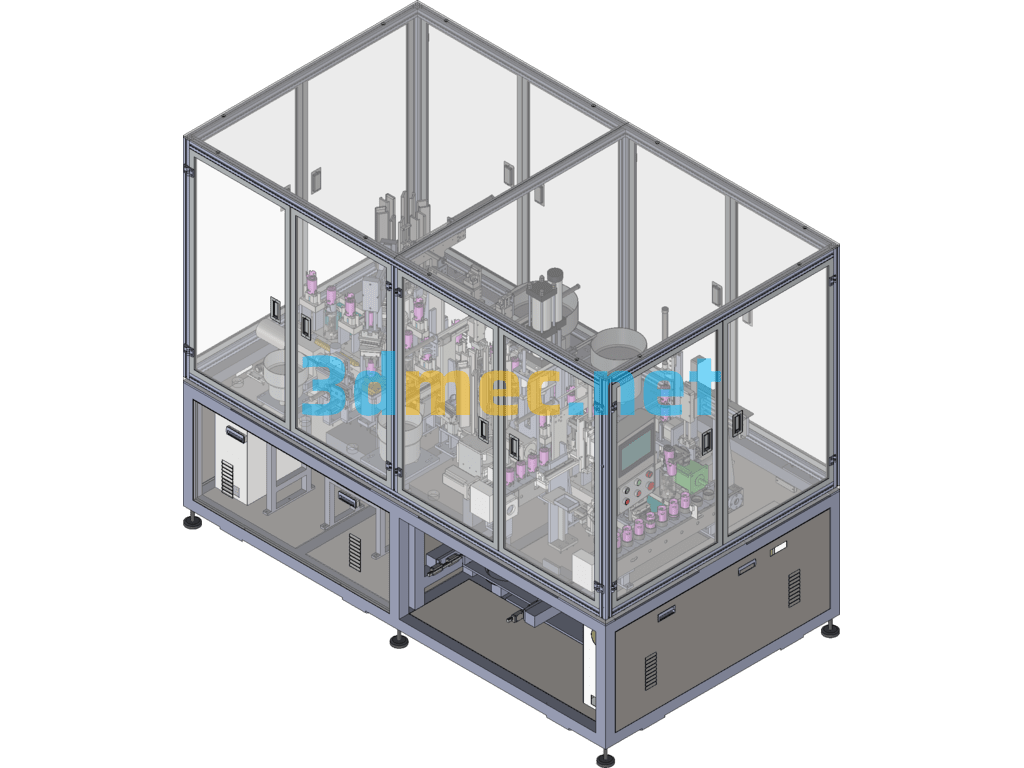

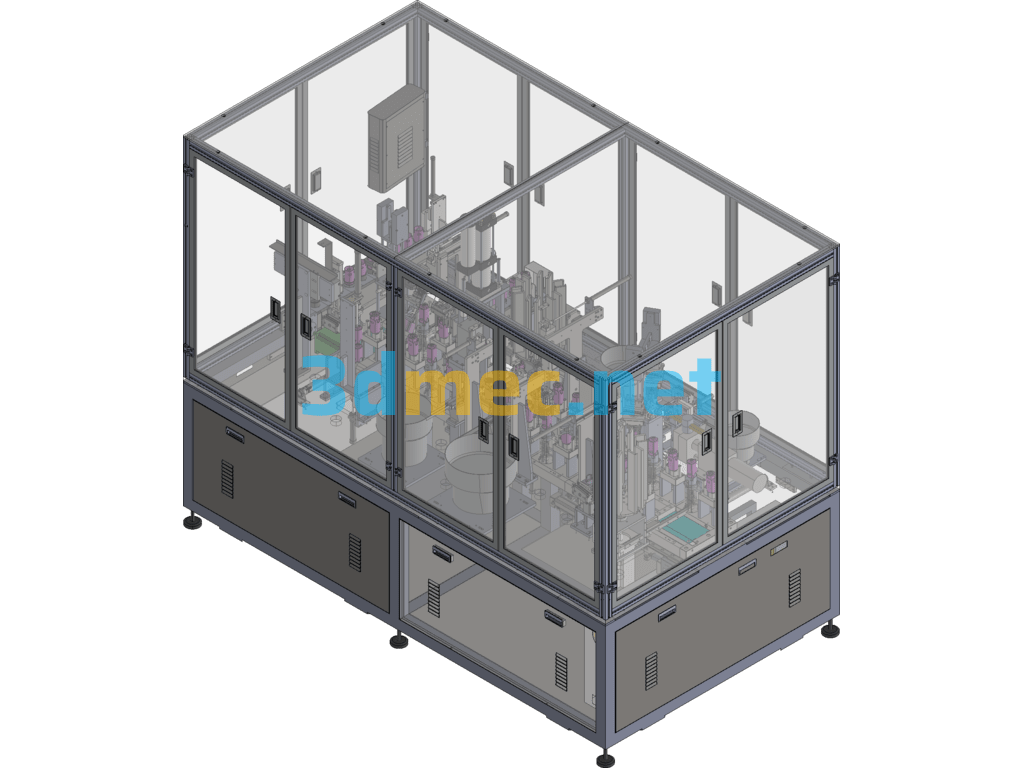

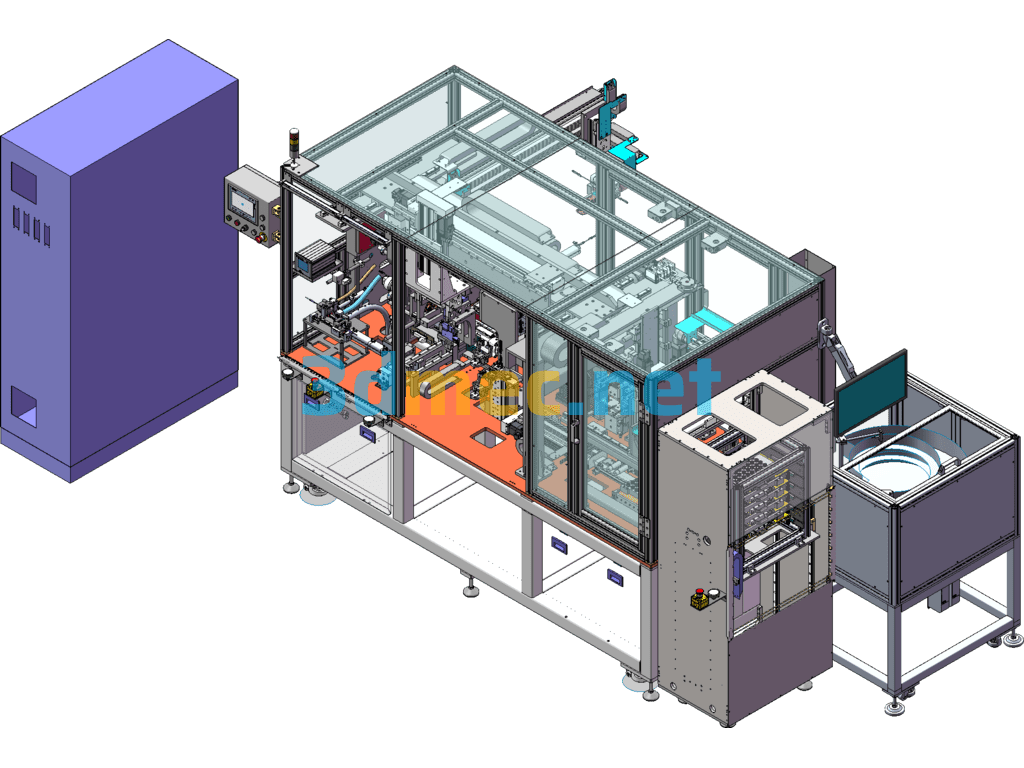

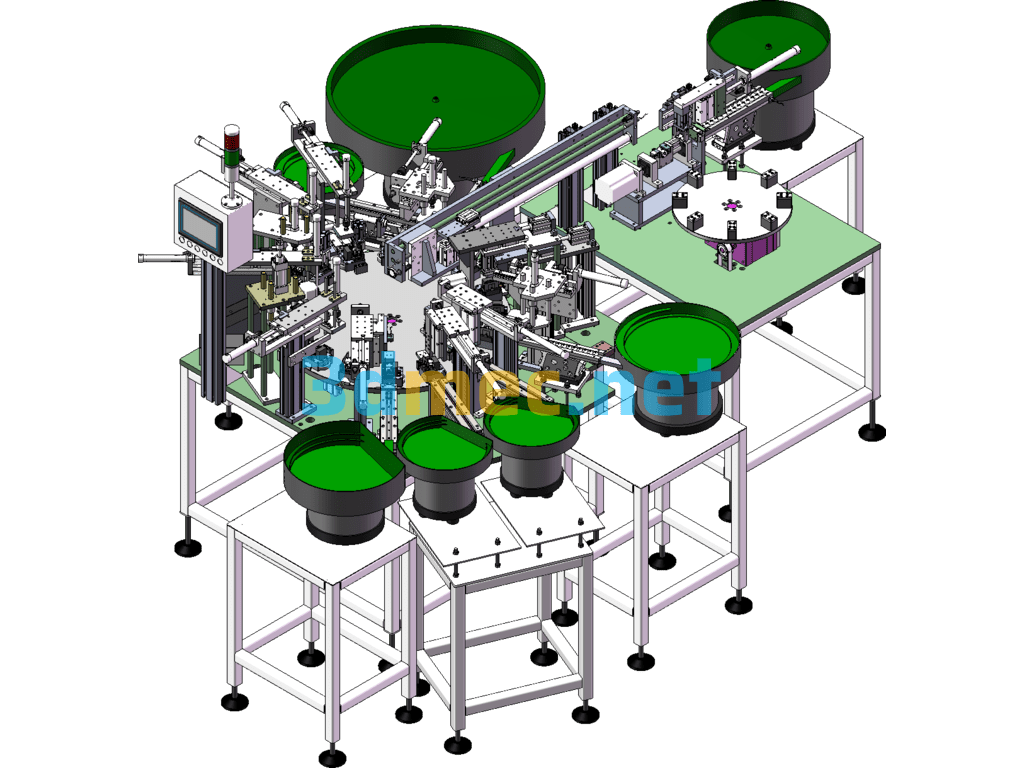

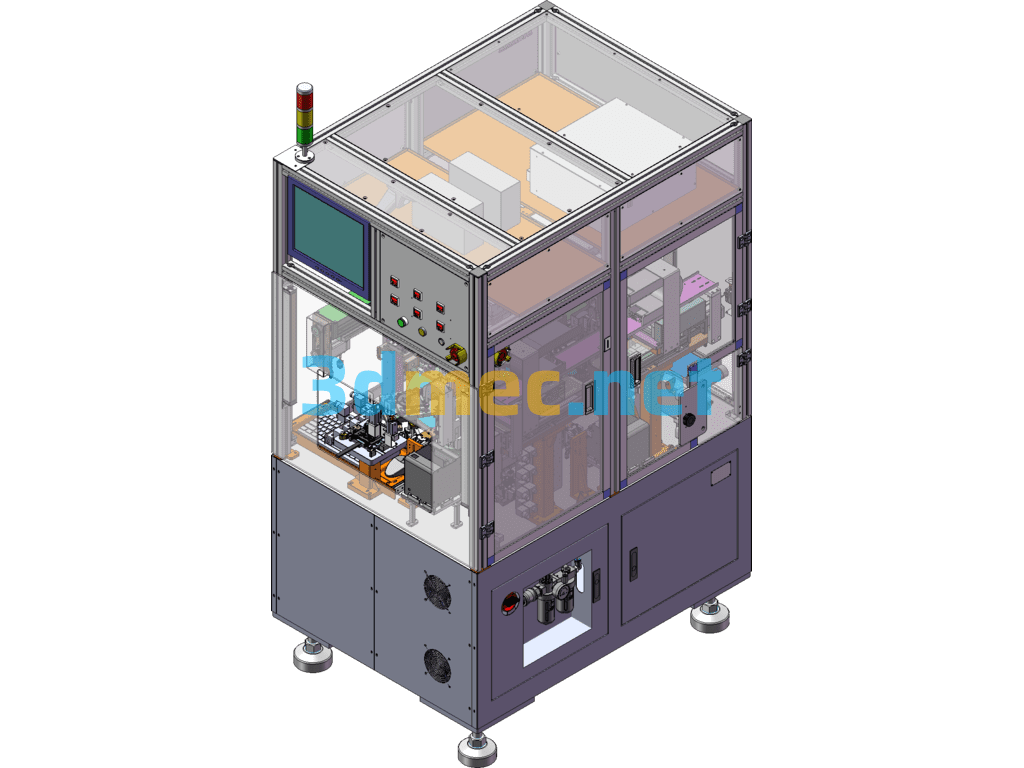

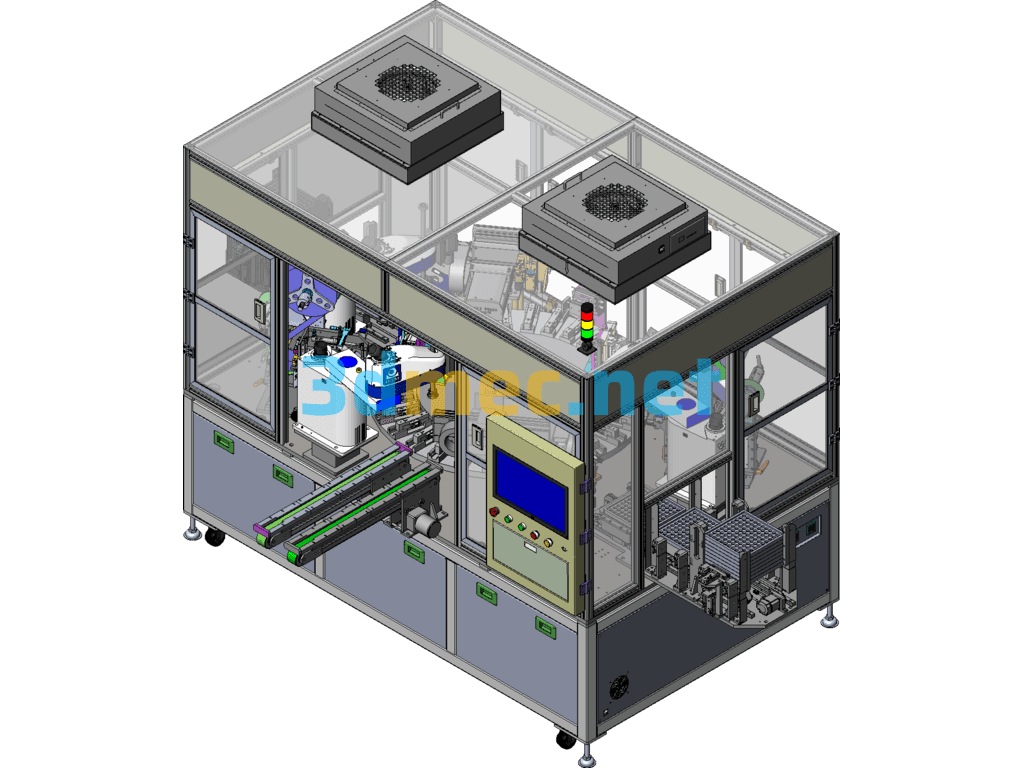

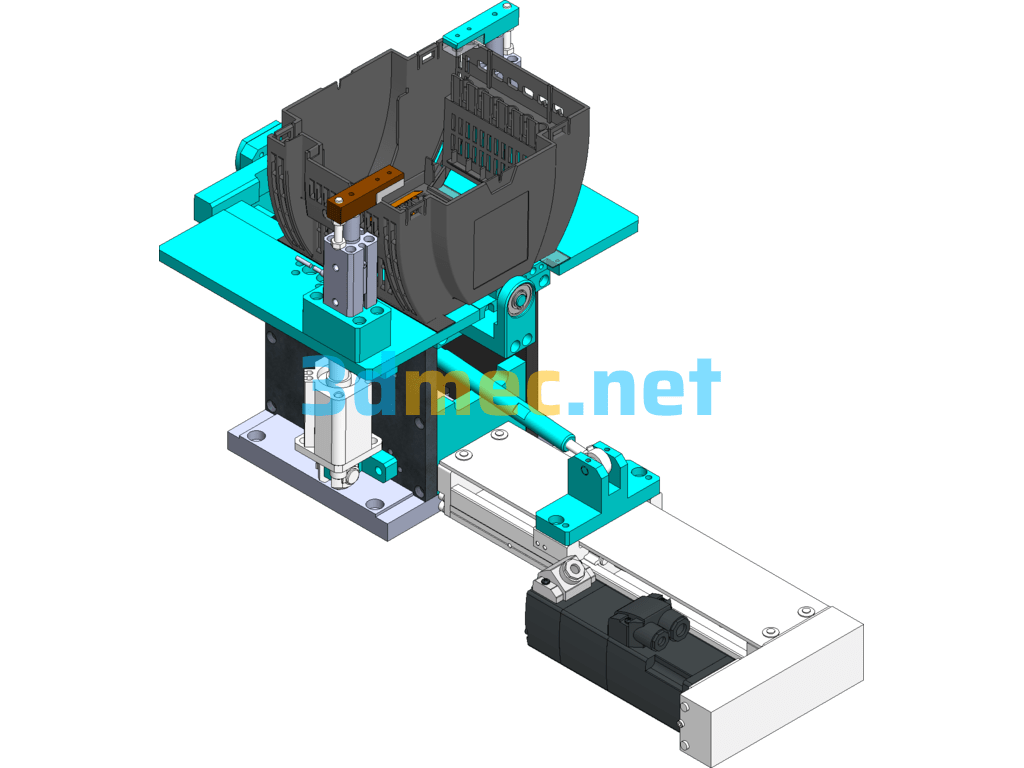

Non-standard equipment for micro motor assembly machine, 3D digital model of fully automatic DC motor assembly line. This automated line equipment can meet the function of automatic riveting bearings on the back cover. Due to the large number of assembly and functional stations, it is impossible to introduce them. Now we can only briefly introduce the following