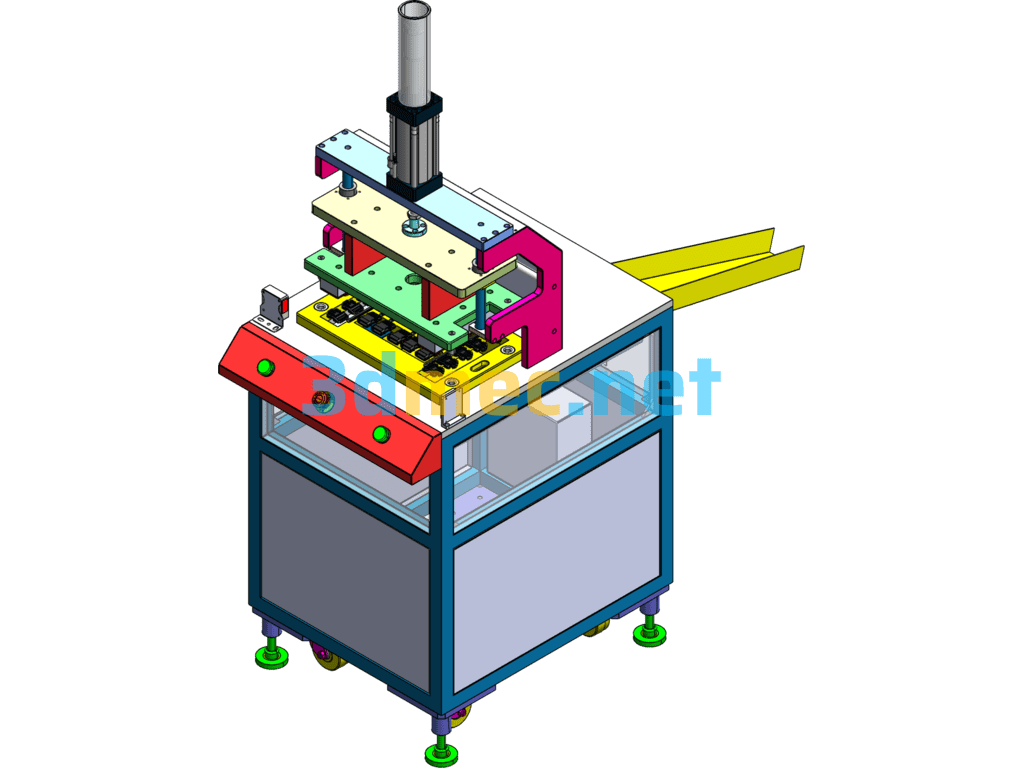

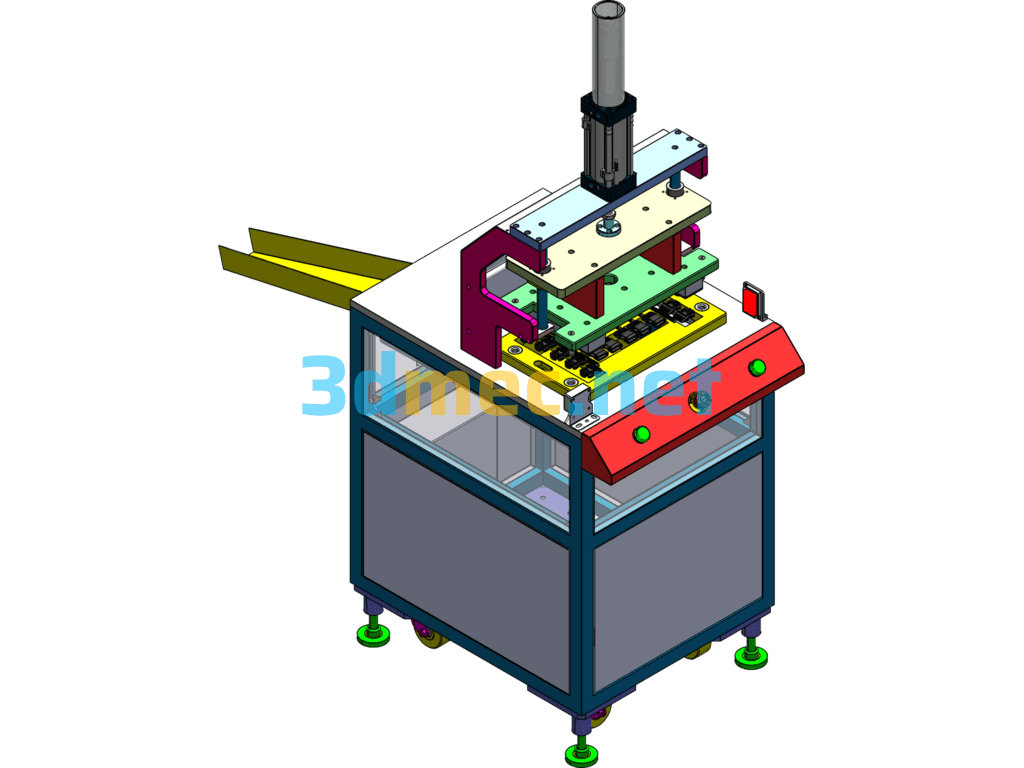

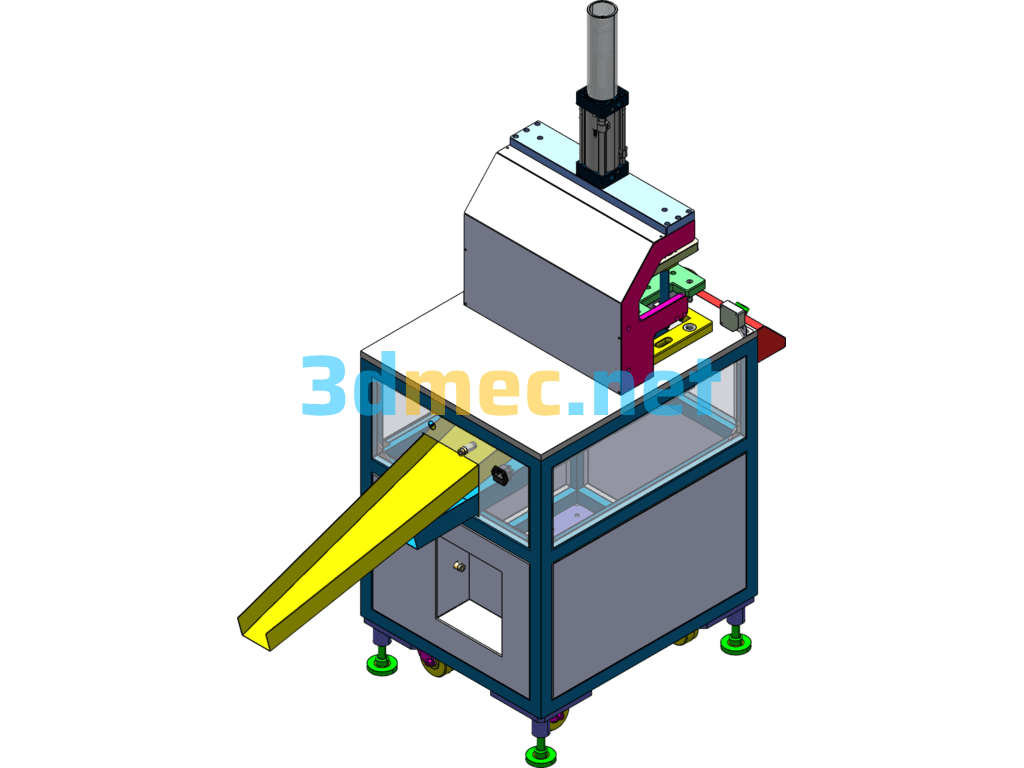

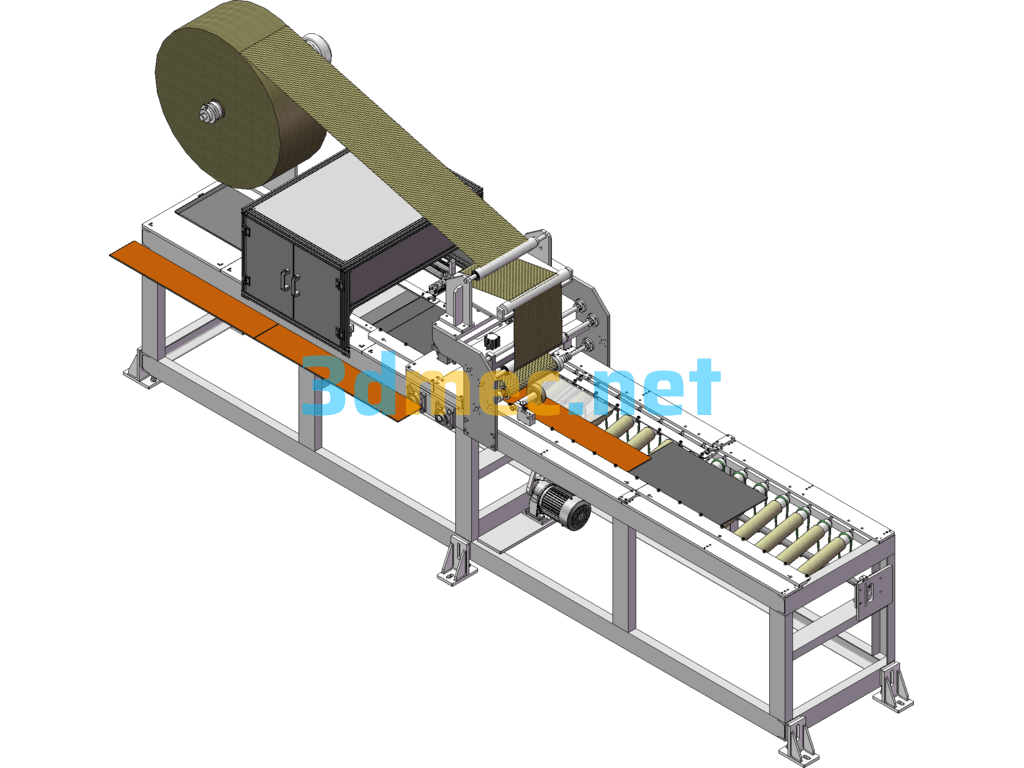

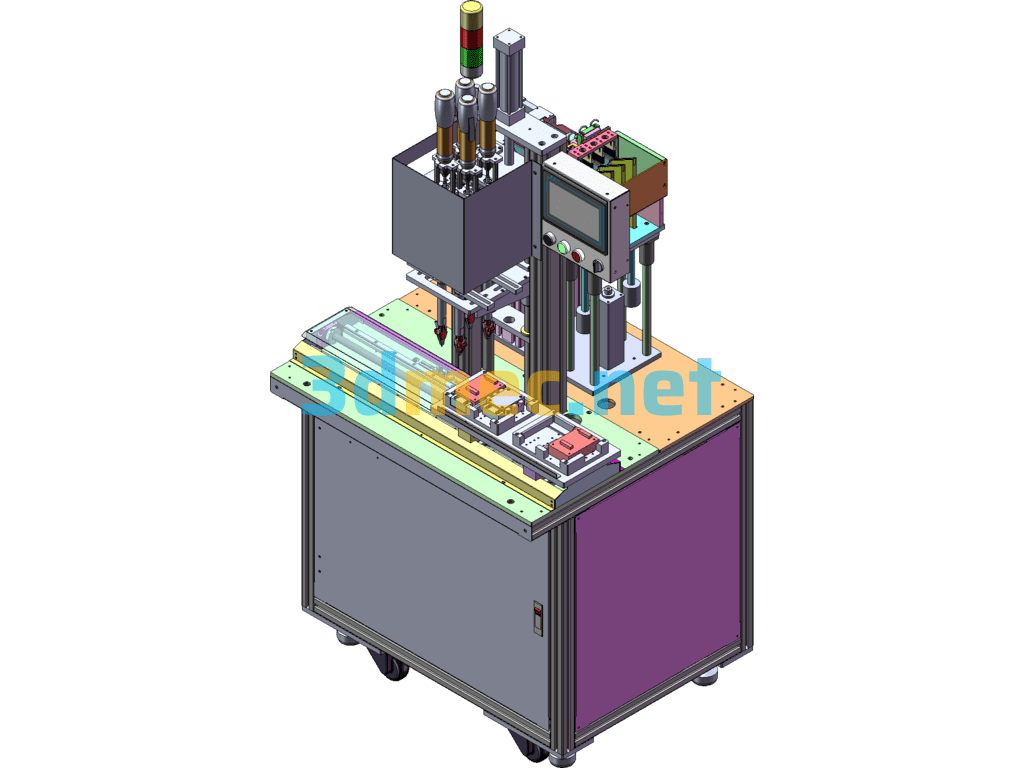

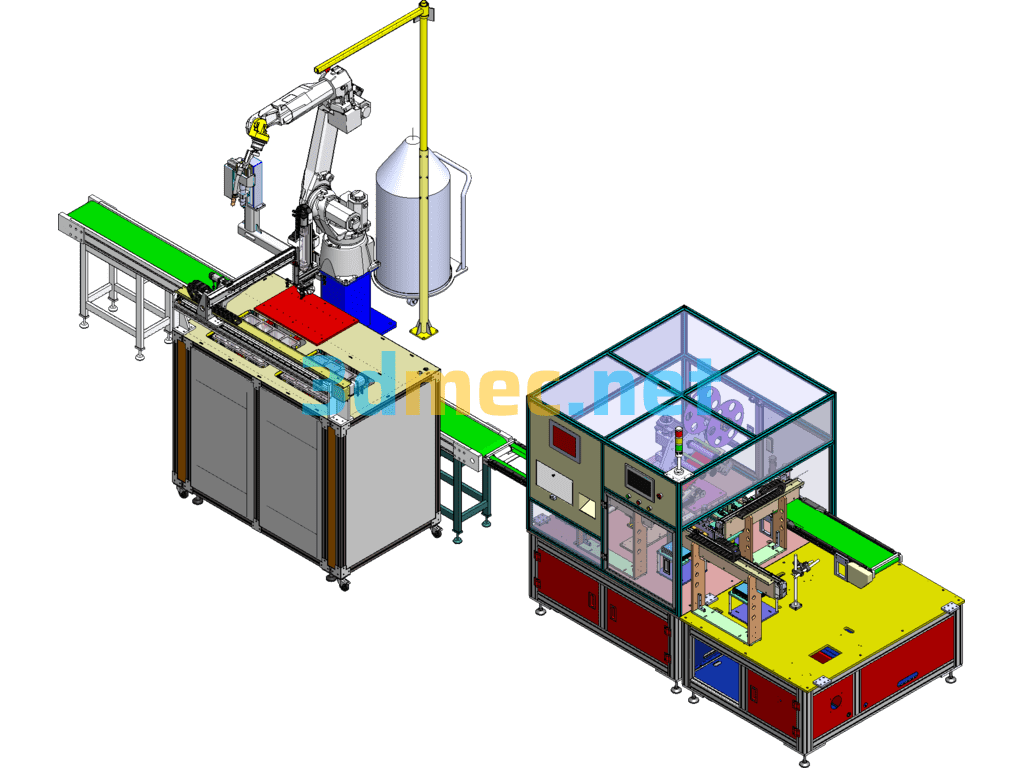

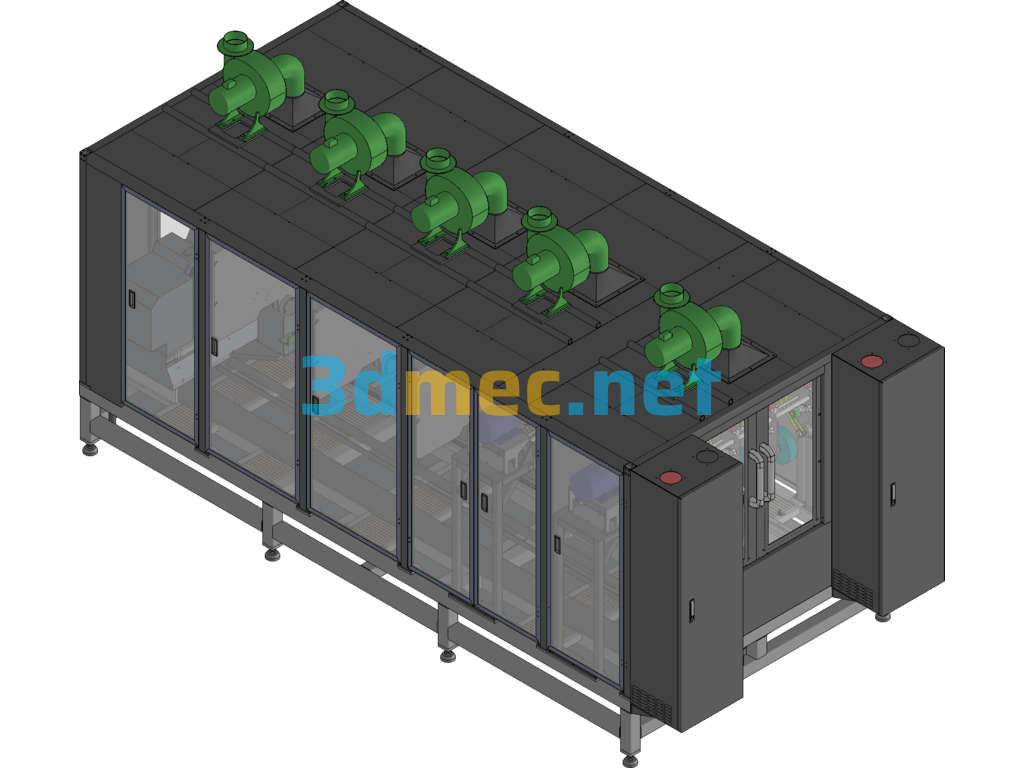

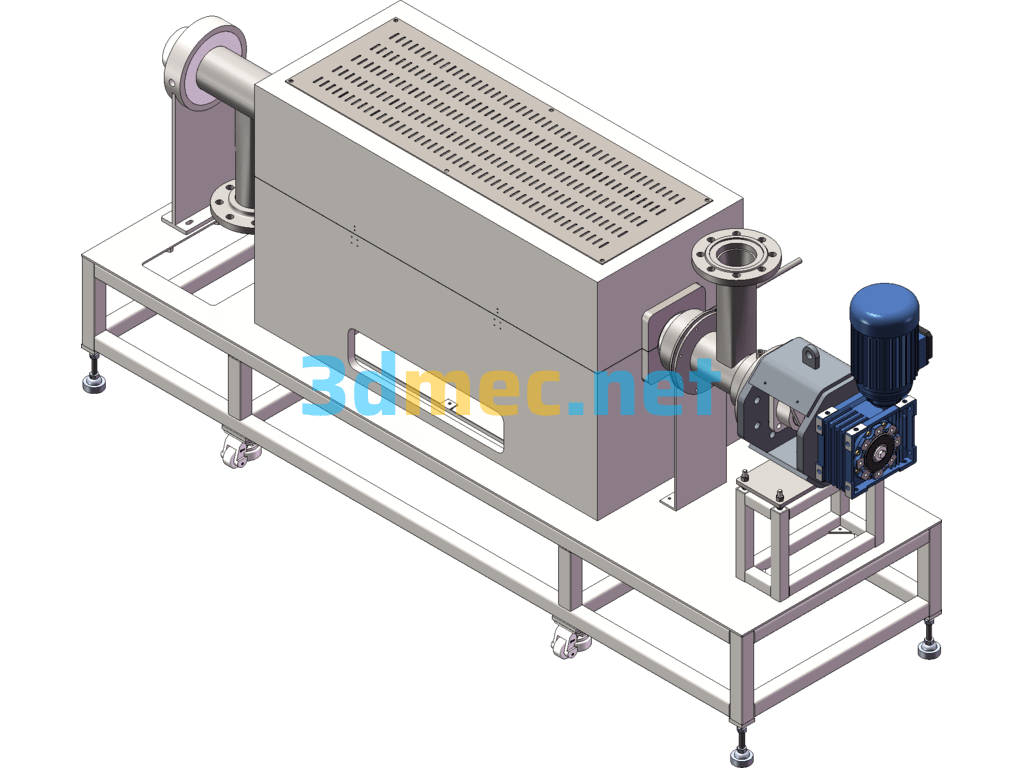

The SolidWorks source file of the 3D model of the plastic sprue cutting machine has editable parameters and can be used as a reference for the scheme.

1. Function: Replace manual sprue removal.

2. Features: Efficient, high quality, stable, safe, reliable, easy to operate.

3. Occasions of use: Need to cut sprues, etc.

4. Four major advantages of equipment operation compared with manual operation:

A. Efficiency: increased by more than 100%

B. Quality: reliable

C. Cost: varies depending on customer needs

D. Safety: reliable protection for operators

5. Power: single-phase AC220V power supply; clean compressed air above 5KG/cm2

6. Appearance size: L*W*H=650*700*750mm

The sprue refers to the joint between the frame and the parts formed when the factory casts the model. It is also called “soup mouth” (gate), which means the inlet and outlet of the hot liquid plastic flow. A special term for injection molding, the melted plastic flows into the mold cavity through the sprue. If you want to make a model, you need to cut the parts from the frame. You can cut the parts smoothly by cutting off the nozzles that connect the parts to the frame. The goal here is to use the bevel shears to cut the nozzles on the edges of the parts beautifully and neatly. This is when a plastic nozzle cutting machine will be used.

Specification: Automatic Plastic Cutting Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Plastic Cutting Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.