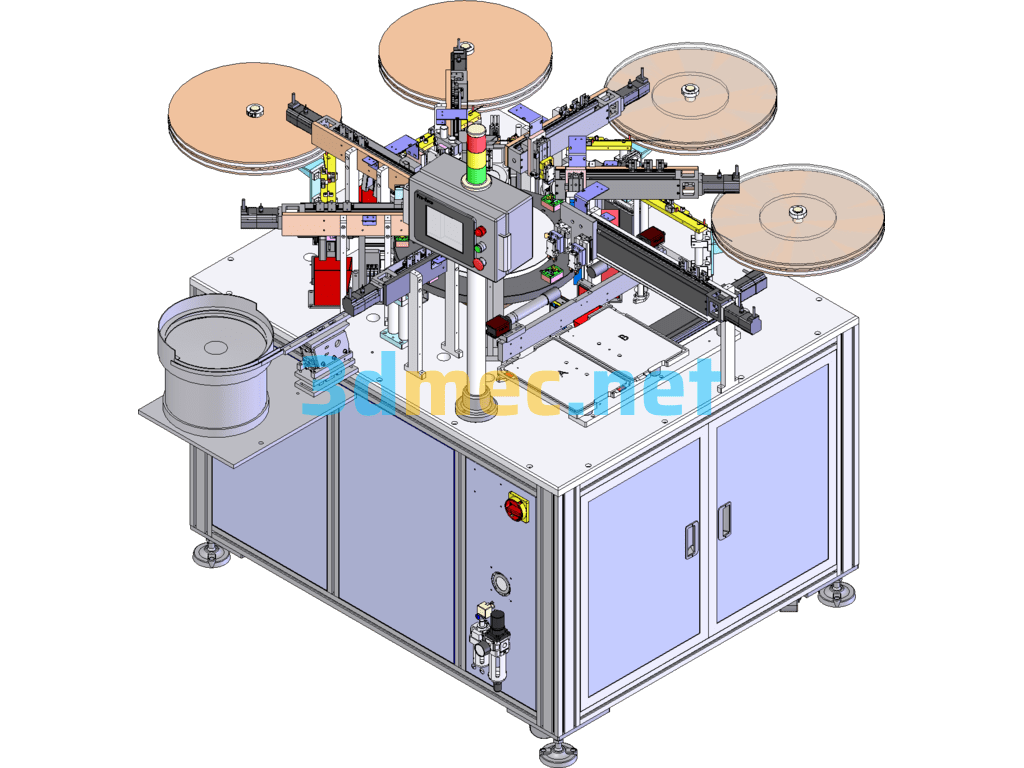

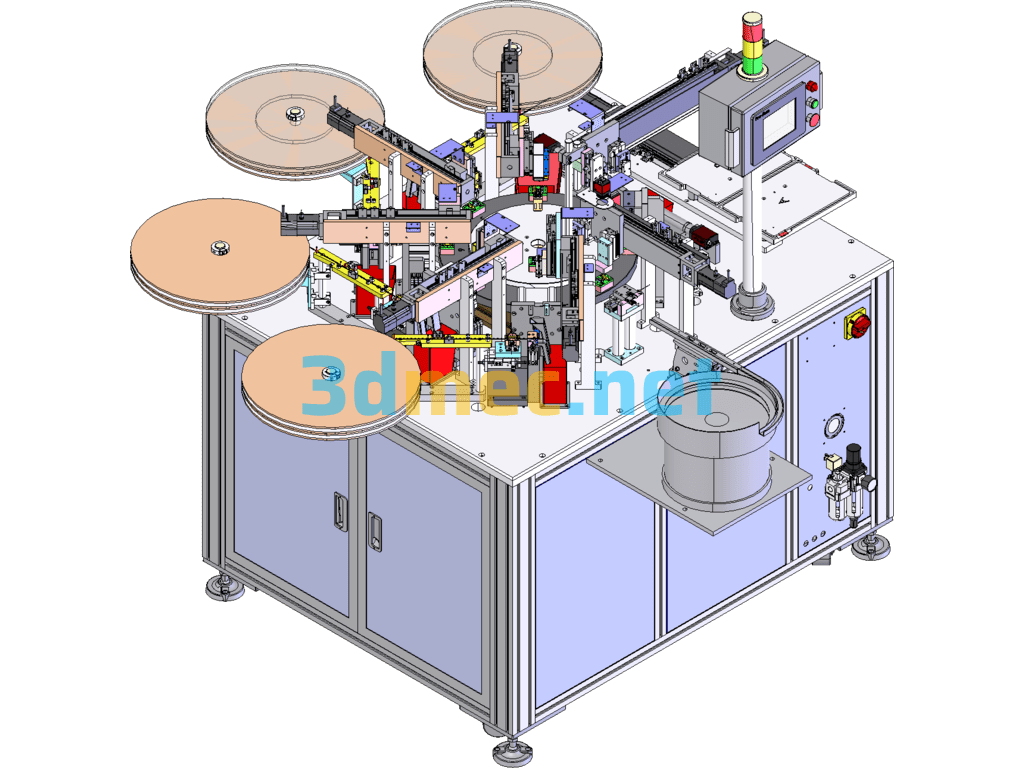

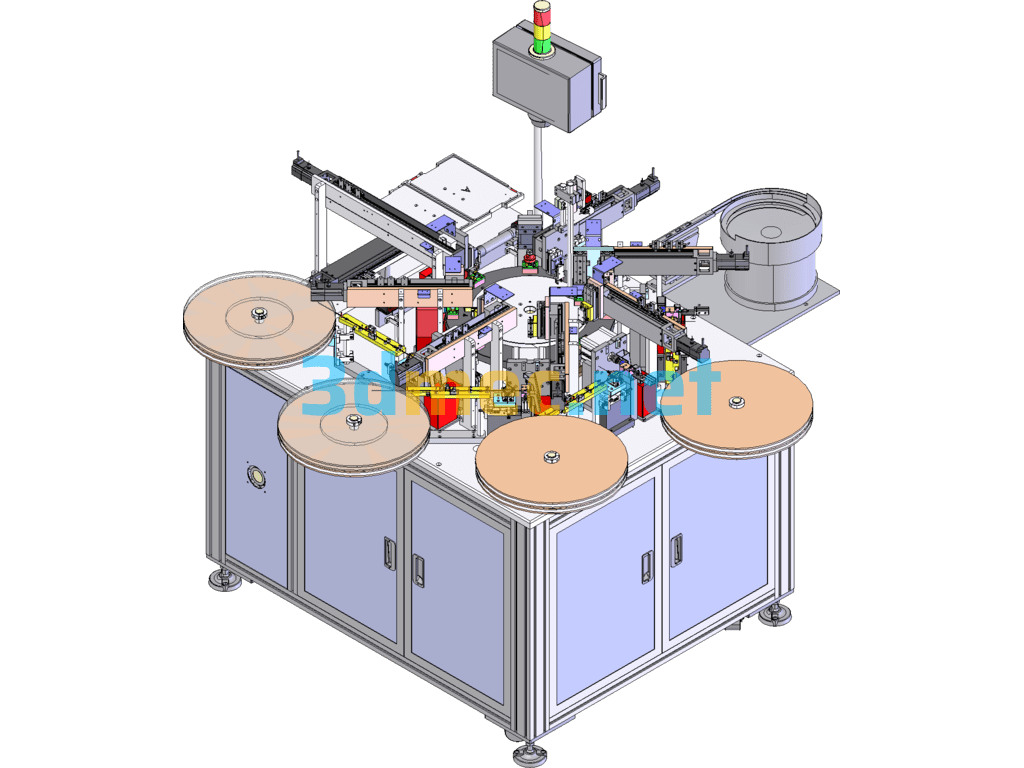

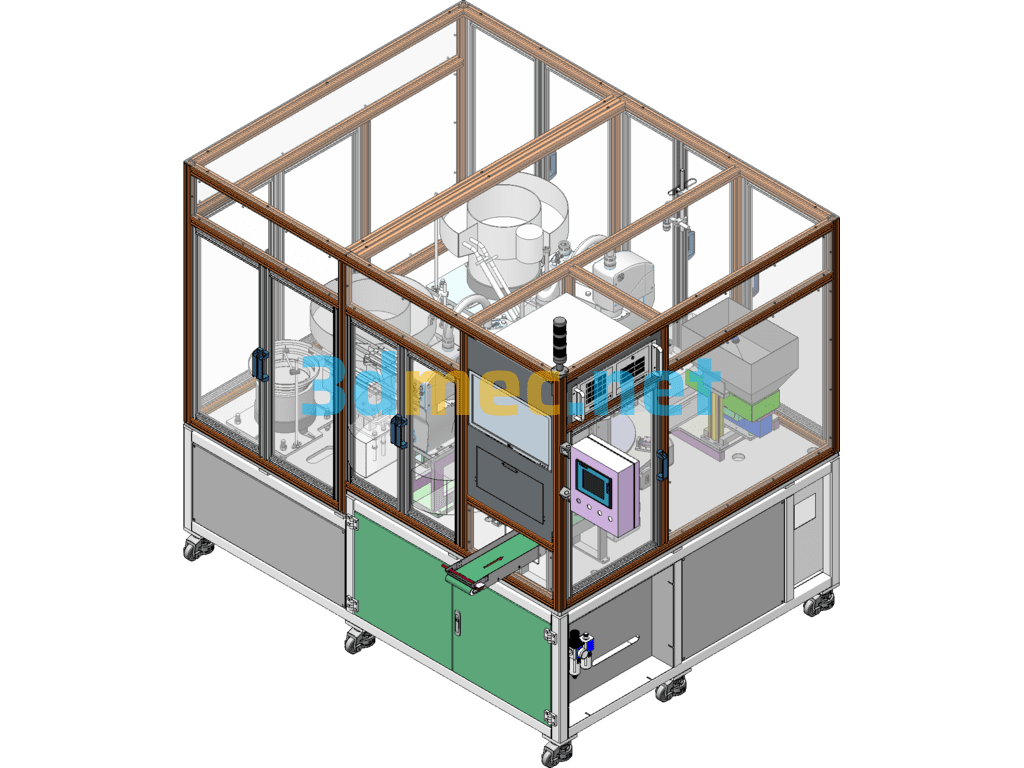

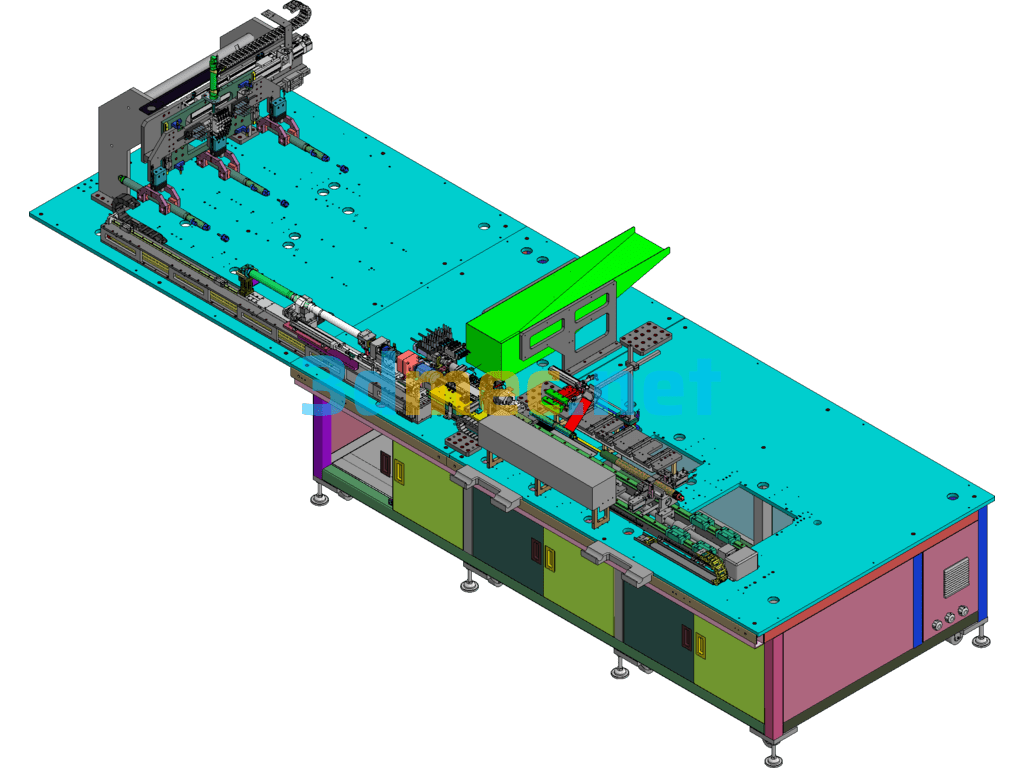

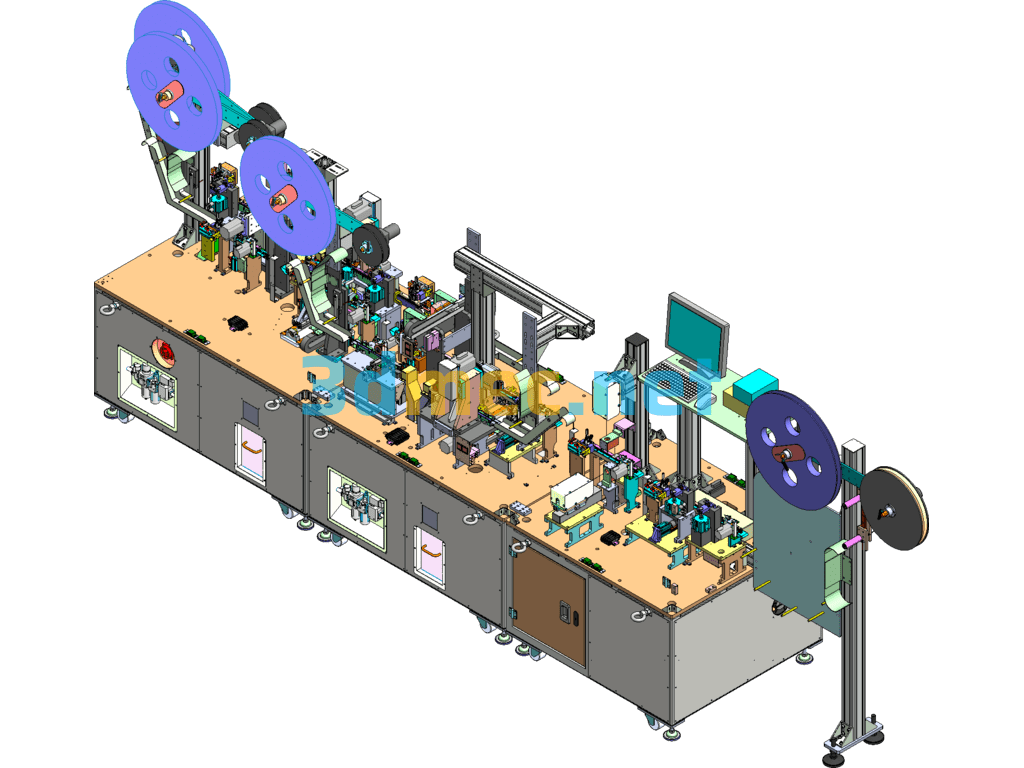

