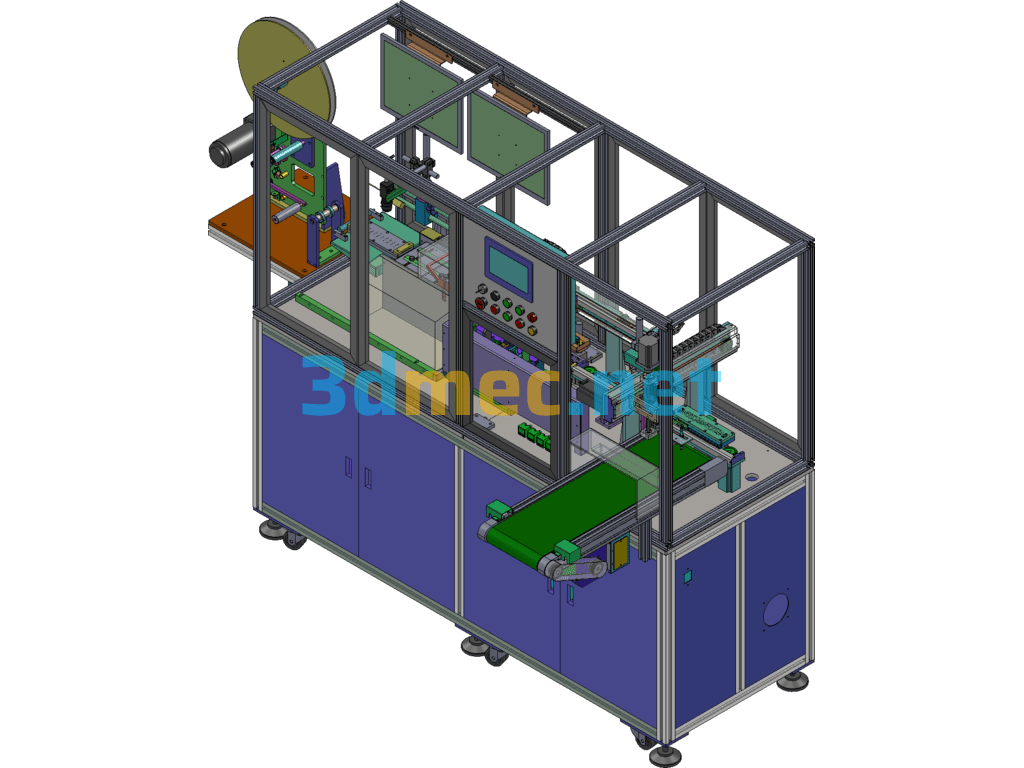

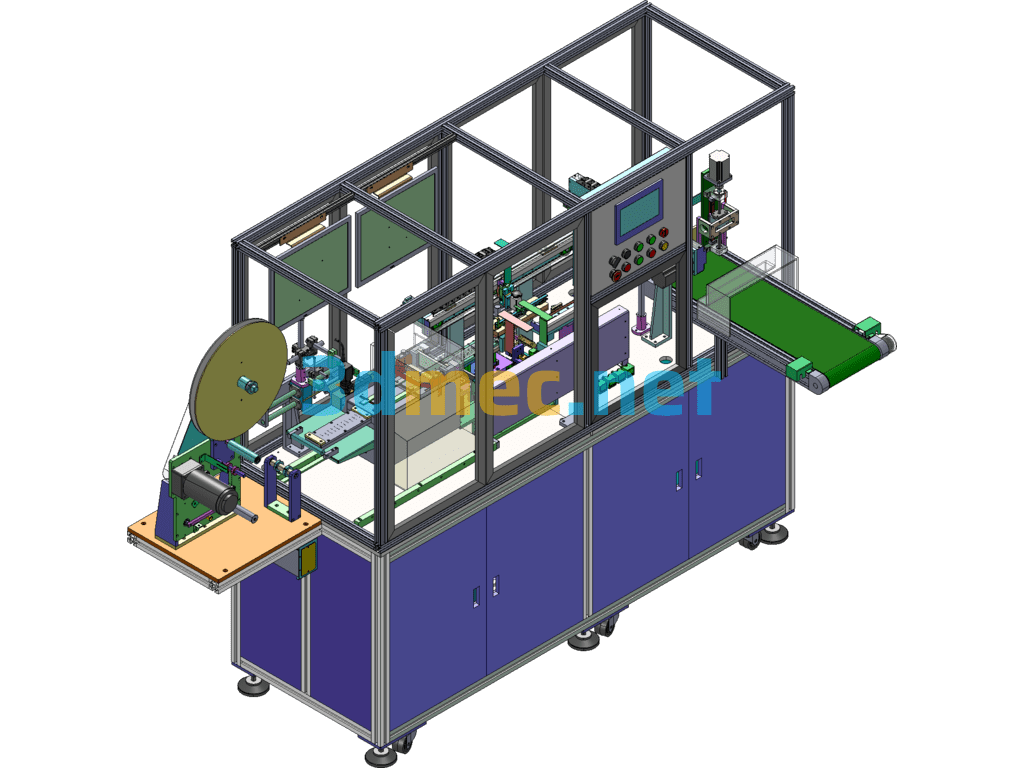

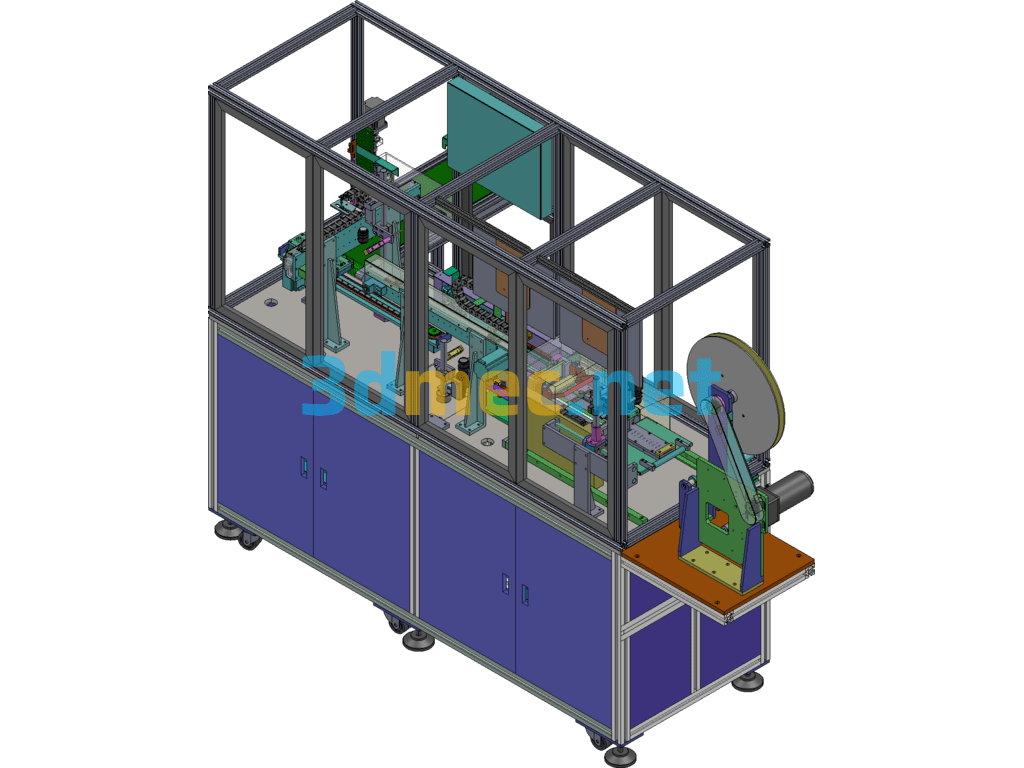

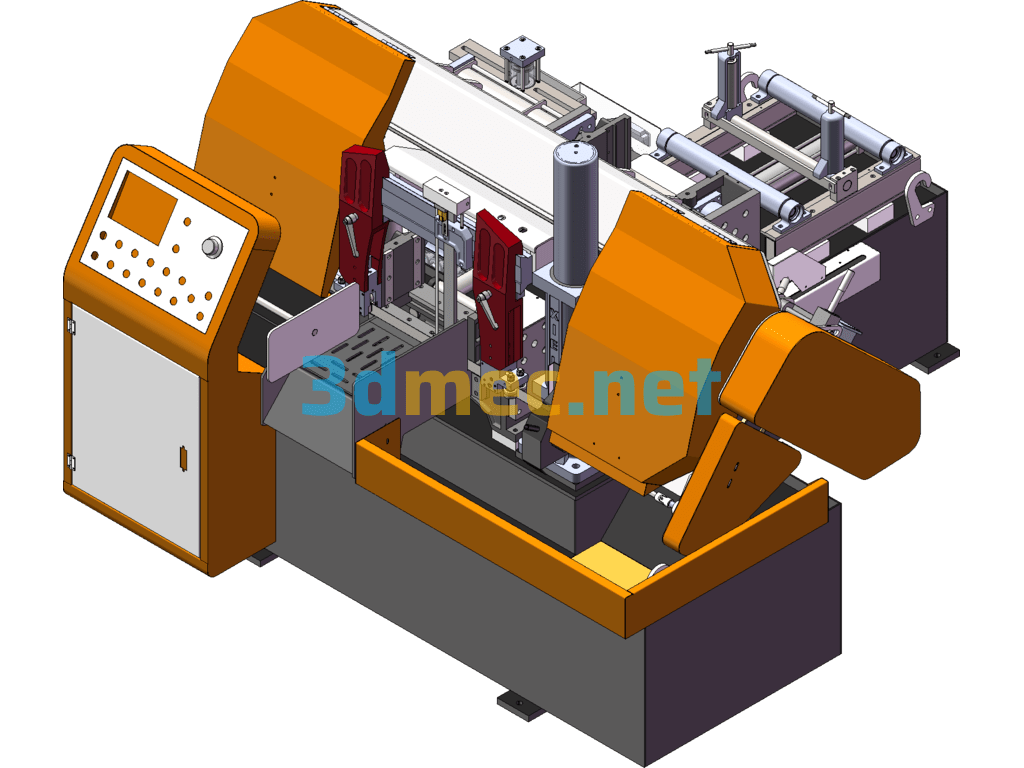

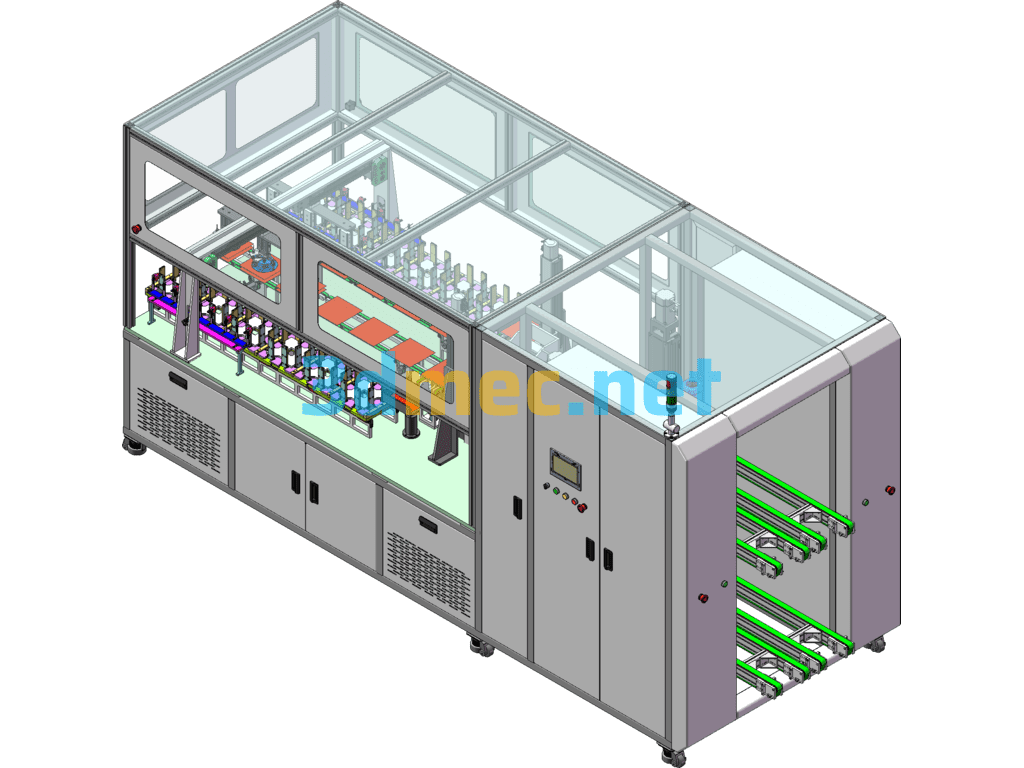

FPC cutting and testing machine screen cable cutting equipment FPC soft cable cutting machine 3D model This equipment is a fully automatic machine for screen connection and wiring processing in Apple mobile phones: the equipment is mainly used for equal length cutting and fracture detection of FPC soft cables , the equipment operates in a tray loading mode. Manually, you only need to place each roll of cable into the loading tray on time. The equipment automatically feeds the material and can cut it according to the set length. FPC cutting and testing machine mobile phone screen wiring processing equipment 1. Equipment description: The products suitable for this equipment are: FPC, FFC, FDC, processing and cutting of various mobile phone screen connection lines. This equipment is a fully automatic machine for screen connection and wiring processing in Apple mobile phones: the equipment is mainly used for equal length cutting and fracture detection of FPC flexible cables. The equipment uses a tray loading operation method. Manually only needs to place each roll of cables on time. To the loading tray, the equipment automatically feeds the material and can cut it according to the set length. The precision and length of the cutting material are controlled by the