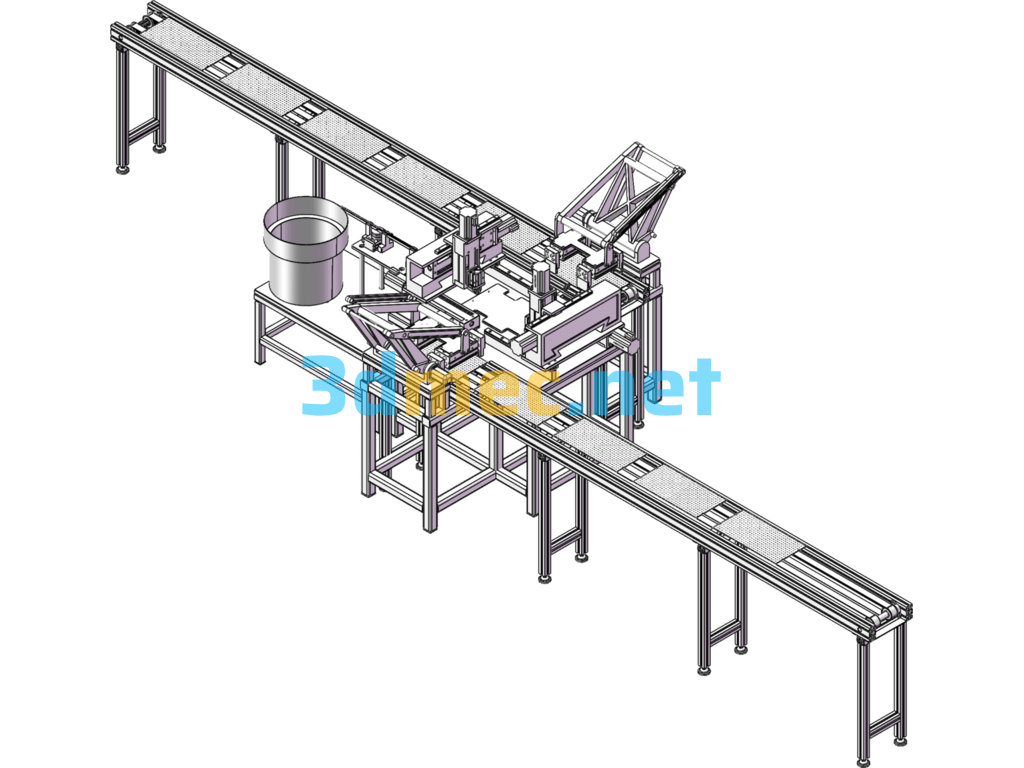

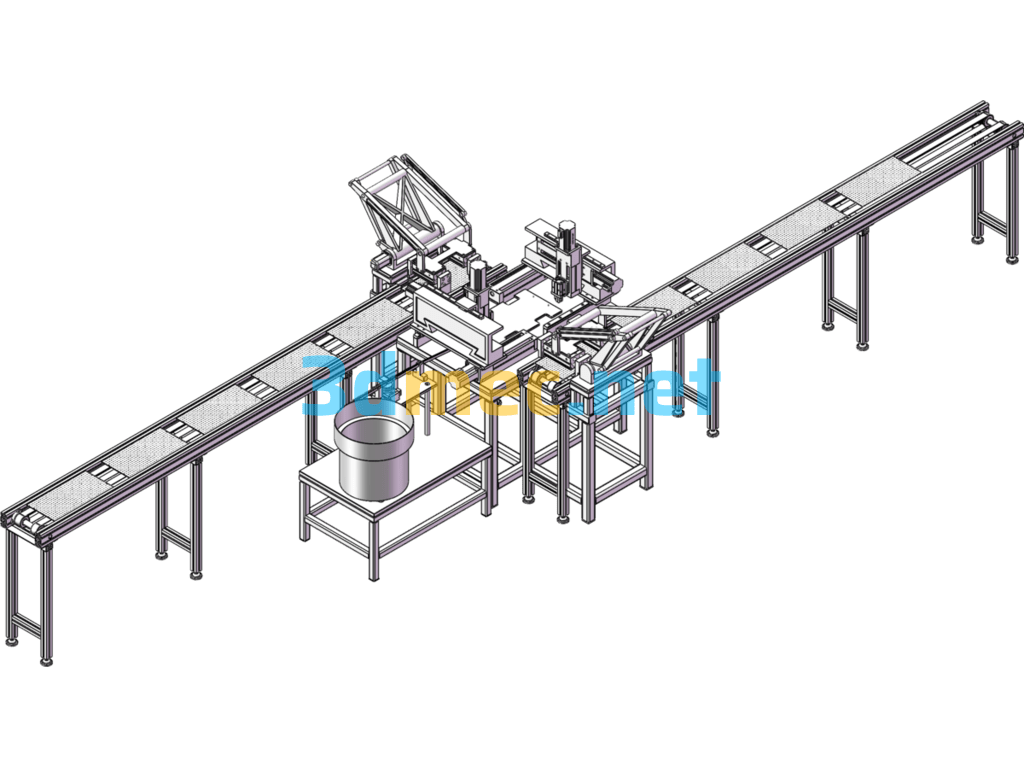

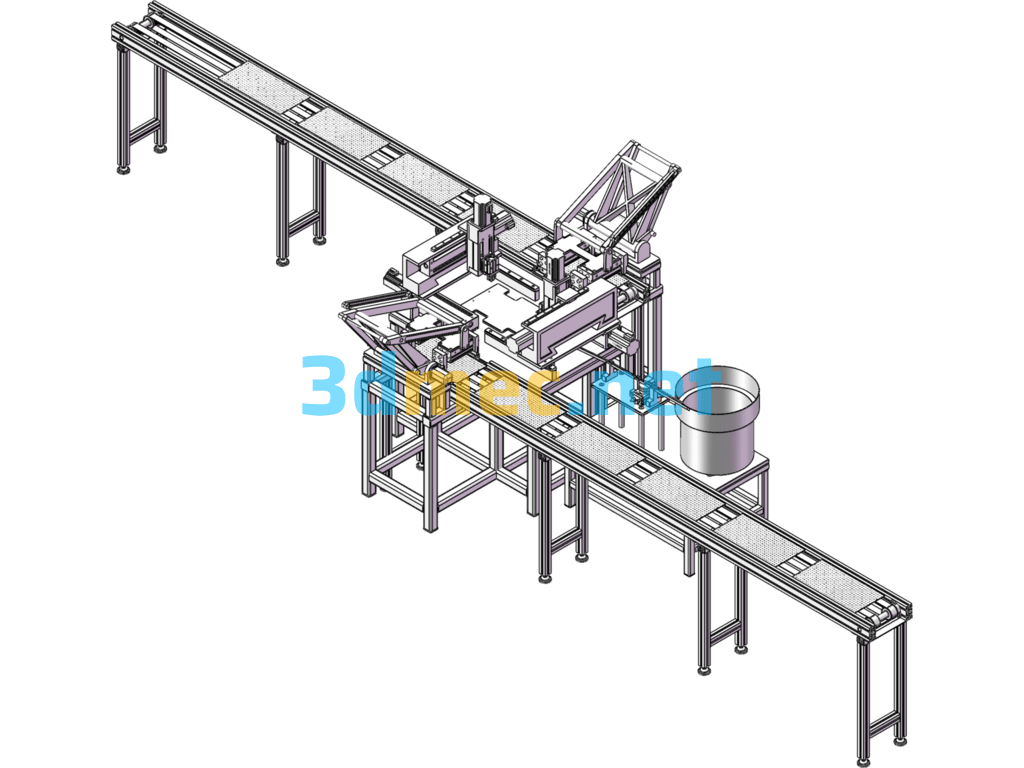

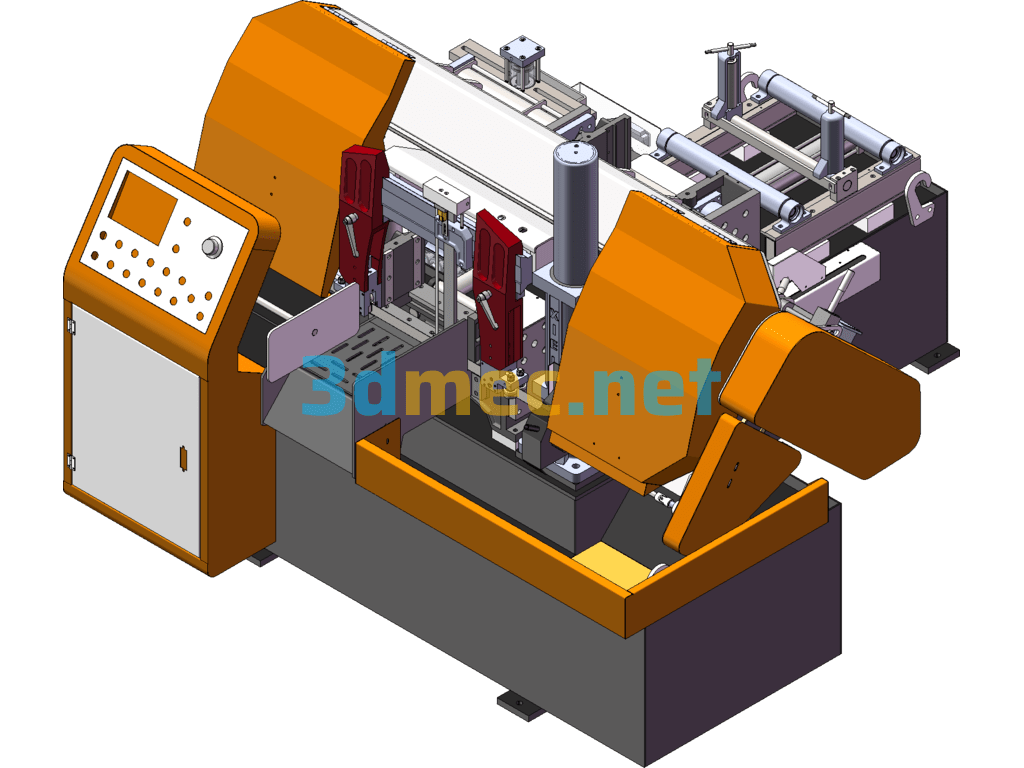

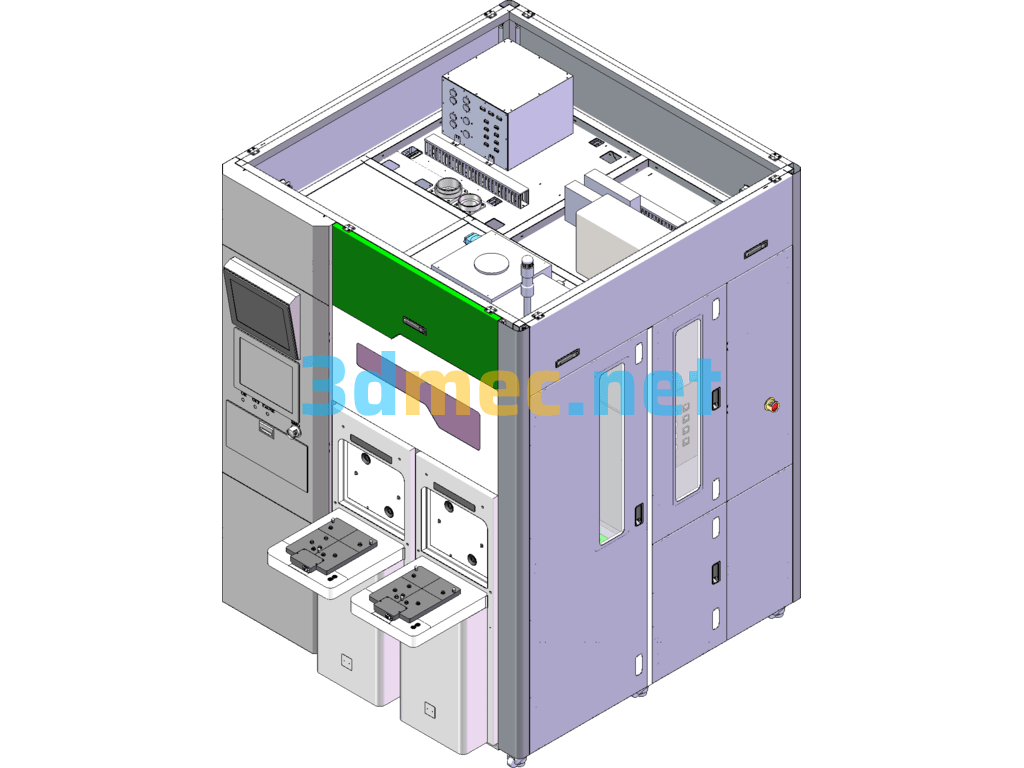

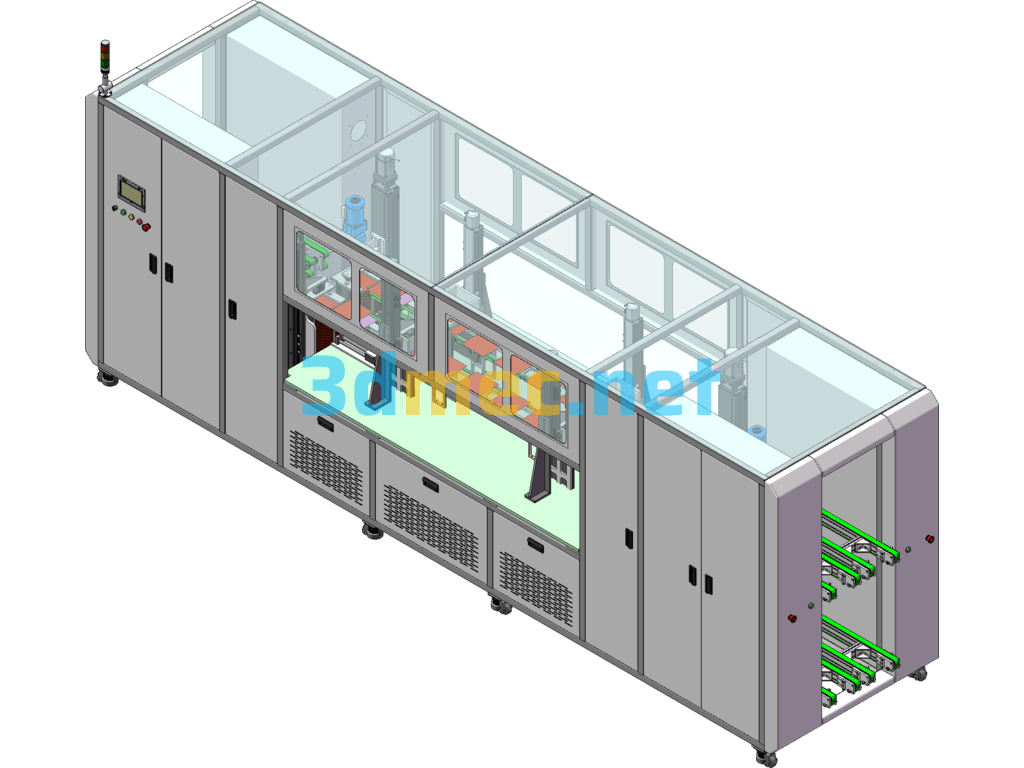

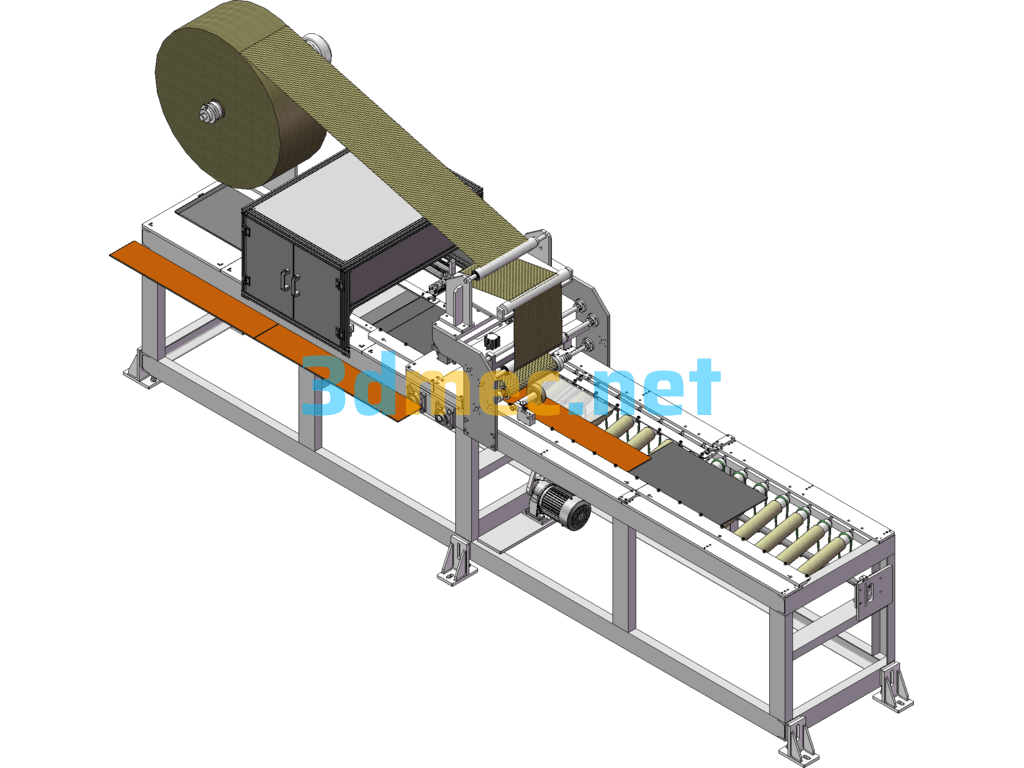

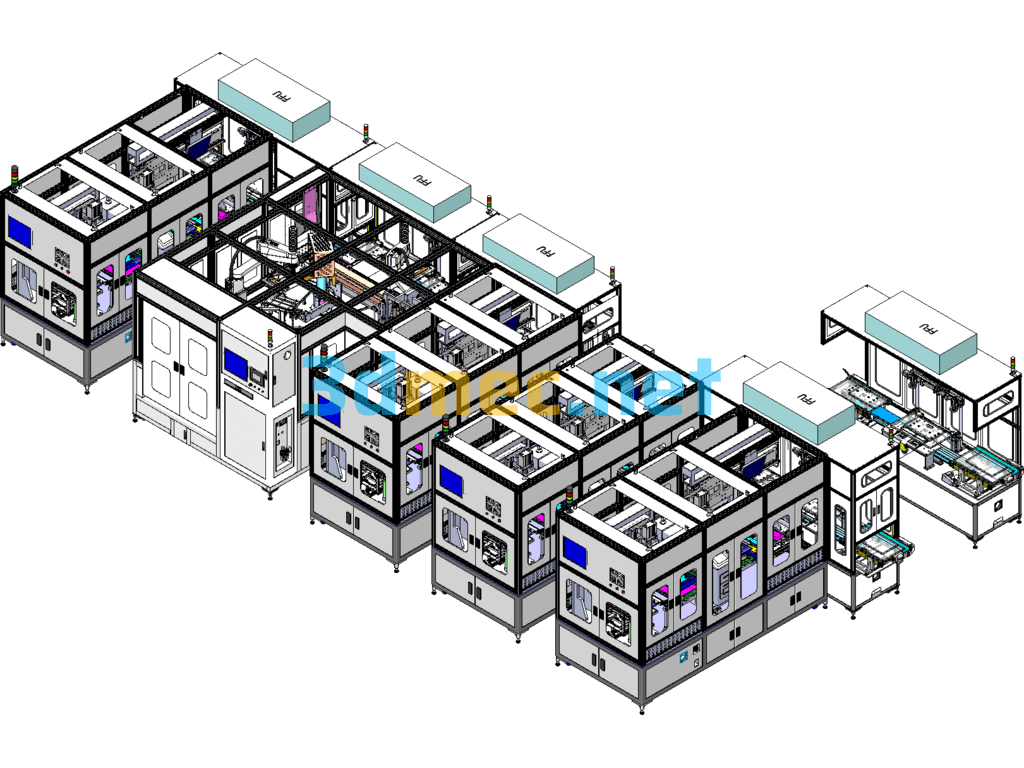

LED board plug-in machine SW design 3D model LED lamps generally include a circuit board and a plurality of LED lamps plugged into the circuit board. Since the positive and negative pins of the LED lamp (corresponding to the long and short pins respectively) must be accurately calibrated with the positive and negative lamp pin holes on the circuit board before they can be inserted normally, manual calibration is required after insertion before the next assembly process can be carried out. If the positive and negative pins of the LED lamp are not accurately calibrated with the positive and negative lamp pin holes on the circuit board before the insertion assembly is performed, it is easy for the positive and negative pins of the LED lamp to be squeezed with the circuit board and the positive and negative pins of the LED lamp to be seriously deformed, which greatly increases the scrap rate of LED lamp assembly. In severe cases, it may even jam the production equipment and affect normal production. Existing LED lamps usually use manual methods to distinguish the positive and negative pins of each LED lamp, cut off the excess length on the LED pins in the pin cutting machine, and then manually insert the LED lamps one by one into the circuit board corresponding to the positive and negative lamp pin holes on the circuit board.

Specification: LED Board Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “LED Board Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.