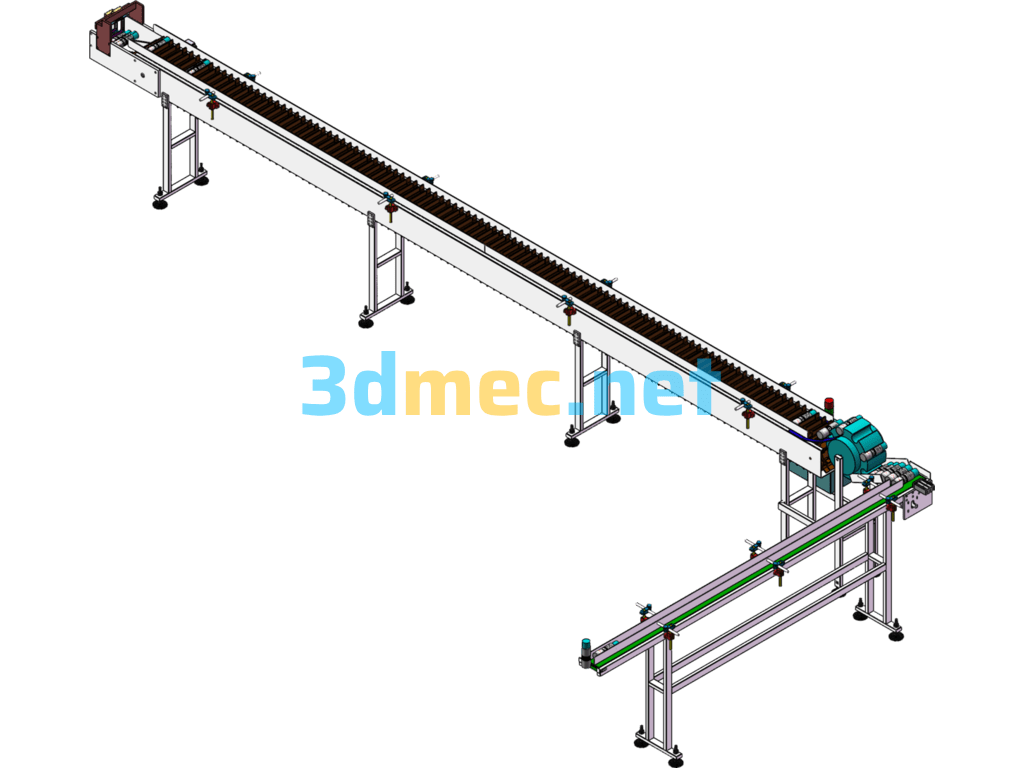

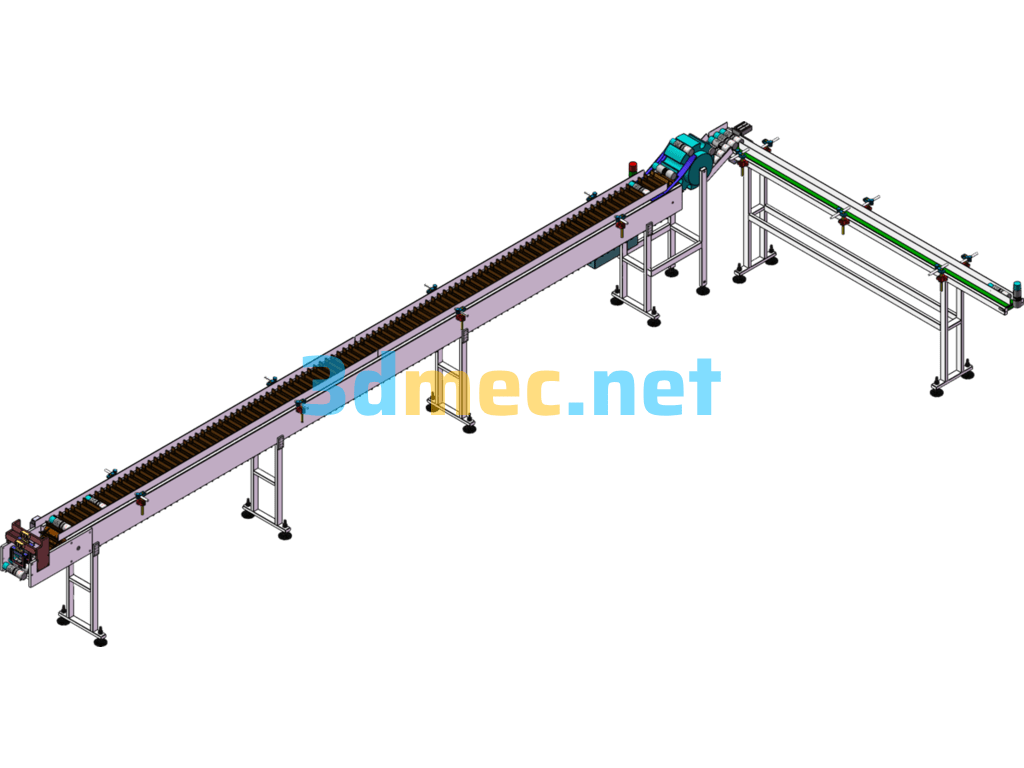

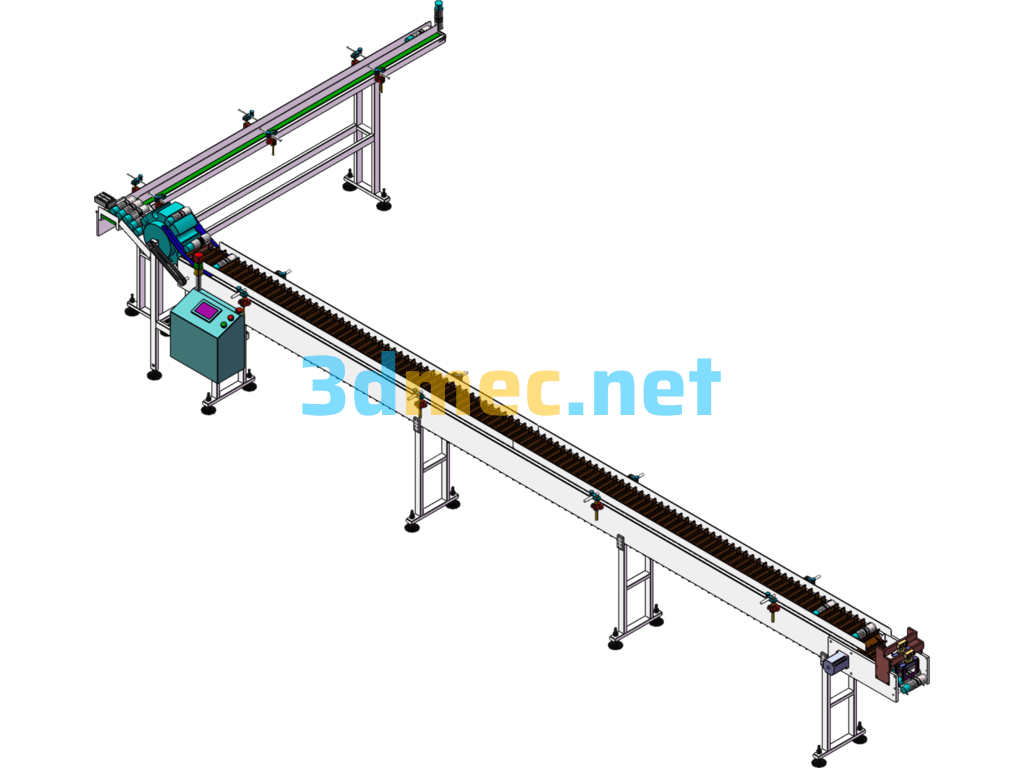

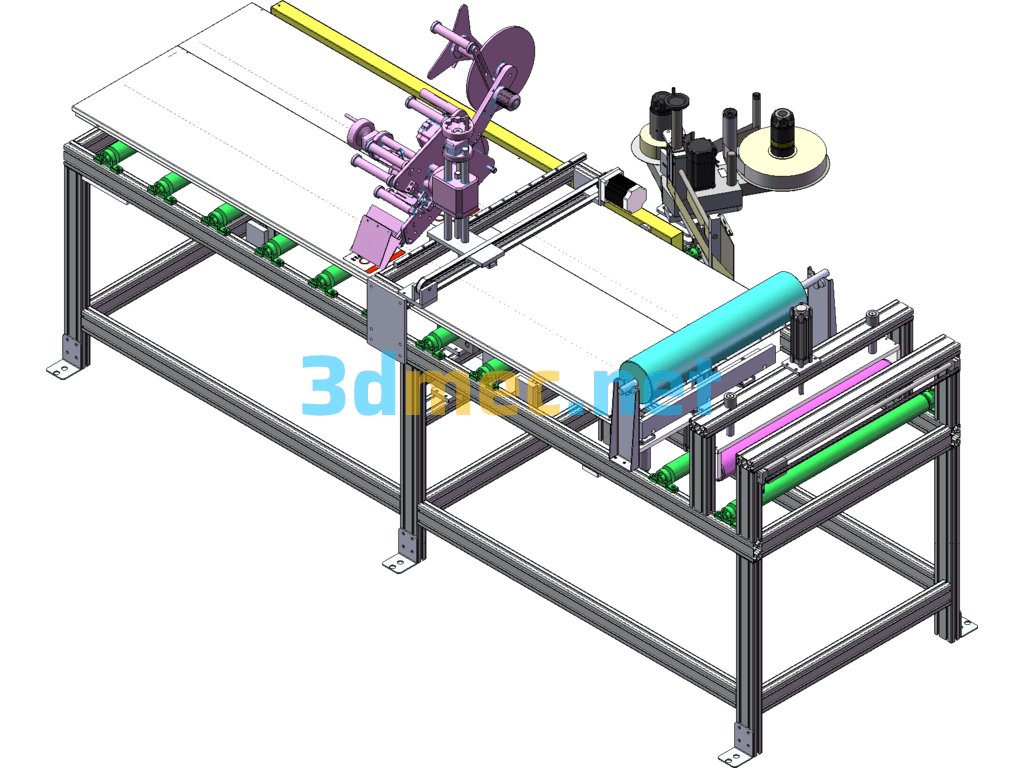

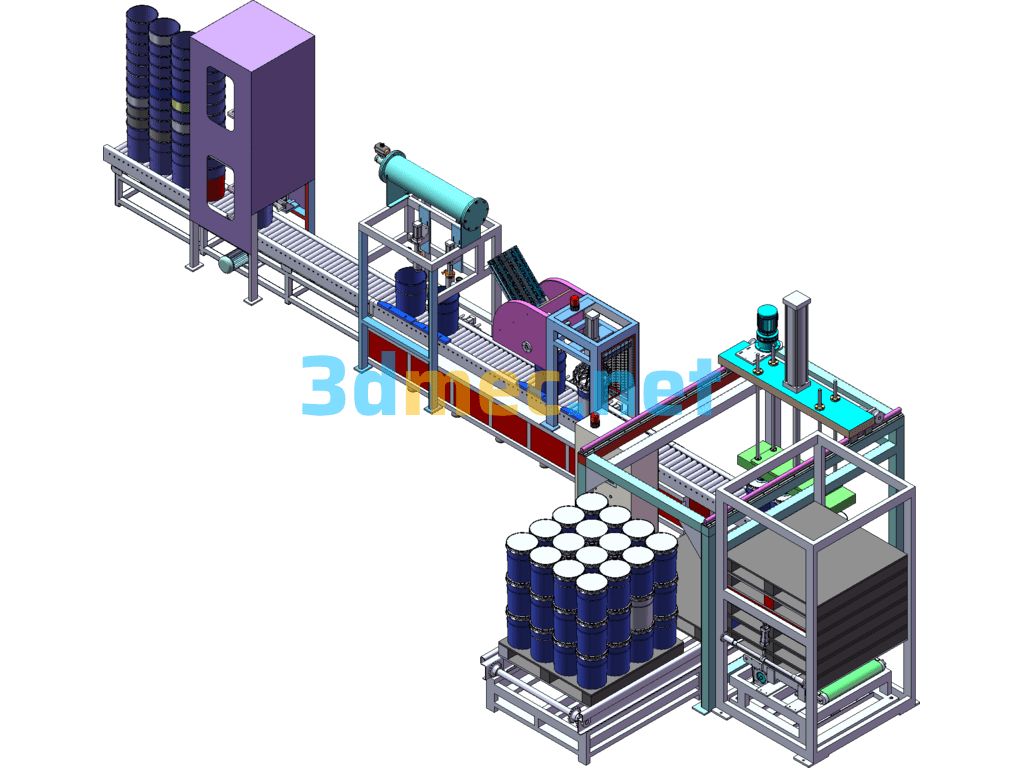

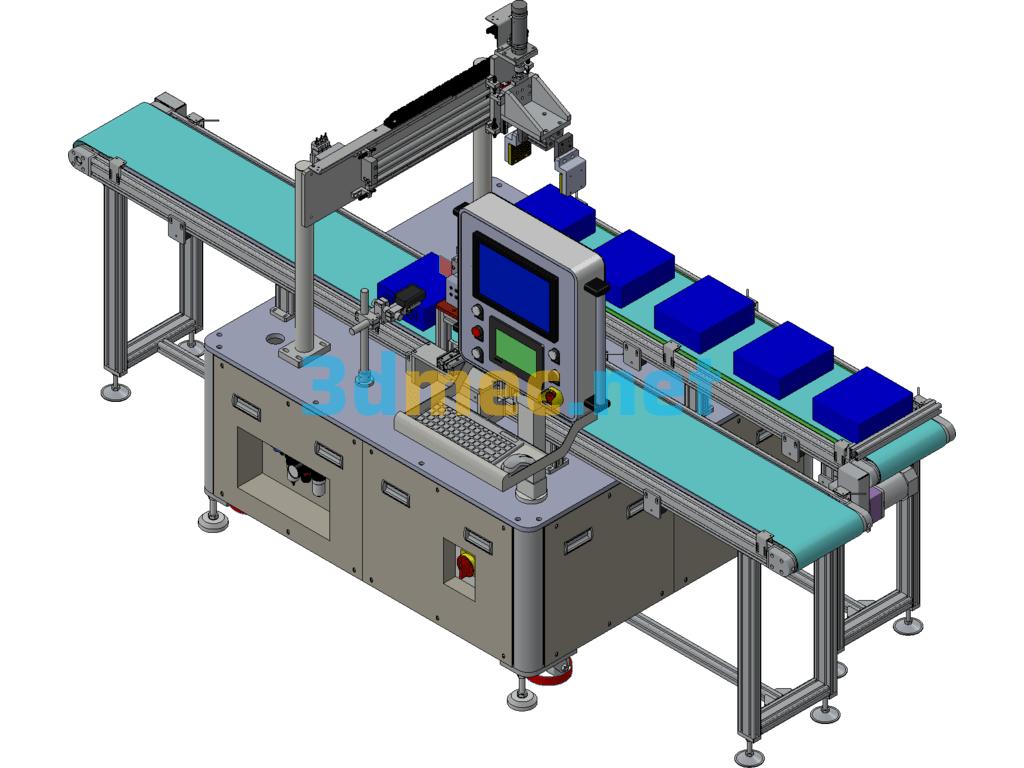

A well-known cosmetics company customized a 3D model of a bottom coding conveying line. This equipment is designed for bottom coding of round bottle cosmetics. The first section of the product is connected to the company’s existing conveyor belt. The two cylinders at the end control the products to fall one at a time, which is connected to the company’s packaging machine. The middle clamping plate transition is for the convenience of bottom coding! This is also the first time I boldly designed a clamping plate mode! Before, bottom coding was achieved with clamping belts or double conveyor belts, but considering that double conveyor belts are prone to bottle overturning, I chose this design! For your reference, I believe it will be helpful to those who design non-standard equipment! Welcome to download! All SW2012 parameters are editable

Specification: Bottom Inkjet Conveying Line (Custom-Made Equipment For A Well-Known Cosmetics Company) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Bottom Inkjet Conveying Line (Custom-Made Equipment For A Well-Known Cosmetics Company) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.