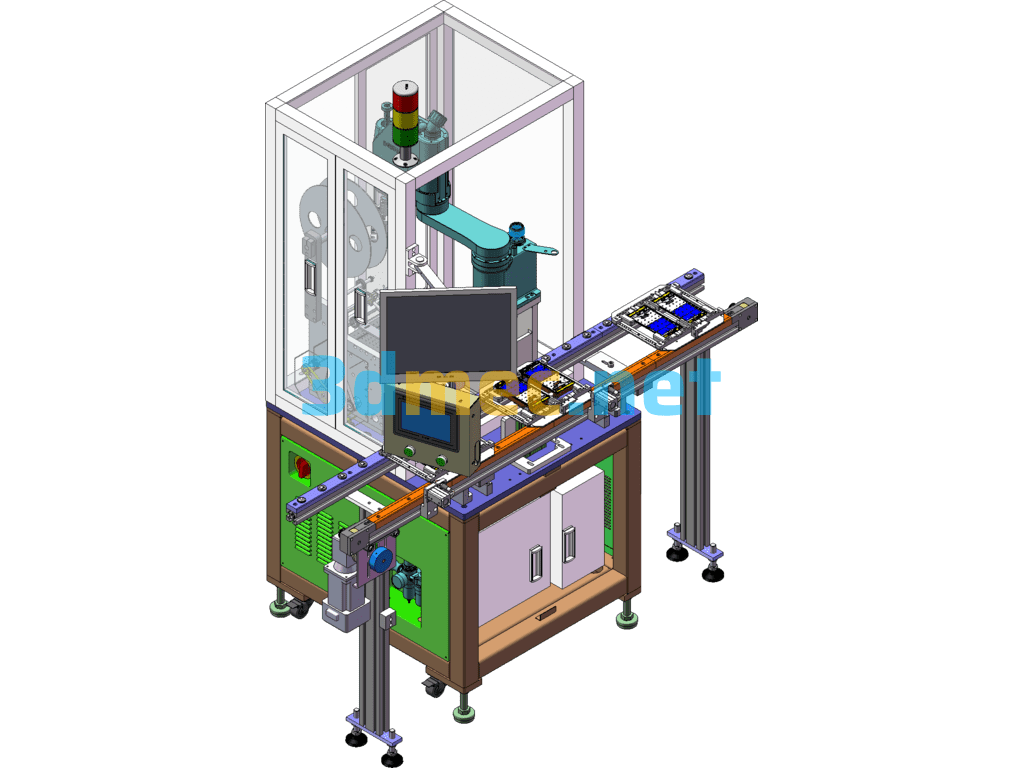

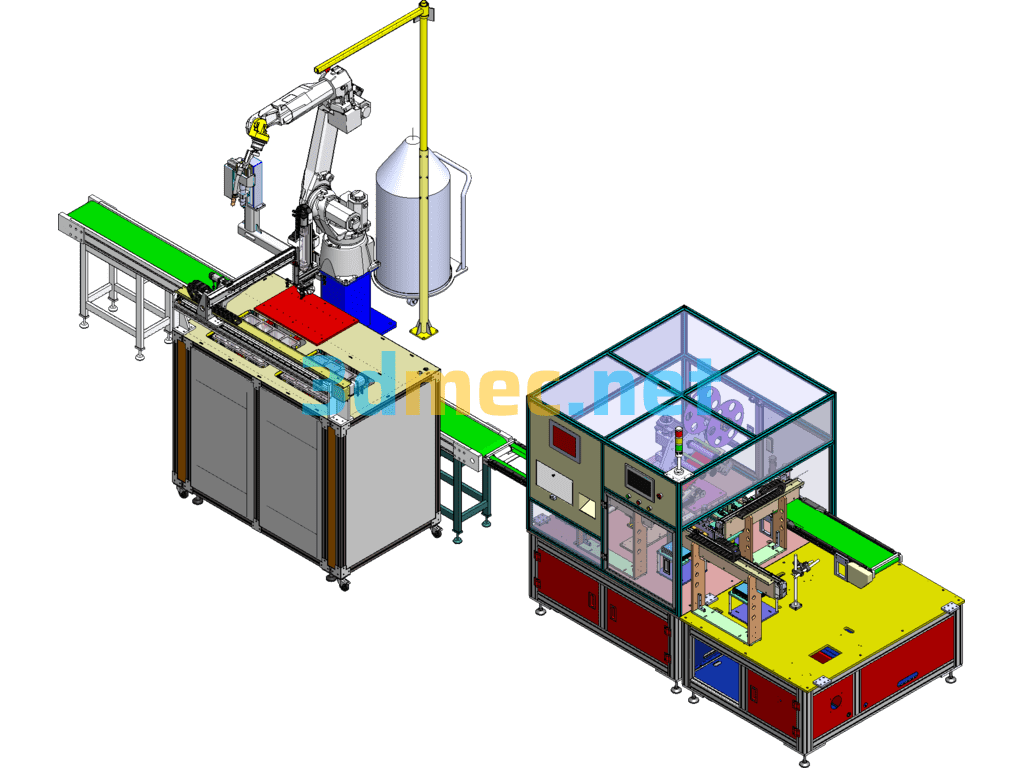

Automatic Mold Clamping And Locking Machine For Multi-Specification Pipe Pile Molds (Already In Mass Production, With Actual Pictures Attached) – 3D Model SolidWorks

