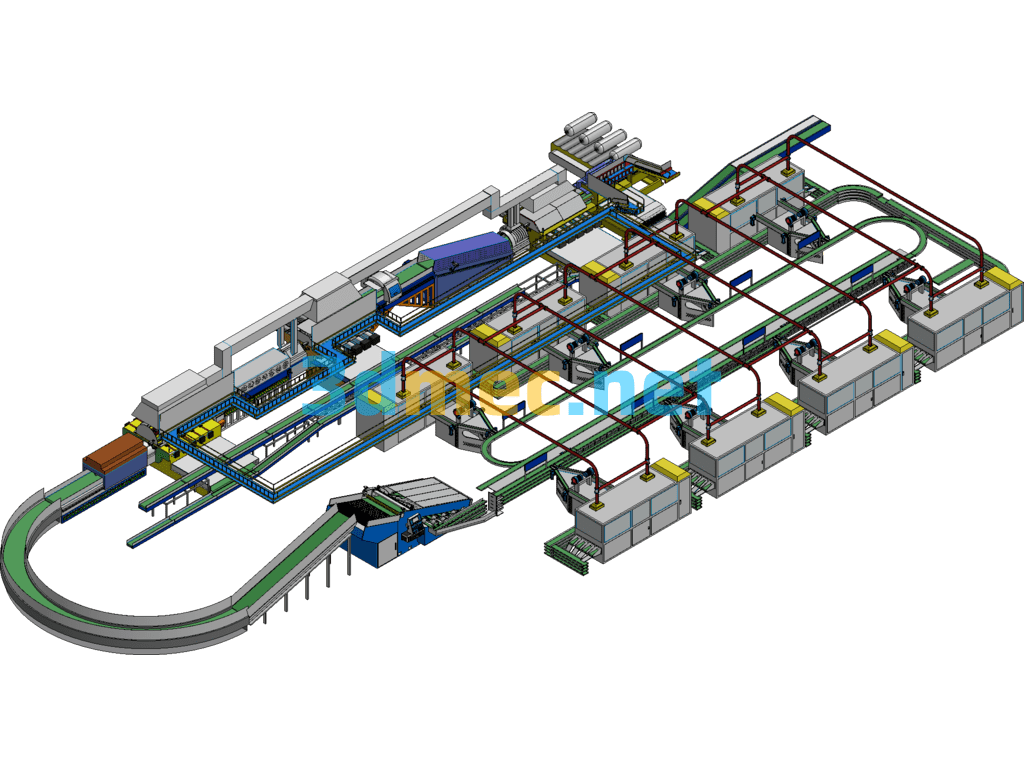

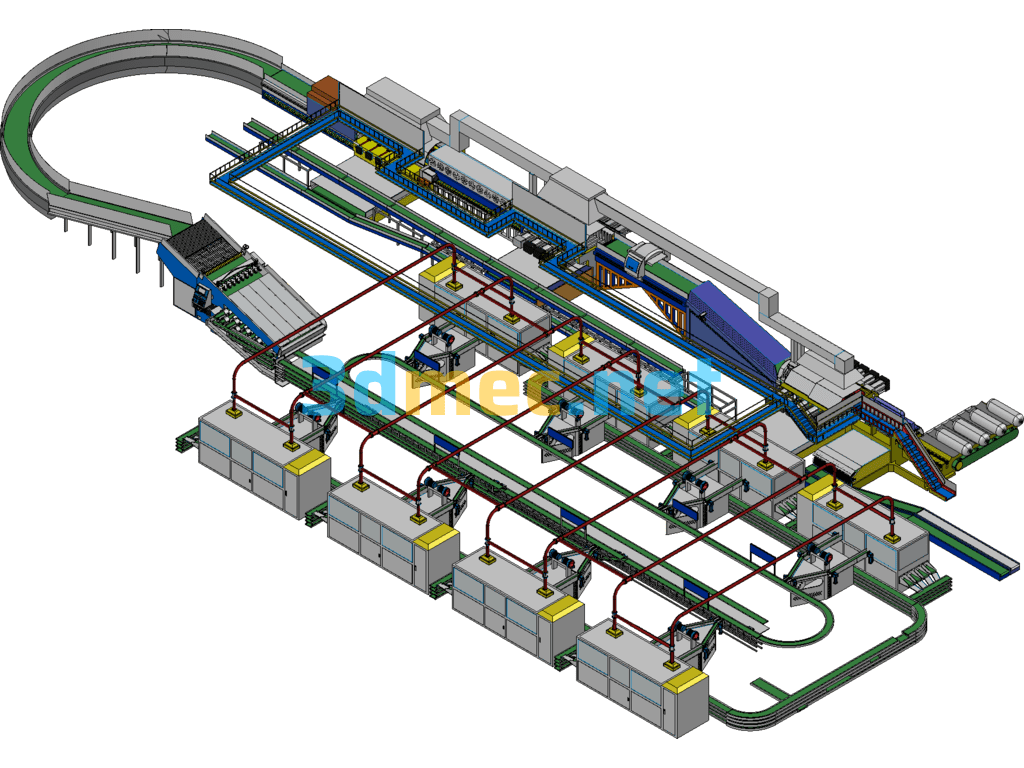

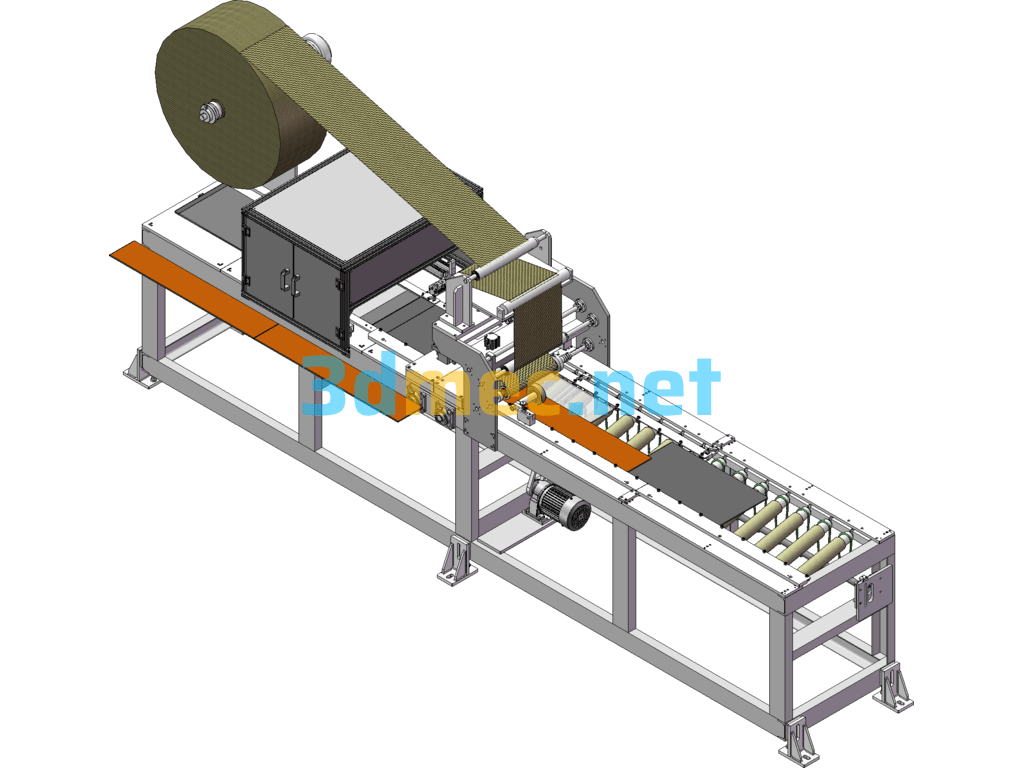

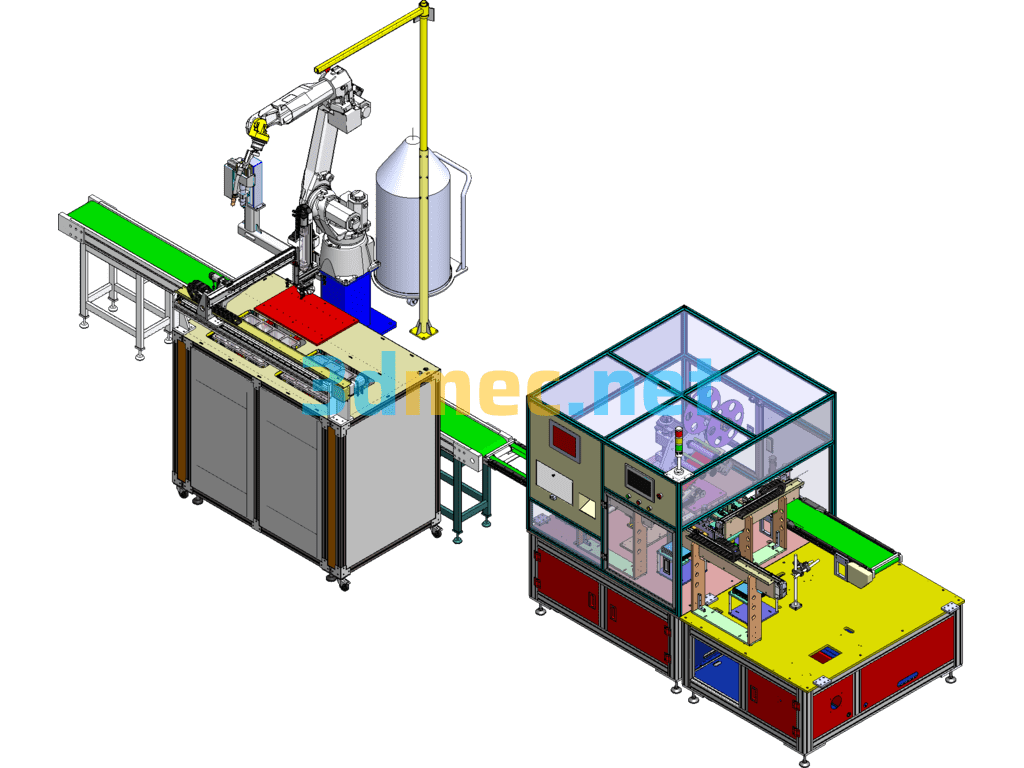

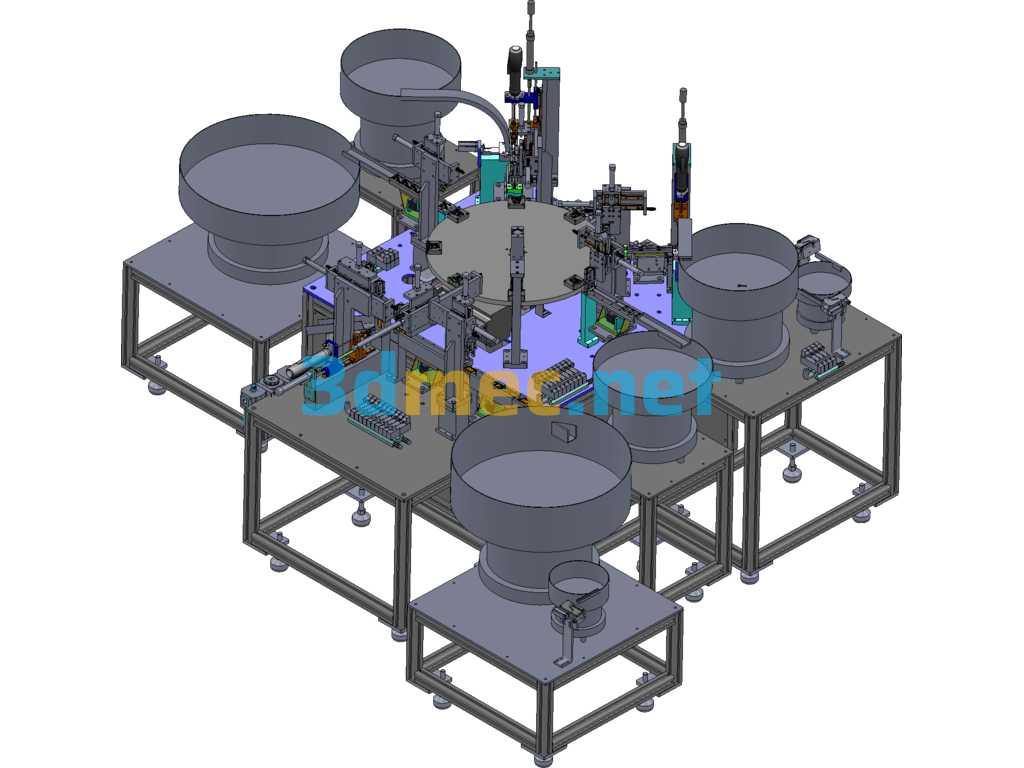

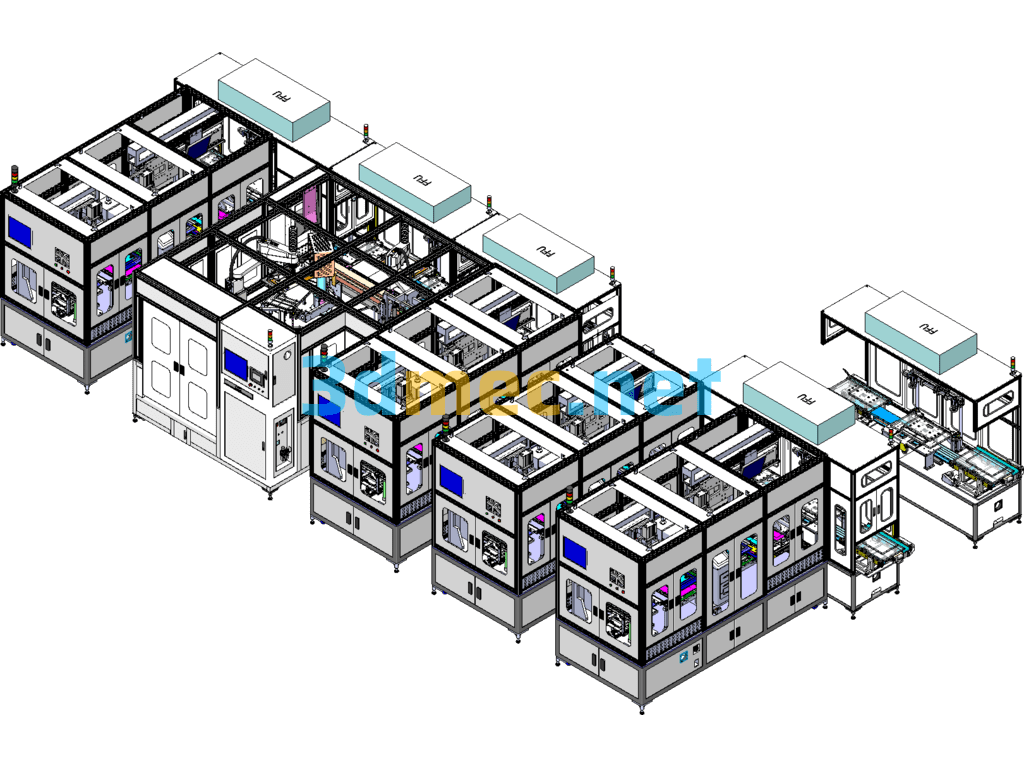

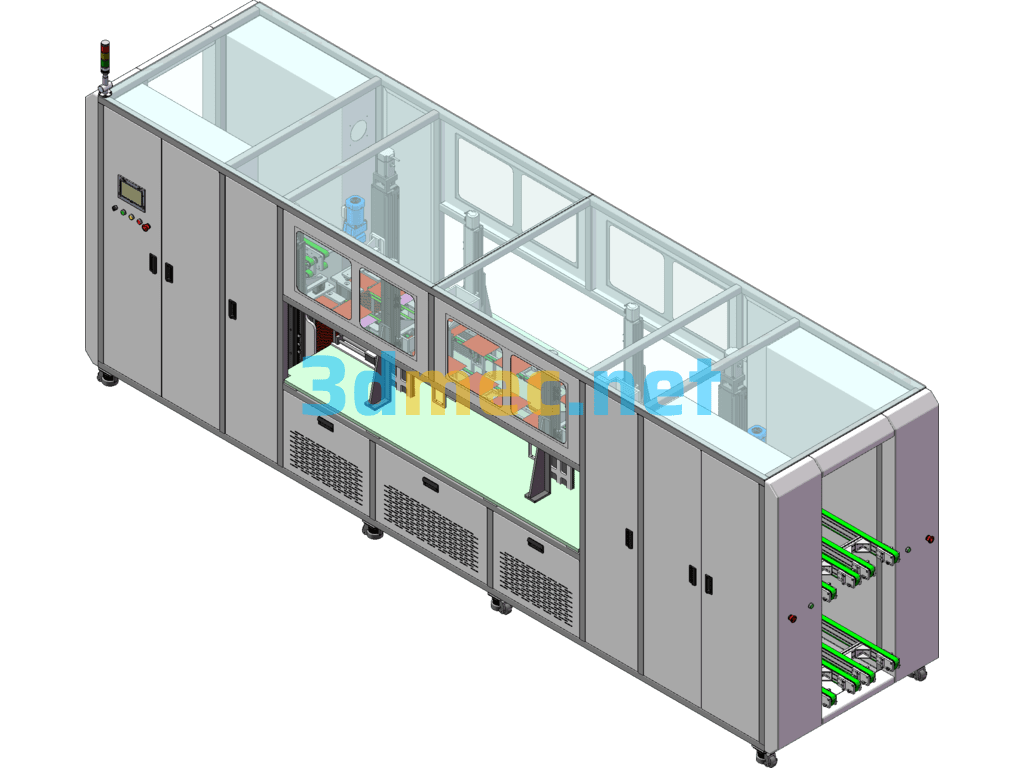

Process description n This process adopts one drag two control mode, a camera control system simultaneously recognizes and controls the left and right recognition cameras. n Through the camera reads the material and recognizes the 1234 grade products, the system feeds back to the PLC controller to distinguish and exclude the 1234 grade products. n