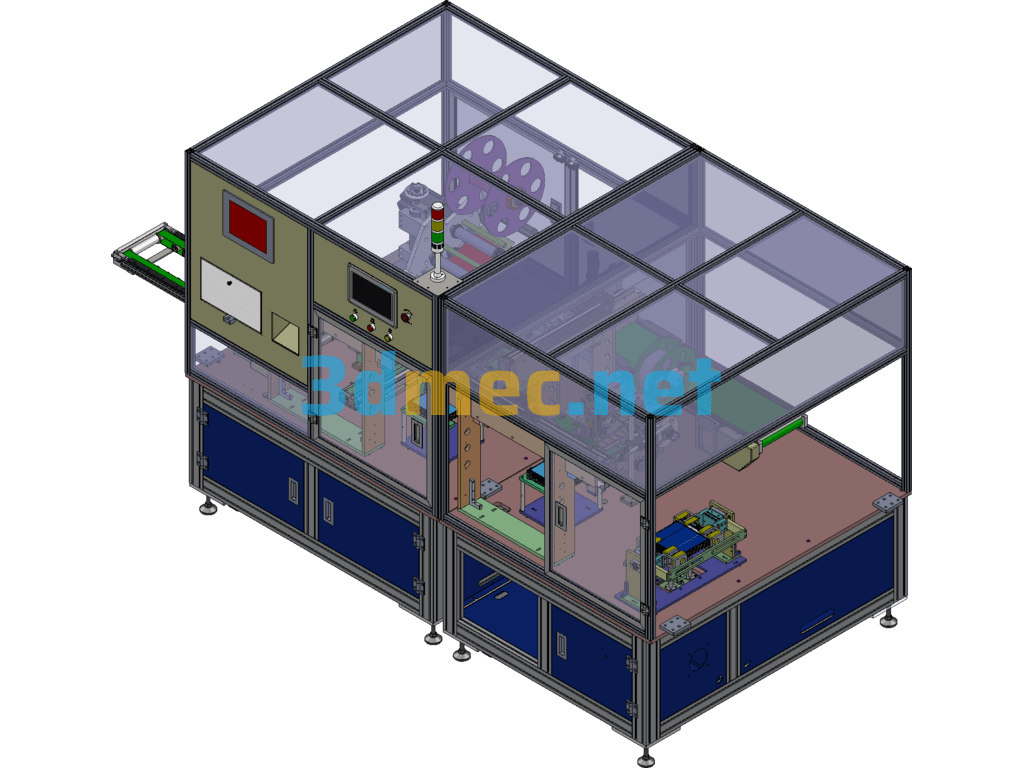

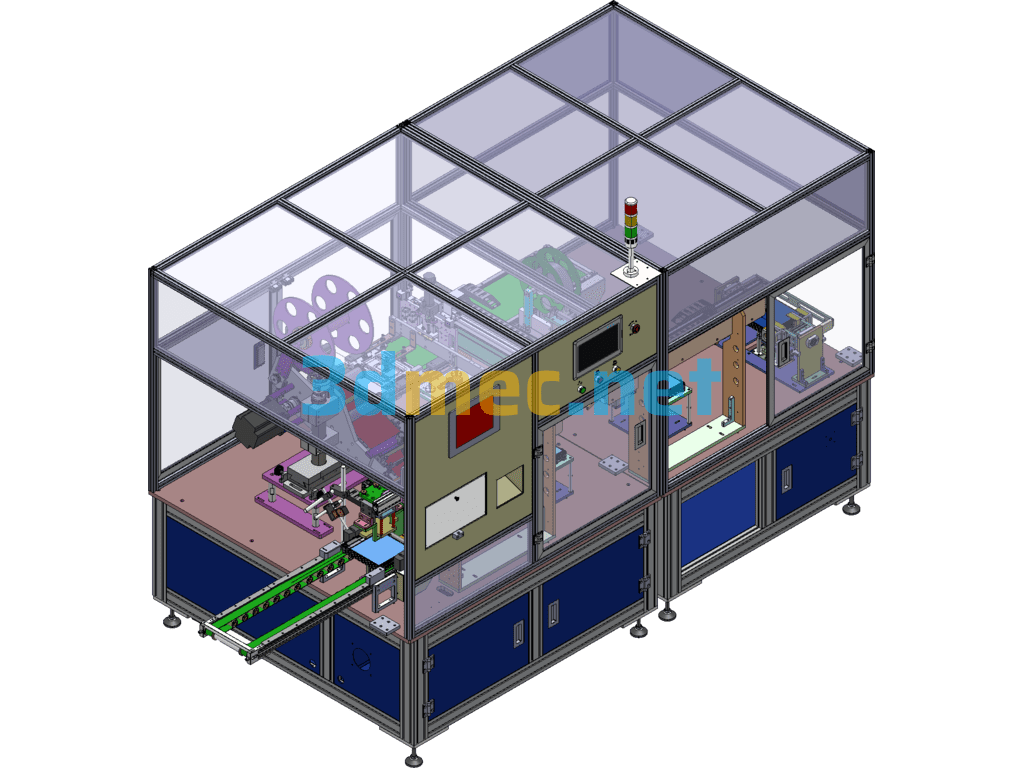

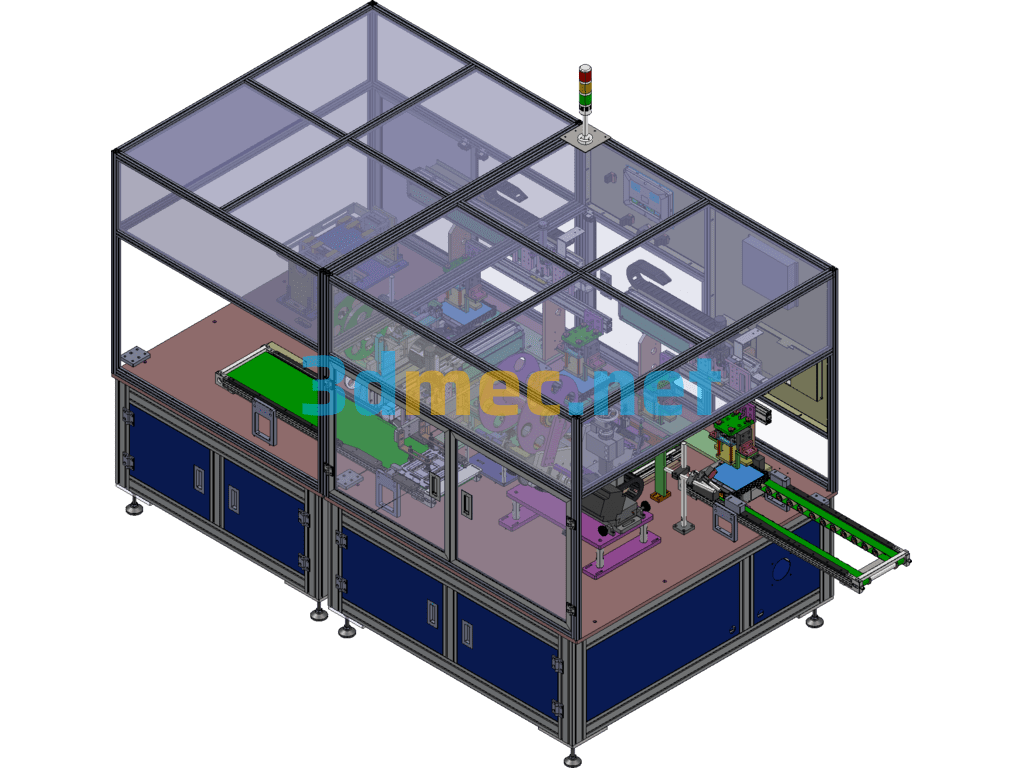

