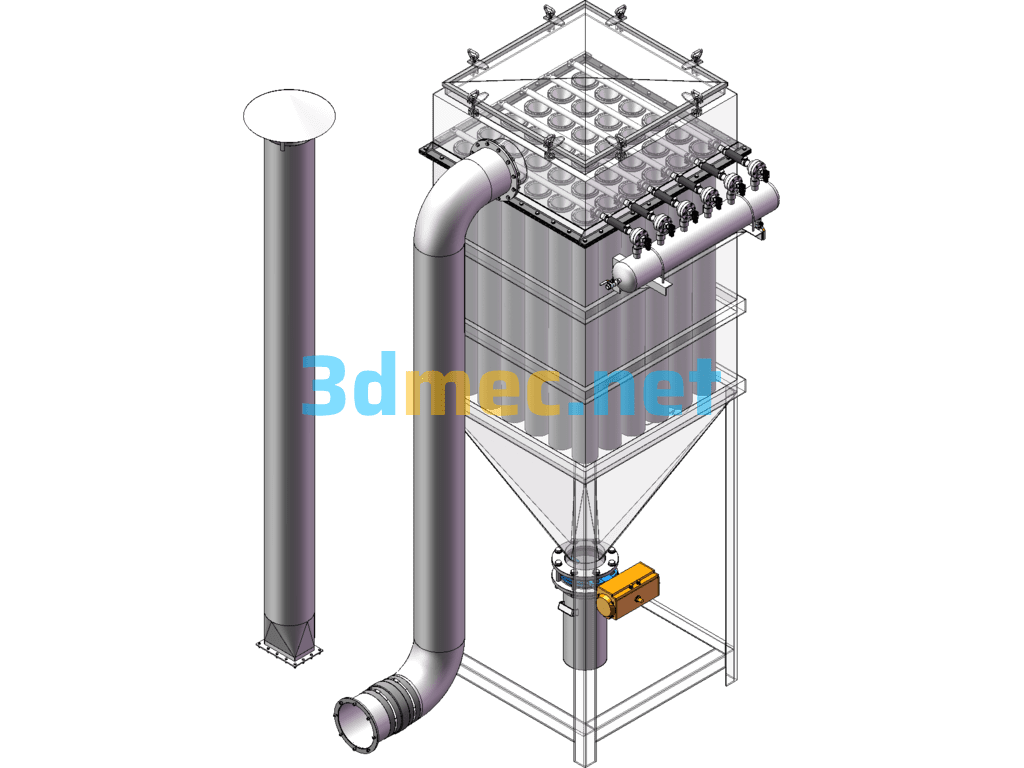

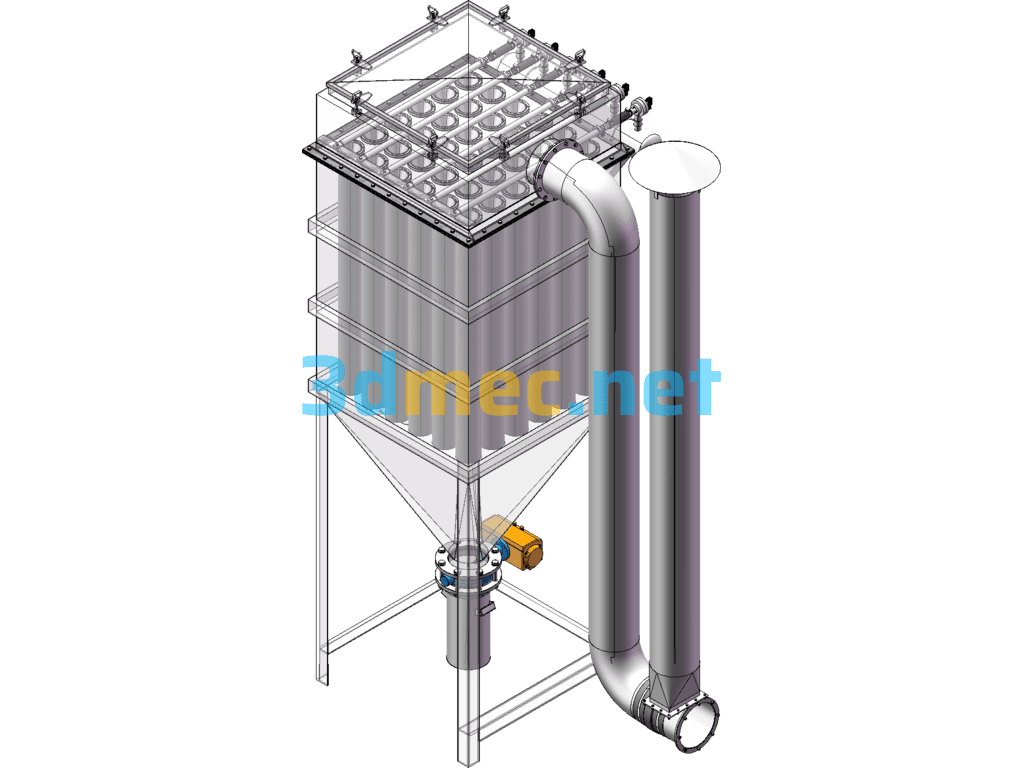

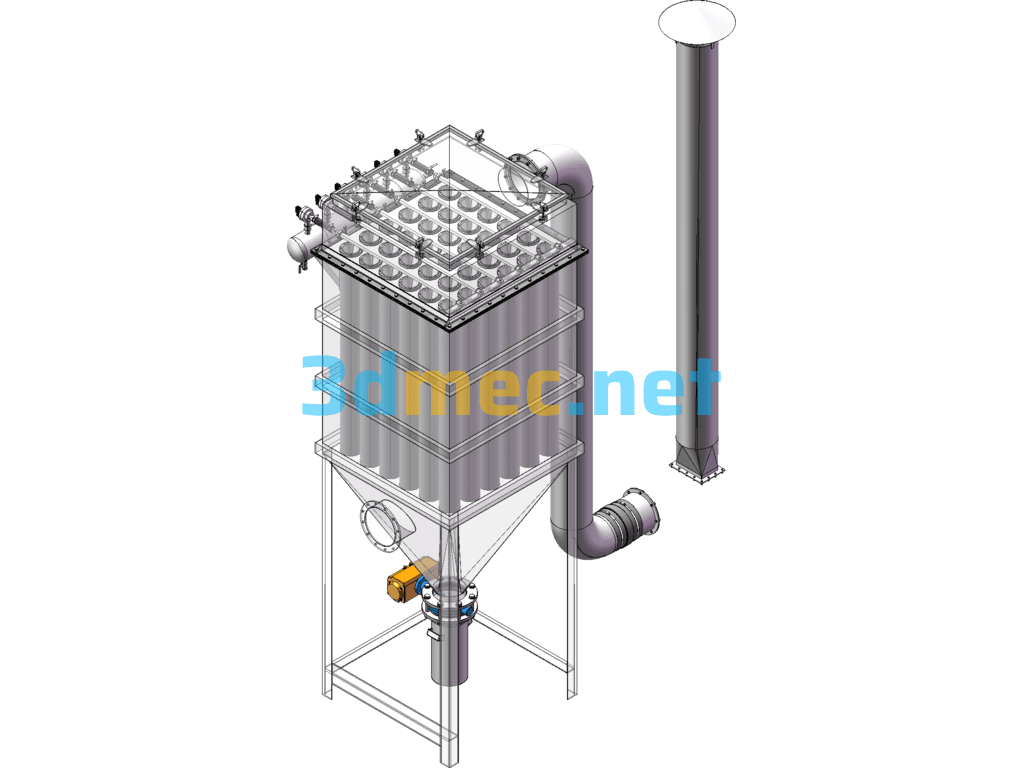

This dust collector adopts a cyclic chamber offline pulse cleaning method. The cleaning process is that the cleaning controller sends a signal, first the lifting valve of a bag chamber is closed to cut off the filtering airflow of the chamber, and then the pulse valve is opened to spray 0.4-0.6MPa compressed air into the box in a very short time (0.1-0.2 seconds). The compressed air expands at a high speed in the box, causing the filter bag to vibrate and deform at a high frequency. Coupled with the effect of the reverse airflow, the dust cake attached to the outer surface of the filter bag is deformed and falls off. After the dust is fully settled, the lifting valve is opened, and the chamber enters the filtering state again, and the secondary dust generated after the spray cleaning is avoided. After a certain time interval, the next chamber is cleaned offline, and the cleaning cycle is repeated chamber by chamber.