functions: automatic housing assembly machine, back cover riveting bearing machine, riveting bearing embossing needle structure is consistent with the existing ones. All assembly and riveting welding and gluing qualities have been tested, and the overall operation of the equipment is stable. The bearing compression spring is pressed without deformation and warping, and the four rivet points are crimped reliably; the bearing swing force is 2.8~8kgfcm; the cylinder and hydraulic press must ensure that the product riveting is reliable; so the structure has been designed to be very compact during the design. The glue adding position is consistent with the sample; no glue is allowed in other positions; . After the housing is completed, deformation and scratches are not allowed. . The bearing compression spring is pressed without deformation and warping, and the four rivet points are crimped reliably; .Bearing swing force 2.8~8kgfcm;The equipment has manual adjustment function. In manual mode, each action of the machine has corresponding buttons on the touch screen and signal output indication;This set of fully automatic DC motor assembly production line drawings is an unmanned automatic line developed for needle micro motors. The equipment is a whole back cover and stator housing, which is operated by one person for loading and unloading. The beat is ≤5 seconds and the single machine conversion time is ≤5 minutes;The machine is fully automatic and does not require human intervention under normal circumstances. The loading and unloading manipulators have loading/unloading functions respectively. In addition, the equipment can meet the automatic riveting bearings, inserting magnetic tiles, magnetizing, welding terminals, and adding glue to the housing. There are also automatic feeding of housing, bearings, bearing compression springs, magnetic tiles, slingshots, terminals, and glue (manual arrangement of the housing). After the housing is magnetized, the magnetic flux after magnetization is automatically detected. Unqualified products need to be detected. There is a savings mechanism for detecting defective products. There is a continuous defective shutdown alarm function and a glue adding machine A and B glue stirring and mixing evenly; It is a motor assembly line with the most complete functions.

Specification: Micro Motor Assembly Machine Non-Standard Equipment/Full Automatic DC Motor Assembly Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “Micro Motor Assembly Machine Non-Standard Equipment/Full Automatic DC Motor Assembly Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.