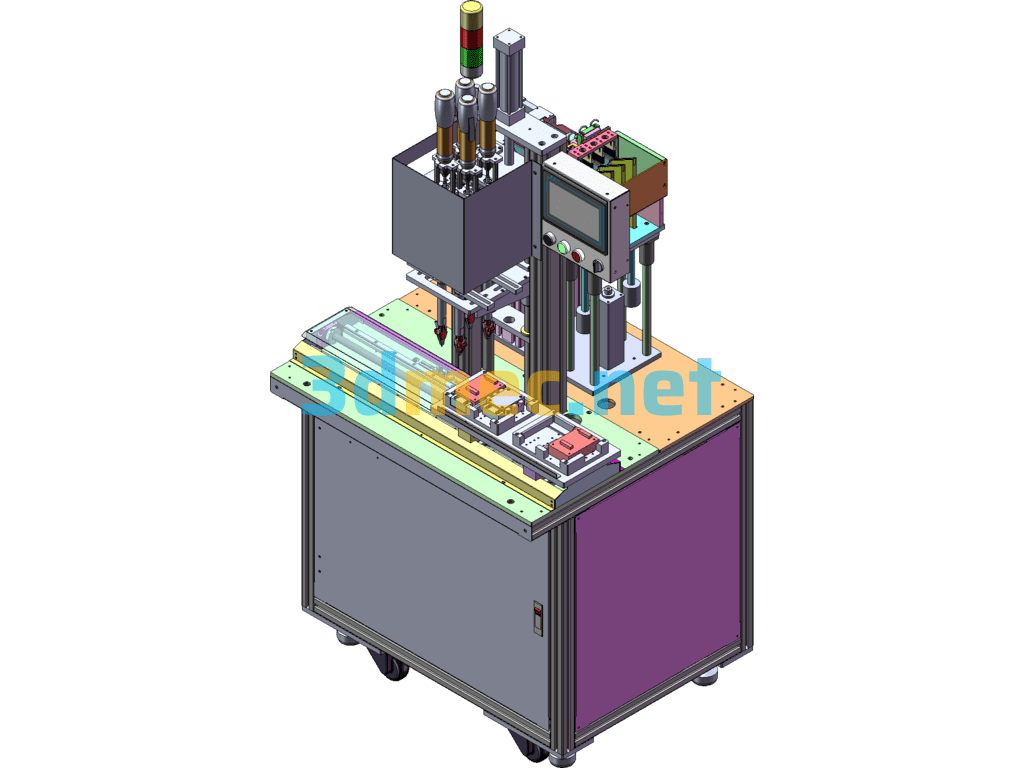

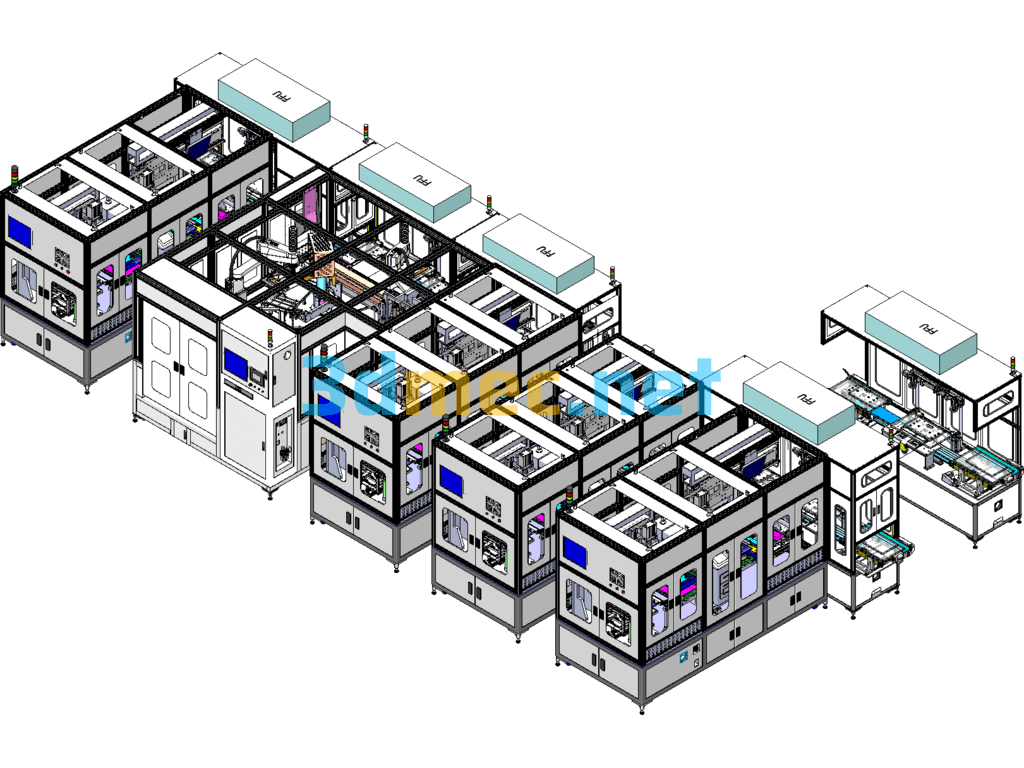

Automatic Insulation Film And Barcode Sticking Equipment/Power Battery PET Protective Film Sticking Machine – 3D Model SolidWorks

