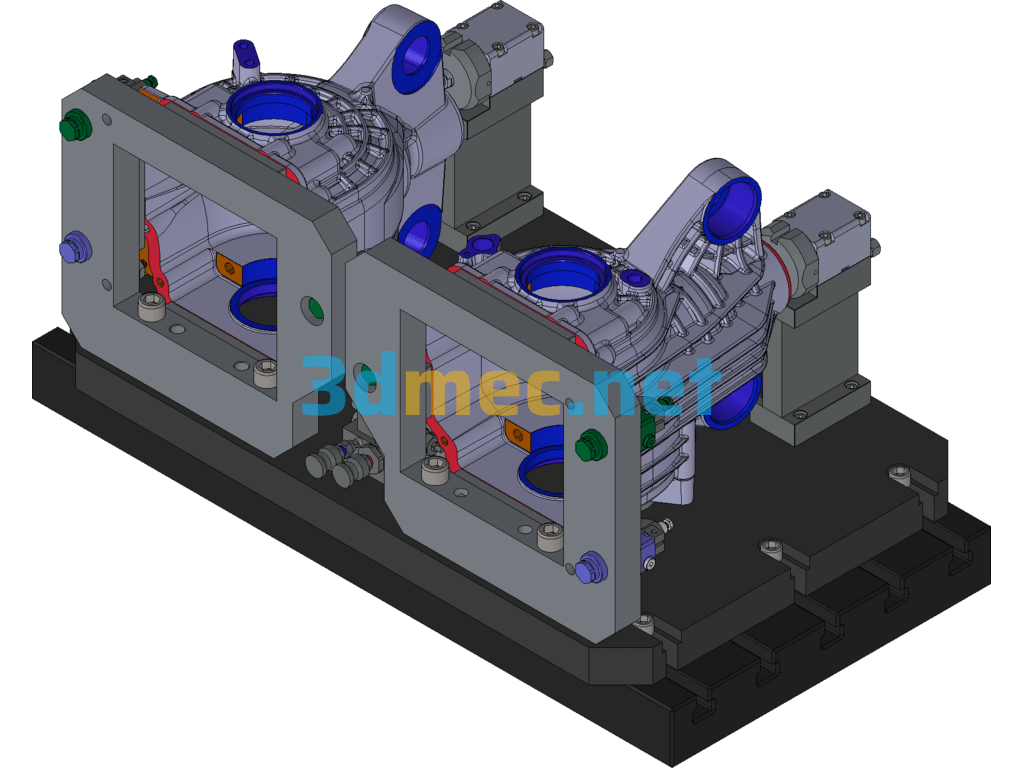

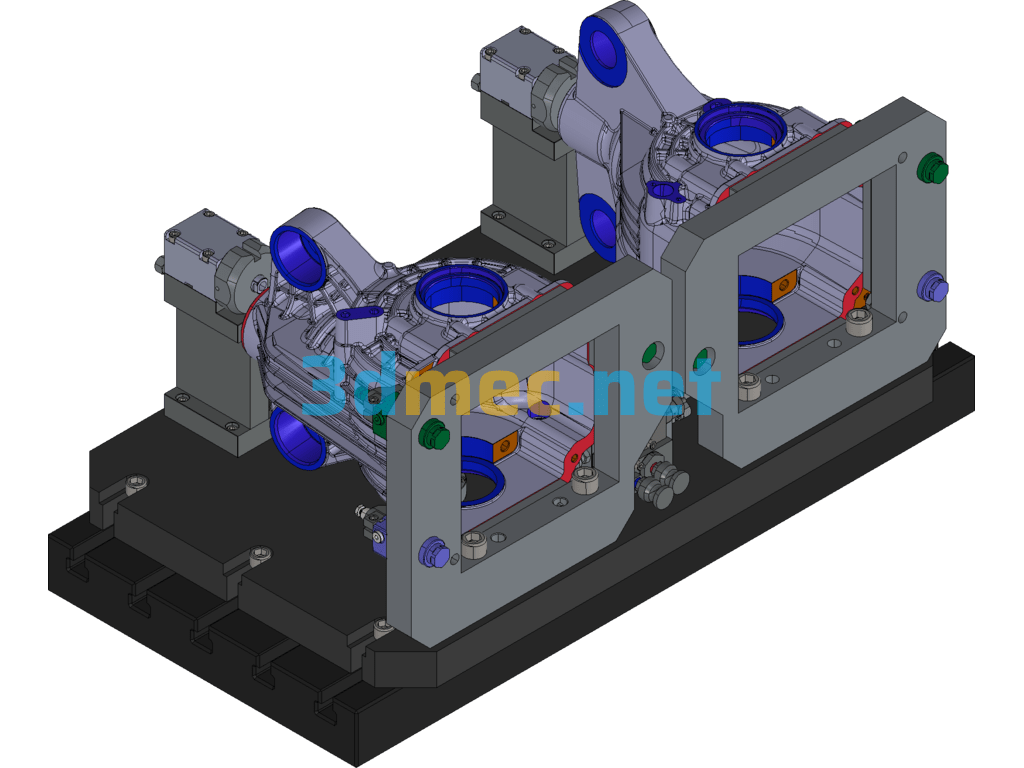

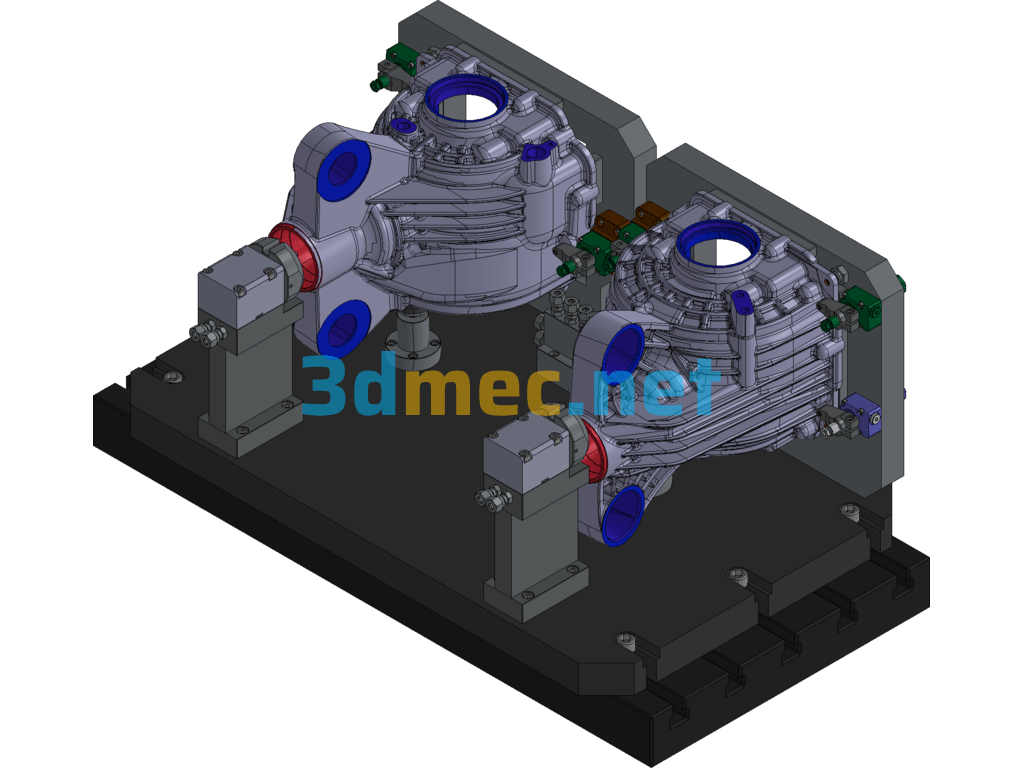

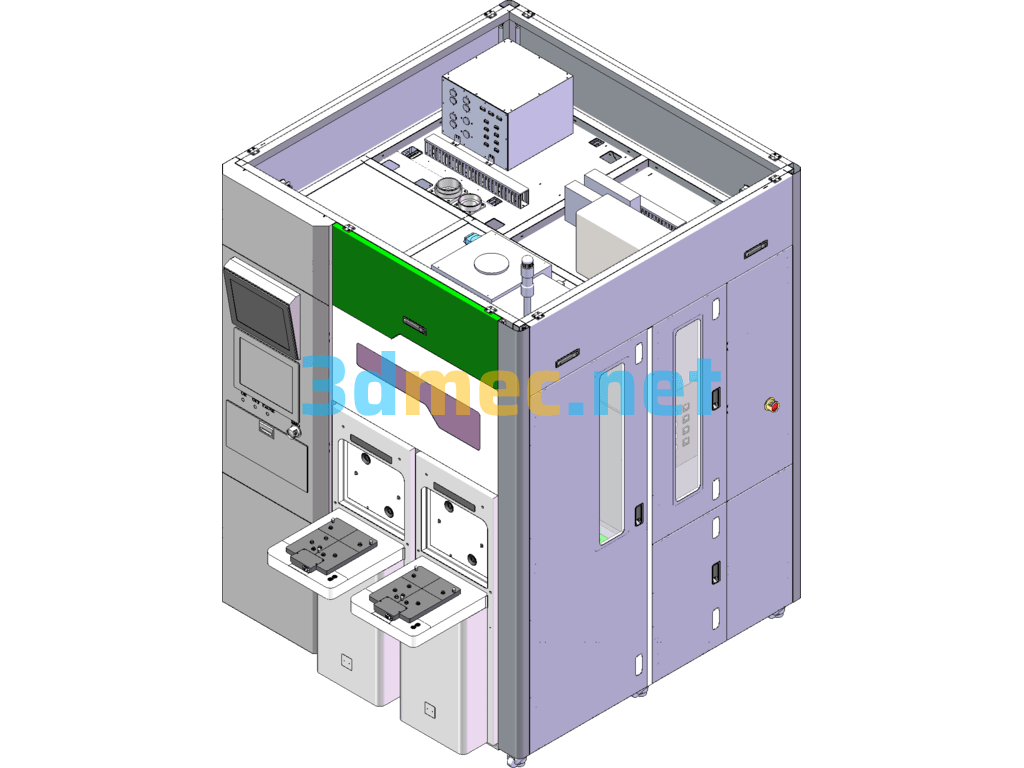

Fourth order: Equipment used: VMC850 (same as first order)

Processing part: After installing the other half of the bearing on the E reference surface, process the C, D reference holes, end faces and boss surface related features;

Clamping principle:

Use the mounting surface processed in the first order as the installation surface, and center the two 2-φ8 pin holes in the FF view, with two pins on one side;

Plan requirements:

Clamp two pieces at a time: the first piece (first station) processes the C reference and related features; the second piece (second station) processes the D reference and related features, and the C, D references (bearing holes) are finely bored with one cutter, and the tool must not interfere in the middle cavity

