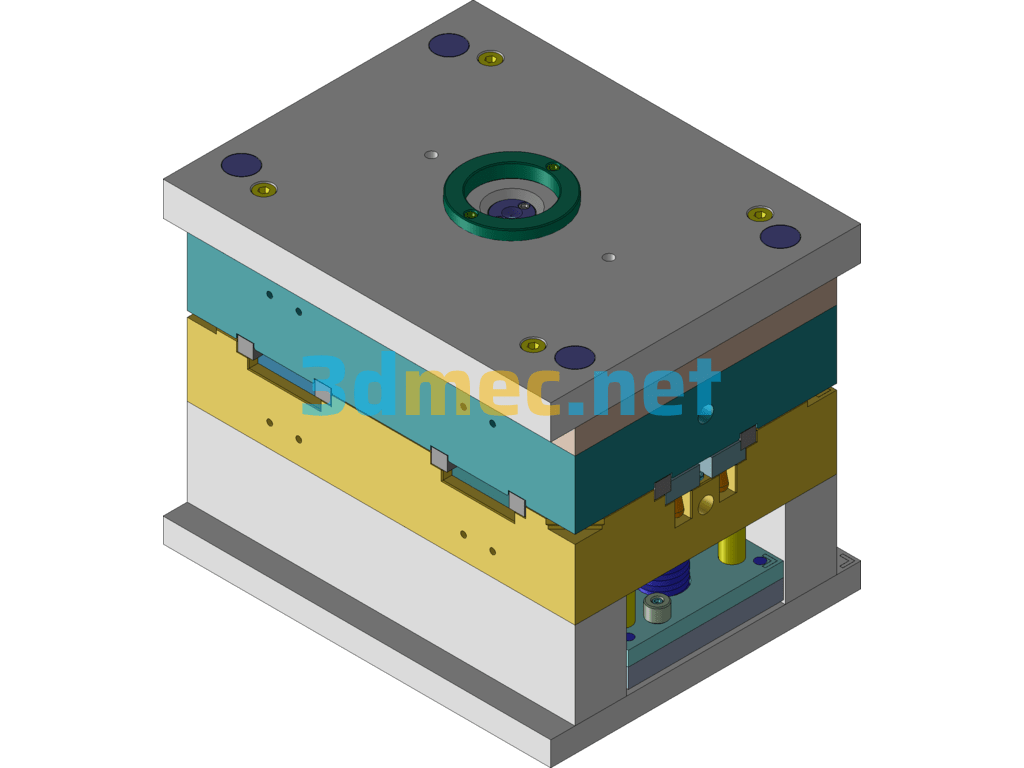

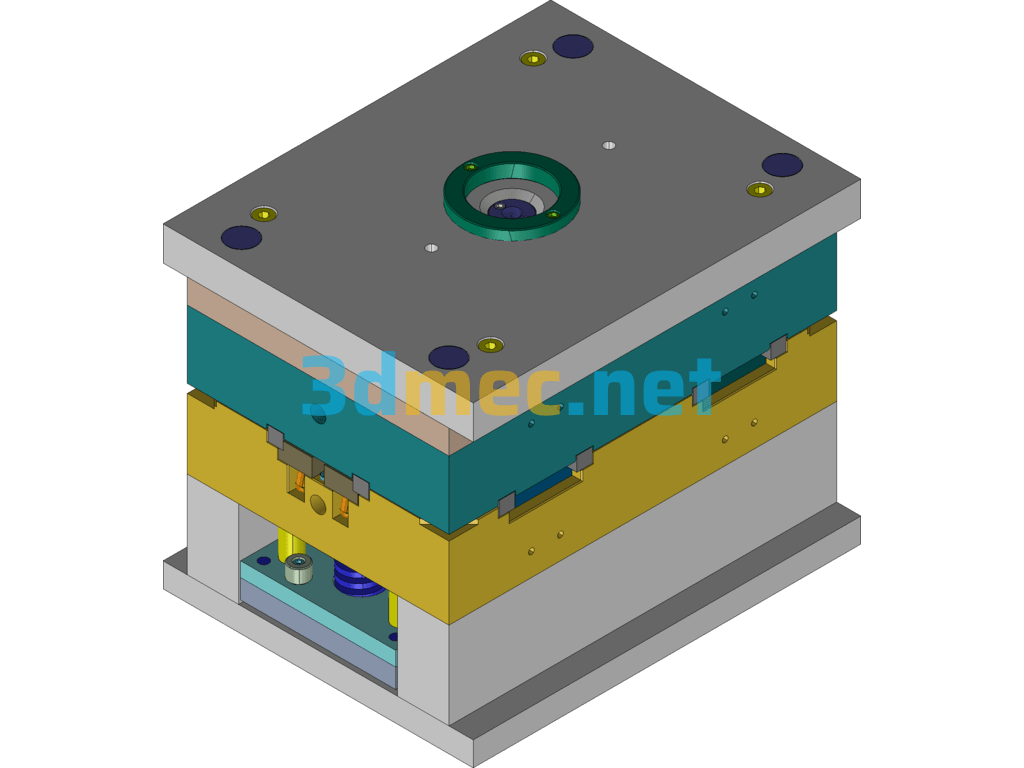

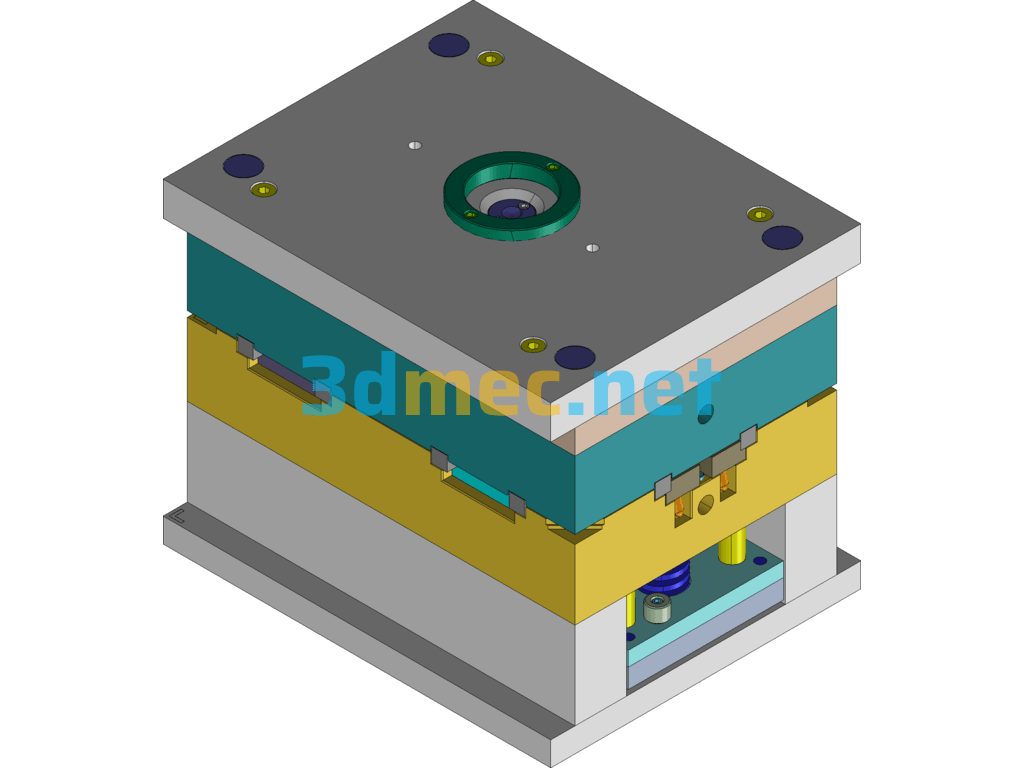

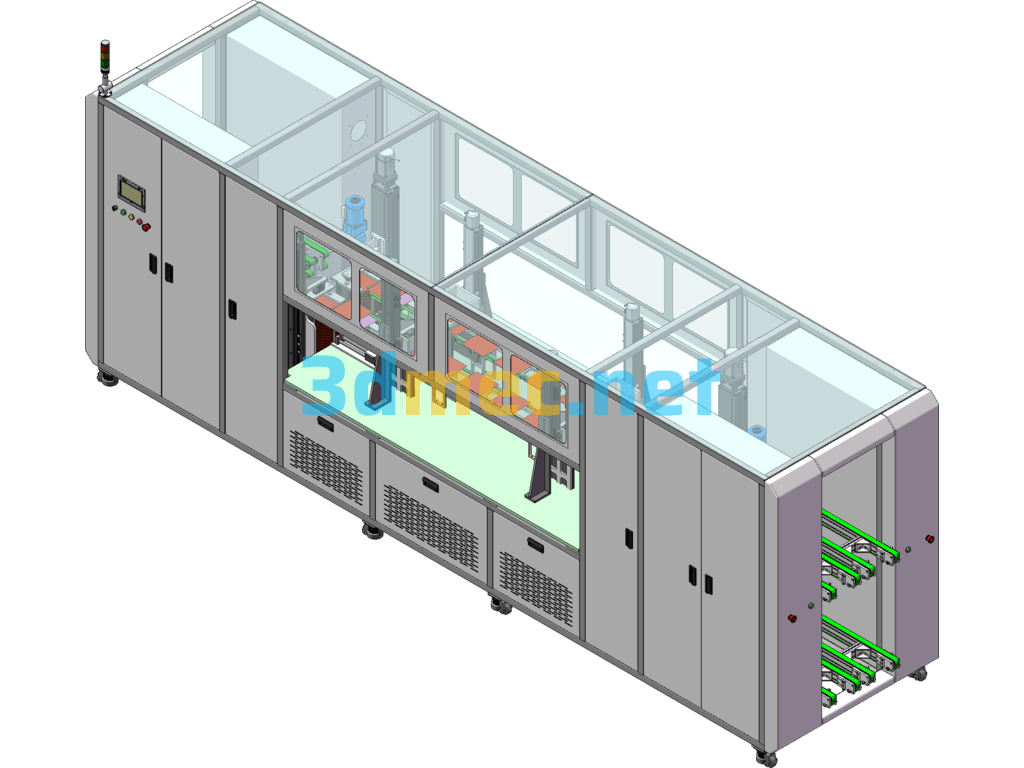

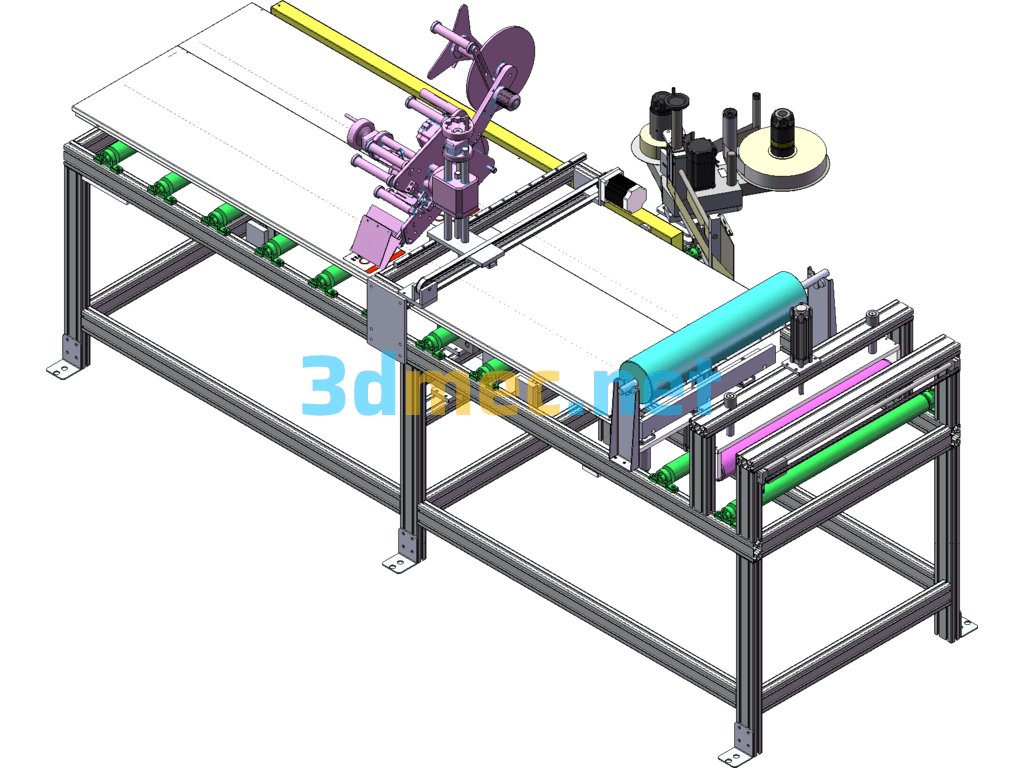

The mold is a three-dimensional and two-dimensional design of an injection mold for an electrical square box. The mold frame adopts a three-plate mold frame, point gate injection, and a side core pulling mechanism.

The movement of the injection mold to open the mold and close the mold is briefly introduced:

Introduction to the action of opening the mold: When the injection molding machine completes the injection molding pressure holding and cooling molding process, the injection mold needs