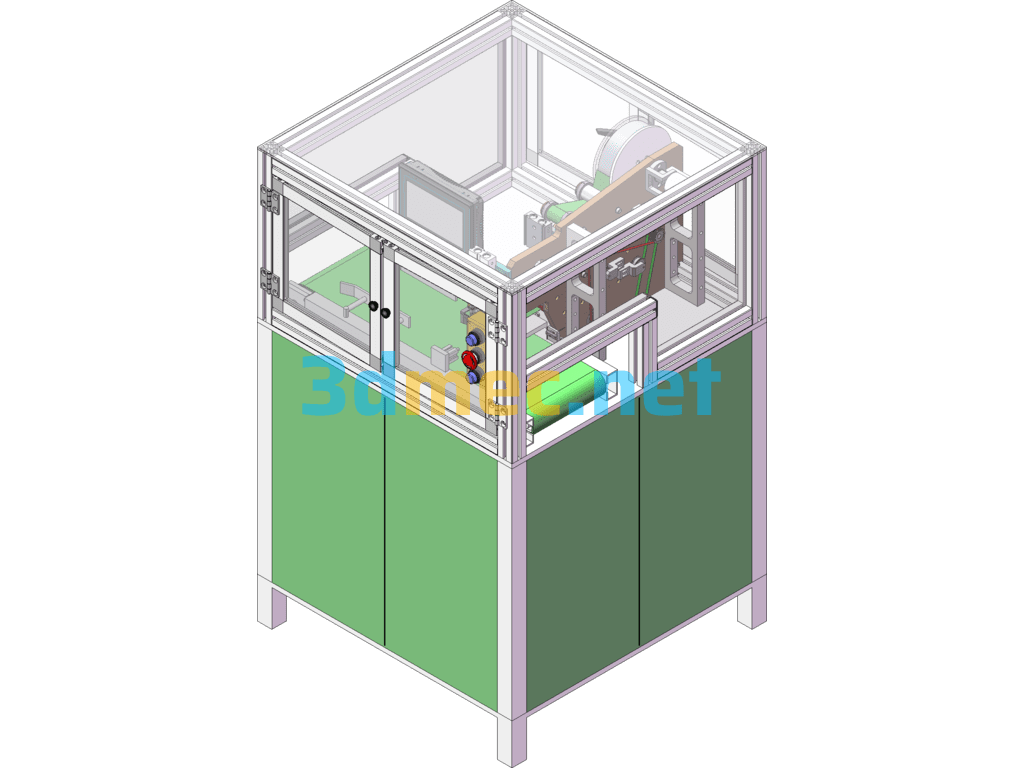

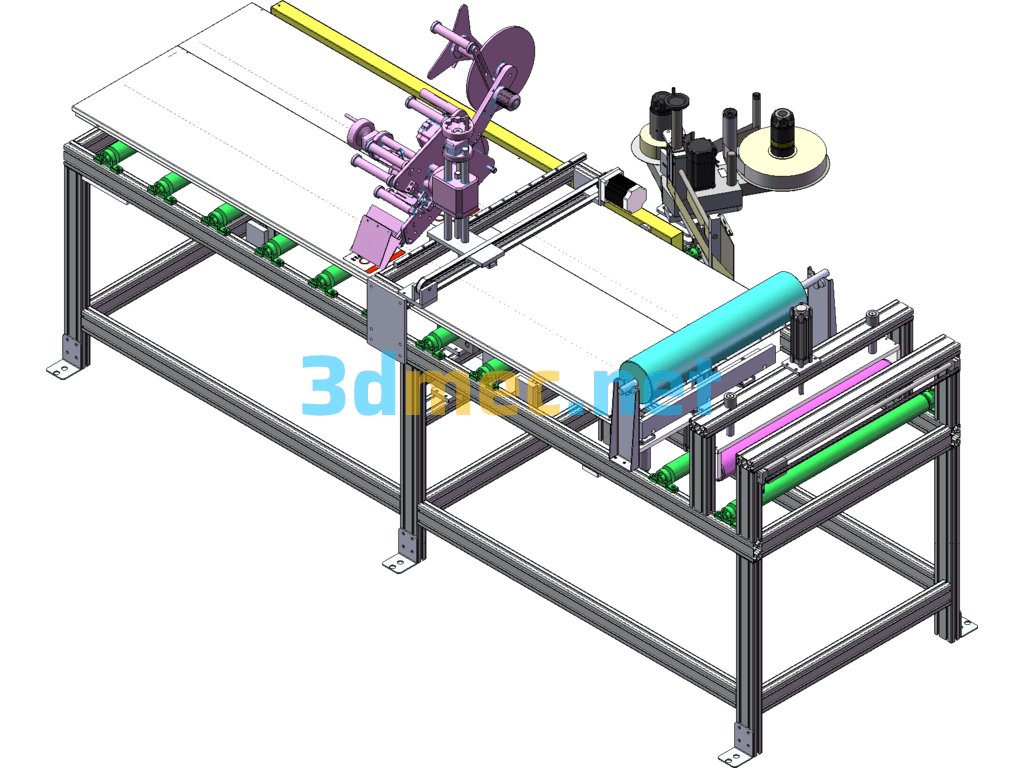

According to the requirements given by others, 10 pieces of labels are pasted per minute, and the length, width and height of the label are 20×30×20. The sales size of the product can be adjusted appropriately. We use the existing standard parts