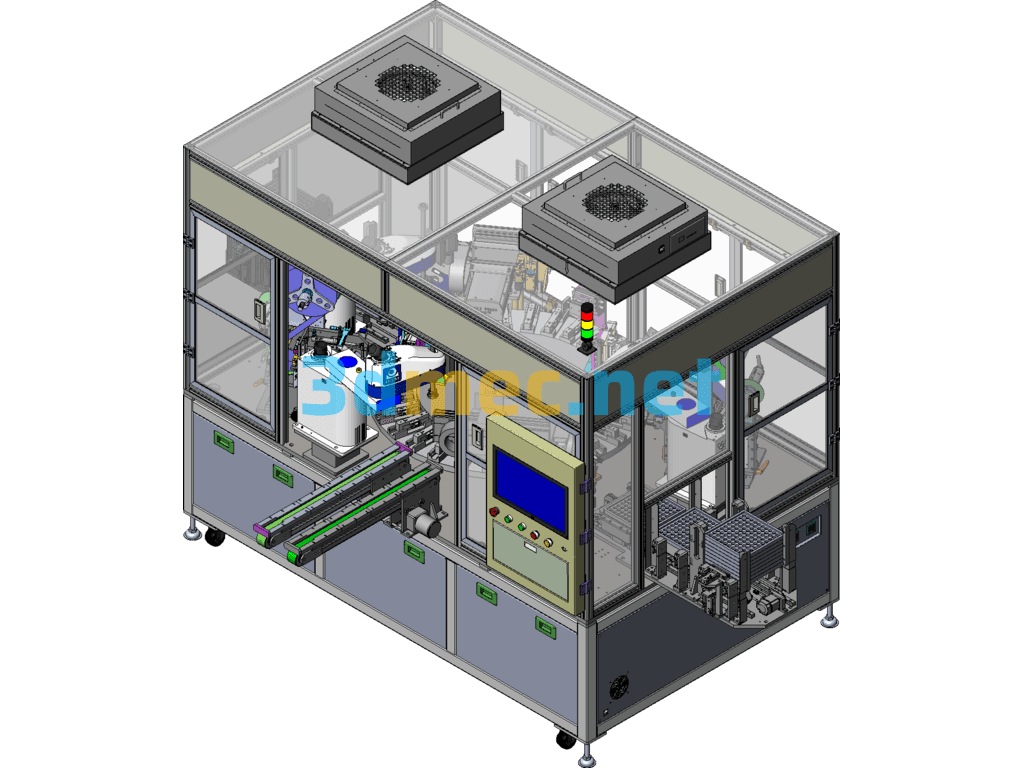

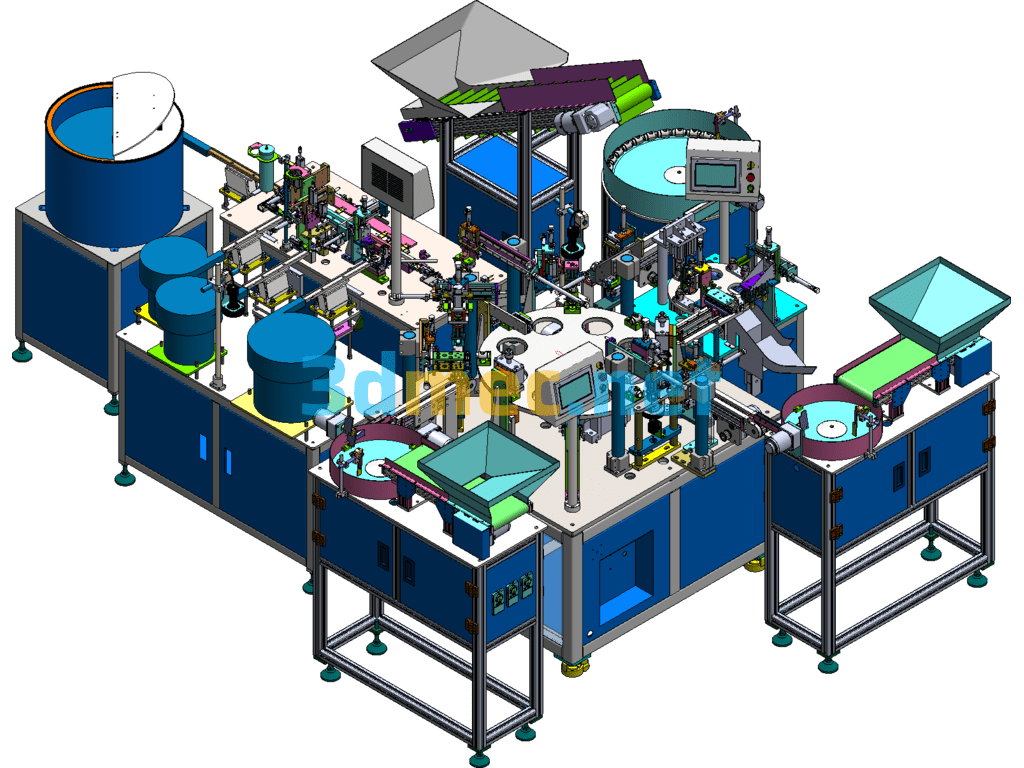

Automatic assembly process of elastic tentacles:

1. Manually place the products into the AB fixtures and position them;

2. The vibration plate material and the spring feed roll are manually loaded into the equipment;

3. The plastic body is positioned after passing through the array and is grabbed into the indexing plate by the body module;

4. Four groups of springs are assembled, with feeding mechanism, slitting mechanism, assembly and grabbing mechanism;

5. After the assembly of 4 springs is completed, they are grabbed and assembled into product AB by the assembly grabbing module, and the operator unloads the material after completion;

Specification: Automatic Assembly Equipment For Elastic Antenna (Produced Including BOM, DFM) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Assembly Equipment For Elastic Antenna (Produced Including BOM, DFM) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.