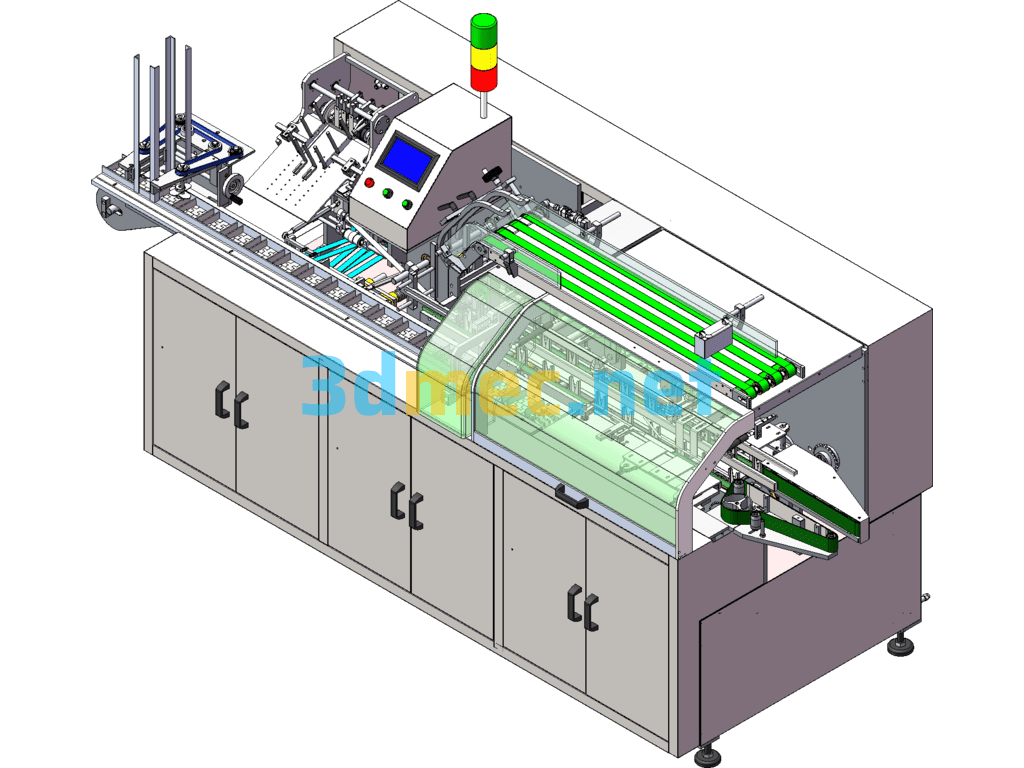

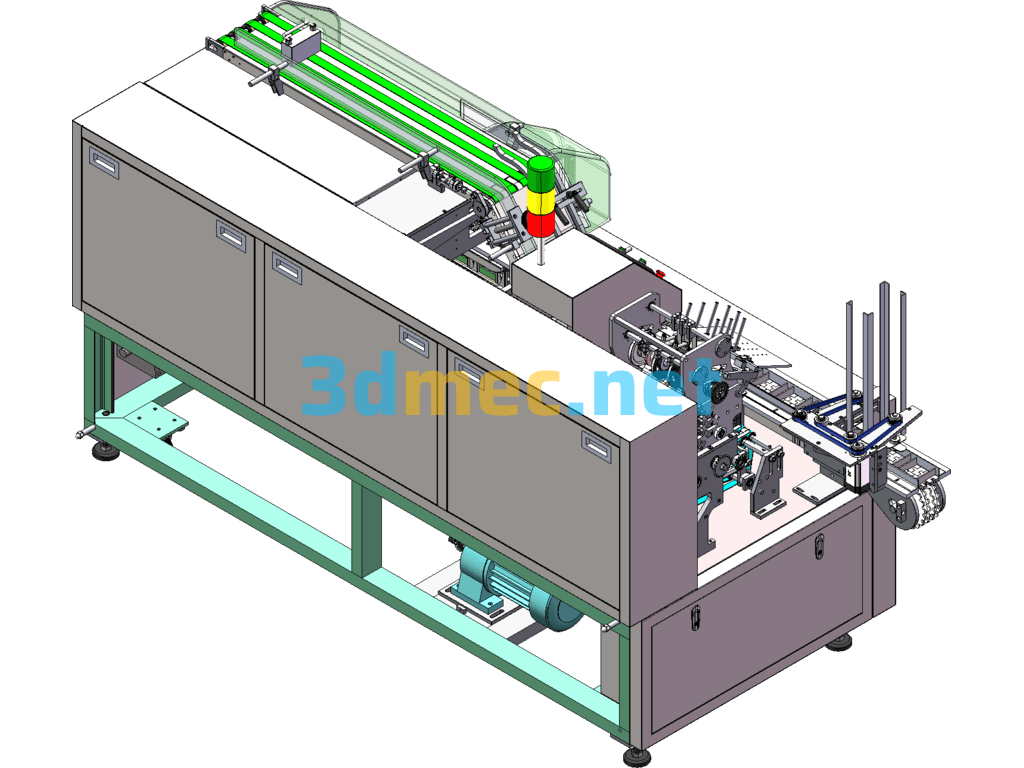

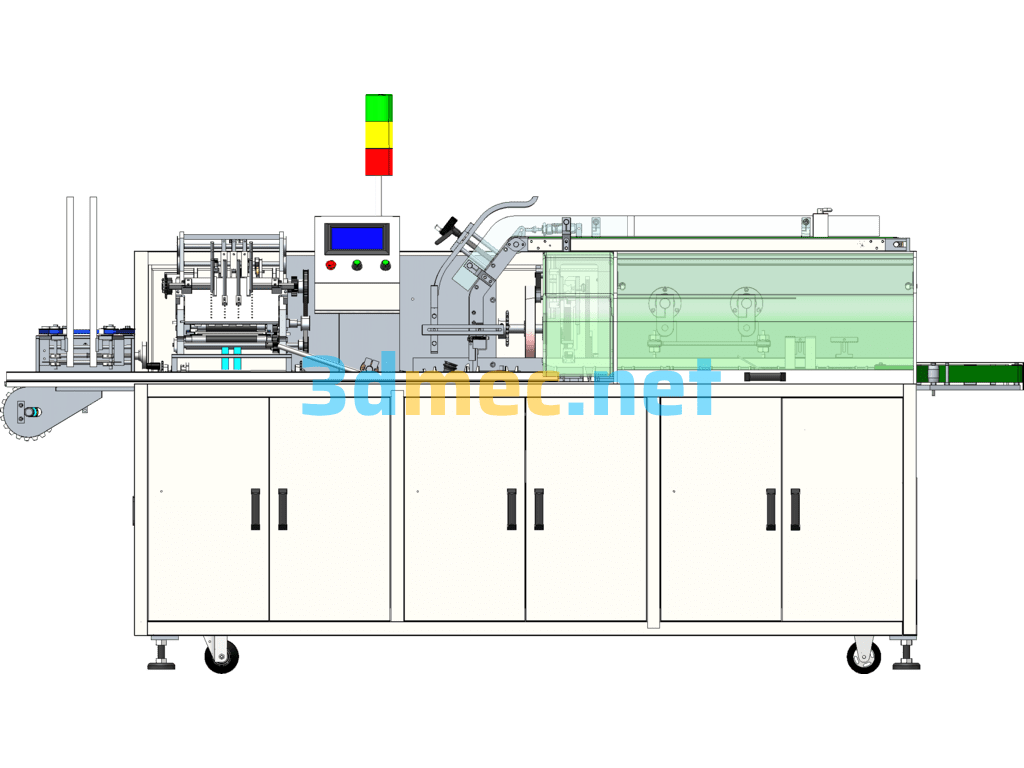

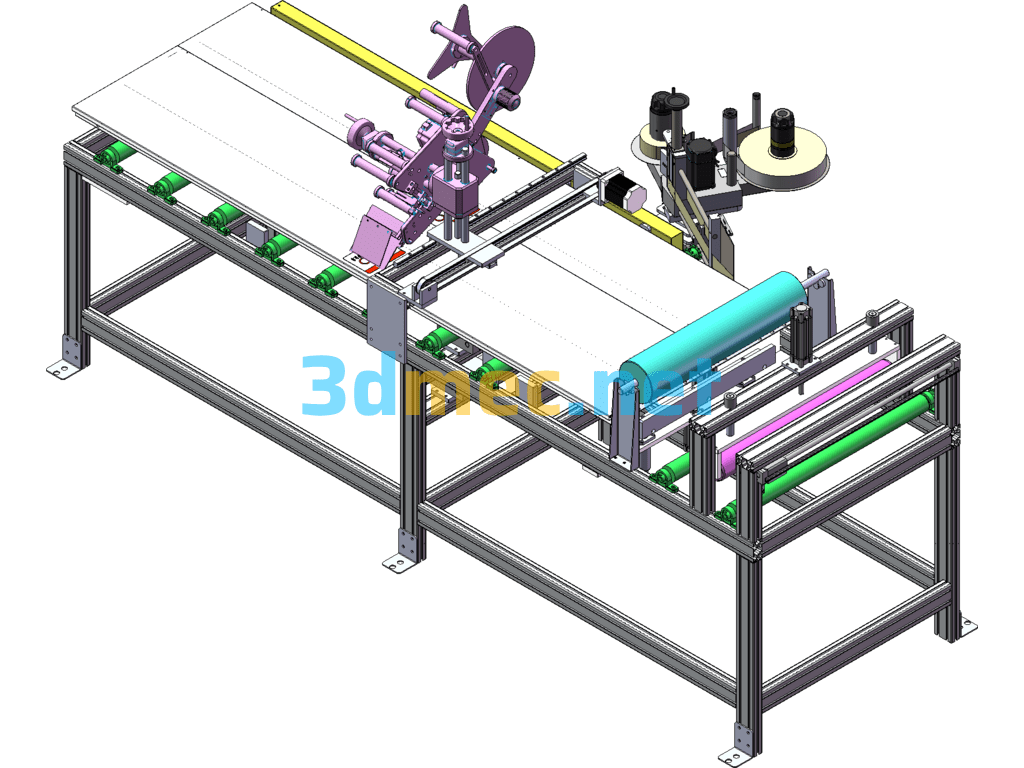

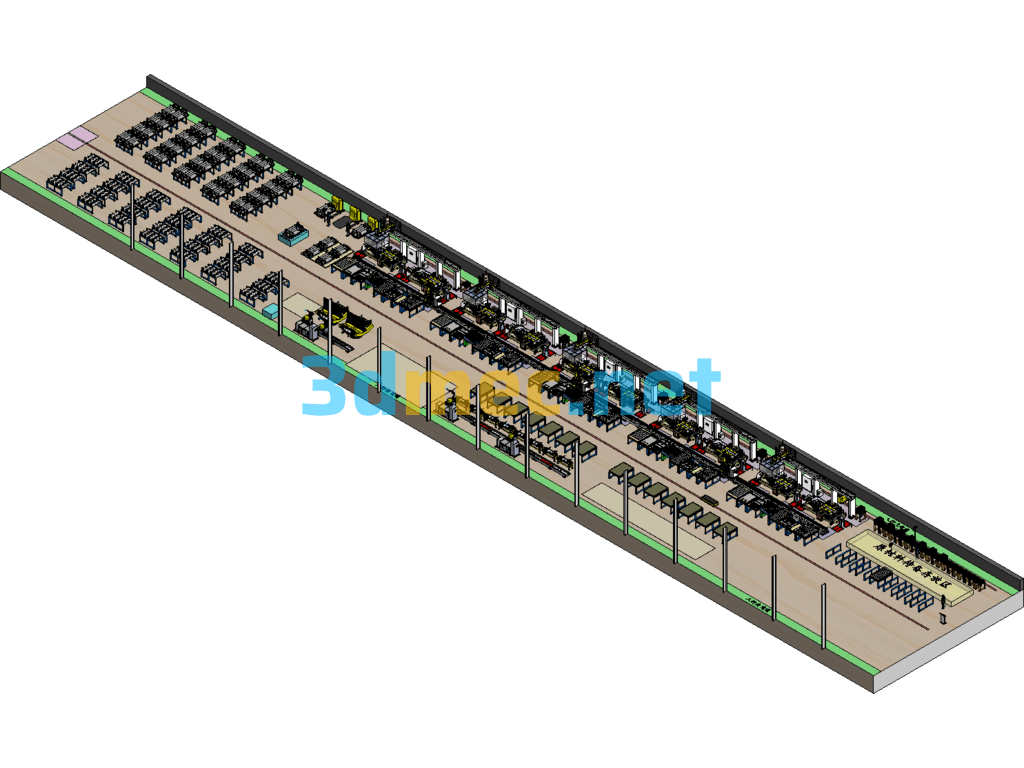

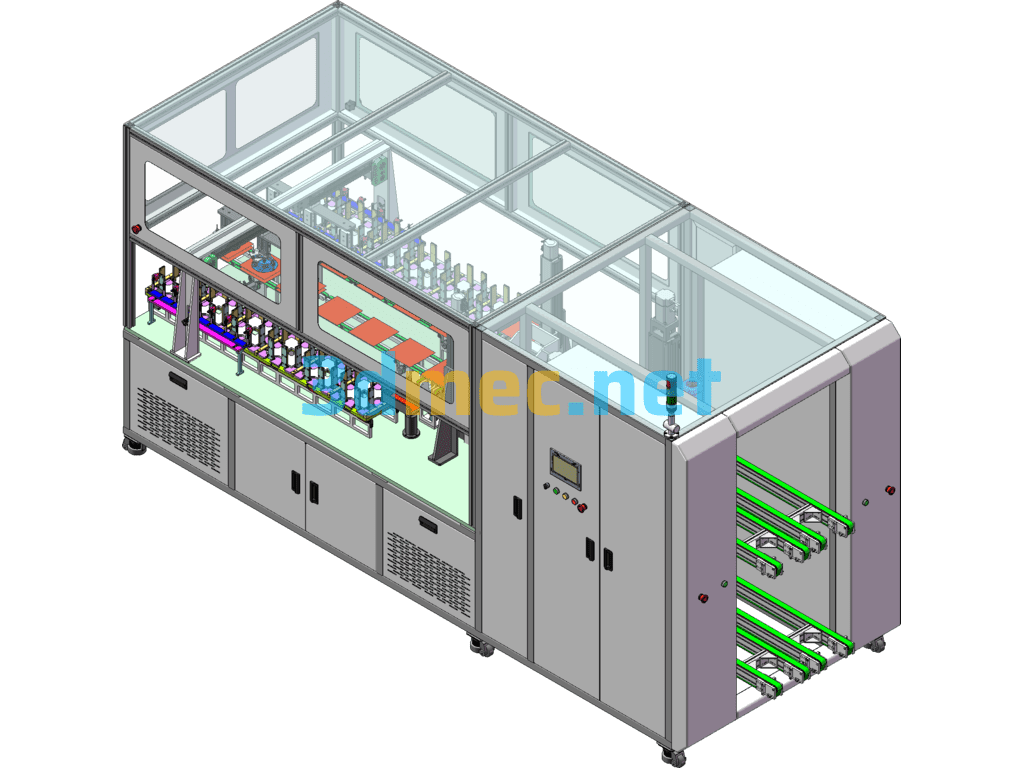

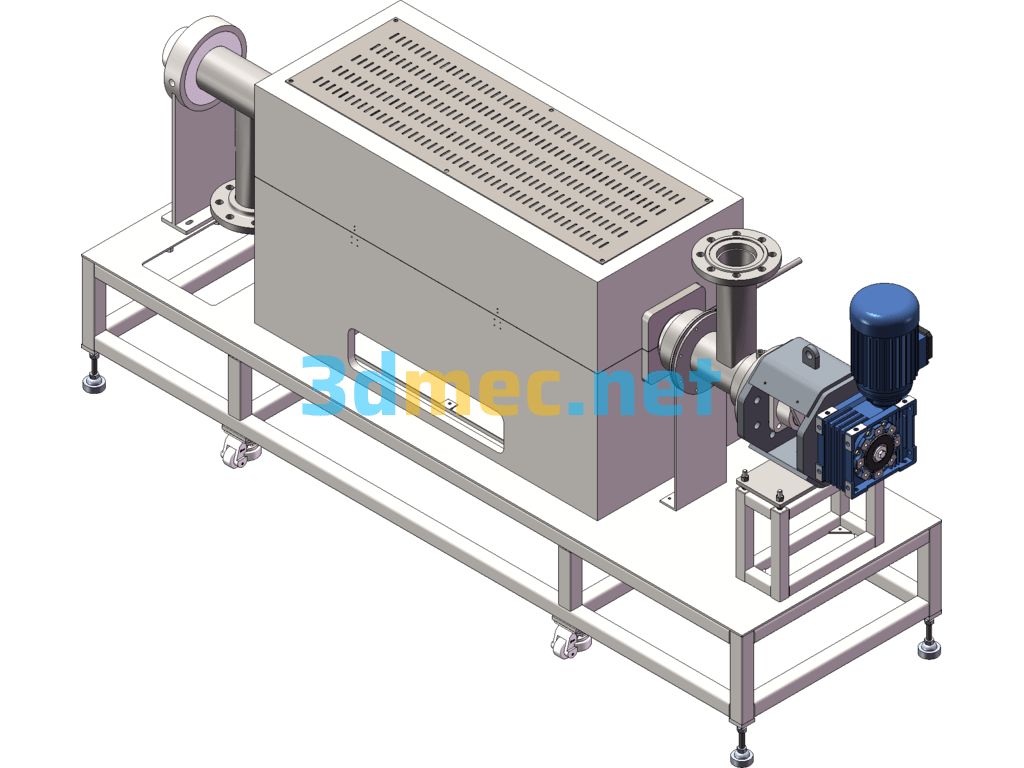

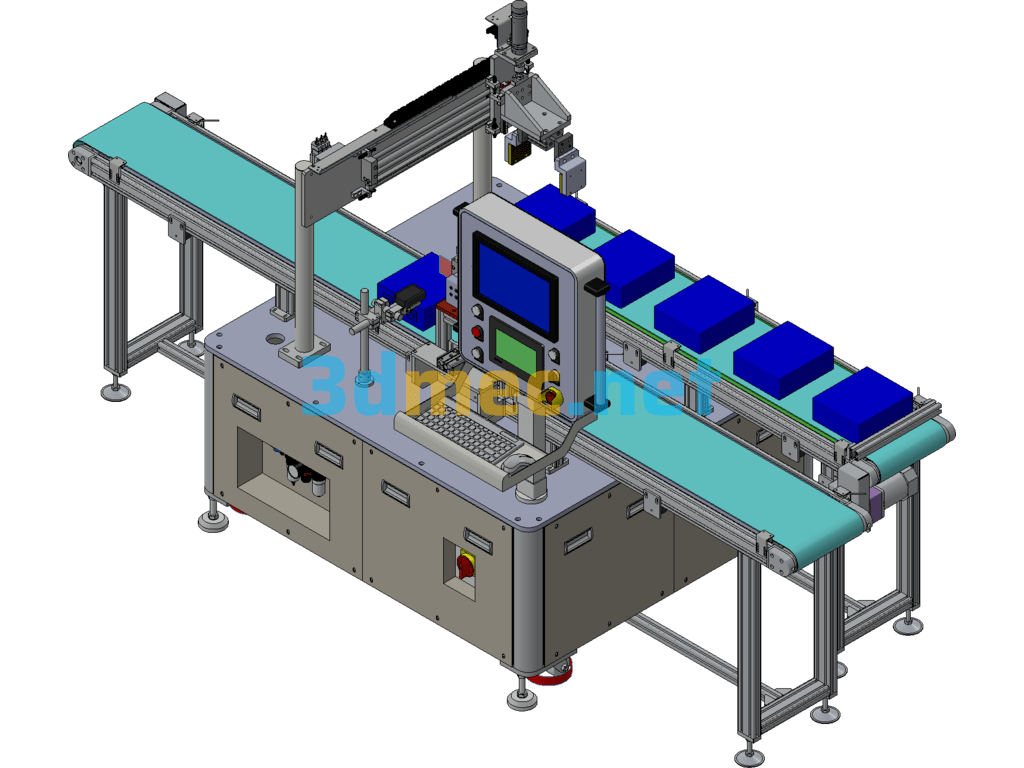

Automatic high speed cartoning machine Continuous cartoning machine Automatic cartoning machine Also can do mask packaging machine n Working Principle The feeding of automatic cartoning machine is generally divided into three entrances: the entrance of instruction manual, the entrance of medicine bottle and the entrance of machine package box. The whole process from carton feeding to final packaging can be roughly divided into four stages: a guide rail clamps the carton fixed and a push