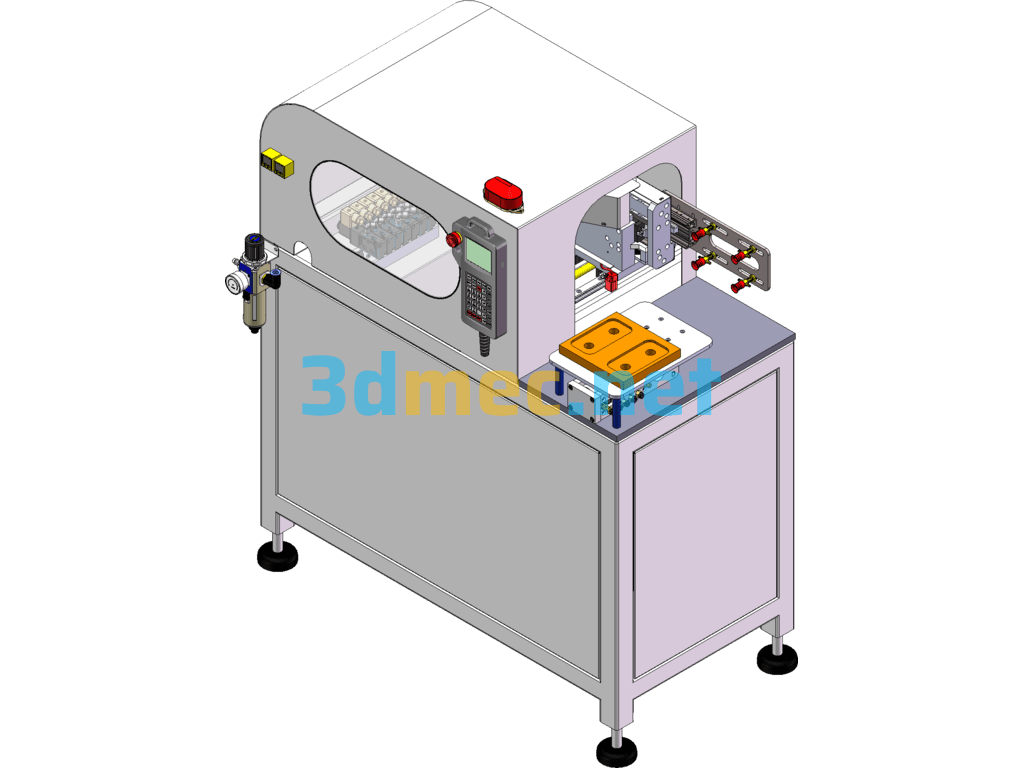

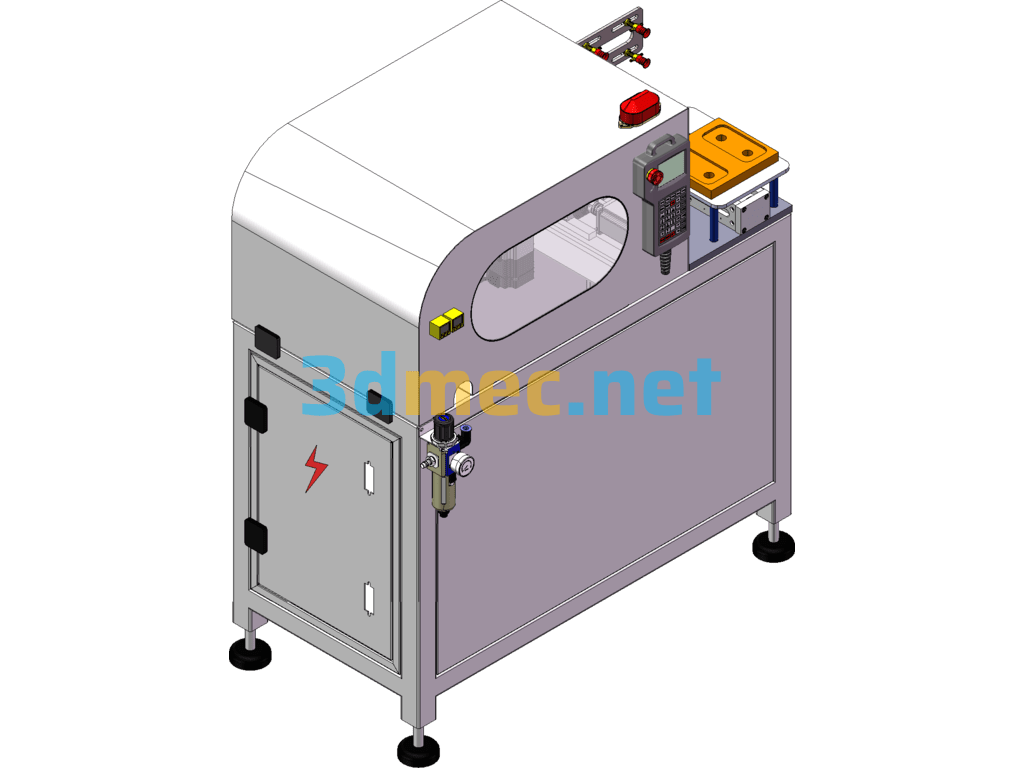

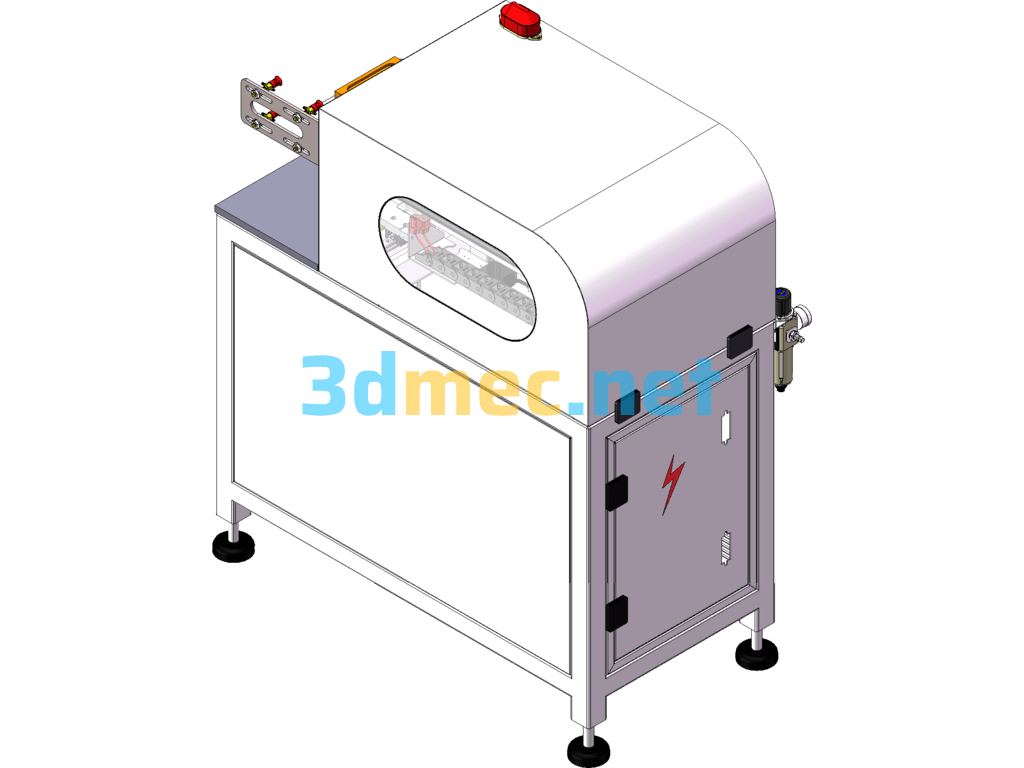

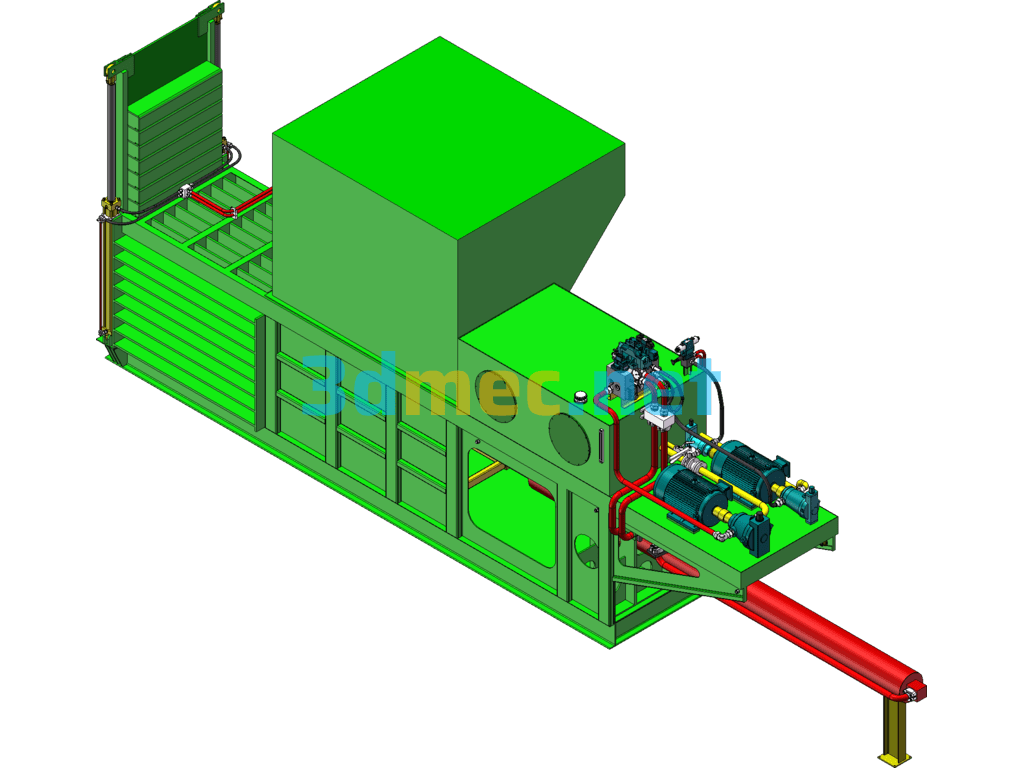

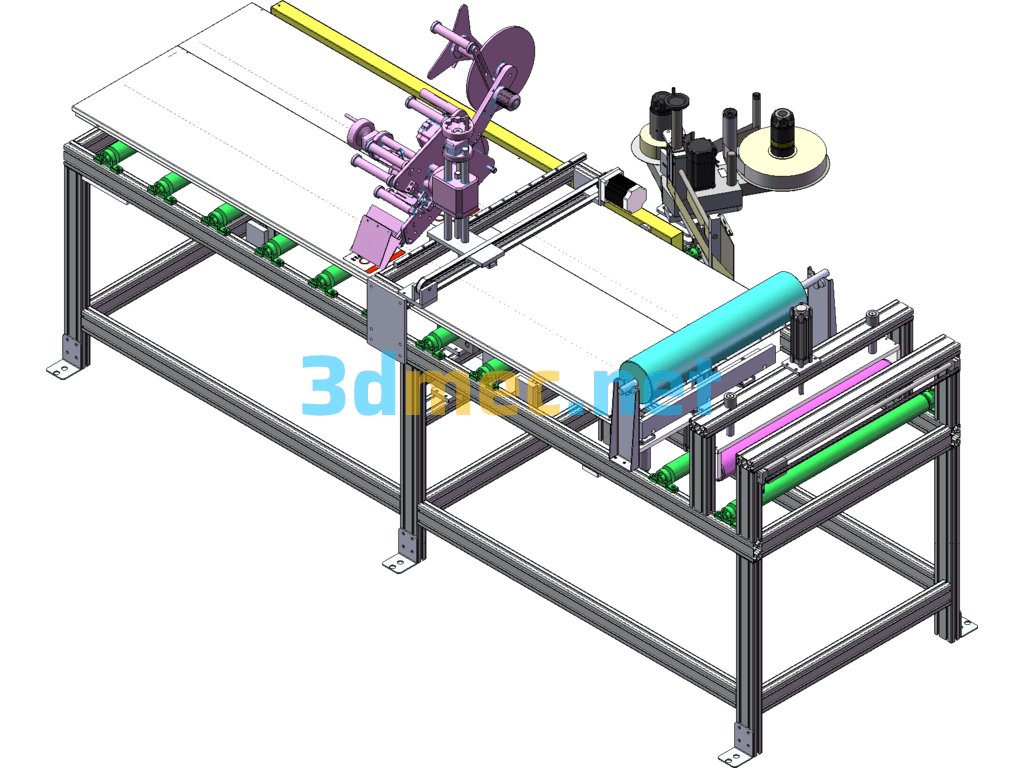

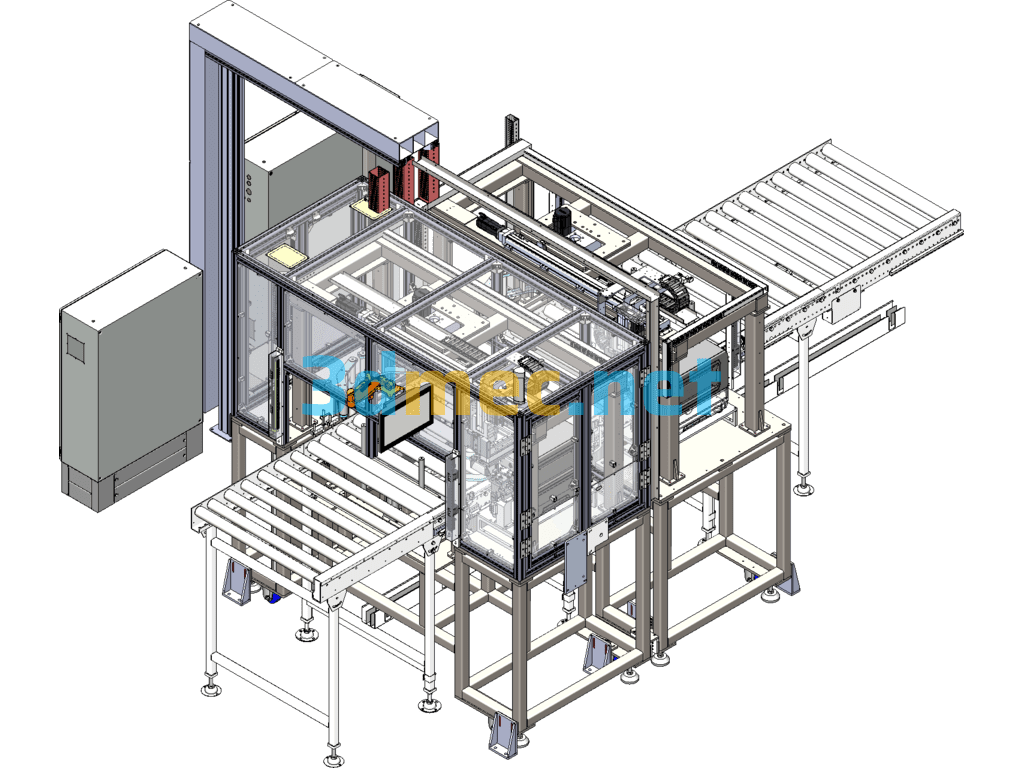

Non-standard automatic in-mold labeling robot

Introduction to in-mold labeling technology

Advantages of in-mold labeling and solutions to process problems:

In foreign countries, in-mold labeling technology has long been widely used. It has only been gradually derived to my country in recent years. This new technology is not only recognized by industry insiders, but also rapidly and widely used.

