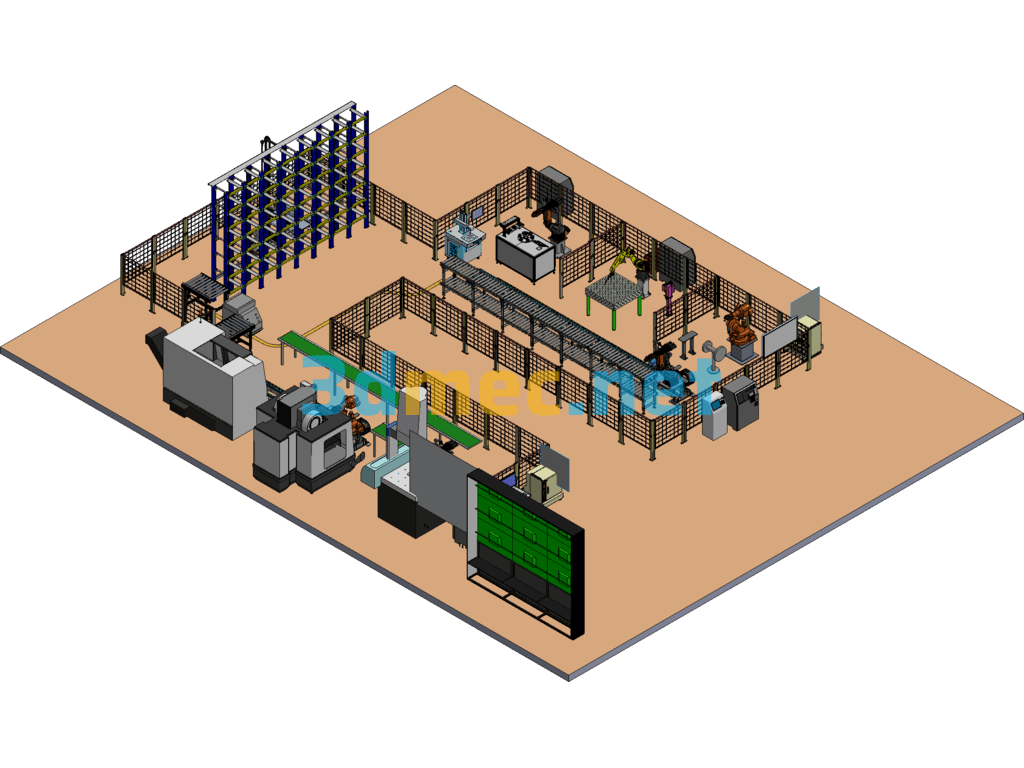

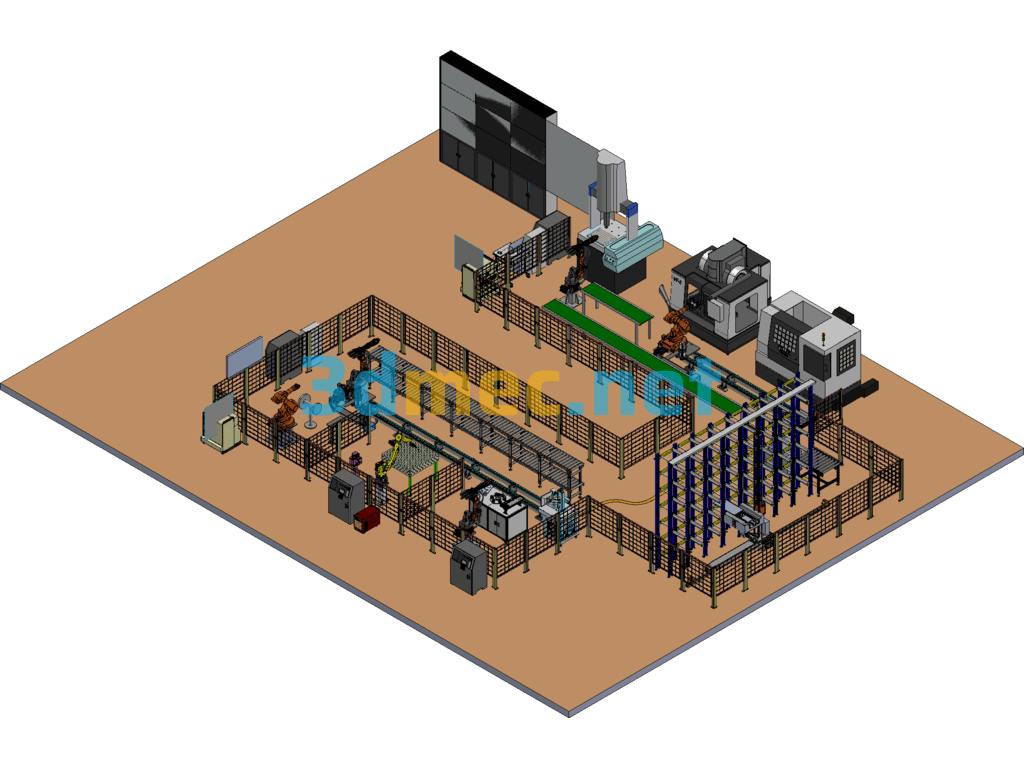

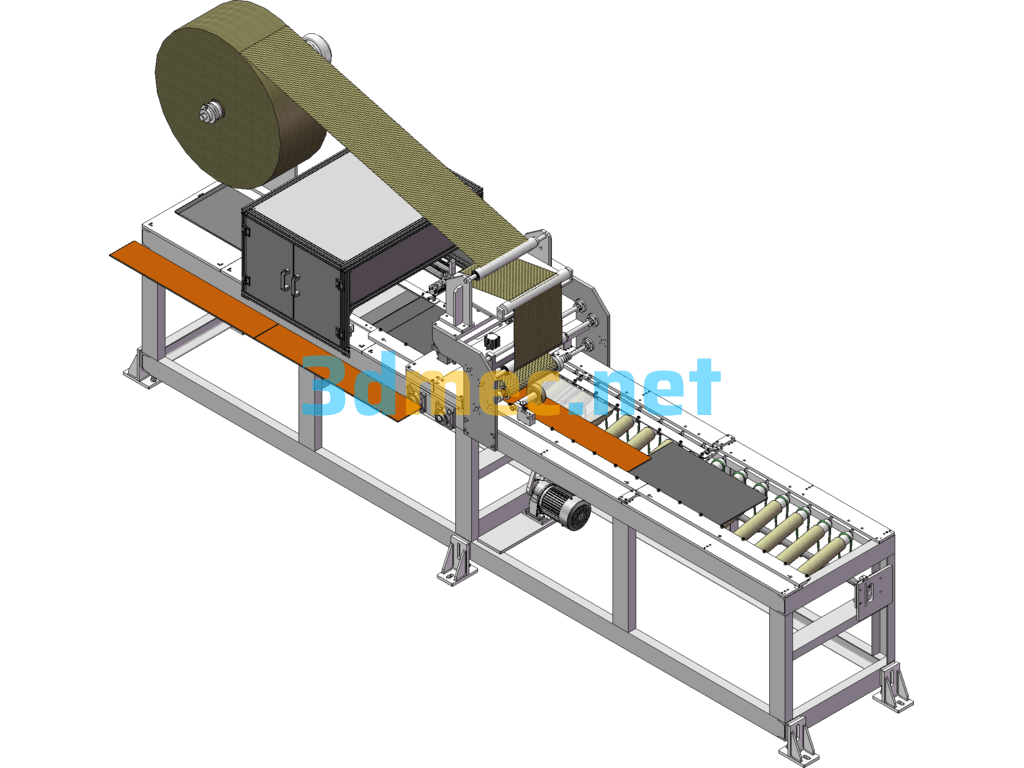

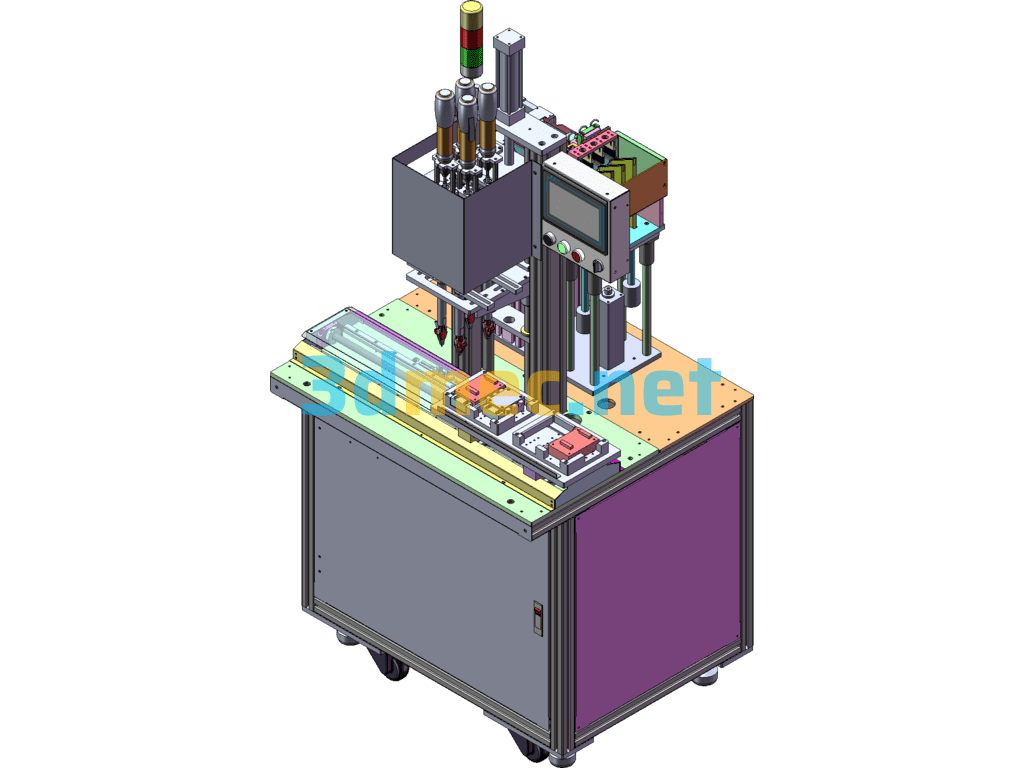

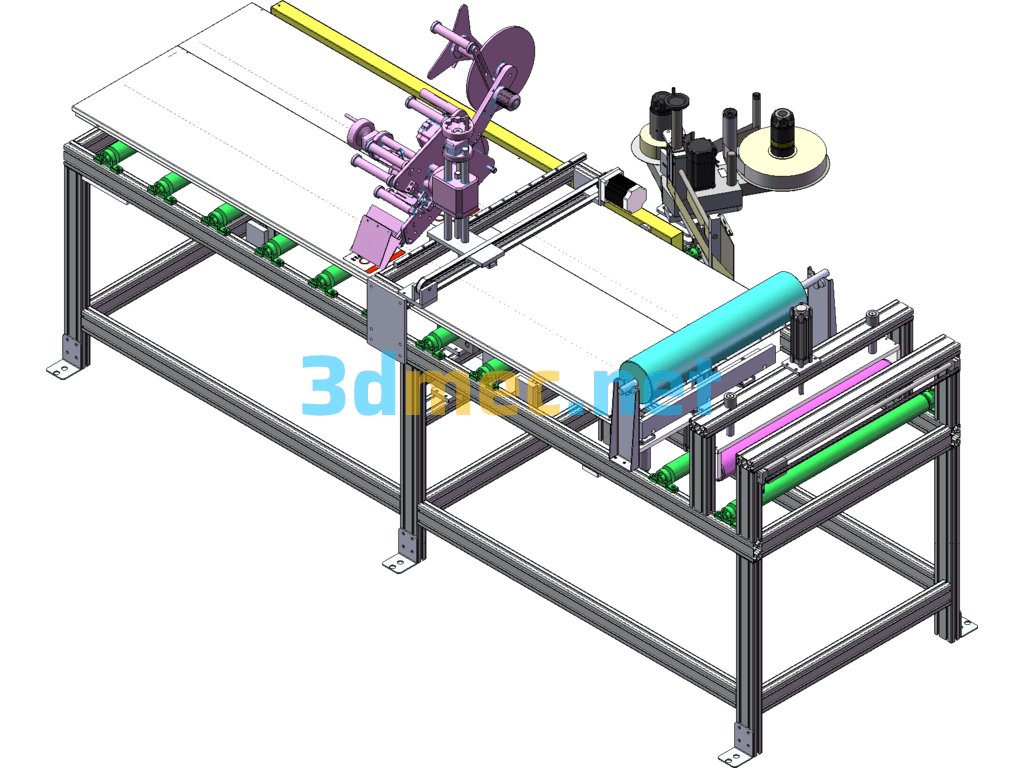

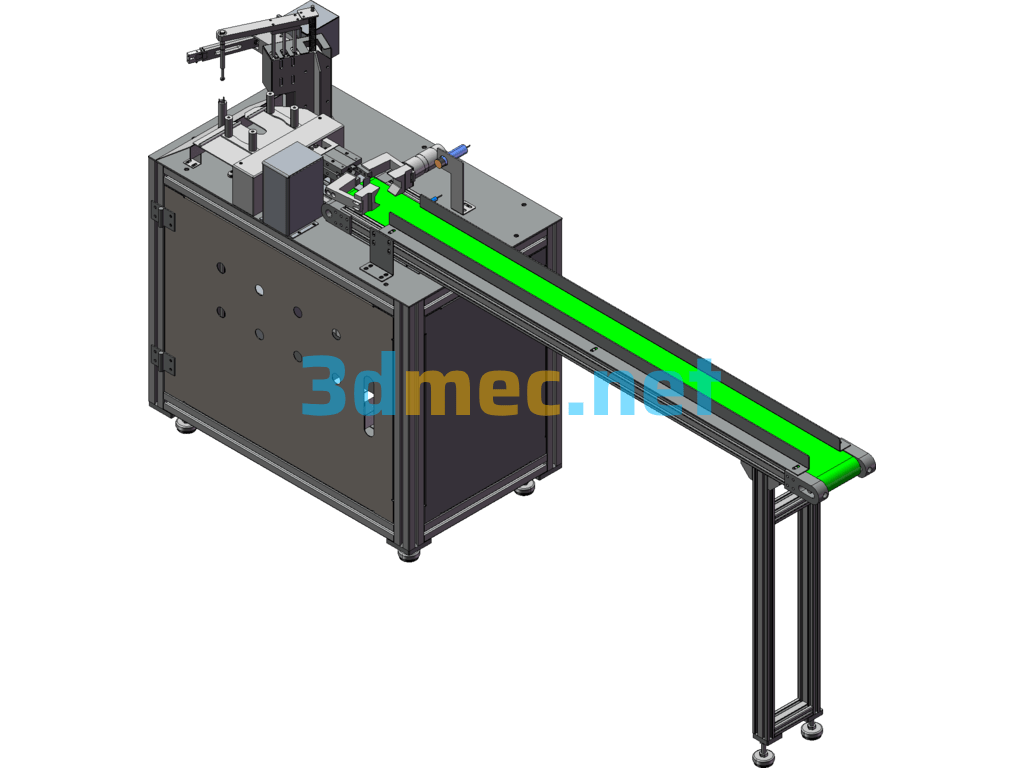

The intelligent manufacturing training base consists of a set of flexible intelligent manufacturing production line systems, including CNC lathes, vertical high-speed machining centers, stereoscopic warehouses and stackers, and robot grinding, welding, assembly loading and unloading, three-coordinate detection, conveying devices, laser marking, etc., which enable the automated stereoscopic warehouse to store materials and finished products. Materials and finished products are transported through conveyor lines. The robotic machine tool loading and unloading system connects the conveying device and the CNC lathe or vertical high-speed machining center. The materials are formed into finished products after processes such as turning, milling, drilling, grinding, and welding. The machine tool loading and unloading robots place the processed finished products on the conveyor line and send them to the automated stereoscopic warehouse through the AGV conveyor line.

Specification: Intelligent Manufacturing Training Base Program – 3D Model Exported

|

User Reviews

Be the first to review “Intelligent Manufacturing Training Base Program – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.