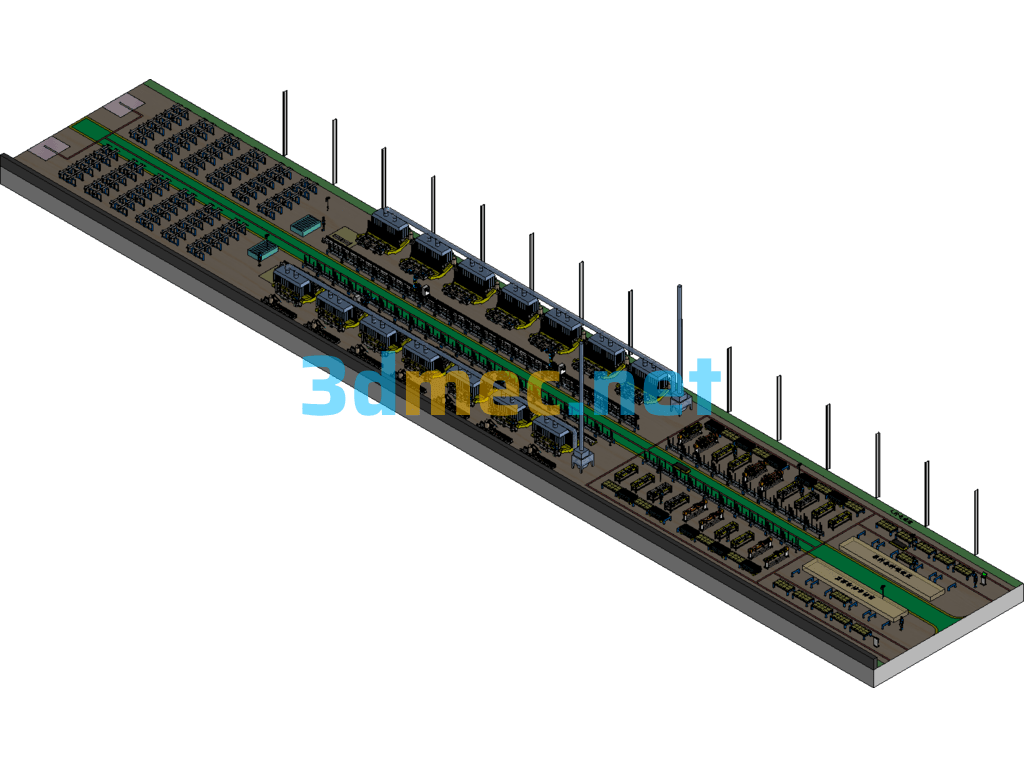

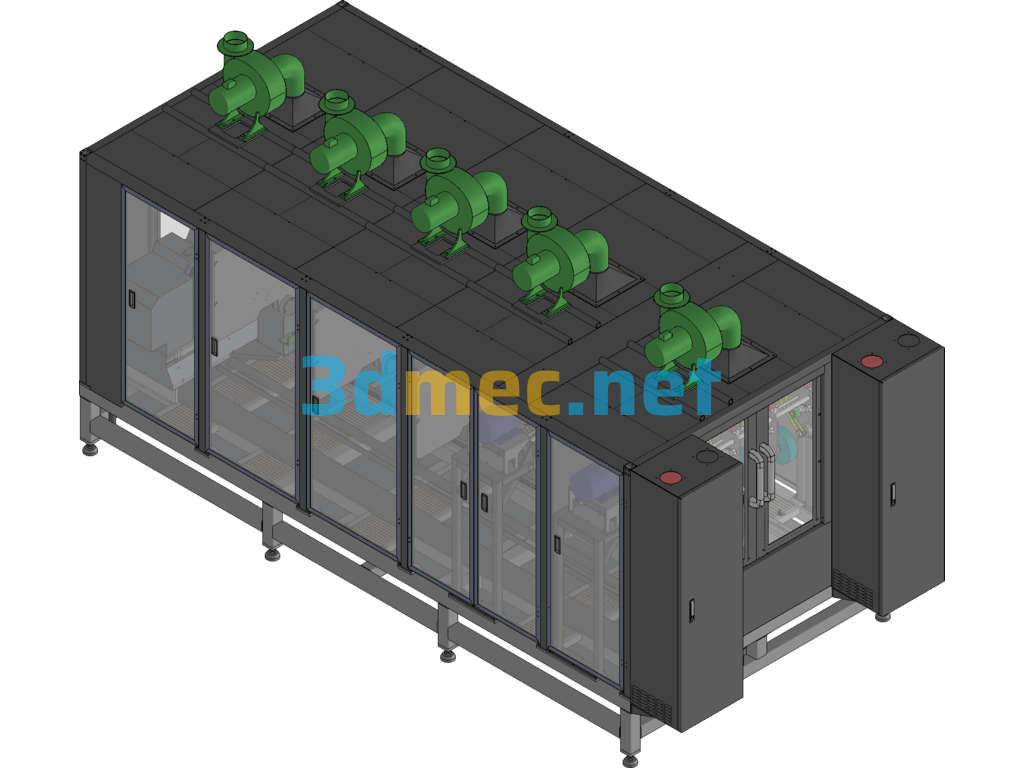

Specification: A Rear Shell Reduction Fixture (Fourth Order) – 3D Model Exported

|

User Reviews

Be the first to review “A Rear Shell Reduction Fixture (Fourth Order) – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.