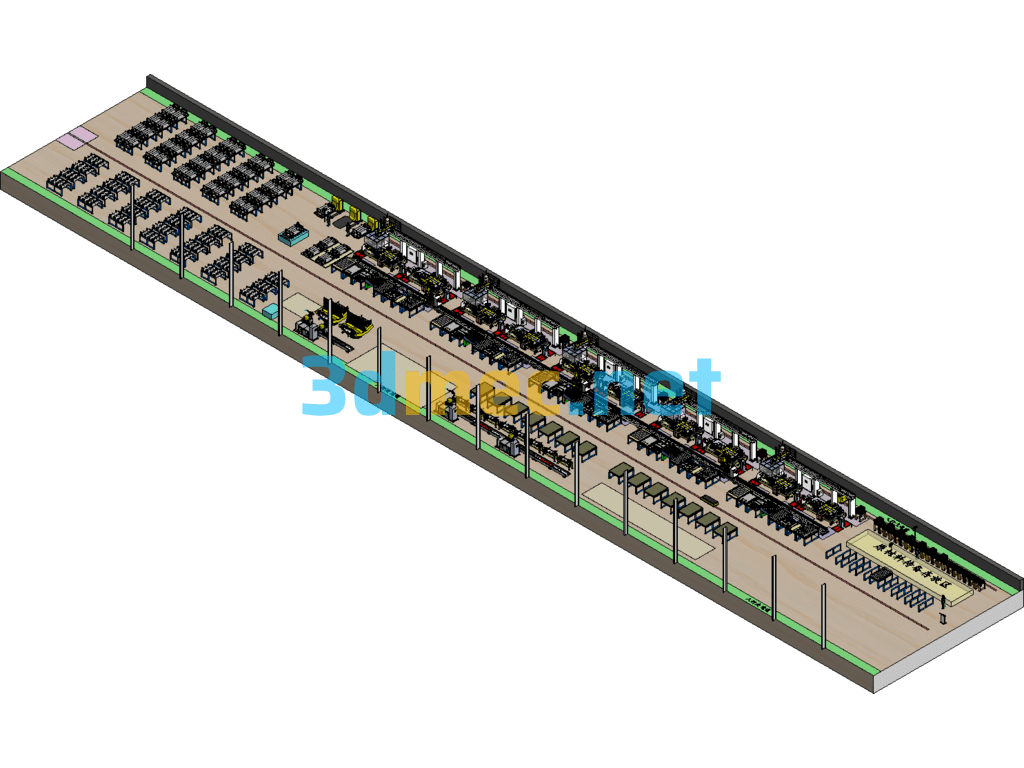

Automatic Pole Piece Forming And Die Cutting Machine – 3D Model SolidWorks

1. Suitable for automatic film forming of gap coating and rolling pole pieces of lithium batteries.

2. The pole piece coil is actively unwound by the unwinding mechanism, passes through the tension part, fits with the circulating support belt, and is sent to the punching mechanism by the servo-driven traction roller. The punching mechanism uses a laser knife die to punch and shape the fed pole piece, and the dragging belt sends the formed piece to the receiving platform. The edge material is automatically rolled up, and the pole piece is collected manually.

3.The unwinding device adopts magnetic powder tension adjustment, which can freely and conveniently adjust the unwinding tension;

4.The feeding side adopts imported electric eye tracking correction method, and the correction accuracy is ±0.15mm;

5.The drag belt feeds the material, and adopts synchronous control of the feeding and traction servo motors to ensure that the pulling length is accurate and stable each time;

6.The drag belt can work in a cycle to reduce material consumption (Note: the working life of the drag belt is ≈10,000 knives);

7.The punching adopts electromagnetic force to transmit power, does not use compressed air, saves air source consumption, reduces the noise of the working environment, and is particularly suitable for the environmental requirements of dust-free rooms;

8.The die-cutting host adopts a mature machine base, which is stable and reliable.

Specification: Automatic Pole Piece Forming And Die Cutting Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Pole Piece Forming And Die Cutting Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.