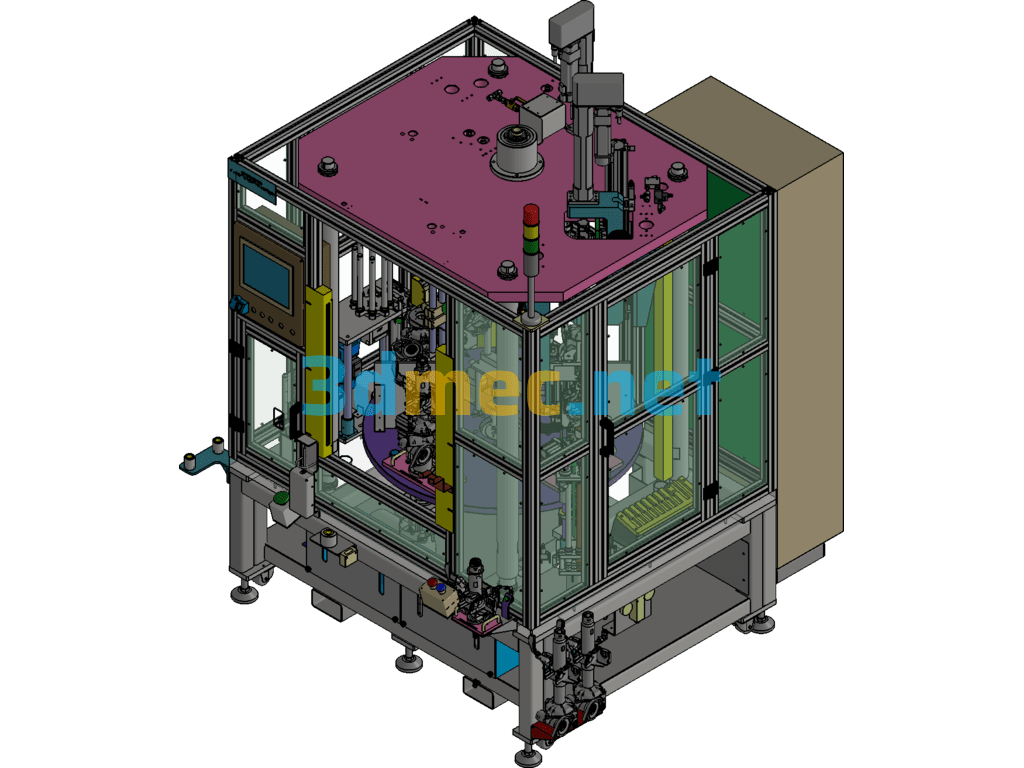

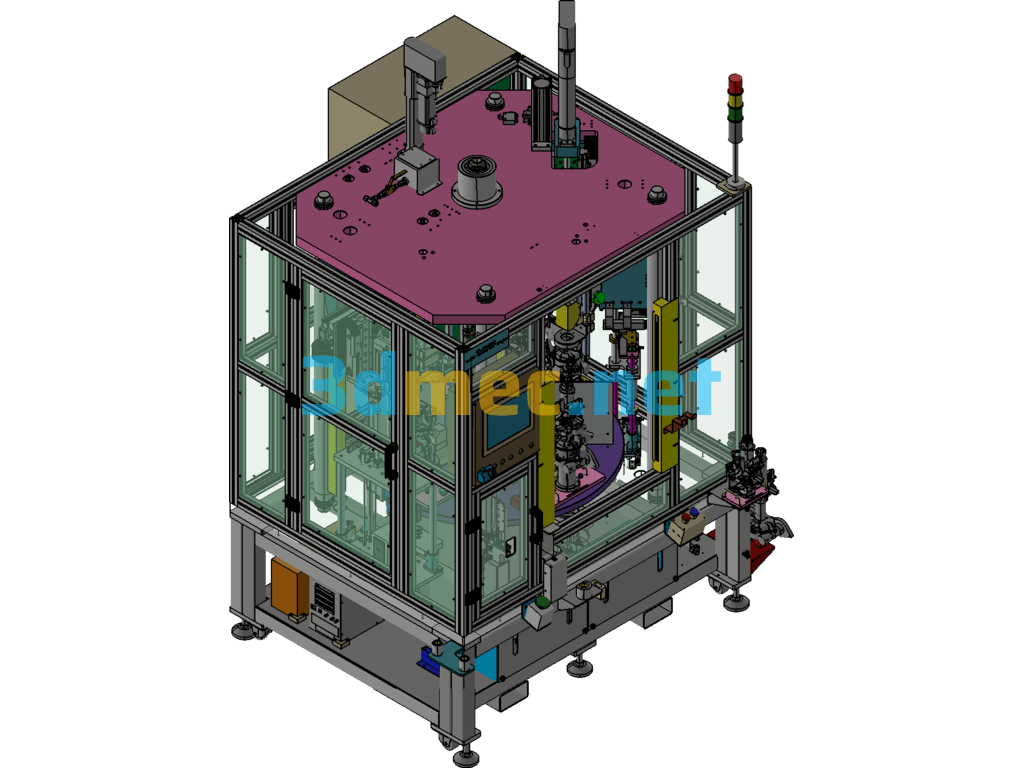

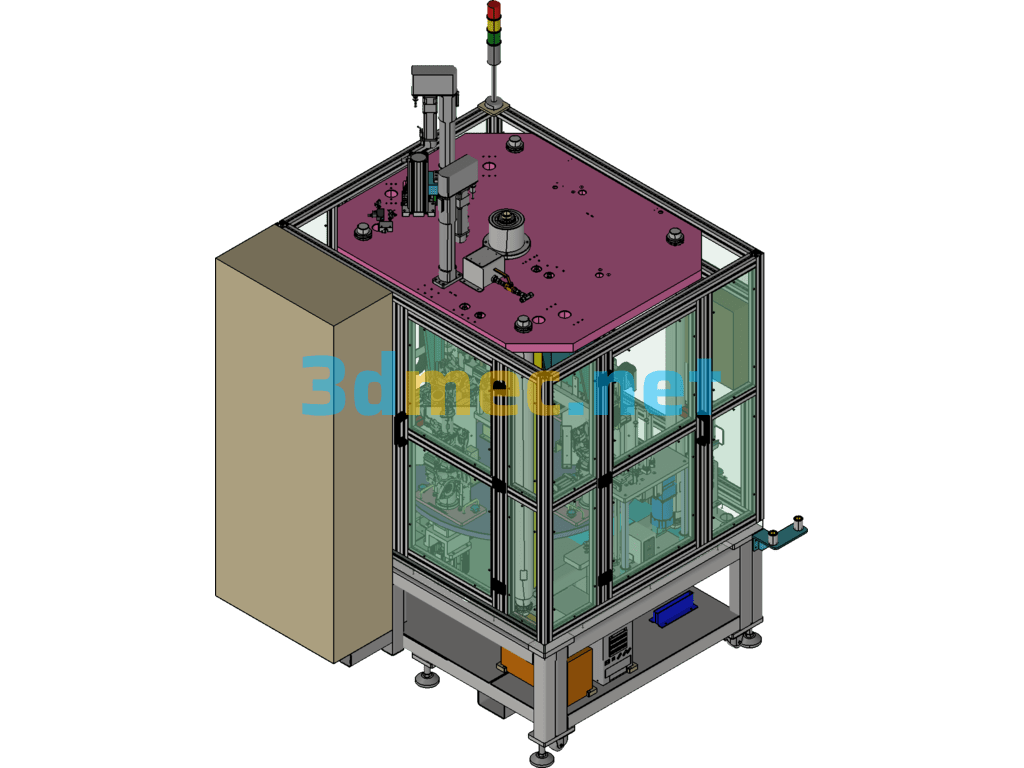

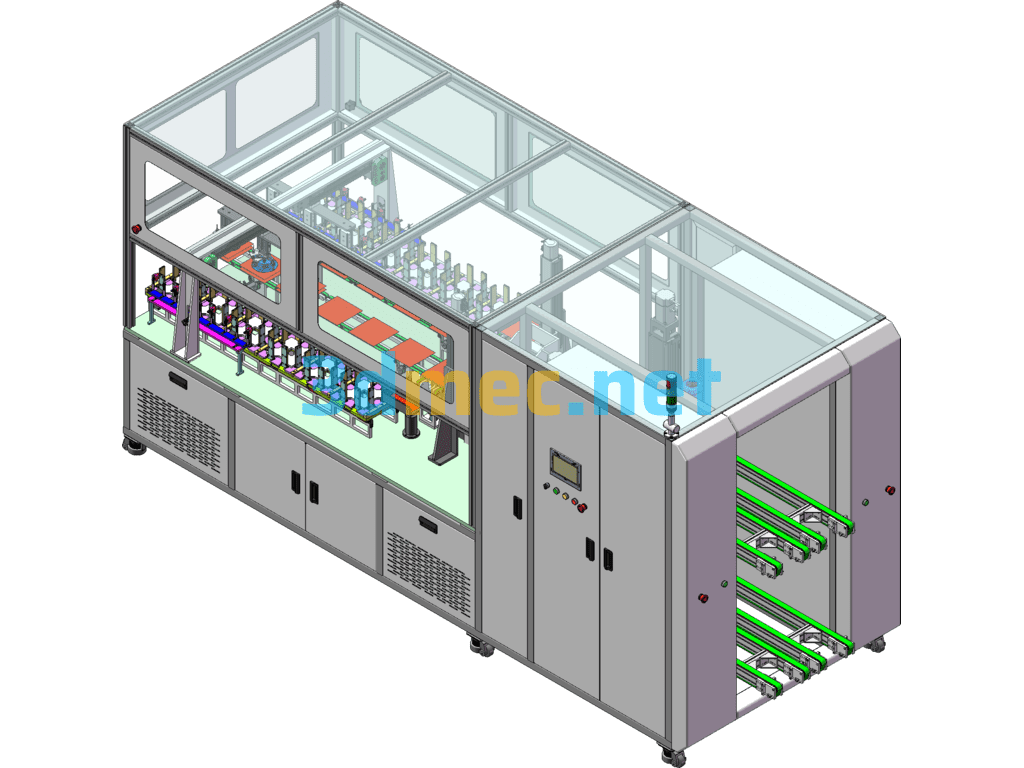

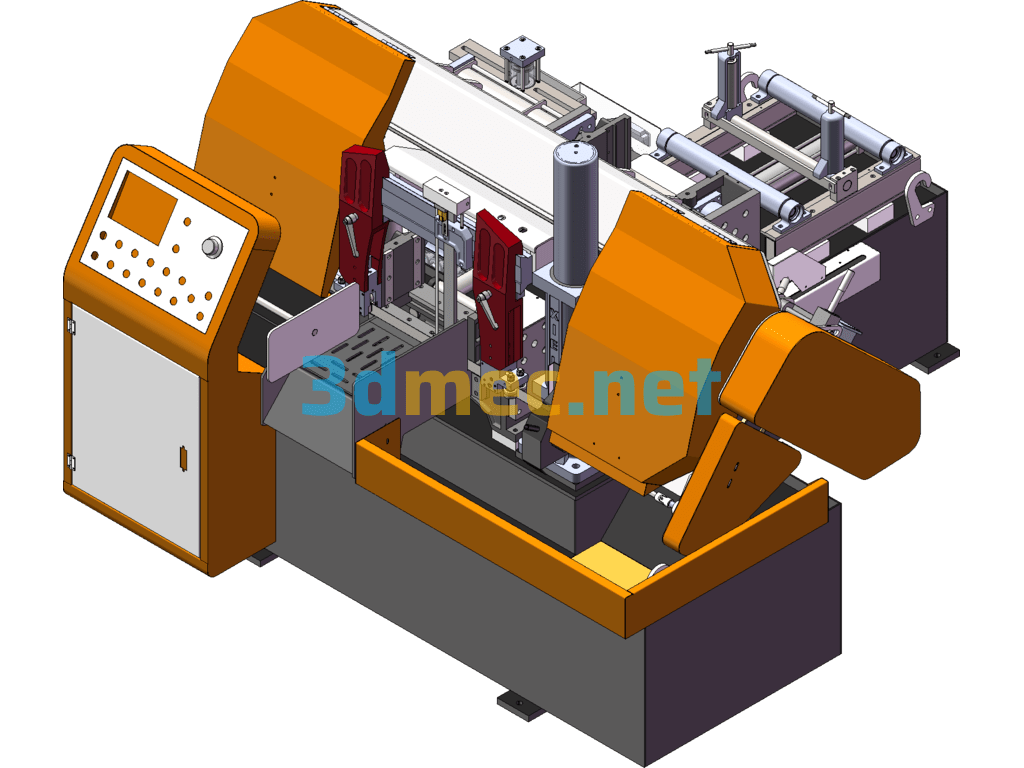

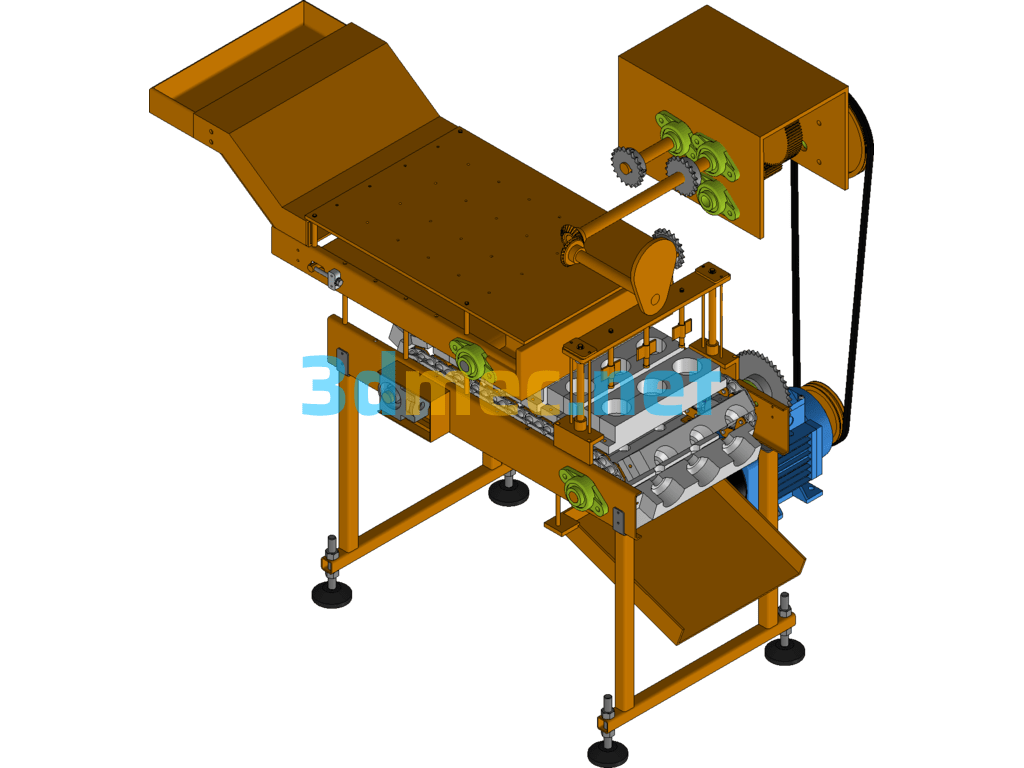

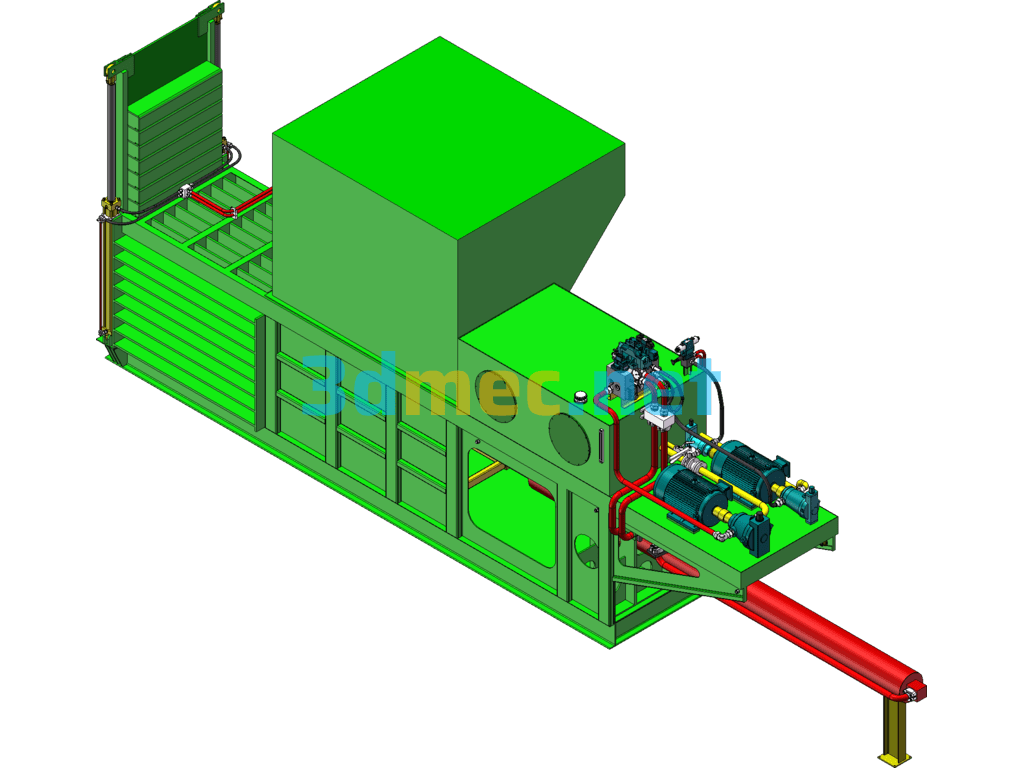

Automatic Circlip And Shaft Assembly Machine OP170 & OP180 – 3D Model Inventor

OP170 & OP180

1.Purpose: Manually install the lower retaining ring and manually oil the upper column tube; automatically assemble the rubber buffer pad, automatically press the upper column tube, automatically pull the shaft, and press the retaining ring.

2.Compatible products: A13TE, ZTM11E, FE-3DA

3.Equipment operation process (50s)

STA0 (28s)

1.Take the upper column tube and place it in the oiling station for automatic oiling (manual 2s)

