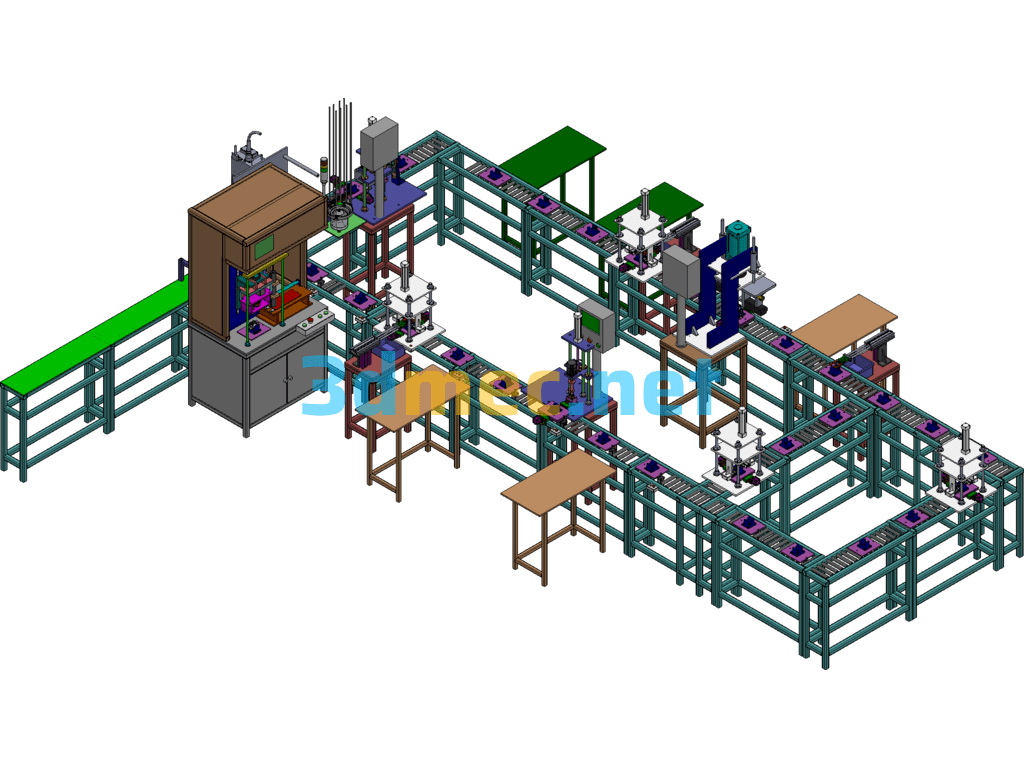

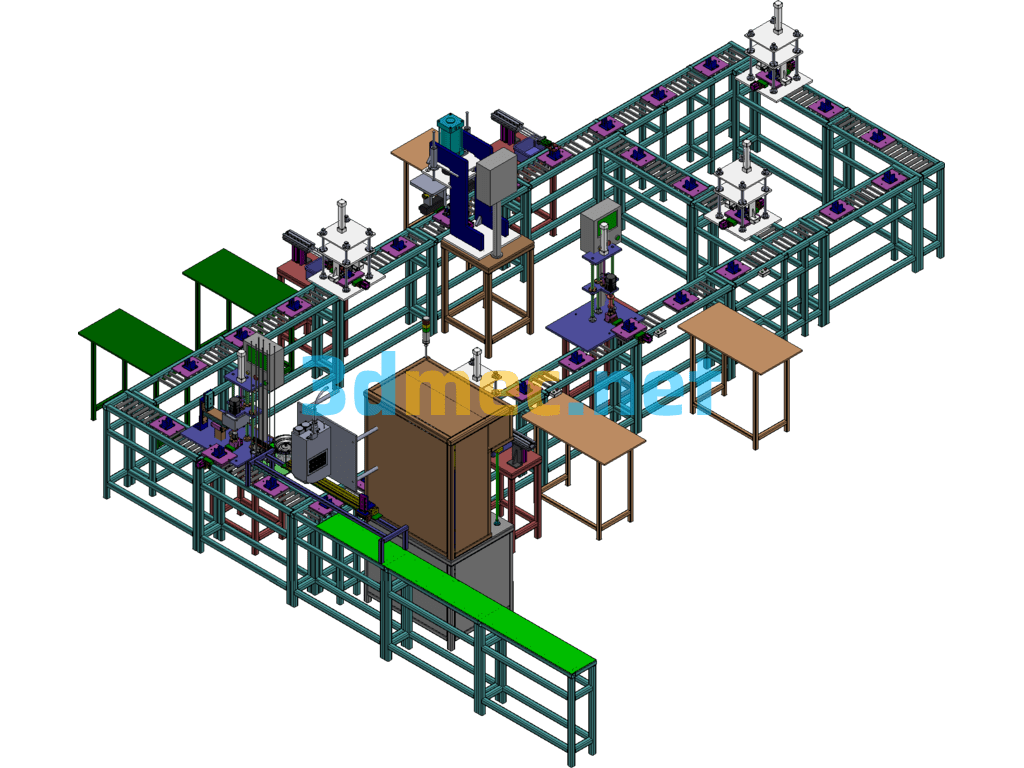

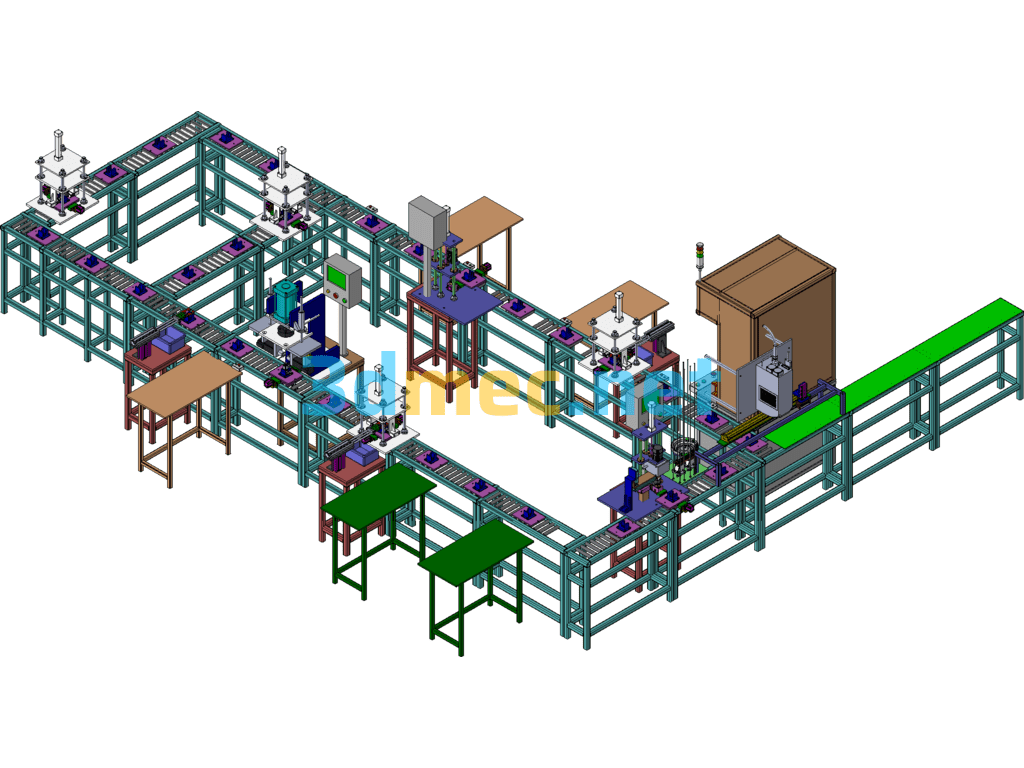

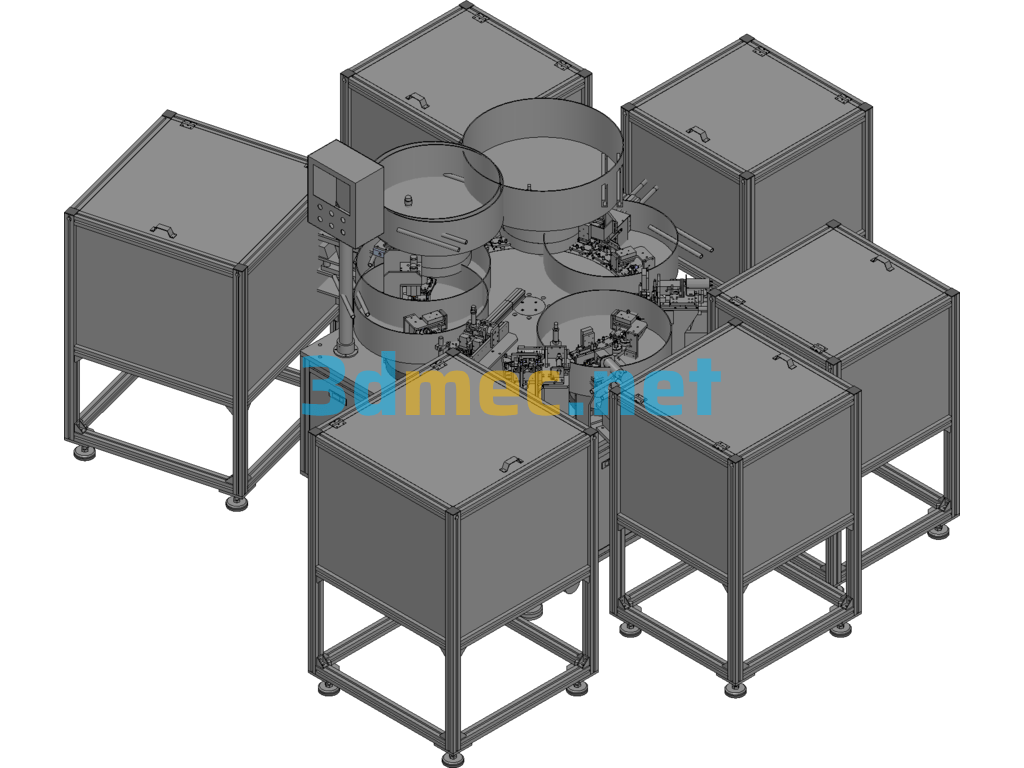

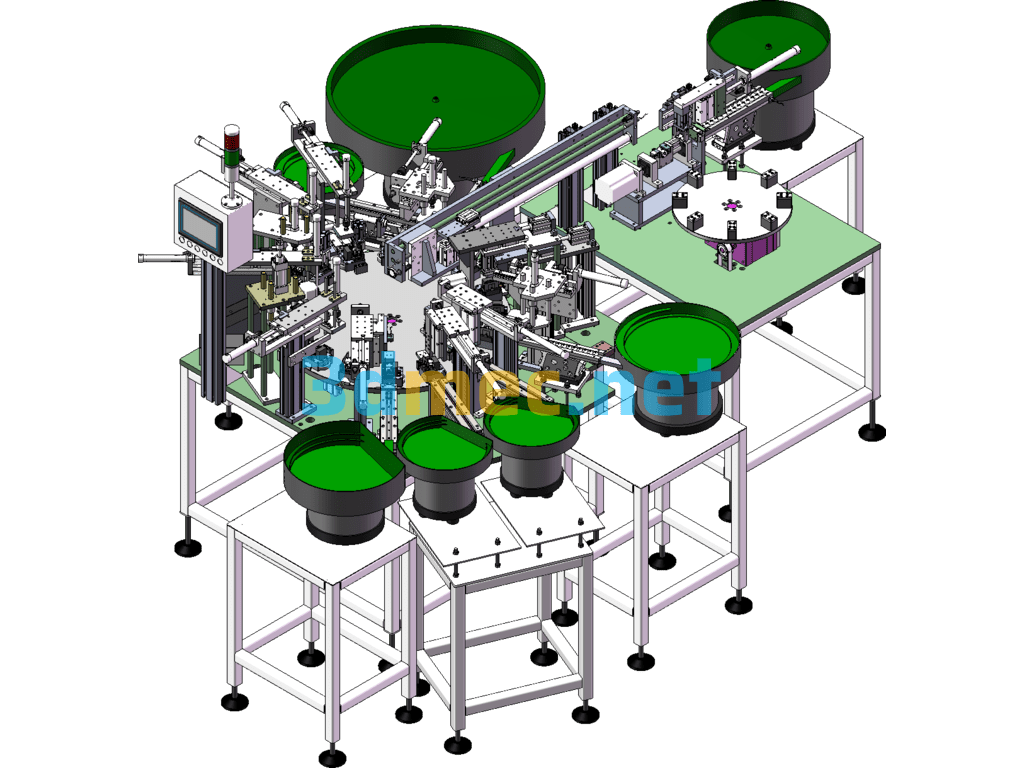

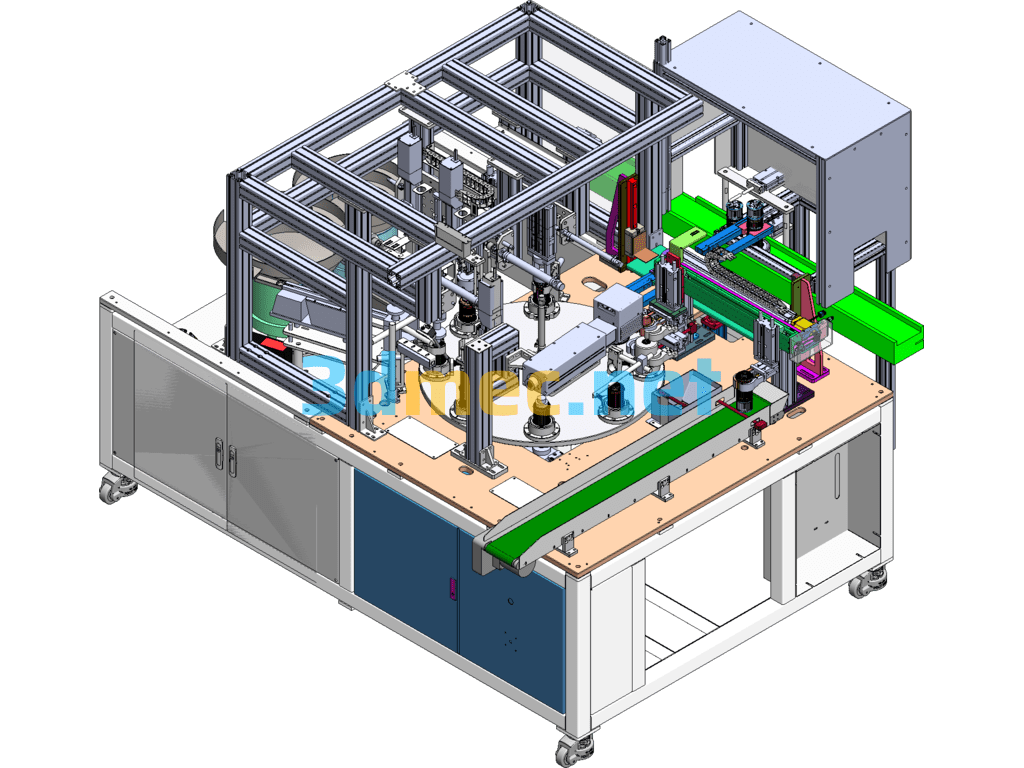

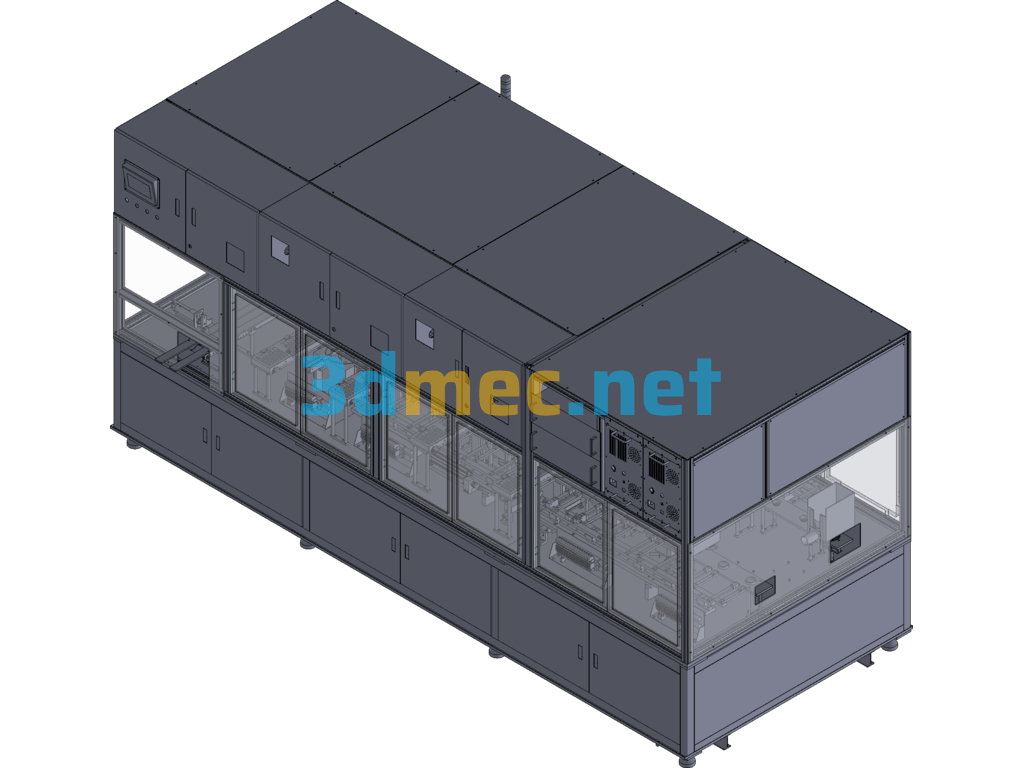

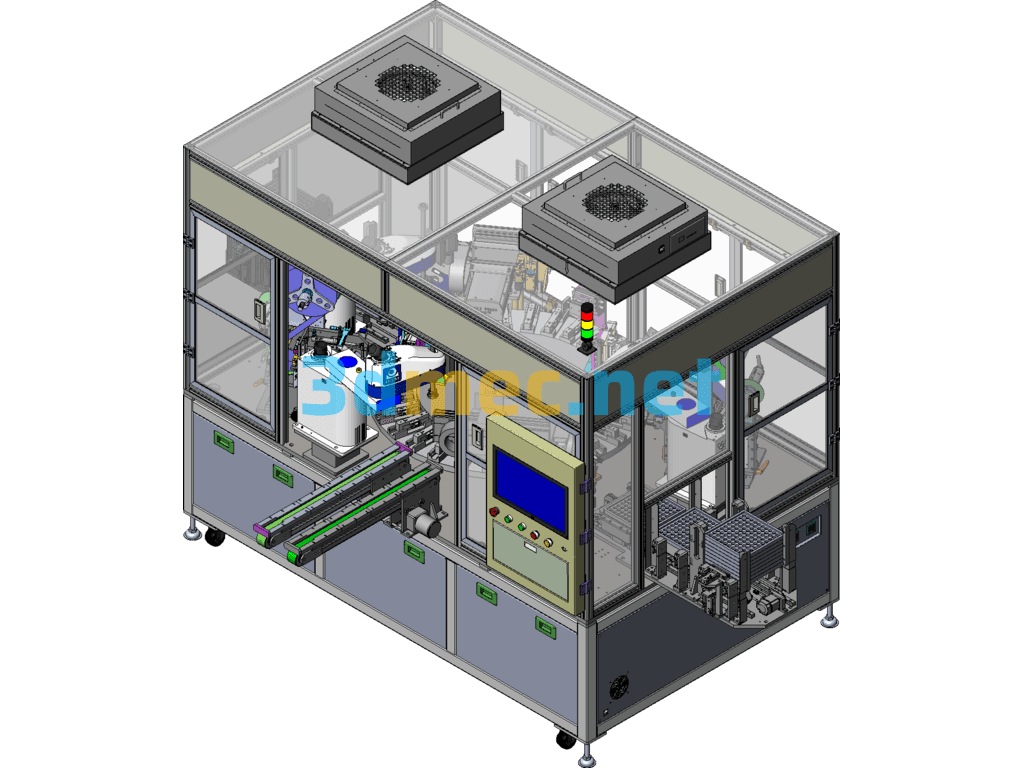

The water cut-off valve production line is designed in both manual and automatic ways according to the actual on-site operation area of the customer and meets the production requirements. High-efficiency and high-quality production needs are achieved through manual assisted operation, automatic operation and automatic detection. The production line consists of auxiliary production lines and automatic assembly lines, with automatic interception, unqualified sorting system and automatic assembly system. The measurement system consists of “leakage detection system”, “electrical performance monitoring system” and “flow detection system”. The production line is designed as a manual assisted workbench + assembly line, with a total length of 6.4 meters and a width of 4.4 meters. It adopts a circular assembly line + accompanying tooling to save space and facilitate product turnover, and can also prevent mistakes. Except for the manual auxiliary workstations, the products are transported through the assembly line. According to the assembly and detection sequence, the corresponding workstations are set along the line. Due to the various types of water cut-off valves, the production line can meet or be compatible with the production needs of different types of water cut-off valves, ensuring the coordinated and unified production rhythm of the entire line. The operating space between each workstation is sufficient and practical, independent of each other, and interconnected.

Specification: Water Shut-Off Valve Production Line (Sorting, Assembly And Testing Functional Equipment) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Water Shut-Off Valve Production Line (Sorting, Assembly And Testing Functional Equipment) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.