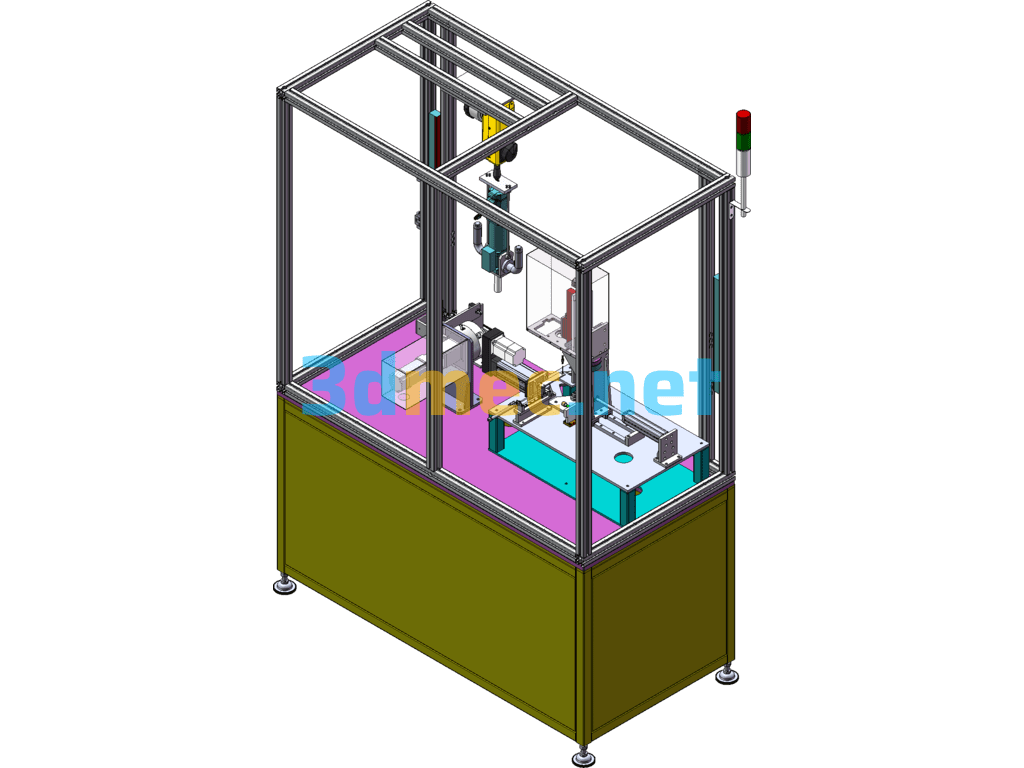

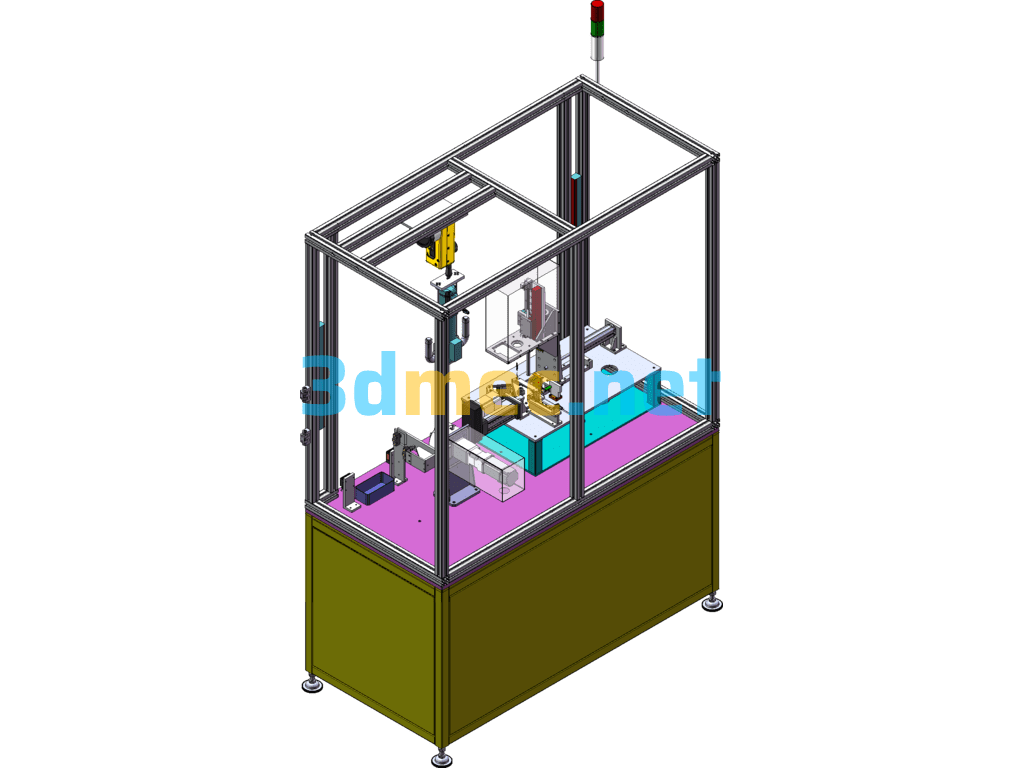

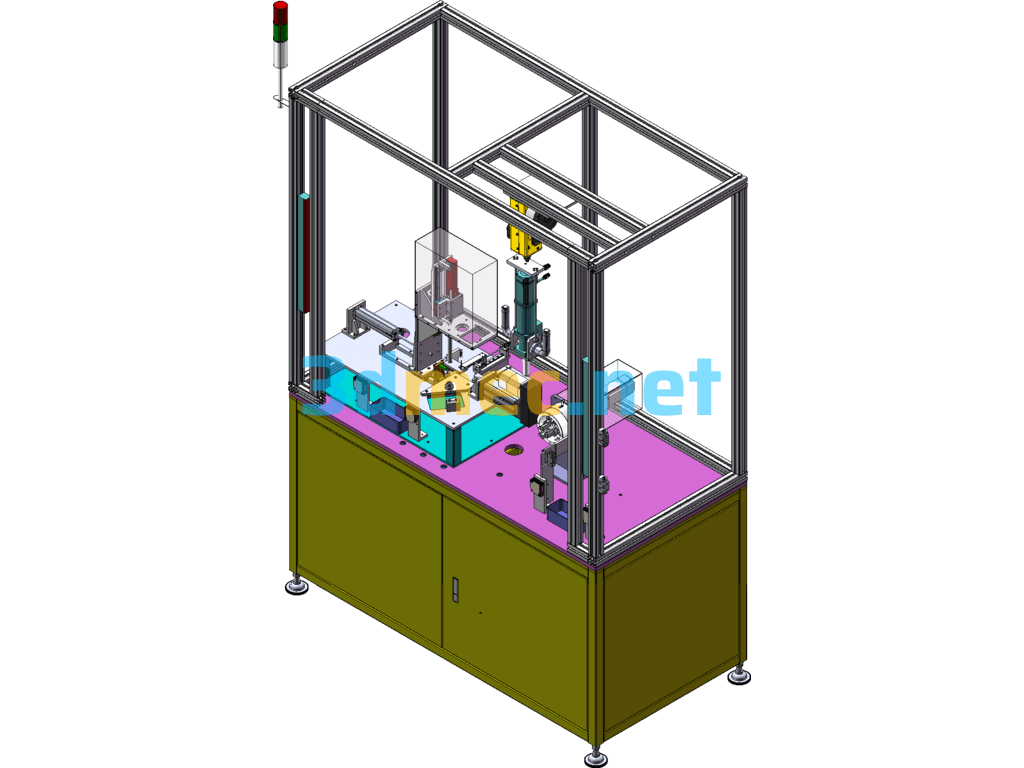

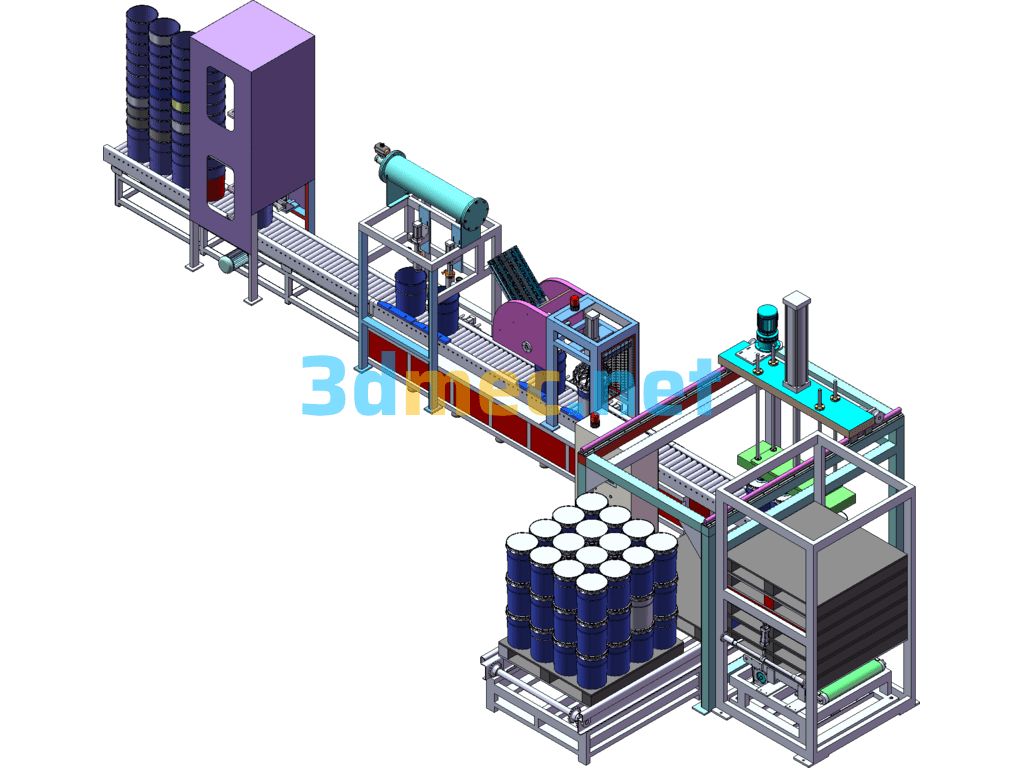

After The Bolts Are Locked, The Screw Locking Equipment Is Tested By Pressing The Bolts Together (Including DFM) – 3D Model SolidWorks

The product of the press-fit detection and screw locking equipment is manually placed in the fixture for positioning, and the pressure and pressing distance of the body are controlled by the electric cylinder. The bolts are manually locked. After the pressing is completed, it is manually transferred into the rotating module to position and clamp the inner hole. The rotation uses a displacement sensor to detect the pressing depth and whether the bolt is locked.

Specification: After The Bolts Are Locked, The Screw Locking Equipment Is Tested By Pressing The Bolts Together (Including DFM) – 3D Model SolidWorks

|

User Reviews

Be the first to review “After The Bolts Are Locked, The Screw Locking Equipment Is Tested By Pressing The Bolts Together (Including DFM) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.