2.Take the reduction gearbox assembly and place it in the retaining spring installation fixture, and manually install the retaining spring (manual 14s)

3.Scan the oiled upper column tube and install it in the automatic equipment (manual 6s)

4.Scan the workpiece with the lower retaining spring installed and install it in the automatic equipment (manual 6s)

STA1 (17s)

1.Manual unloading (manual 3s)

2.Take the pipe column assembly and place it in the lower fixture on the turntable (manual 3s)

3.Oil application is completed 4. The phased clamping cylinder clamps the adjustment bracket (automatic 1 second)

5. The pipe column straightening cylinder pushes the tilted pipe column straight (due to the spring force pulling the tilt) (automatic 1 second)

6. The axial positioning claw clamps the upper pipe column (automatic 1 second)

7. Take out an upper pipe column and put it into the oiling fixture (manual 3 seconds)

8. Press the start button (manual 1 second)

9. The upper pipe column transfer mechanism moves the upper pipe column to the middle waiting position (2 seconds)

STA2 (8 seconds)

1. The pressure plate cylinder extends (1 second)

2. Confirm that the press cylinder is extended and press the steering shaft to the bottom (2 seconds)

3. The pressure plate cylinder retracts (1 second)

4.Confirm that the press cylinder is retracted (2s)

Visually inspect whether the lower retaining ring is installed in place (2s)

STA3 (13s)

1.The buffer pad grabbing mechanism puts the buffer pad into the steering shaft (6s)

