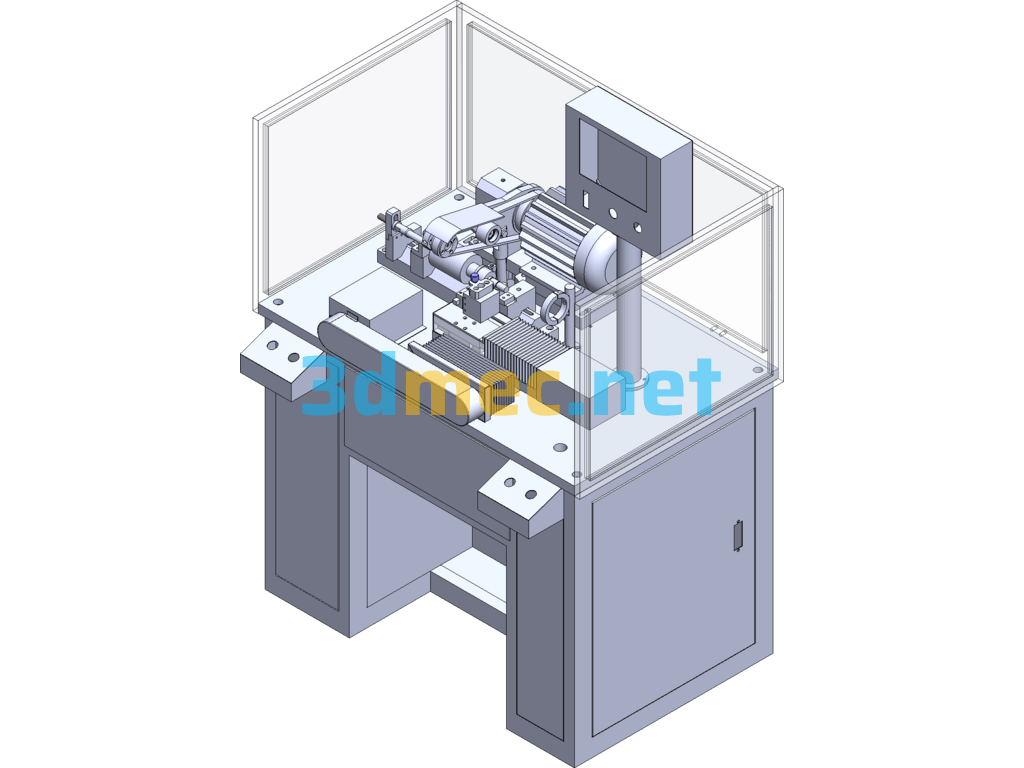

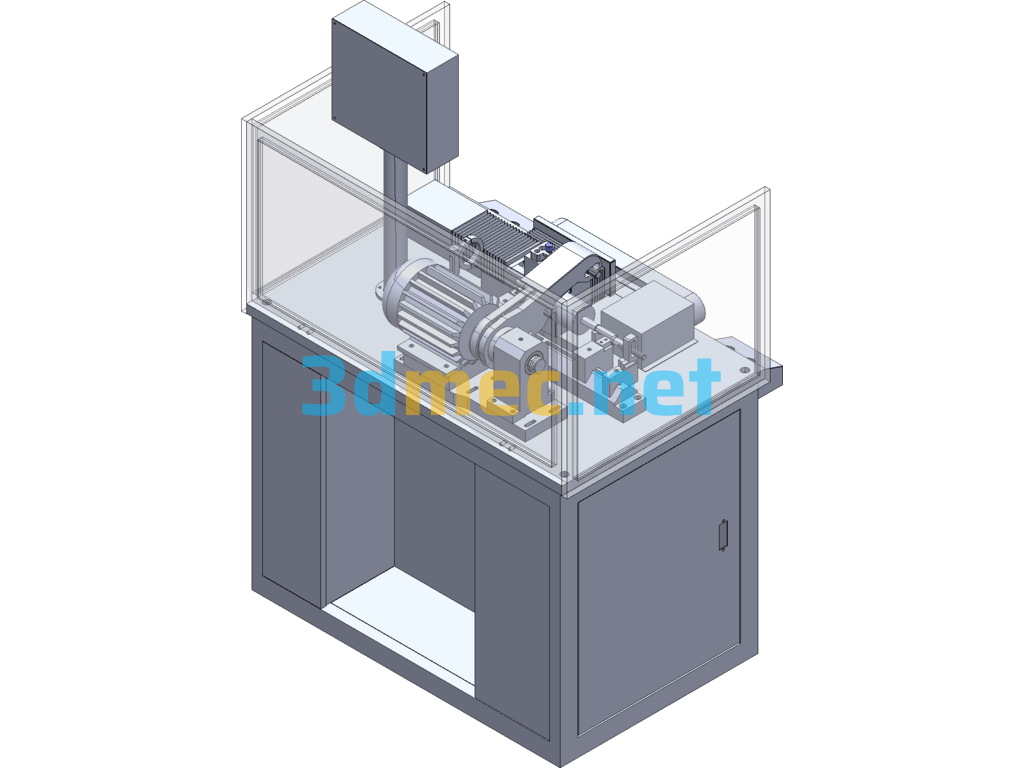

I. Performance and Features:

1. This machine is suitable for precision turning of the outer circle of the commutator or rotor core.

2. X and Y axes use imported brand (THK) precision rolling screw guide rail transmission.

3. The grinding grade diamond V-shaped frame is durable and has stable precision.

4. It adopts Japanese PLC for program control, equipped with touch screen, and has high system reliability.

5. X and Y axes use Japanese servo system, with stable turning accuracy and quality, and can pass the tool multiple times.

6. Optional chip sweeping device and dust suction device.

II. Technical parameters:

1. Turning part: outer circle of rotor commutator;

2. Diameter of rotor core: ≤Φ80mm;