optical fiber sensor and the encoder of the feeding motor. The cutting accuracy can reach 0.01, which is very accurate and can be cut out. The length of the cable needs to be further detected by the CCD vision system. This is a simple but very precise device. When the optical fiber detects the incoming material, the cutting machine starts to automatically cut the material. The cut material is sucked by the robot to the photographing position. The appearance and length are detected. The picking robot and the unloading robot work simultaneously to suck the detected products into the unloading conveyor belt. The FPC will be stacked before unloading. The quantity of each stack is also based on the value set by the customer. To carry out the operation, humans only need to collect materials on the conveyor belt. The intermediate and unloading machines have self-designed slide rails and synchronized wheel structures, which reduce the cost and ensure accuracy. The overall operating principle of the equipment is like this. , the above fully automatic working principle of this equipment. two. The main structure and precision of the equipment are as follows: 1. FPC loading: The roll material is manually loaded at a scheduled time, and the equipment automatically alarms when there is no material. The manual material changing speed is fast, the automatic feeding and positioning are accurate. 2. Cutting: The automatic cutting speed is fast. The latest research and development is based on the Japanese FPC cutting machine design and modification. The cutting accuracy can be controlled within the range of 0.02. It is ahead of the cutting machines of other domestic manufacturers and the speed can reach 3,000 pieces per small. FPC left and right, and has a material shortage alarm function. 3. Detection position: After the FPC is cut off, its appearance, length, size, etc. are further visually inspected. Discharging inspection: Each stack of products is also visually inspected during unloading and discharging, and has an NG alarm function. 4. Automatic unloading: The PVC conveyor belt is used for unloading. The materials transported each time are accurate and do not affect production. The equipment can operate 24 hours a day. The above are the functions and principles of this equipment. You can download other more ingenious design structures and have time to study and study them slowly. In short, this is a very good set of FPC automatic cutting machine drawings. You are welcome to study and study them. Thank you. three. Equipment performance and main configuration description: 1. Cutting detection speed: about 3000 pcs/min. 2. Repeated cutting accuracy: 0.02. 3. Description of main accessories: 1), CCD camera: German brand BASLER; 2), sensor: OMRON; 3), PLC: Japan Mitsubishi high-speed series; 4), solenoid valve: original Japanese brand; 5), control system: Independent development. 