plate to open the carton, at the same time there will be two forward-moving clamps from below, from the front and back direction of the carton side of the cardboard box, so that the box opens at a right angle and move forward to the filling area. After filling in the filling area, the machine’s mechanism will bend the ears into the left and right rails before closing the lid. Before closing the lid, the mechanism bends the tongue of the carton, and then a pusher plate pushes the lid to bend so that the tongue is inserted into the box and the latch is tightened. The closing action is a key action, the completion of good or bad with the structure of the carton and the accuracy of the machine adjustment has a great relationship. Automatic high-speed cartoning machine drawings (full cam type), there are 2 motors to achieve dozens of action cycles, instructions, products together with automatic loading into the box: contains solidworks2015 STP XT format, contains parts drawings Parts assembly diagrams Total assembly diagrams A total of more than 1,400 parts This product is suitable for pharmaceuticals aluminum-plastic plate block, round bottles, anisotropic bottles, cosmetics, auto parts supplies, toothpaste, This product is suitable for the cartoning and packing of medicine aluminum-plastic plate block, round bottle, heterosexual bottle, cosmetic, auto parts, toothpaste, office supplies, poker, etc. and similar articles, and it can open the carton, carton and seal the carton automatically. The machine adopts PLC control and photoelectricity to monitor the action of each part, and it automatically rejects unqualified articles