in the past and the market to modify and redesign a machine suitable for customers.

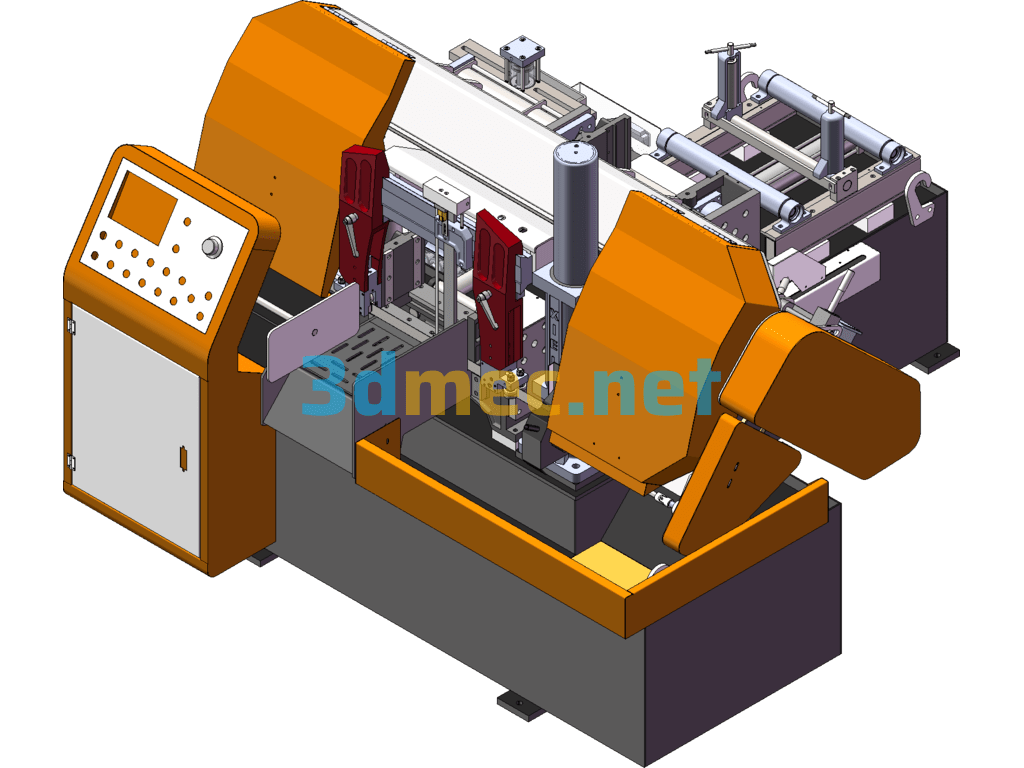

This equipment is a machine that passes the label of the roll film through the fixed mold peeling module, and then it is sucked by the suction cup, and the cylinder is actuated to stick it on the product.

