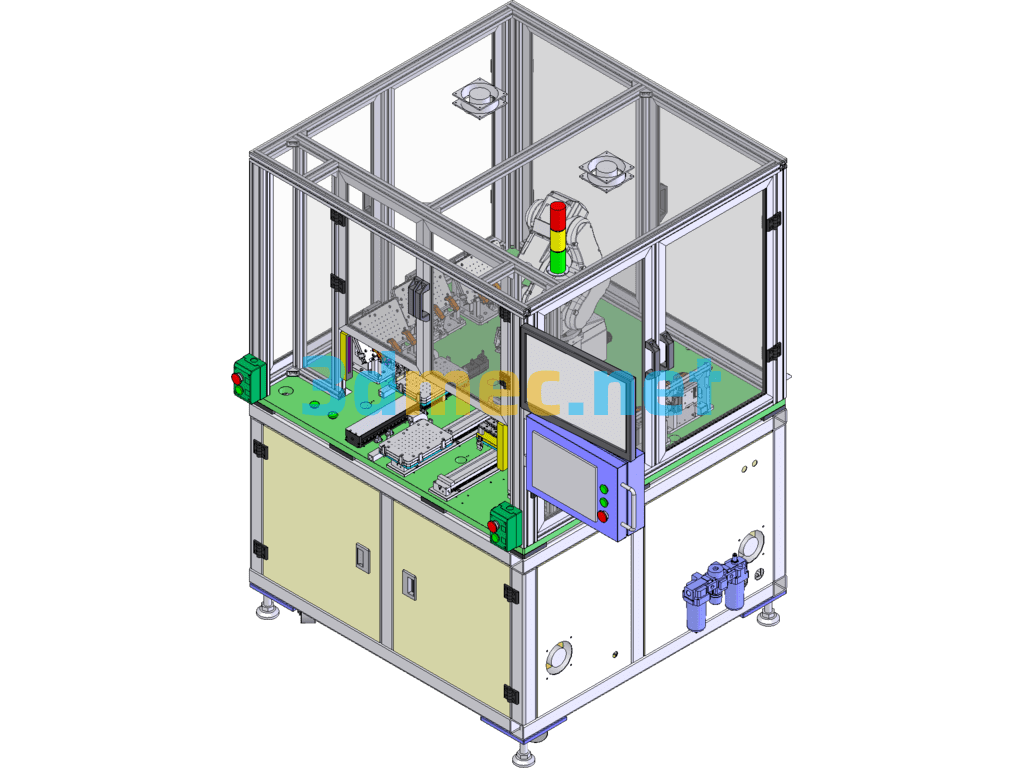

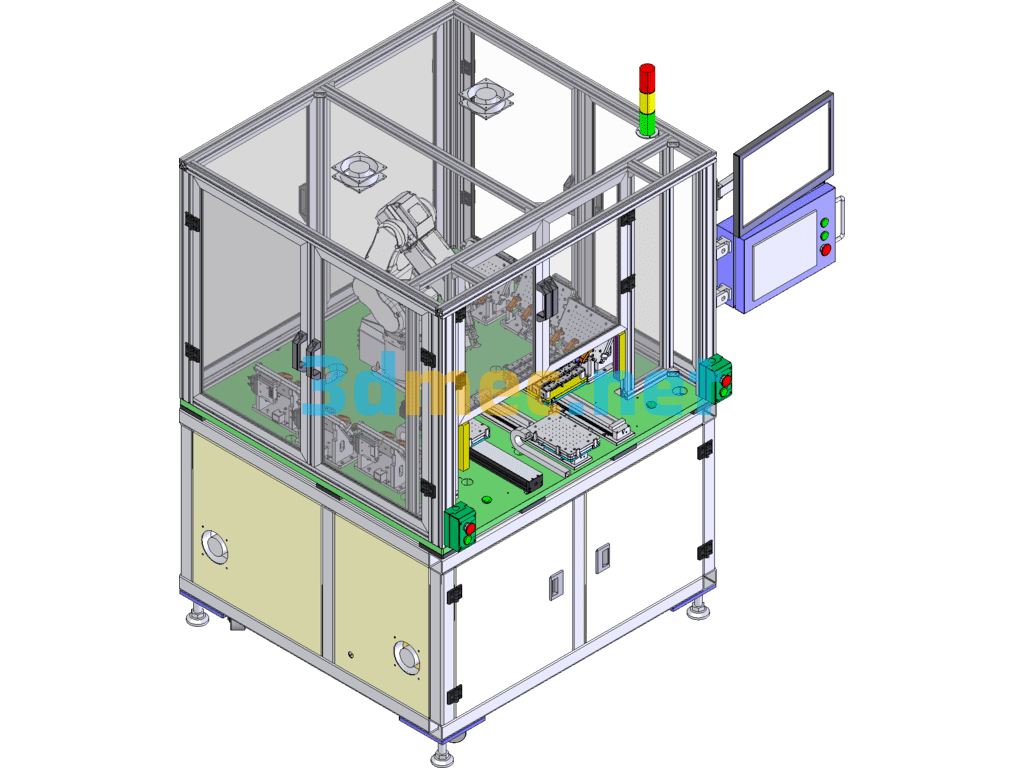

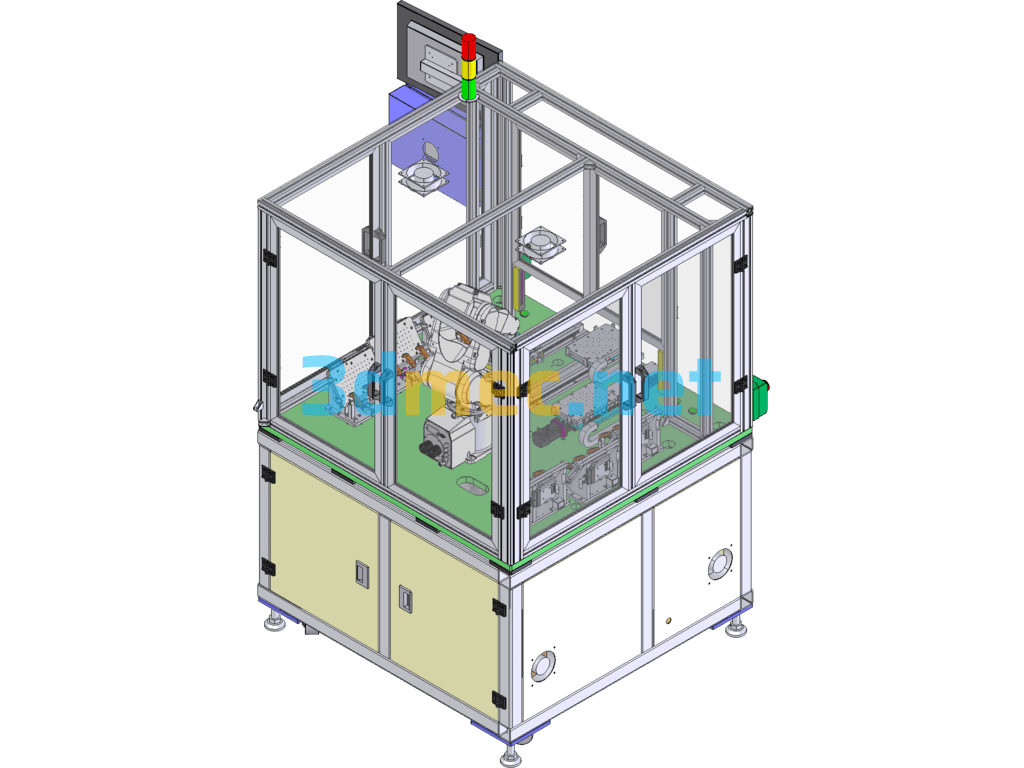

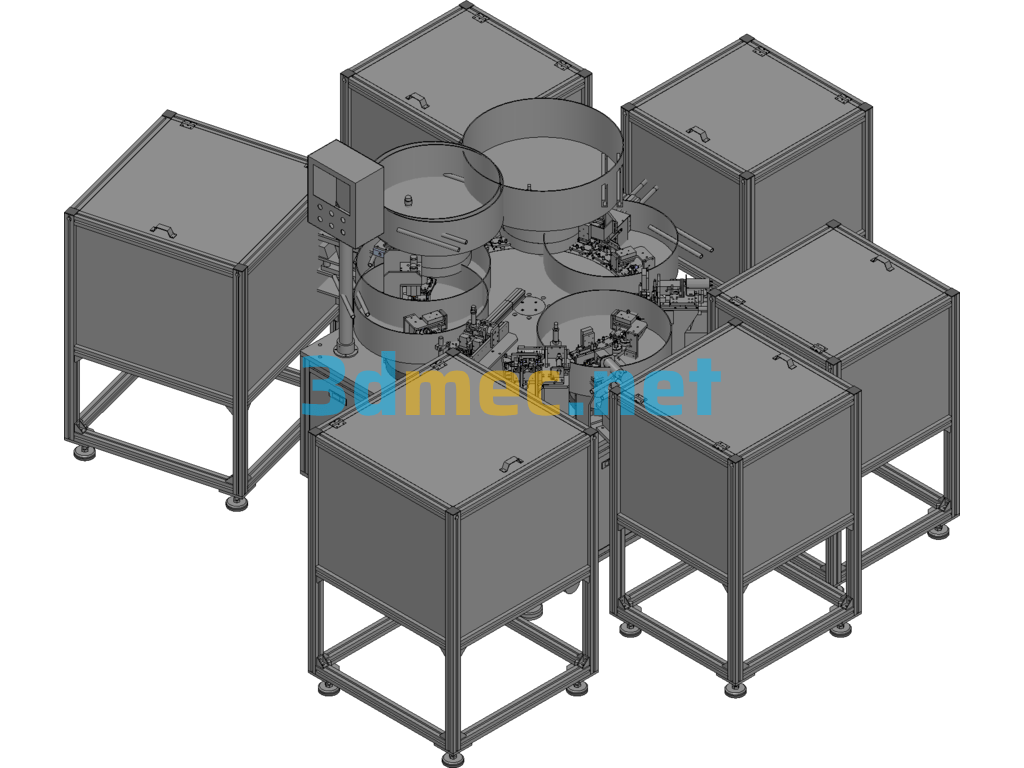

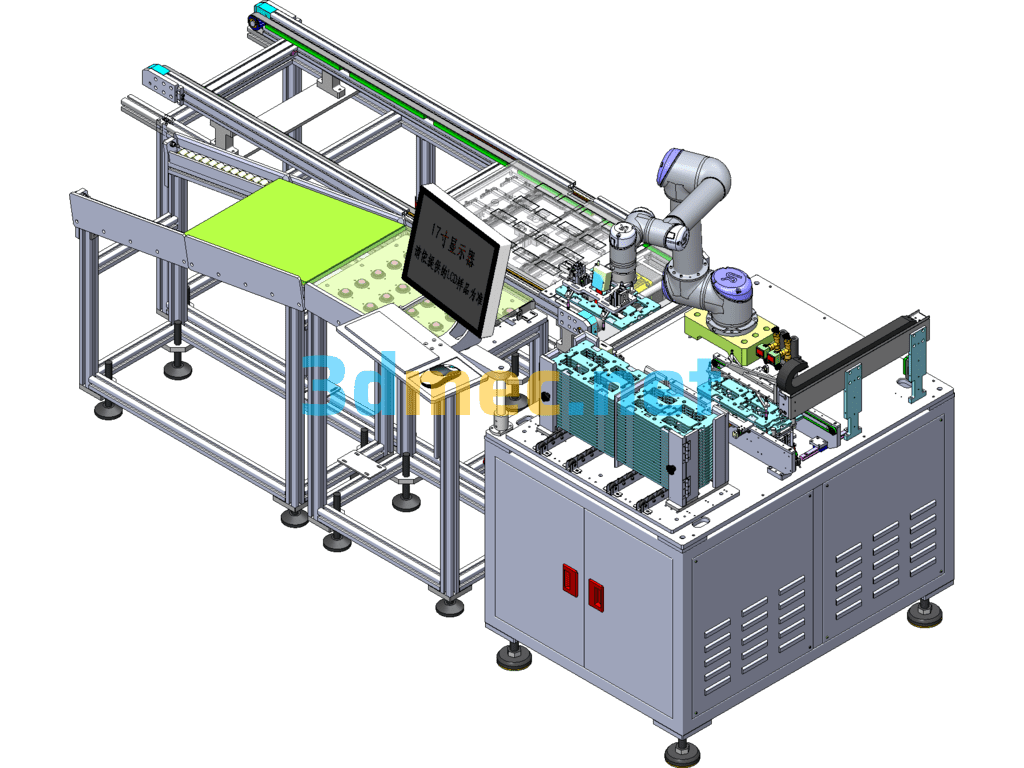

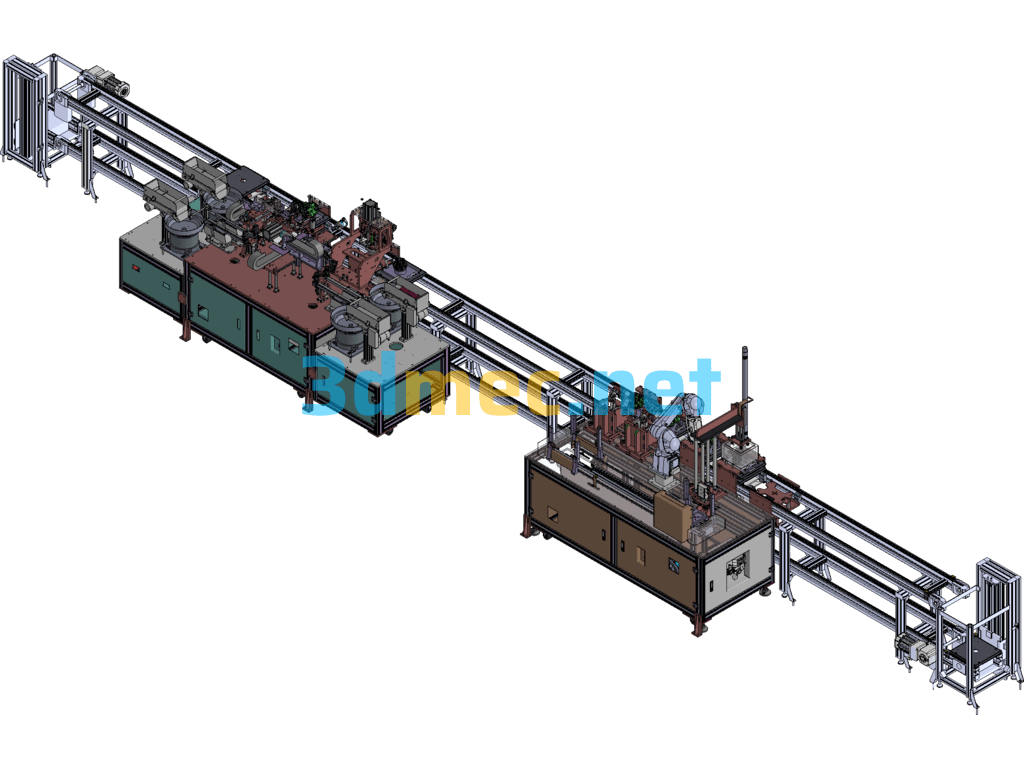

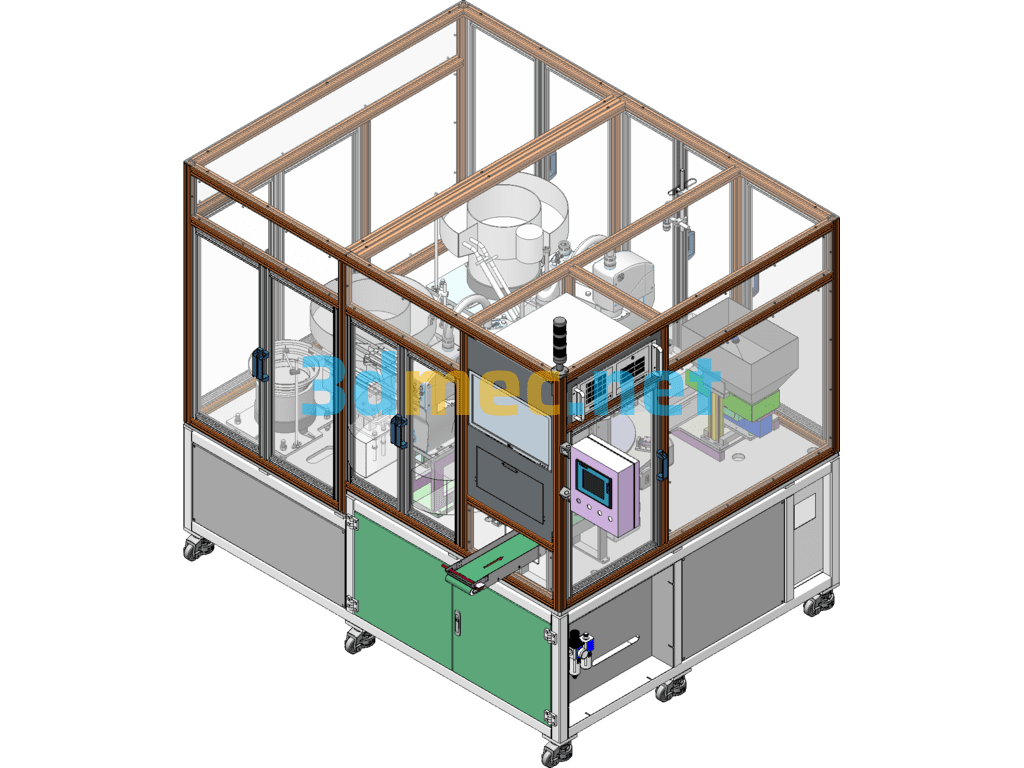

Automatic Magnet Assembly Heat Holding Equipment (Produced Equipment Including DFM) – 3D Model SolidWorks

Automated magnet assembly hot press equipment process: 1. The magnet fixture is manually placed in the equipment; 2. The flat shell is manually loaded to the shell loading station; 3. The robot absorbs the shell and the magnet fixture to prevent the pressure holding station from visually positioning and assembling the magnet; 4. Heat the pressure holding magnet; 5. After completion, the robot grabs and unloads to the shell unloading;

Specification: Automatic Magnet Assembly Heat Holding Equipment (Produced Equipment Including DFM) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Magnet Assembly Heat Holding Equipment (Produced Equipment Including DFM) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.