3. Length of rotor core shaft: ≤270mm;

4. Diameter of rotor core shaft: Φ1.5~Φ15mm;

5. Diameter of commutator outer circle: Φ4~Φ40mm;

6. Maximum processing length: ≤25mm;

7. Radial runout of processed commutator: ≤0.005mm;

8. Axial runout of processed commutator: ≤0.005mm;

9. Production efficiency: 10 seconds/piece (turning 2 times);

10. Input power: 3KW;

11. Air source pressure: 0.5~0.8MPa;

12. Machine size: 900x700x1480mm;

13. Weight: 350kg;

14. Special customization available

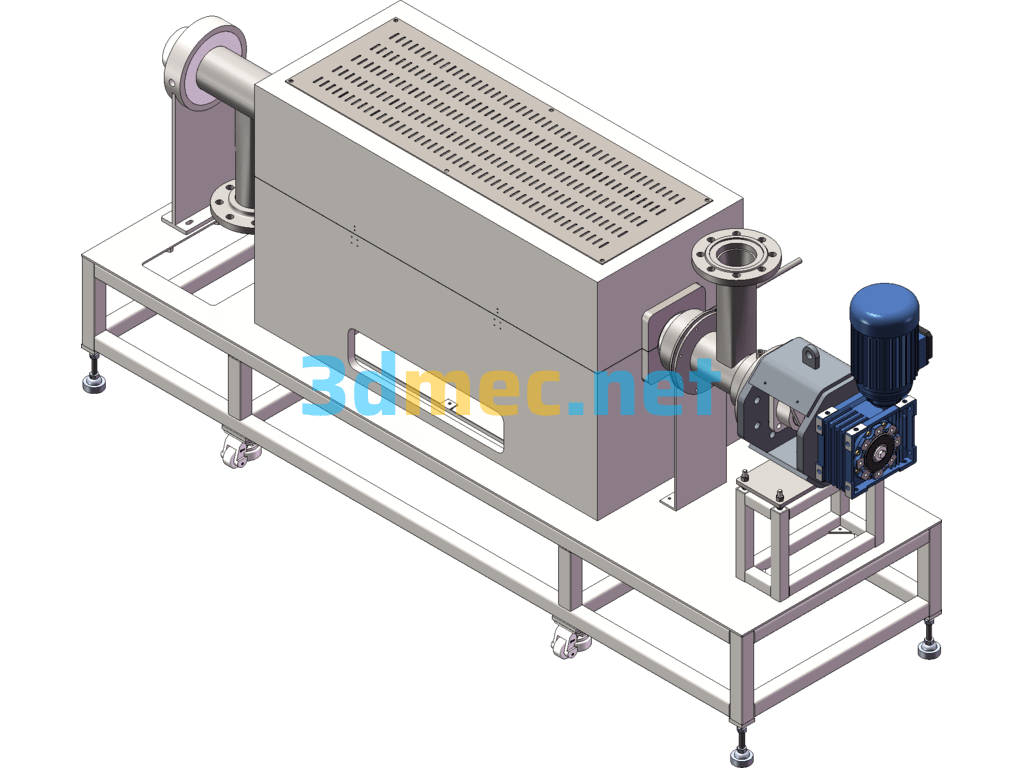

Specification: Single-Blade Dual-Servo Precision Turning Machine Type Ⅰ 3D+ Engineering Drawing – 3D Model SolidWorks

|

User Reviews

Be the first to review “Single-Blade Dual-Servo Precision Turning Machine Type Ⅰ 3D+ Engineering Drawing – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.