4. Human-machine interface, the software automatically comes with a toolbox, a convenient Microsoft Windows operating system specially developed for ordinary employees; 5. Production data report statistical functions: CPK, PLATO, defective type items, defective proportions and other automatic generation functions can be used for It provides the basis for improving the process in the production workshop; 6. Testing data output system: This screening machine has data communication function, data output and storage function. The data exported by the software can be connected to the printer through the LAN for paper printing. 4. Main technical parameters: Category specification parameters Overall machine dimensions: 1500*1100*1800MM (L*W*H) Input voltage: AC-220V50Hz or AC-380V 50Hz optional Maximum power of the whole machine: 1.2KW (at 220V) Input air source pressure: 0.4-0.6 Mpa Air consumption: 1.5 L/min Production efficiency (C/T): ≤2.0 S/one equipment utilization rate: ≥95% Processing method: automatic feeding, cutting, automatic CCD detection , Automatic blanking robot motion resolution: 0.005 mm Robot repetitive positioning accuracy: ≤±0.01 mm Material changing method: Manual material changing programming method: Touch screen parameter modification

Specification: FPC Cutting Inspection Machine Screen Cable Cutting Equipment FPC Soft Cable Cutting Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “FPC Cutting Inspection Machine Screen Cable Cutting Equipment FPC Soft Cable Cutting Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.