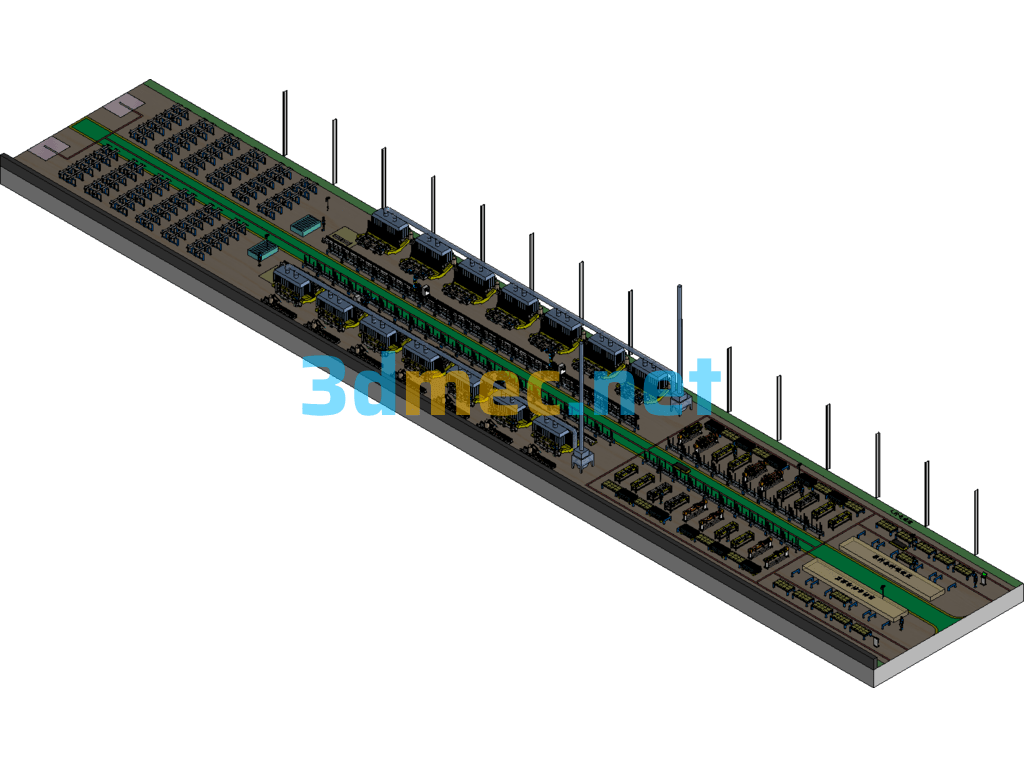

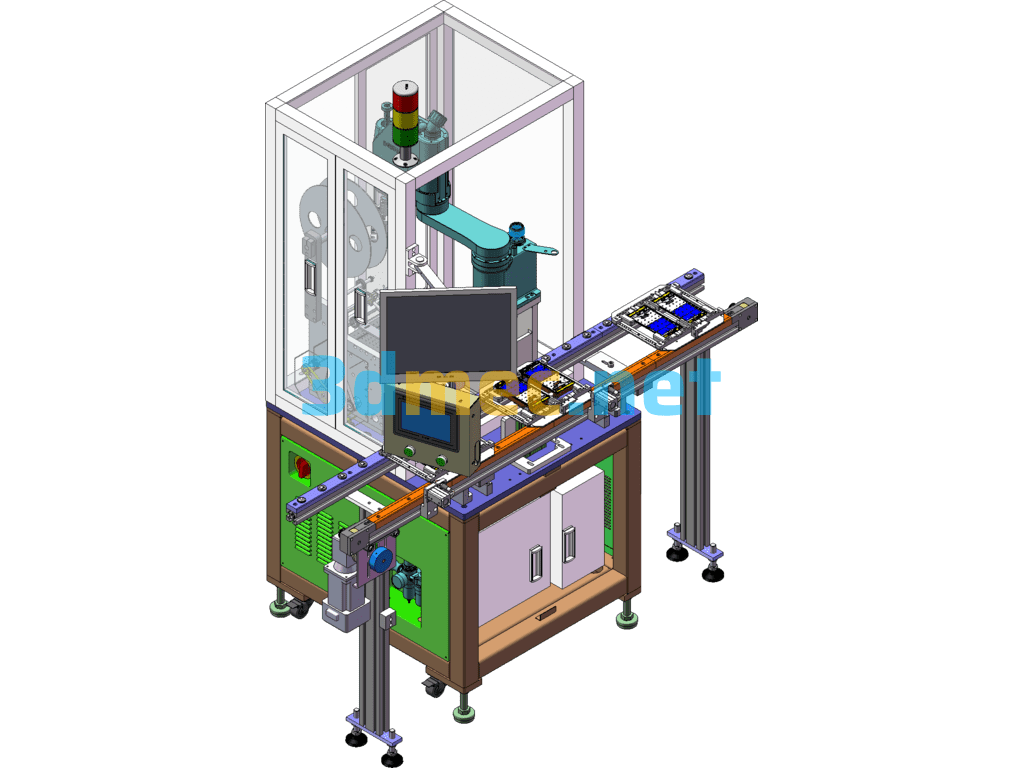

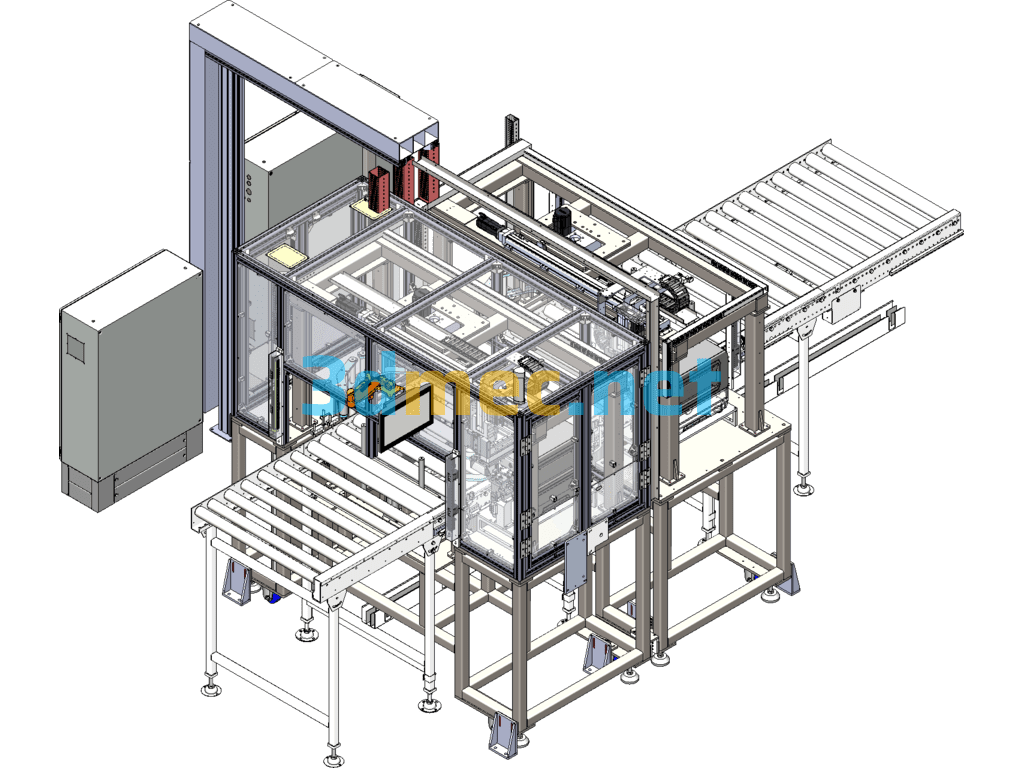

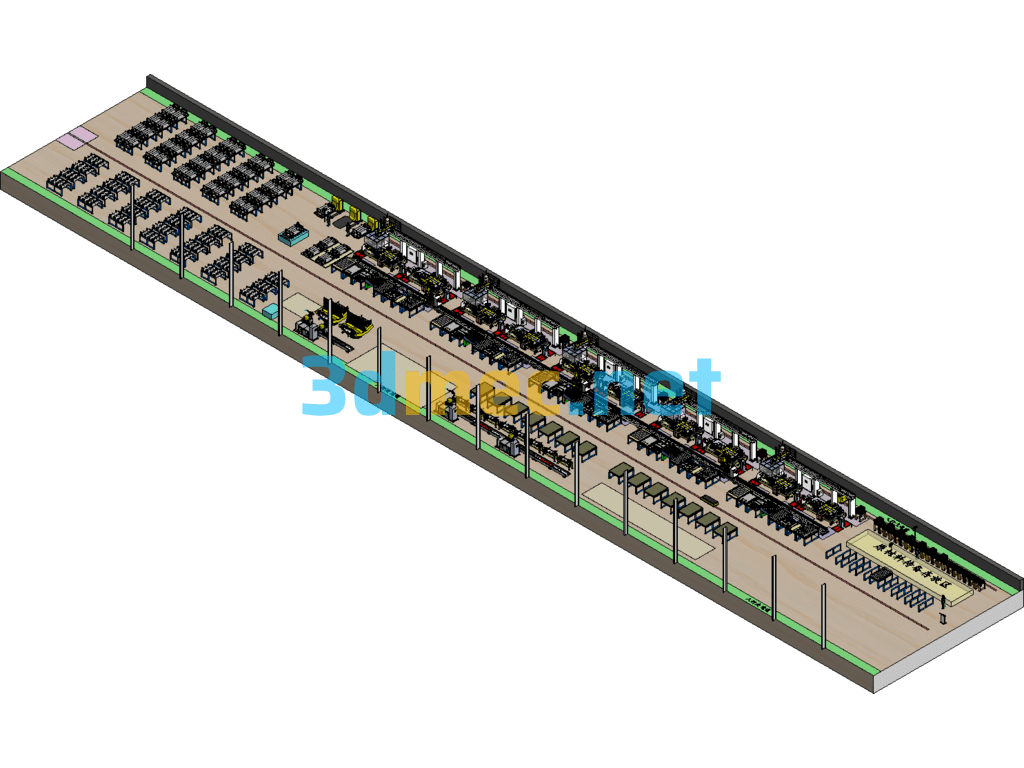

Specification: Pulse Bag Dust Collector – 3D Model SolidWorks

|

User Reviews

Be the first to review “Pulse Bag Dust Collector – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.