to be opened next. The power for opening the injection mold comes from the hydraulic cylinder at the rear part of the injection molding. When the injection molding control system issues a mold opening command, the hydraulic cylinder starts working, and the cylinder drives the plate behind the injection molding to start moving. Since the movable mold part of the injection mold is fixed on the plate behind the injection molding, it will move backward with the plate behind the injection molding. Since the fixed mold part of the injection mold is fixed in front of the injection molding, it is stationary when the mold is opened, but this is a mold frame structure with a double parting surface, and the cavity fixed plate needs to be movable.

So when the mold is opened

1.First, the first parting is performed. The cavity fixed plate is separated from the unloading plate. The power of its movement is from the nylon plug mechanism installed between the movable mold fixed plate and the fixed mold fixed plate. Under its friction, it moves to the specified distance. This distance is the overall length of the diverter. Since the slider is fixed on the fixed mold fixed plate and the oblique pin is fixed on the panel, the slider also moves a certain distance relative to the oblique pin. Due to the action of the oblique pin, the lateral core pulling movement will also occur. The limit mechanism for pulling the distance uses a limit screw for limit.

2.Next is the second parting. On the basis of completing the first parting, the mold opening movement continues. At this time, the unloading plate will start to move. The role of the unloading plate is to forcibly separate the runner condensate from the hook rod. This movement distance is generally sufficient in 8mm~10mm. Like the first mold opening, the slider and the oblique pin are not completely separated. The lateral core pulling continues and the core pulling action is completed. The limit screw is also used for control. The purpose of the first two partings is to open the space of the mold so that the runner condensate can be taken out.

