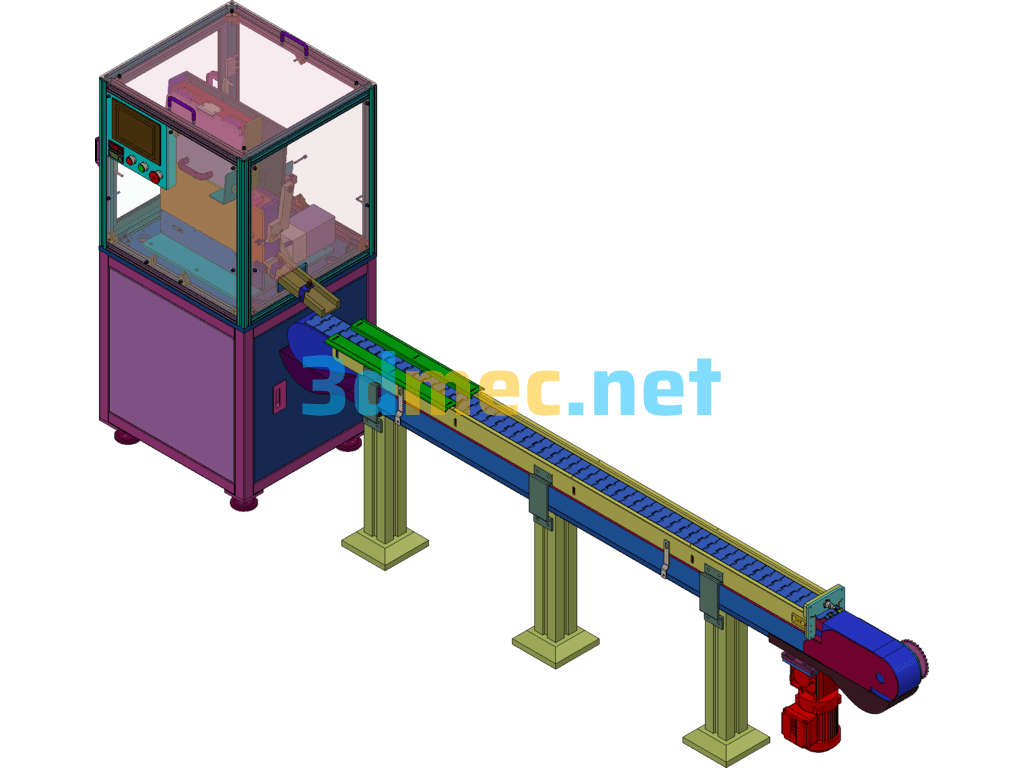

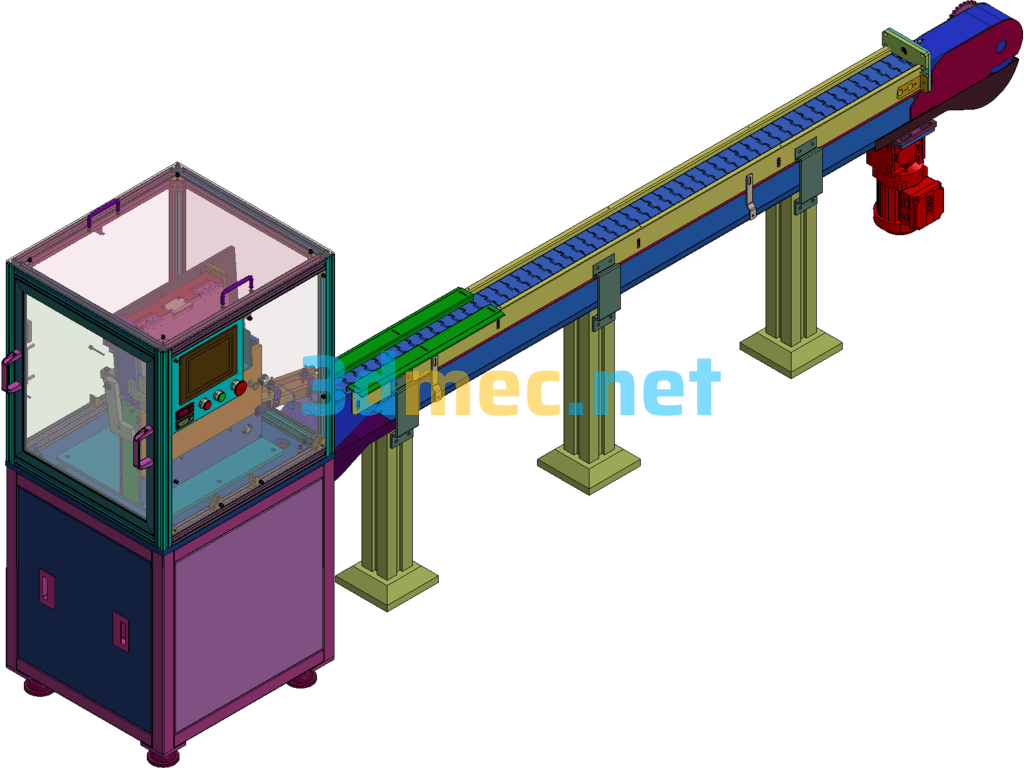

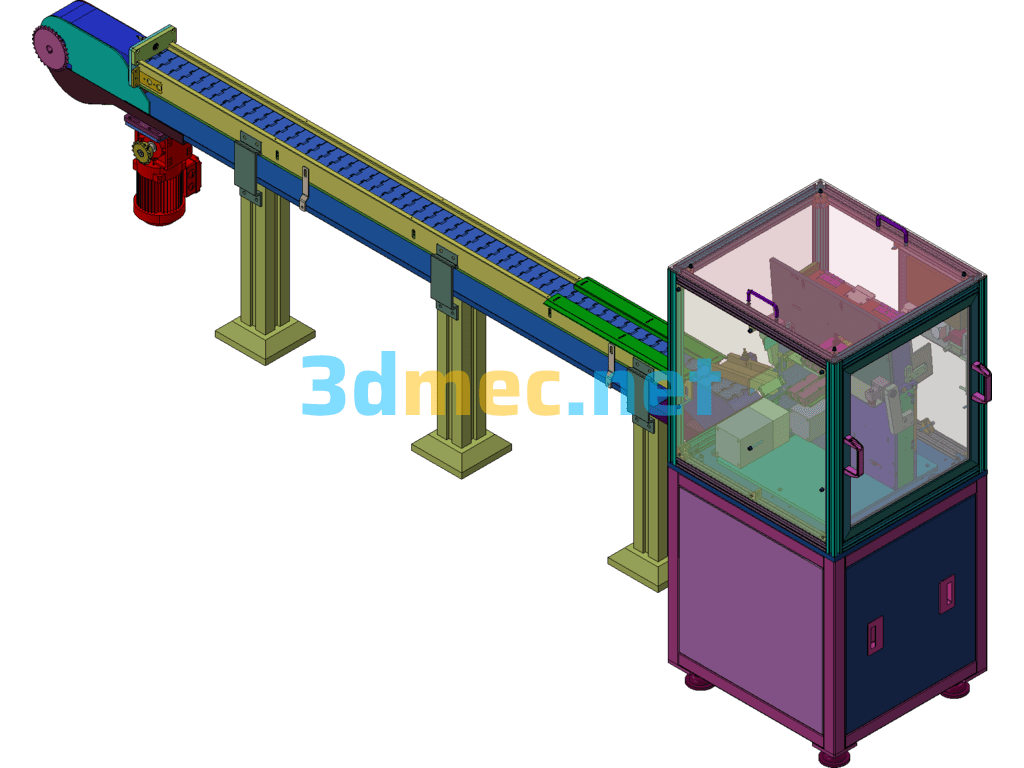

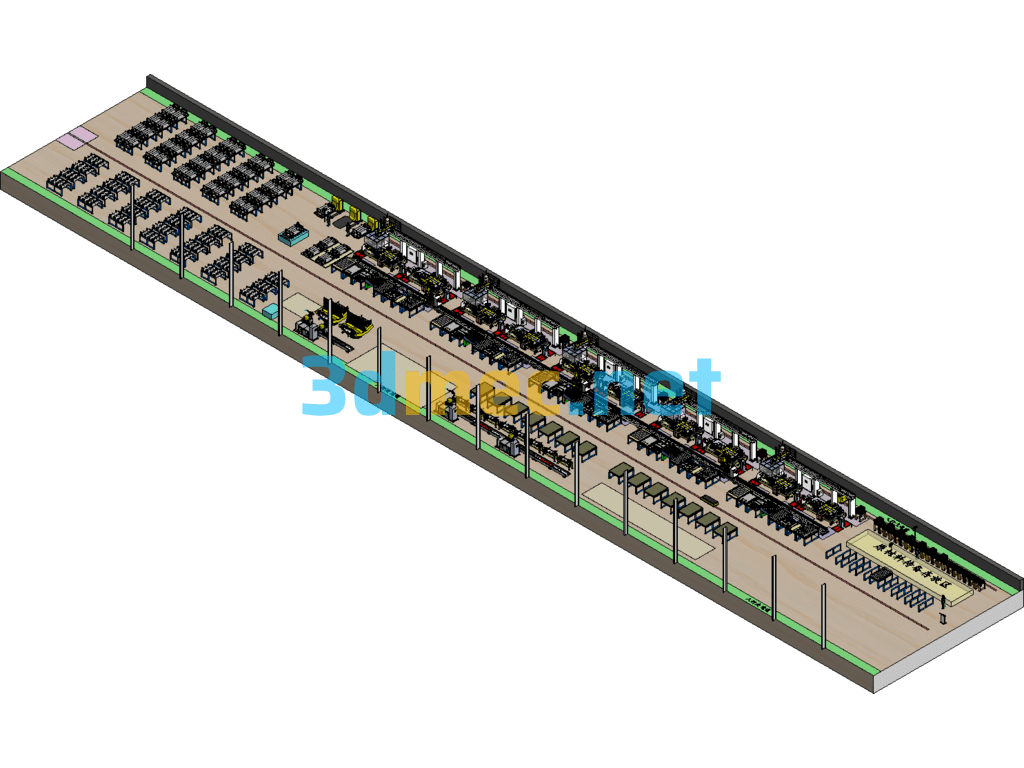

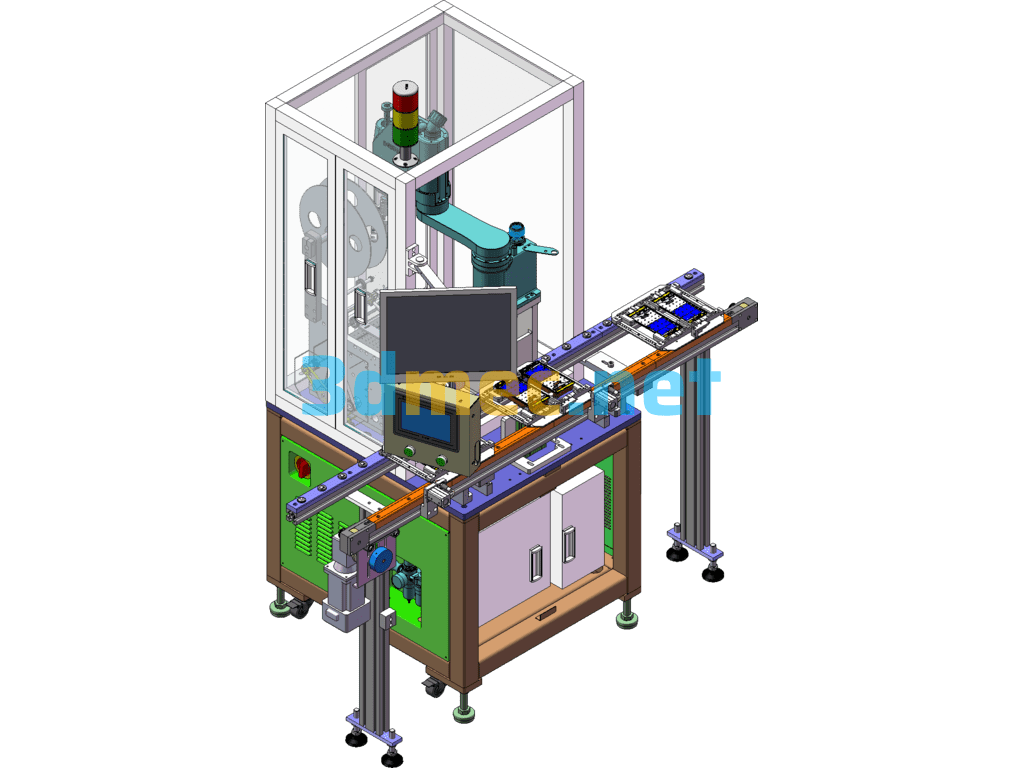

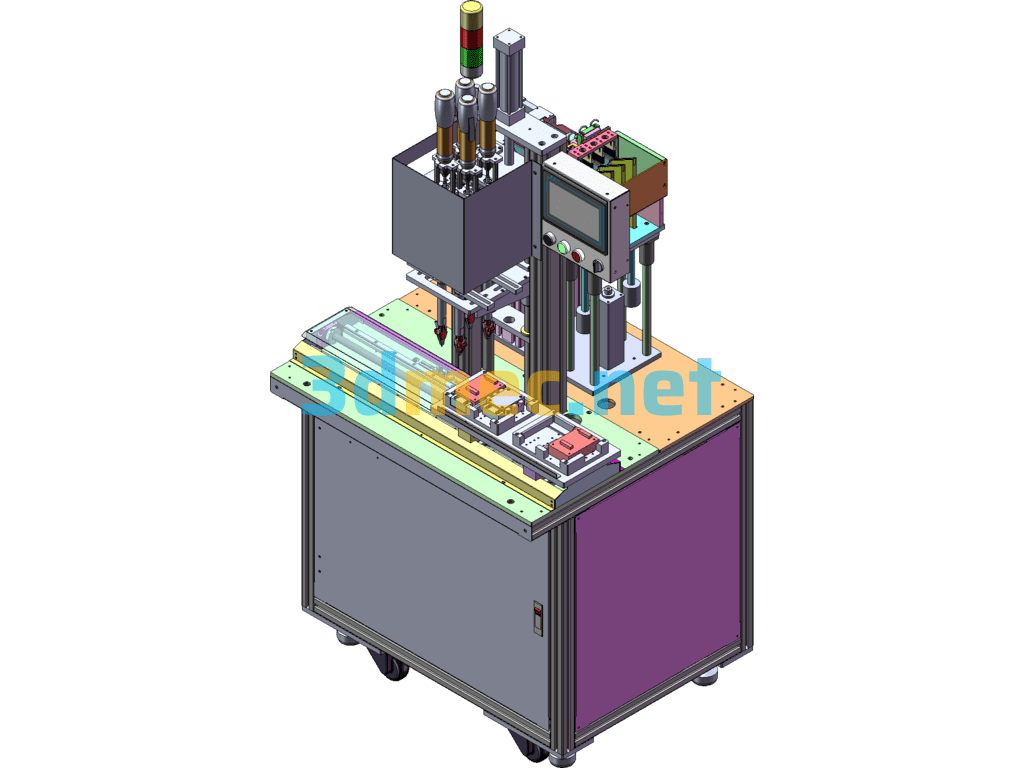

Automatic Loading Equipment For Wire Boxes – 3D Model SolidWorks

The mechanism of this equipment is designed by SW2016 and includes editable part features. This equipment adopts automatic lifting and arranging feeding method and is equipped with advanced sensors. No material will not be assembled. After the cylinder is actuated, the nuts of the wire box will be rechecked to avoid the occurrence of no nuts in the finished wire box to the greatest extent (the workpiece is too small, it is easy to assemble a large number of defective products without nuts in the wire box, and it is impossible for employees to check one by one), fully guaranteeing the qualified rate of the product. This machine only assembles one component at a time, and the speed can reach 50-70 pieces/minute. The control method adopts PLC control, touch screen display and operation, which is simple and easy to learn. Each action of this equipment can be operated separately on the touch screen, and if the equipment has an action failure, the problem will be directly displayed on the touch screen in text, which is convenient for users to troubleshoot. Synchronously assemble the wire box nut iron sheet. Before assembly, it will check again whether the nut is in place. The equipment without nuts or less nuts will not assemble the iron sheet, avoiding the phenomenon that the iron sheet is installed but there is no nut. Contains STP and UG general editable formats

Specification: Automatic Loading Equipment For Wire Boxes – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Loading Equipment For Wire Boxes – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.