during operation. If there is any abnormality, it can stop automatically and show the reason in order to solve the trouble in time, and the machine can be used separately, or it can be used in conjunction with blister packaging machine and its hot solvent device or other equipments to form a complete set of production line. Main performance and structural characteristics: 1, automatic opening (suction) box, folding instructions, feeding, feeding, playing the batch number, sealing the box, detecting the waste and other processes, smooth operation, low noise. 2, PLC and human-machine interface, the machine can be used in the production line. 2, using PLC and man-machine interface automatic control system, stepless frequency conversion speed regulation, high degree of automation, easy to understand the operation. 3, the use of international famous brand electrical components, stable and reliable performance. 4, mechanical overload automatic shutdown function, to ensure the safety of man and machine. 5, Automatically reject the finished products which lack of packaging or instructions to ensure the quality of finished products. 6, with fault display, alarm and finished product counting functions, easy to maintain and deal with faults. 7, All kinds of automatic dischargers and conveyors can be designed according to customers’ requirements. 8, can be equipped with hot melt adhesive machine using hot melt adhesive spraying sealing or design hot melt adhesive brushing device. 9, with aluminum-plastic packaging machine, pillow packaging machine, filling machine, soap machine, spray code machine (or regulatory code system), labeling machine, online weighing instrument, three-dimensional packaging machine, heat shrink packaging machine, banding and bundling machine, other production lines and other production lines to achieve docking and linkage production. Main technical parameters power supply: Ac380 volts three-phase five-wire power supply 50 Hertz total power 2.5 kilowatts of production capacity of the host running speed: 50-120 boxes / minute gas consumption: 20 cubic meters / hour (pressure 0.5-0.8 MPa) Weight: about 1.2 tons

Specification: Automatic High Speed Cartoning Machine Continuous Cartoning Machine Automatic Cartoning Machine SolidWorks 3D Model

|

User Reviews

Be the first to review “Automatic High Speed Cartoning Machine Continuous Cartoning Machine Automatic Cartoning Machine SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.