2.The cylinder presses down to press the buffer pad into place (5s)

3.The camera detects whether the buffer pad is pressed into place (2s)

STA4 (23s)

1.The upper column transfer mechanism moves the upper column to the bottom of the servo press (automatically 2s)

2.The lower support mechanism extends to support the lower clamp (1s)

3.The servo press is pressed down to press the upper column into the column assembly (11s)

4.The lower clamp positioning support mechanism retracts (2s)

5.Servo The press retracts to the initial position (3s)

6. The upper pipe column transfer mechanism moves the upper pipe column to STA1 (4s)

STA5 (24s)

1. The servo electric cylinder descends (2s)

2. Tighten the servo rotation and insert the guide sleeve into the input shaft (2s)

3. The retaining ring feeding mechanism sends a retaining ring to the guide sleeve (7s)

4. The push cylinder releases the push claw (1s)

5. The clamping cylinder clamps the guide sleeve again (1s)

6. The servo electric cylinder rises and pulls the guide sleeve to press the retaining ring into the groove (4s)

7. Tighten the servo rotation and remove the guide sleeve (2s)

8. The servo electric cylinder rises and lifts the guide sleeve (2s)

9. The lifting cylinder retracts (2s)

Specification: Automatic Circlip And Shaft Assembly Machine OP170 & OP180 – 3D Model Inventor

|

User Reviews

Be the first to review “Automatic Circlip And Shaft Assembly Machine OP170 & OP180 – 3D Model Inventor”

You must be logged in to post a review.

There are no reviews yet.