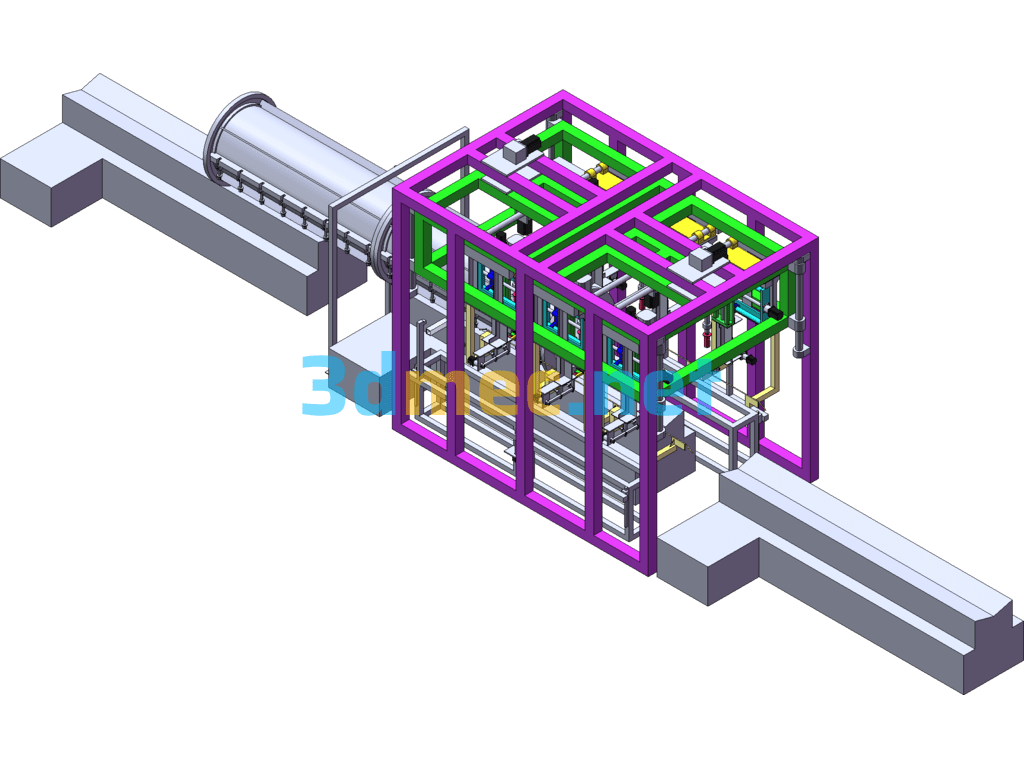

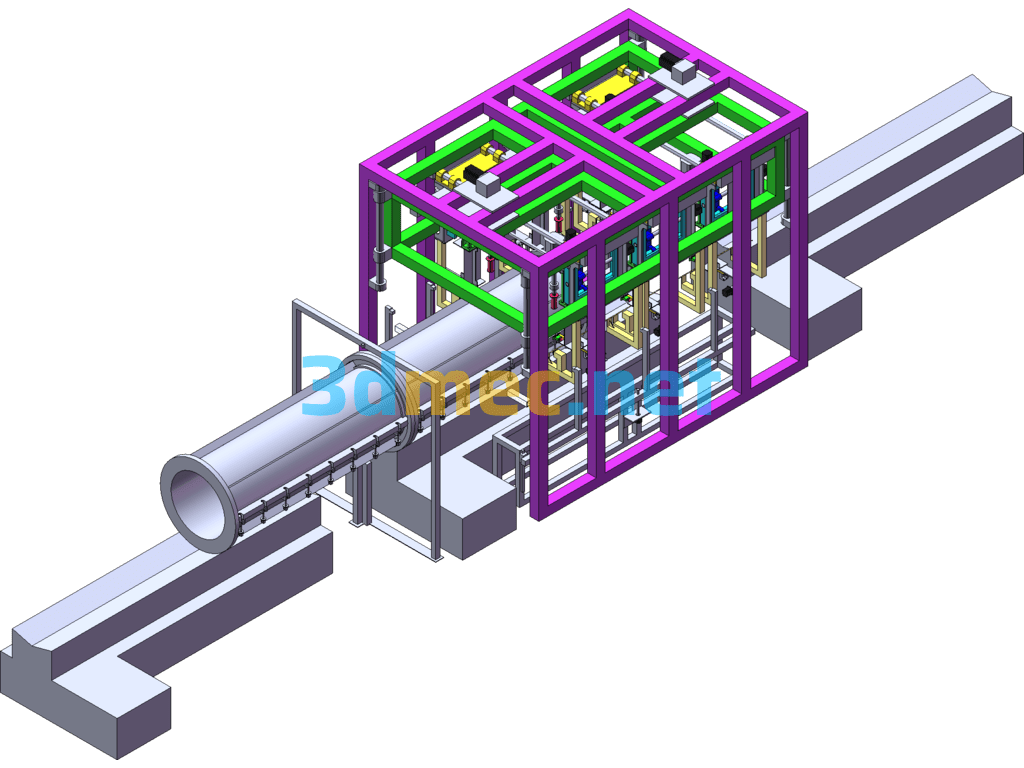

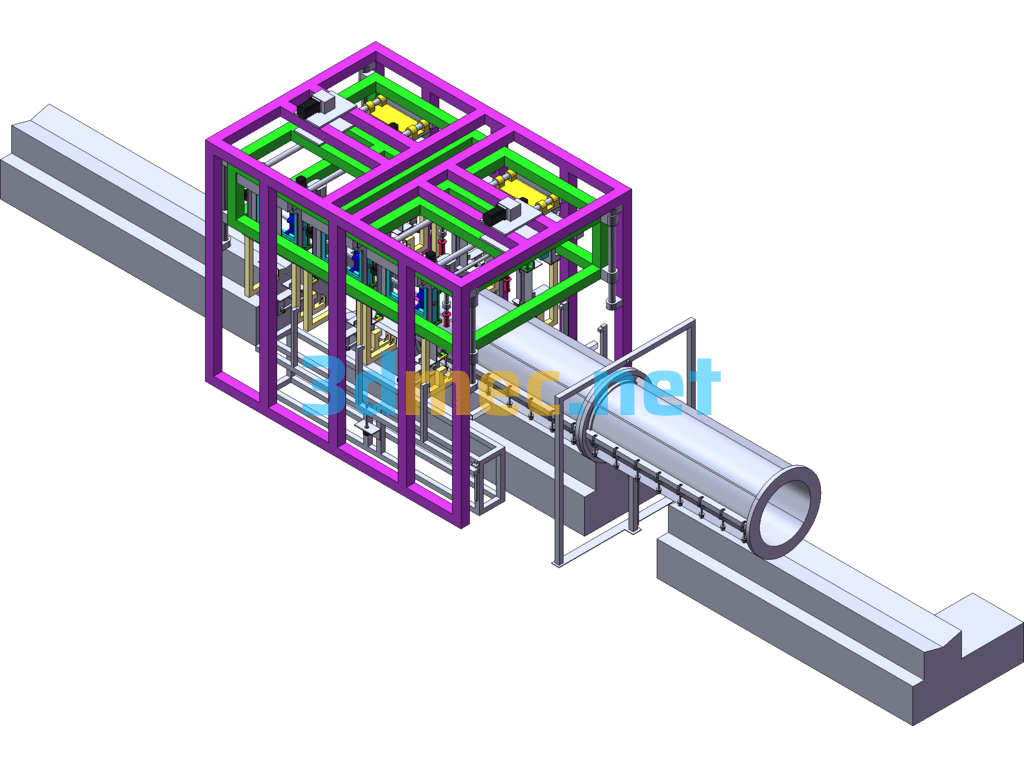

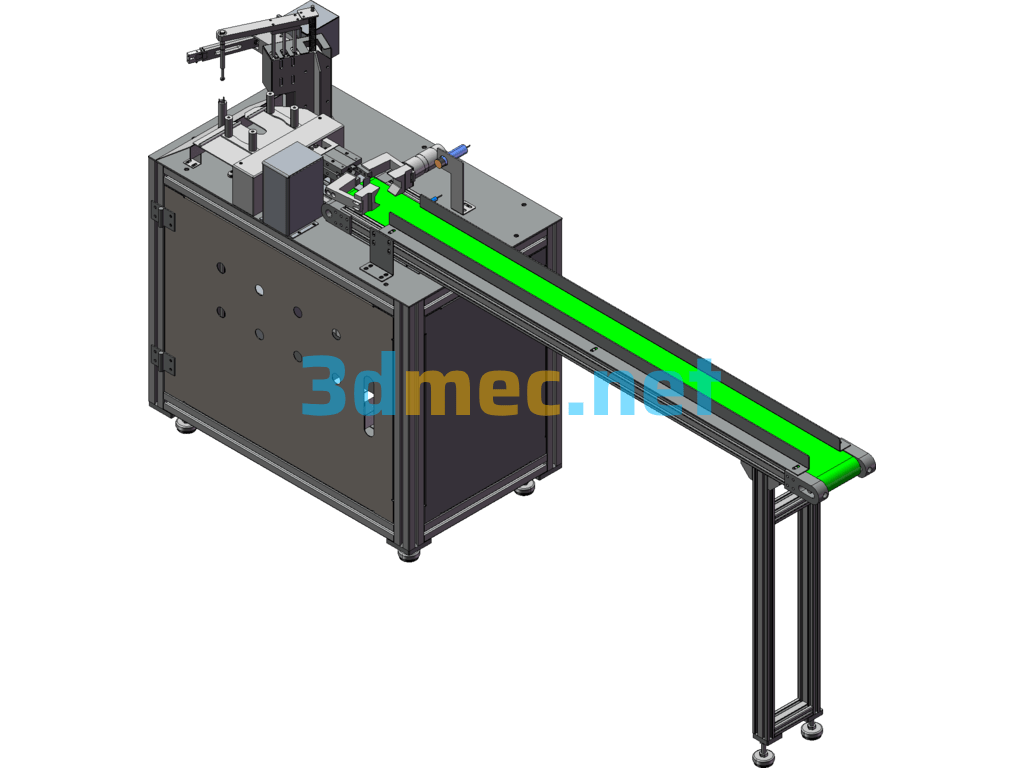

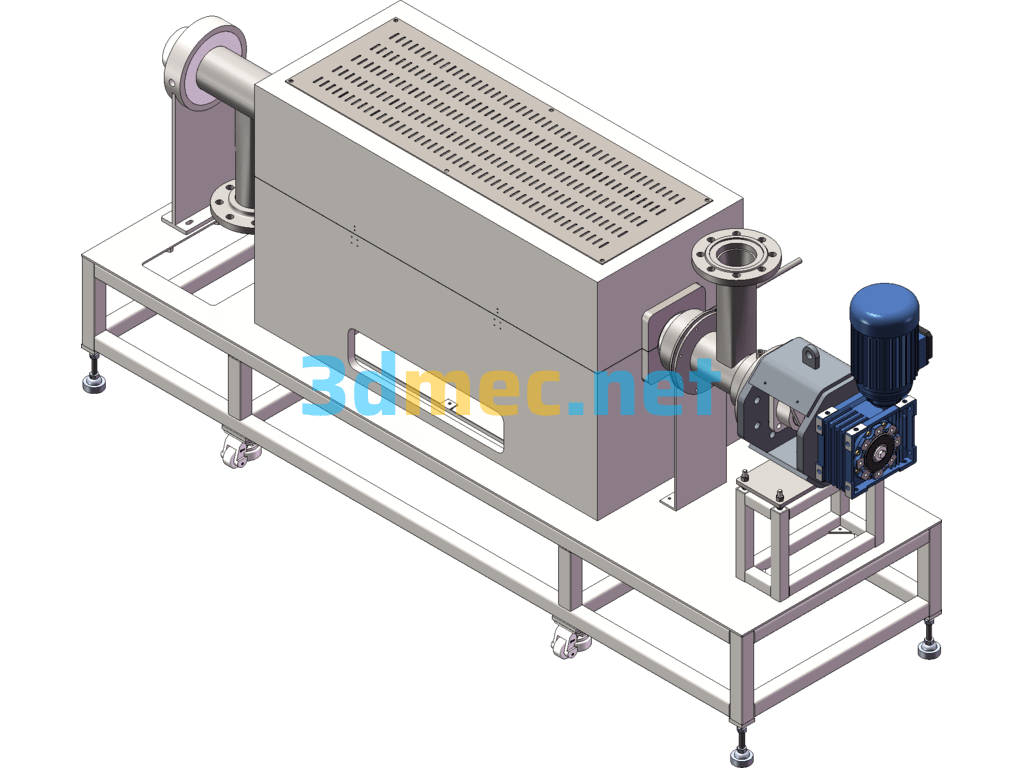

The automatic clamping and locking device for multi-specification pipe pile molds includes a pipe pile mold conveying device, an outer frame, an inner frame, a detection device, a bolt support rail, and a cannon device installed on a cannon mounting rod, a bolt leveling mechanism, and a bolt straightening and positioning mechanism. The diameter of the pipe pile mold is detected by the detection device, and then the height of the inner frame and the detection device is adjusted by the lifting mechanism, and the distance between the two cannon mounting rods is adjusted by the translation mechanism to adapt to the diameter of the pipe pile mold. Then, the bolts are leveled by a four-bar linkage with an electromagnet, and the horizontal bolts are placed on the bolt