The left and right conveyors are each divided into 22 equal parts, each equal part passes through the camera recognition area, the camera reads the material good and bad, and the data analyzed by the system is fed back to the PLC, which controls the products of all levels. In the designated aliquot position excluded to 1-2-3-4 exit conveyor. Recognized to the first level of material, the first level of material directly out. 2-3-4 exclusion valve does not intervene. Recognized to 2-3-4 level product, will be excluded in the 2–3–4 position, can not go to the first level product n Function Function Flow Description Flow Description n1.1.1.1. This program is designed according to the raw material identification and sorting process, by manually placing the raw material into the loading machine, starting n Equipment, raw materials into the automatic cleaning area for cleaning, cleaning equipment using S-shaped conveyor belt for cleaning n Cleaning equipment adopts S-shaped conveyor way to clean n, S-shaped conveyor effectively let the raw material itself automatically turn over the mud to clean quickly, cleaning using high n The cleaning adopts the high pressure spray washing method, which can quickly clean the surface of the raw materials, and enter the air-drying area, through rapid dehydration, avoiding n Avoid raw materials will be a large amount of water into the visual equipment, after dehydration of raw materials transported to the rapid detachment machine, n The raw materials will be quickly pulled away from a certain distance, and smoothly transported to the testing area, in the testing equipment is installed with dust removal n A dust collector is installed in the inspection equipment to ensure that the camera as well as the handling mechanism are clean. In the high-definition camera and light source, the rapid collection of n The images are fed back to the image processor, which gives accurate signals to the PLC, which controls the system to process the different levels quickly n. Quickly process the different levels. There are two fast conveyors installed in the equipment, the sorted materials are automatically transported to one n level aisle, and a secondary level aisle, which conveys it to the designated box. Includes images of the vision cameras used

Specification: Automated Cristal Visual Recognition Sorting Exported 3D Model

|

User Reviews

Be the first to review “Automated Cristal Visual Recognition Sorting Exported 3D Model”

You must be logged in to post a review.

There are no reviews yet.