In-mold labeling products use special mechanical equipment to send printed composite material labels to the injection mold cavity of special structure, and use the temperature of the injected plastic to melt the label and plastic into one. It is mainly suitable for plastic packaging products made of PE and PP materials.

Advantages of in-mold labeling:

1. It plays an anti-counterfeiting role

The high technical content of in-mold labeling is an effective line of defense against counterfeiting. It is mainly from the selection of high-quality materials, the production of in-mold labels to the design structure and production process of labeling production equipment and molds. They must be closely coordinated with each other and cannot be produced unilaterally, which increases the difficulty of counterfeiting.

2. In-mold labeling can improve the grade of products

In-mold labeling products are more beautiful than silk-screen and off-mold labeling products, with brighter label colors and smoother feel.

It is inevitable for social development that design pursues the aesthetics and fun of goods.

Attract with beauty, and reflect the sense of the times with simple, bright and generous practicality.

In-mold labeling products are practical and low in loss. Compared with silk-screen and off-mold labeling products, there will be no ink loss, label will not warp, fall off, or break. It has the functions of extrusion resistance, waterproof, oil resistance, mildew resistance, friction resistance, acid and alkali resistance, cooling and heat resistance, so that the label is not easily damaged and stained under special circumstances. The price of in-mold labeling products is similar to that of self-adhesive and silk-screen products. The use of in-mold labeling can improve efficiency and does not require manual labeling, eliminating the production link of re-labeling.

Specification: Non-Standard Automatic In-Mold Labeling Robot – 3D Model SolidWorks

|

User Reviews

Be the first to review “Non-Standard Automatic In-Mold Labeling Robot – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.