support rail and moved forward. Then, the bolts are flipped by the four-bar linkage of the bolt straightening and positioning mechanism, and pushed to the slot for positioning by the telescopic push rod, and finally the cannon device is moved down to complete the tightening work. The automatic clamping and locking device for multi-specification pipe pile molds can automatically detect and adapt to the clamping of pipe pile molds with different diameters, lengths, and bolt spacing specifications. The bolts are tightened accurately and efficiently during clamping.

1-bolt righting and positioning mechanism, 101-righting base, 102-righting flip connecting rod, 103-righting rocker, 104-righting driving rod, 105-righting rocker, 106-righting driving motor, 107-righting support rod one, 108-righting support rod two, 109-telescopic push rod, 2-pile mold conveying device, 3-outer frame, 4-inner frame, 401-inner frame guide rod, 402-inner frame slider, 403-inner frame lifting motor, 404-inner frame lifting screw rod, 405-inner frame lifting nut, 406-lateral motion motor, 407-lateral motion screw rod, 408-lateral motion nut, 409-lateral guide rail rod, 5-detection device, 501-detection base, 502-sensor bracket, 503-slot rangefinder, 504-Motor for moving the bracket up and down, 505-Screw rod for moving the bracket up and down, 506-Nut for moving the bracket up and down, 507-Gate-type bracket, 508-Travel switch, 509-Tube diameter rangefinder, 510-Guide rod for moving the bracket up and down, 6-Cannon device, 601-Cannon base, 602-Cannon, 603-Cannon mounting plate, 604-Motor for moving the cannon forward and backward, 605-Screw rod for moving the cannon forward and backward, 606-Nut for moving the cannon forward and backward, 607-Guide rod for moving the cannon forward and backward, 608-Motor for moving the cannon up and down, 609-Screw rod for moving the cannon up and down, 610-Nut for moving the cannon up and down, 611-Guide rod for moving the cannon up and down, 7-Cannon mounting rod, 8-Bolt support rail, 9-Bolt leveling mechanism, 901-Leveling base, 902-Leveling flip connecting rod, 903-Leveling rocker, 904-leveling driving rod, 905-leveling swing rod, 906-leveling driving motor, 907-leveling support rod one, 908-leveling support rod two, 909-electromagnet, 910-leveling forward and backward moving motor, 911-leveling forward and backward moving screw rod, 912-leveling forward and backward moving nut, 913-leveling mounting plate, 914-leveling mounting bracket, 915-leveling guide rod, 10-pile mold, 11-bolt.

Specification: Automatic Mold Clamping And Locking Machine For Multi-Specification Pipe Pile Molds (Already In Mass Production, With Actual Pictures Attached) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Mold Clamping And Locking Machine For Multi-Specification Pipe Pile Molds (Already In Mass Production, With Actual Pictures Attached) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.