Steve Barnes

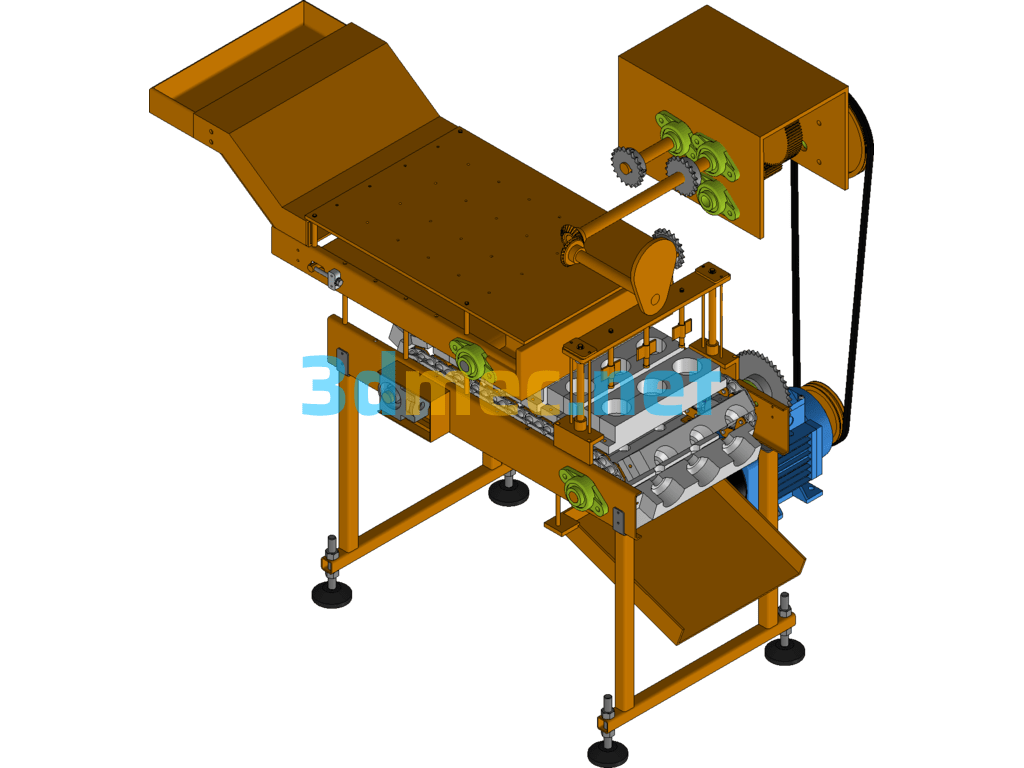

This equipment is an integrated equipment with power soft pack battery pasting PET adhesive tape machine and labeling machine. The drawings of this equipment are 400MB, which totals almost 400 large and small parts drawings. The 3D model of this equipment is designed and drawn using SolidWorks 2012 software. Come out, the full set of drawings are the original and complete set of 3D model design drawings. The products suitable for this equipment are non-standard automatic power battery affixing PET protective film machine labeling machineautomatic insulating film affixing barcode equipment: lithium batteries, polymer batteries, For various types of soft-pack power batteries, the equipment mainly uses a film feeder to affix the film to be applied to the surface of the battery. This set of film feeders can also be used in the packaging industry because it is a standard mechanism. It is also very stable. When the battery comes in from the conveyor belt, the battery manipulator grabs the product and places it on the secondary positioning slide of the laminating station. The slide module at the bottom moves the battery to the laminating position, and then starts peeling off the film and the slide mold The group goes out and applies it while rolling and compressing it. There are basically no bubbles when applied by such a film application machine. The application effect is very good and the film application speed is fast. This film application position is a rolling film application. Its action and principle are: , the product is fixed on the positioning seat and moved to the film sticking position by the module manipulator, and then the film is applied to the surface of the battery by the film pasting machine. The module then moves outward and rolls the film as it goes. This is called a rolling film laminating machine, so this method is used. There will be no bubbles on the surface of the pasted film. After the film is pasted, the transport robot will grab the battery to another station for labeling and barcoding. Before pasting here, an aluminum shell will be installed in the middle of the battery. It is also made of The robot grabs and installs the battery module, and then the robot grabs the battery module for labeling, and then rotates and turns it over for assembly of the battery module and other work processes. This equipment can also be used in different industries for film sticking, such as PET protection for power batteries. Main technical parameters of the labeling machine: Category specification parameters Overall machine dimensions: 3850*1720*1700MM (L*W*H) Input voltage: AC—220V50Hz or AC—380V 50Hz optional Maximum power of the complete machine: 0.5KW (at 220V ) Input air source pressure: 0.4-0.6 Mpa Air consumption: 1.5 L/min Production efficiency (C/T): ≤3.0 S/one equipment utilization rate: ≥95% Processing method: automatic detection, automatic pressing, automatic output Material changing method: Manual material changing programming method: Touch screen parameter modification.

The drawings have a detailed structure and considerable details worth learning.

Specification: Automatic Insulation Film And Barcode Sticking Equipment/Power Battery PET Protective Film Sticking Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Insulation Film And Barcode Sticking Equipment/Power Battery PET Protective Film Sticking Machine – 3D Model SolidWorks” Cancel reply

You must be logged in to post a review.

There are no reviews yet.