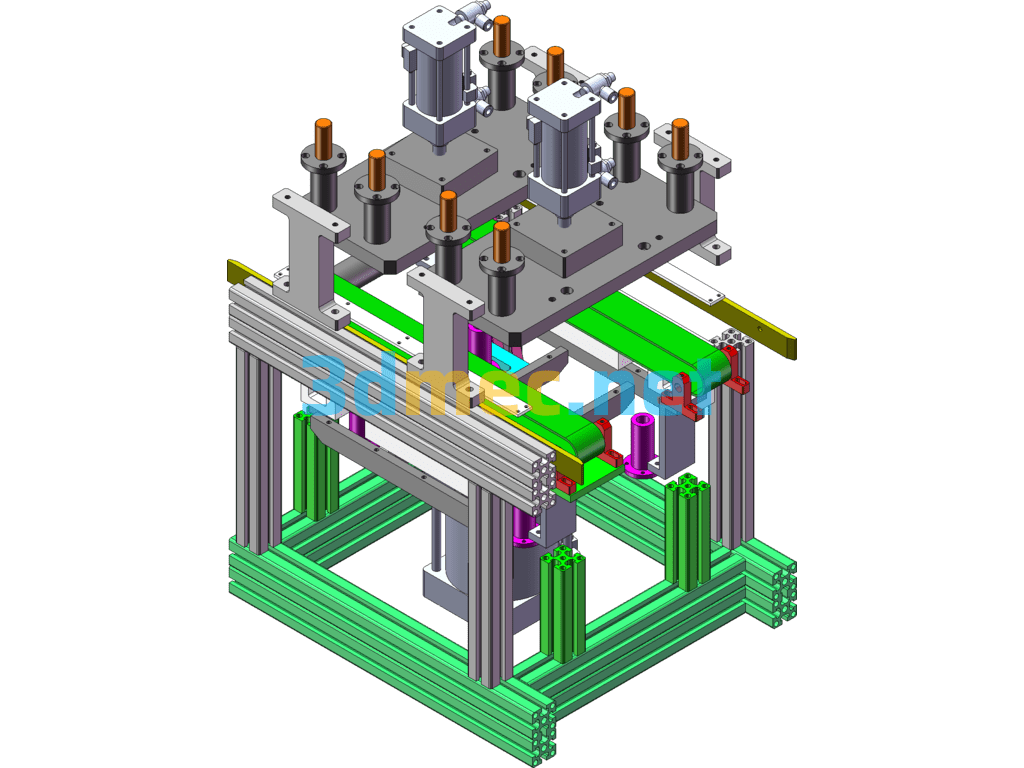

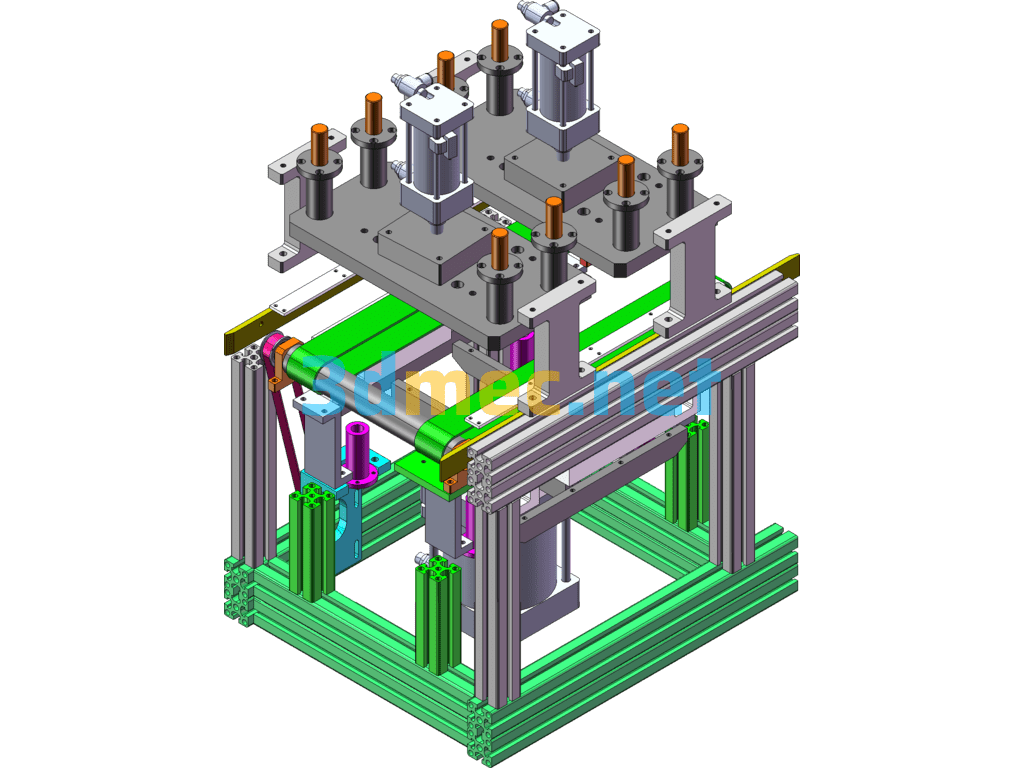

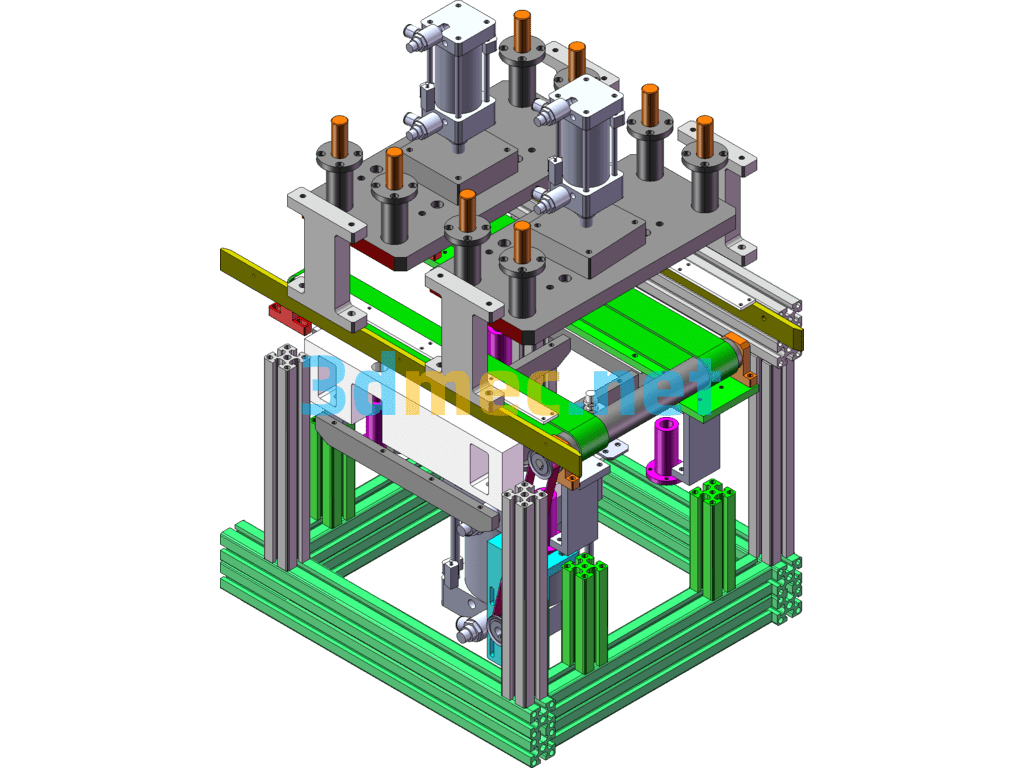

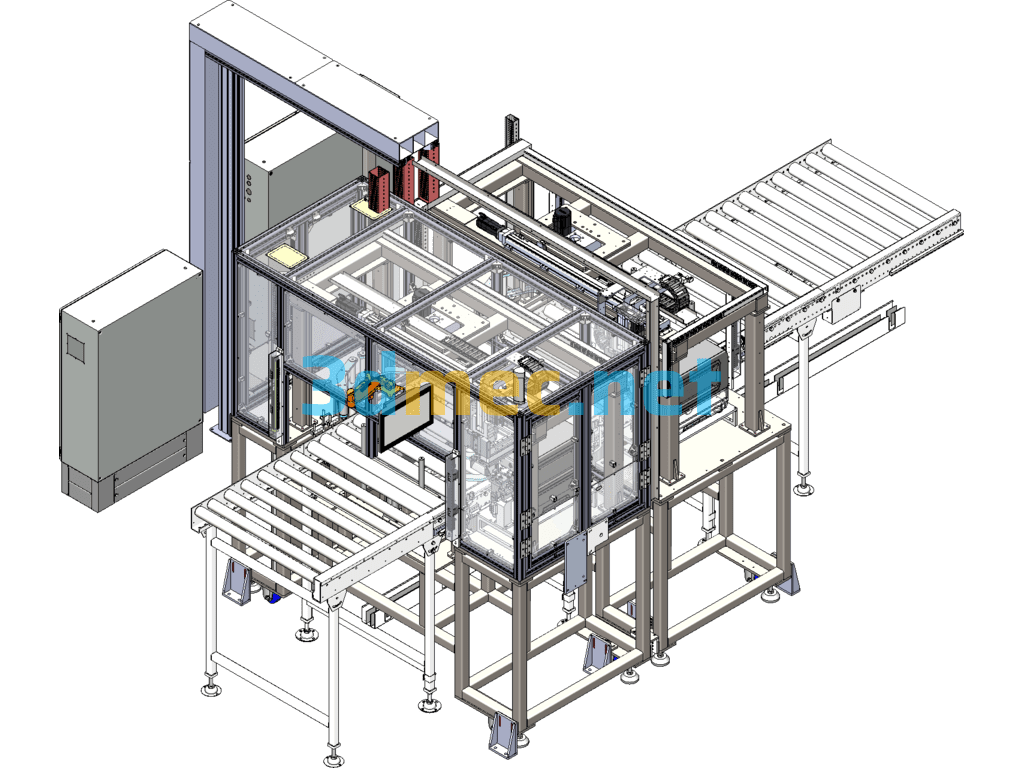

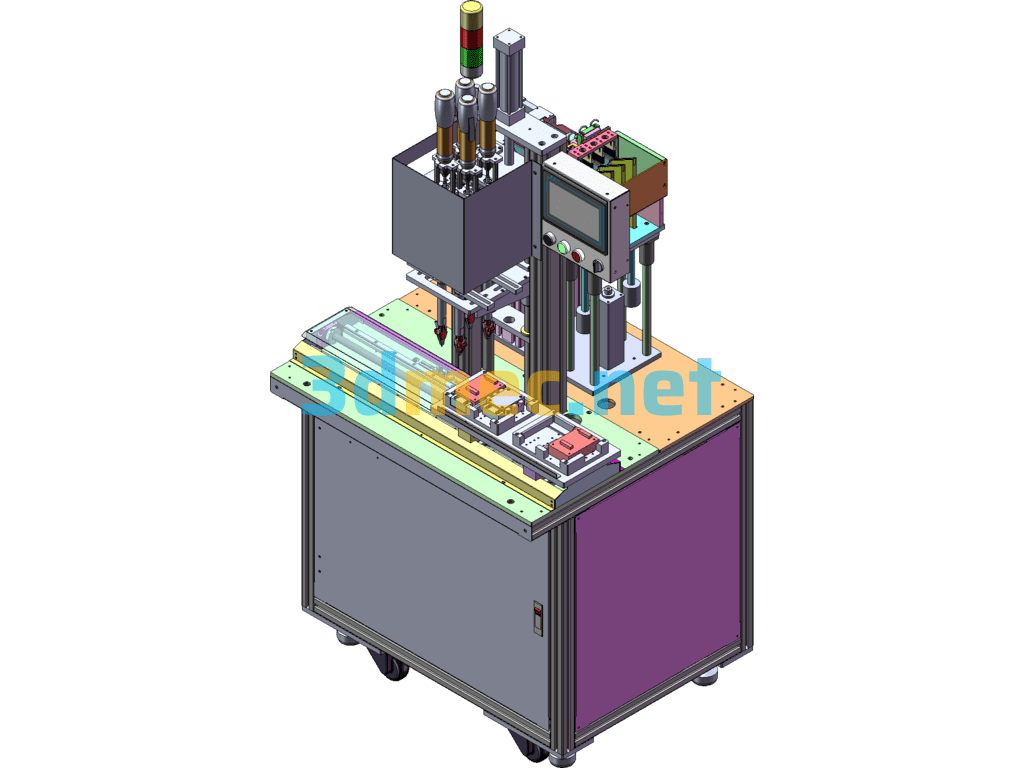

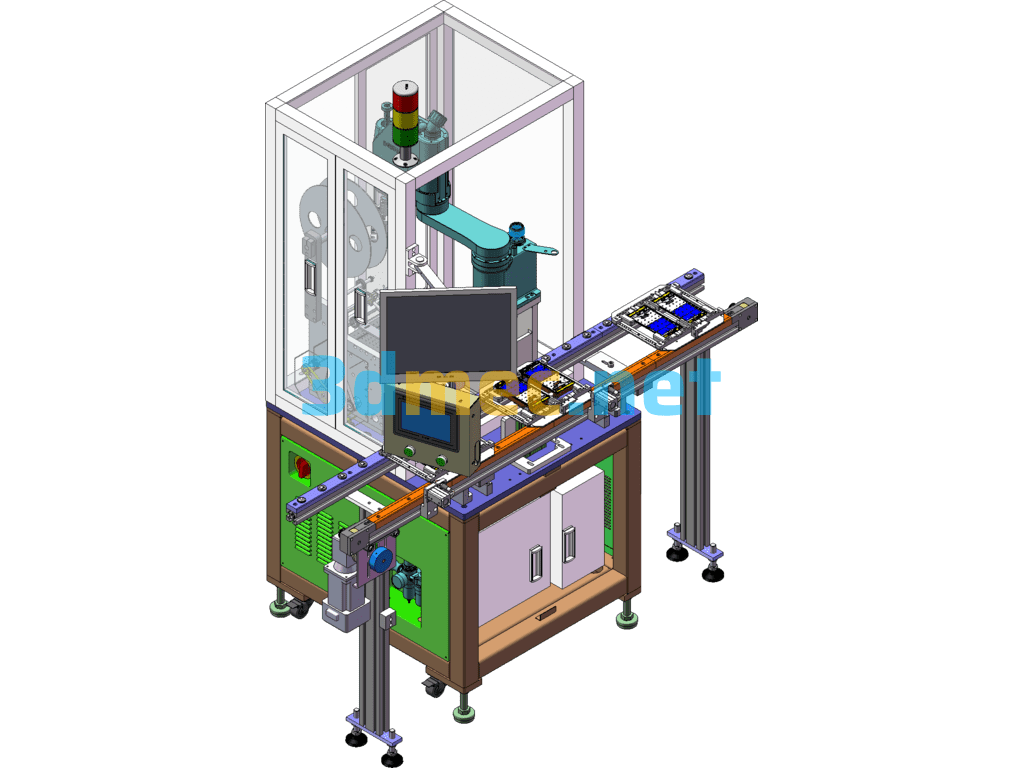

HW Tablet Computer AB Glue Automatic Production Line (Thermal Capacity Glue Dispensing Machine) – 3D Model SolidWorks

very good set of automatic production line for tablet electric metal shell dispensing machines, the structure and parts design are very good, there are more than 1000 SW2011 design source