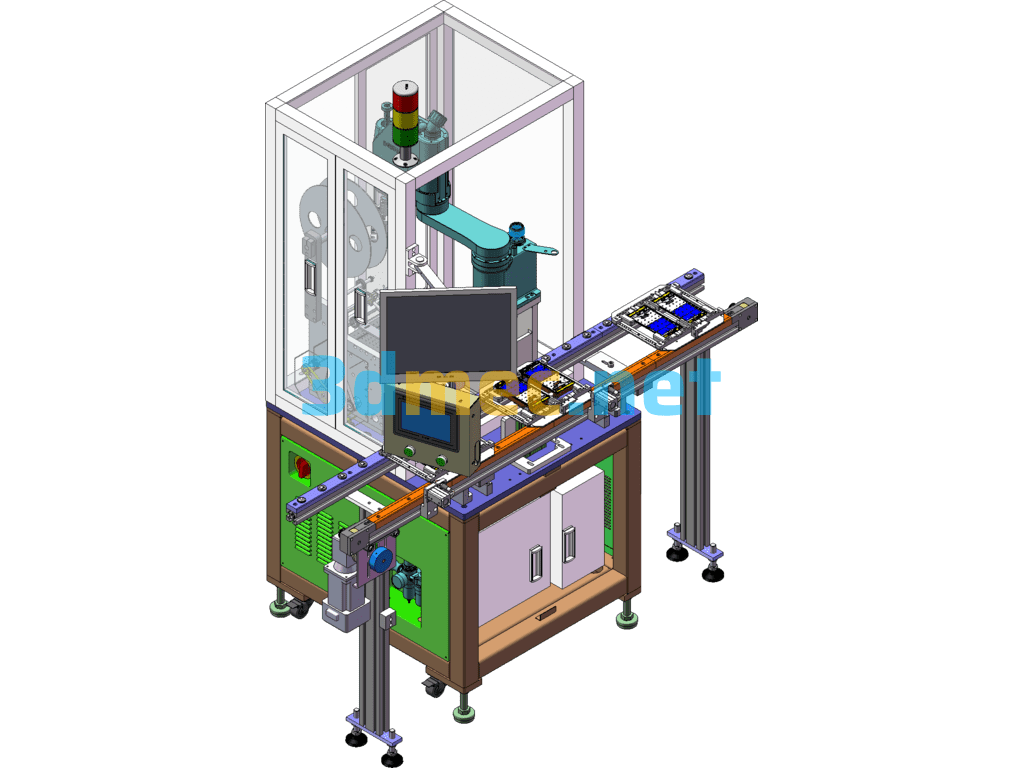

3. The last is the third parting. After completing the previous two partings, continue the mold opening movement, and the movable mold and the fixed mold will be separated at the parting surface. When the movable mold moves to the specified position of the injection molding machine, the product will have enough space to be taken out. At this time, the ejection cylinder configured at the back of the injection molding machine begins to receive instructions and move forward. A round rod of the ejection cylinder pushes the push rod fixing plate of the injection mold to move forward. The push rod on the push rod fixing plate directly acts on the inner surface of the plastic product, and the product is pushed out of the movable mold core. After the product is ejected, the robot arm installed on the upper part of the injection molding machine can take the product out and place it in the specified frame, or the operator can take the product out and place it in the frame. At this point, the entire injection mold opening action is completed.

Introduction to the action of closing the mold: After the product is taken out, the injection molding will enter the closing process. The power for closing the injection mold also comes from the hydraulic cylinder at the rear part of the injection molding. When the injection molding control system issues a mold closing command, the hydraulic cylinder starts working, and the cylinder drives the plate behind the injection molding to move forward. The movable mold part of the injection mold moves forward with the rear plate of the injection molding. When the inclined surface of the inclined pin contacts the inclined surface of the slider, the slider resets. When the reset rod of the movable mold hits the fixed mold fixed plate, the reset rod will drive the push rod fixed plate and the push rod to reset. After the movable mold continues to move forward to the specified position, the parting surfaces of the movable mold and the fixed mold are tightly fitted together, completing the closing action of the entire mold.

Specification: Square Electrical Box Injection Mold 3D+CAD Drawing – 3D Model UG(NX) AutoCAD-ZWCAD

|

User Reviews

Be the first to review “Square Electrical Box Injection Mold 3D+CAD Drawing – 3D Model UG(NX) AutoCAD-ZWCAD”

You must be logged in to post a review.

There are no reviews yet.