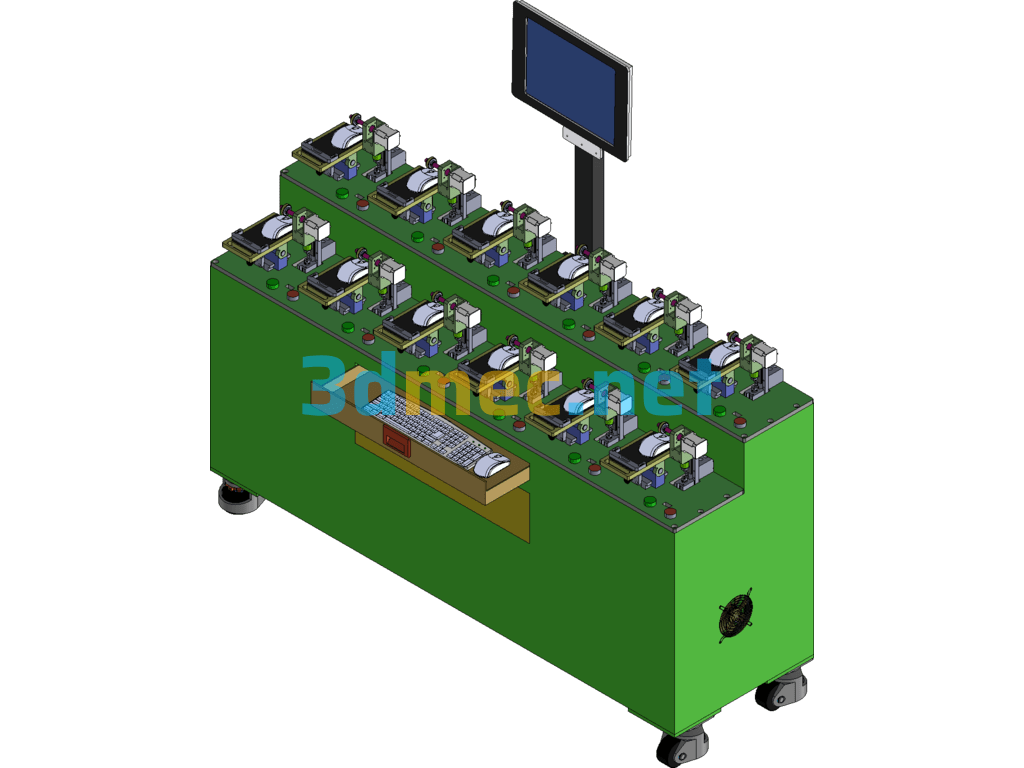

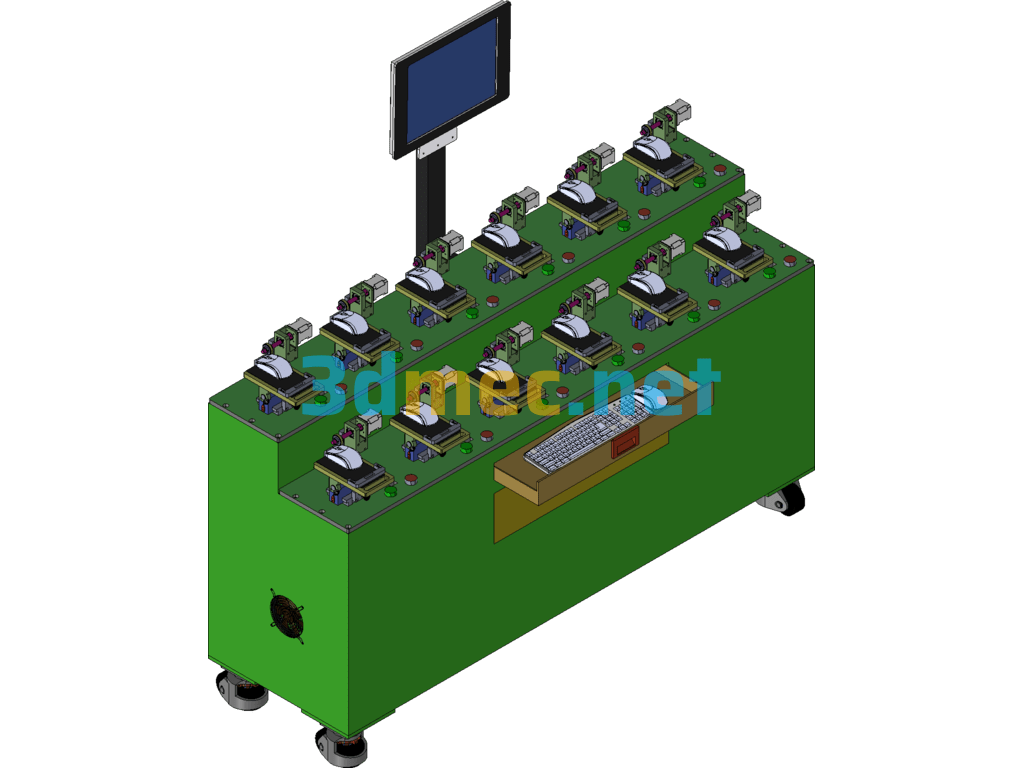

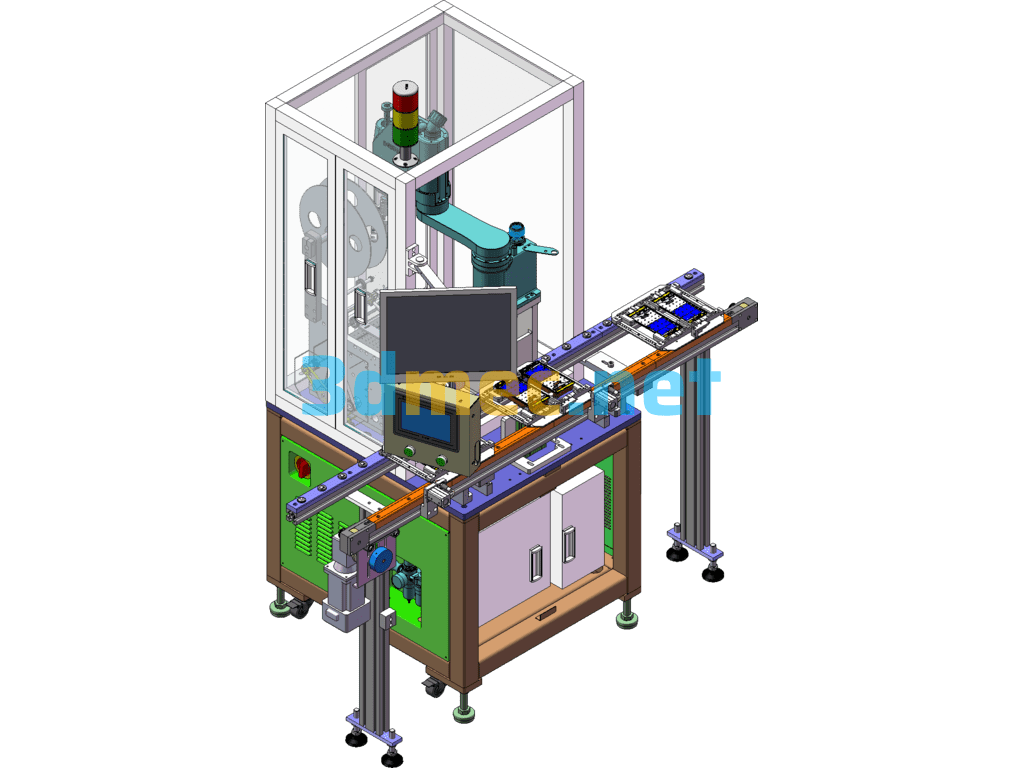

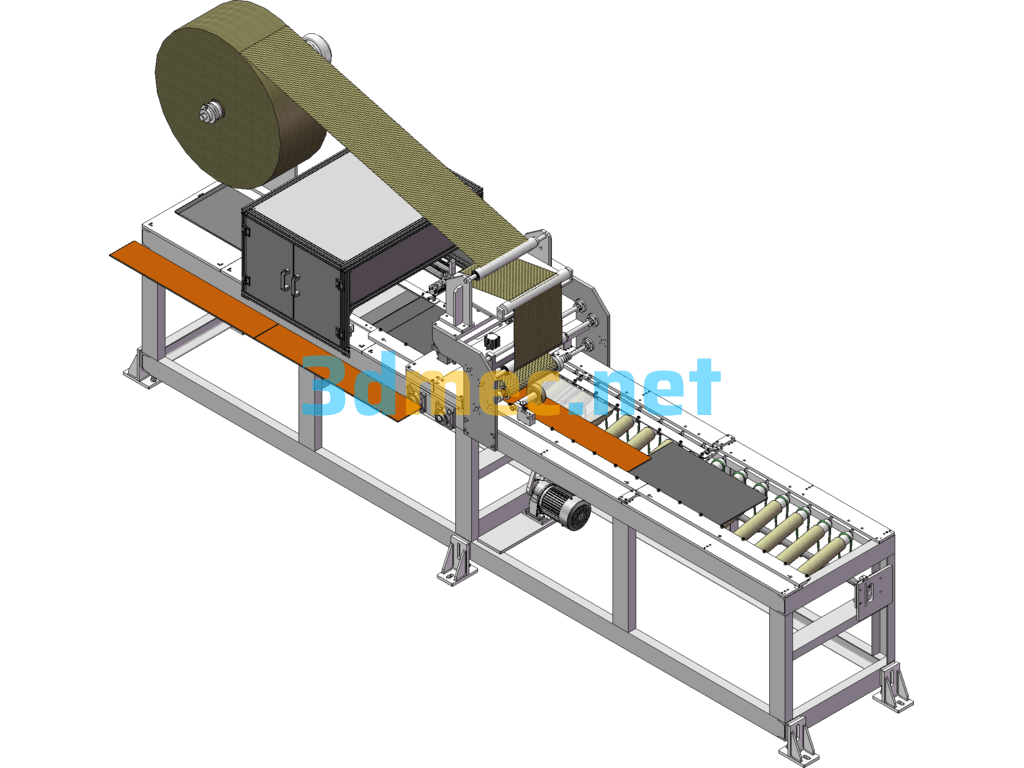

Automatic Control Force Mouse Wheel Test Aging Equipment Second Generation – 3D Model SolidWorks

Parameters of this equipment:

1. It has 12 product test positions (each position can control the force and test separately)

2. The test force is adjustable, and the adjustment force is: 0~1KG;

3. The test roller speed: 2~5 times per second;

4. It has the function of testing the mouse live socket;

5. It is equipped with a set of computers and software to record the number of tests;

6. It can accurately record the force of the product

7. It can stop in an emergency

8. It has the function of setting electrical safety.

The automatic control force mechanism adopts a pulse servo motor to drive the ball screw nut mechanism, which presses down to give the test roller and the mouse roller contact force. The force is given by the pressure sensor to set the force model. When the set value is reached, the servo motor stops running. Maintain this force, the roller rotates the aging test, and the second generation layout changes

Specification: Automatic Control Force Mouse Wheel Test Aging Equipment Second Generation – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Control Force Mouse Wheel Test Aging Equipment Second Generation – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.