files and STP files for large and small parts, which are close to 200M. [The files of the two packages must be opened together to be complete].

Apple tablet computer shell hot-capacity glue dispensing production line This equipment is mainly used to dispense glue for the back shell of Huawei tablet computers and then flip and press the metal shell and plastic shell with AB glue applied together. The conveyor line automatically flows out to the hot pressing position. The automatic conveyor line is divided into two stations for hot pressing. Because the hot capacity time is relatively long, a station is used for hot pressing to reduce the production cycle. The main working principle of the entire production line is: manually put the metal shell on the glue dispensing fixture position, start to dispense AB glue, flip it over to let the metal shell and plastic shell press together, the conveyor belt sends the flow plate to the hot pressing position, and starts hot pressing. The hot pressed ones automatically flow out to the main conveyor belt, flow from the main conveyor belt to the rear end for manual material collection, and then the flow plate flows into the glue dispensing position, and the metal shell and plastic shell are manually placed. Since the workstations and equipment are relatively complex, I will briefly introduce them here.

Specification: HW Tablet Computer AB Glue Automatic Production Line (Thermal Capacity Glue Dispensing Machine) – 3D Model SolidWorks

|

User Reviews

Be the first to review “HW Tablet Computer AB Glue Automatic Production Line (Thermal Capacity Glue Dispensing Machine) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.