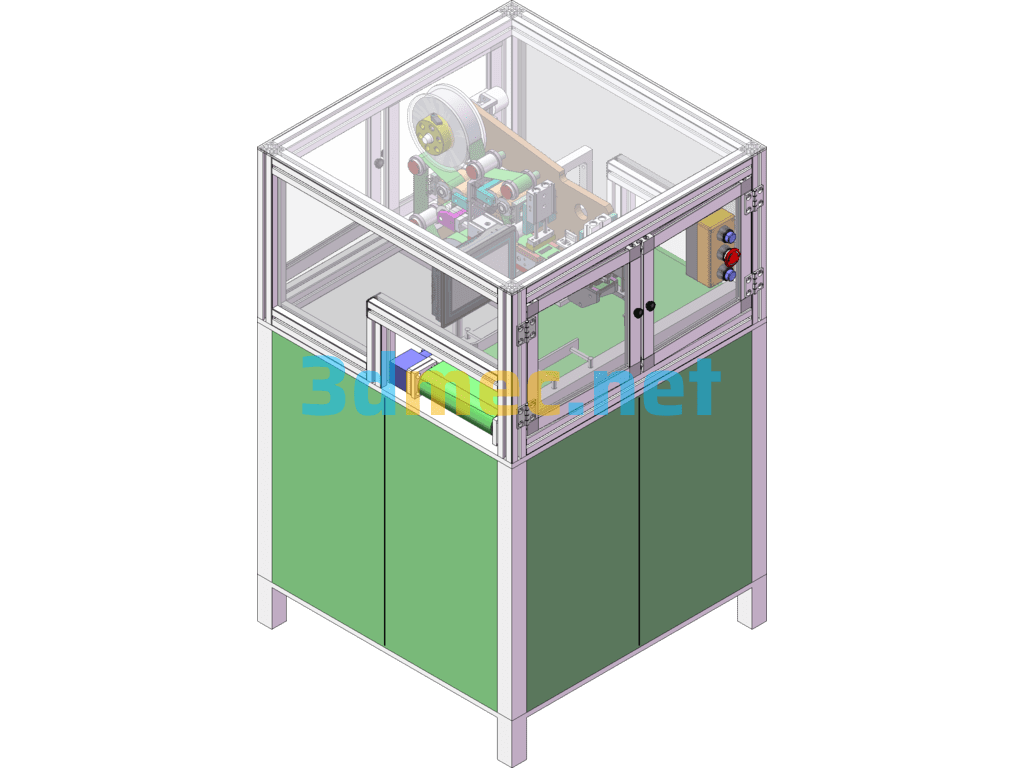

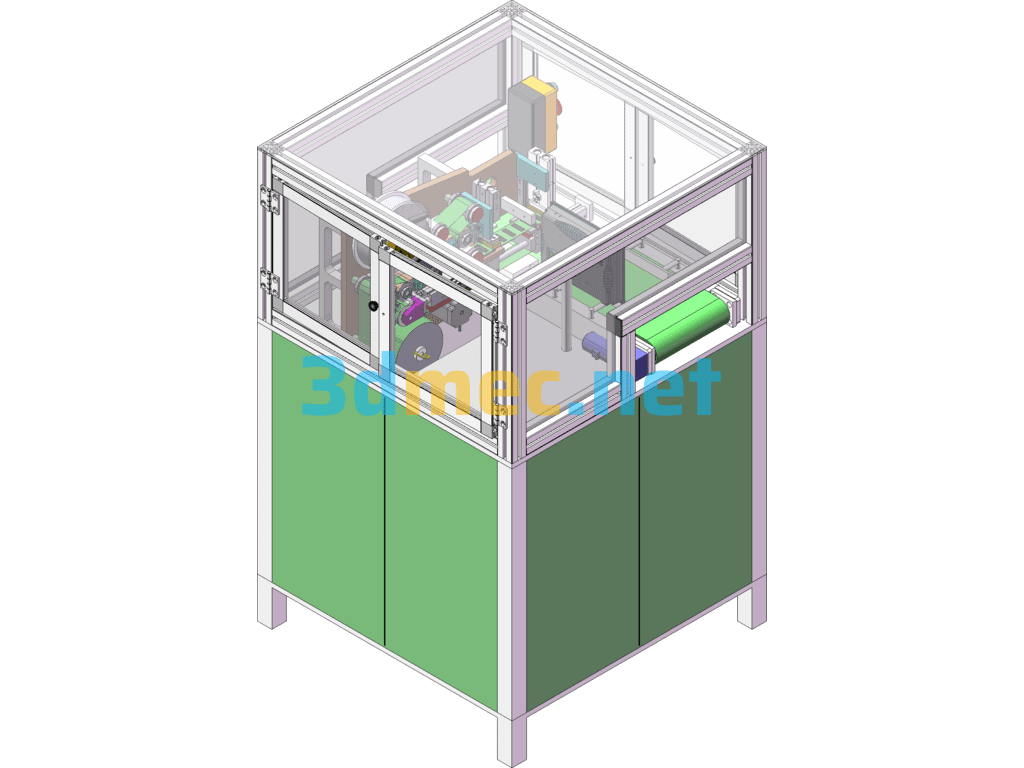

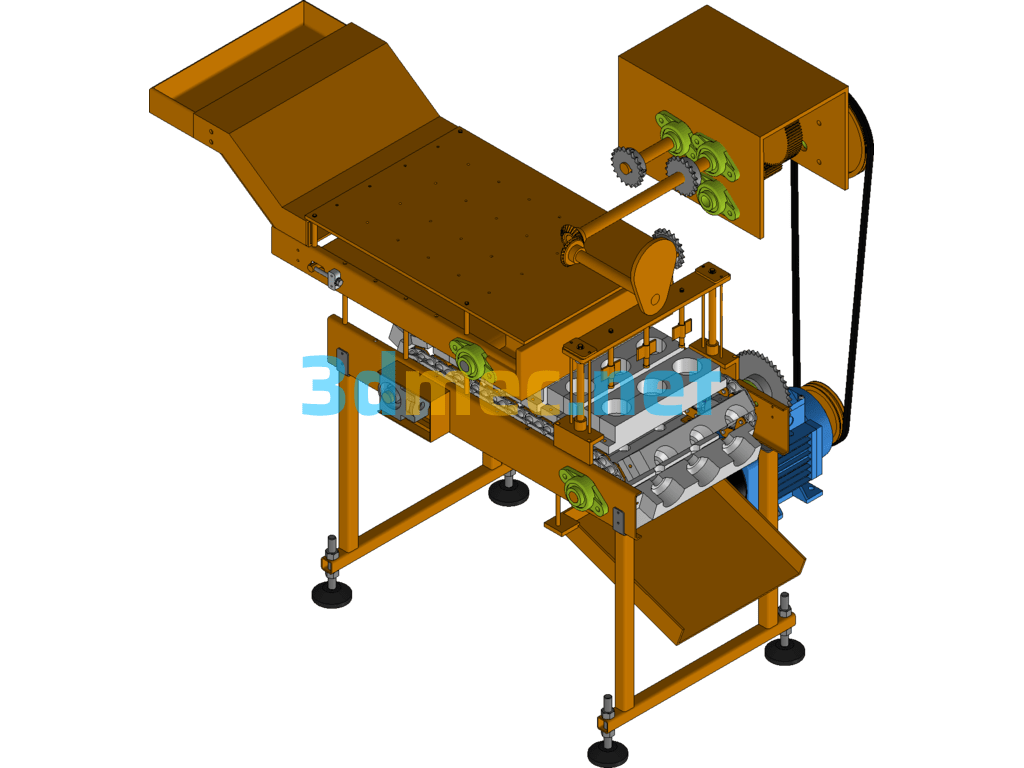

1. The motor drives the reel, and the reel drives the roll film to rotate. The film is used to achieve retraction and release, tension control and quantitative film feeding;

2. The film stripping cylinder is actuated to tear off the label;

3. The suction cup cylinder is actuated to suck the label, the film stripping cylinder is retracted, and the suction cup cylinder is pressed down to label;

4. The assembly line transports the product, and the baffles on both sides of the assembly line guide the product. The cylinder and the adjustable block work together to accurately position the product, thereby ensuring the accuracy of the film;

Specification: Fixed Mold Stripping Module Fully Automatic Labeling Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fixed Mold Stripping Module Fully Automatic Labeling Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.