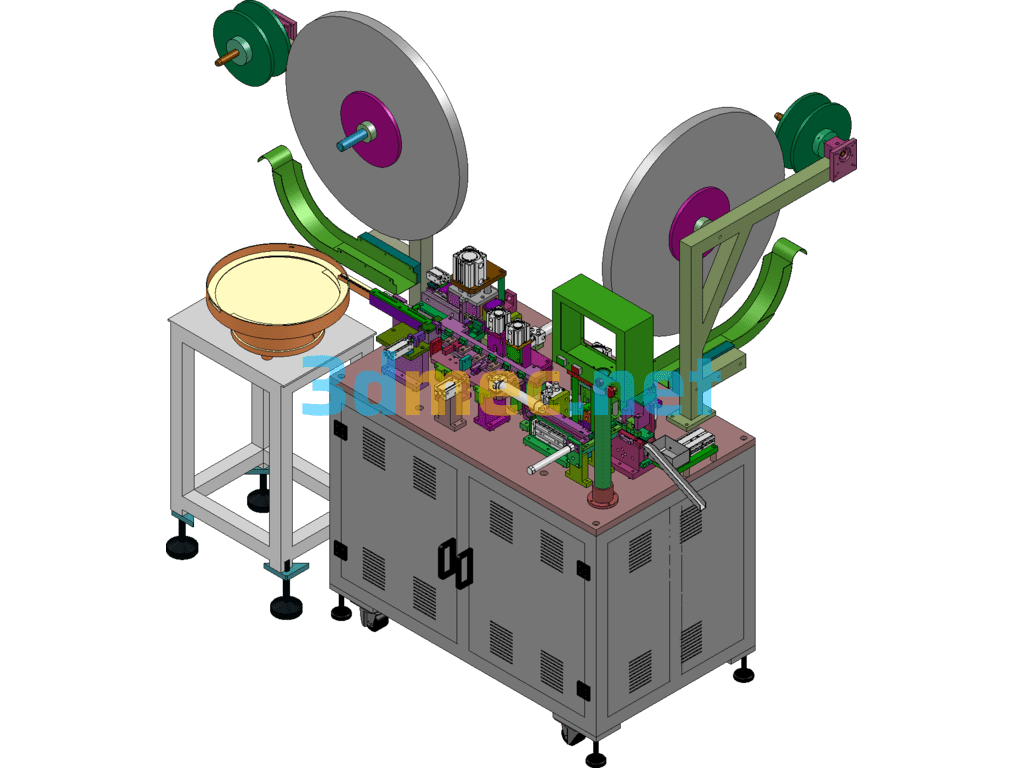

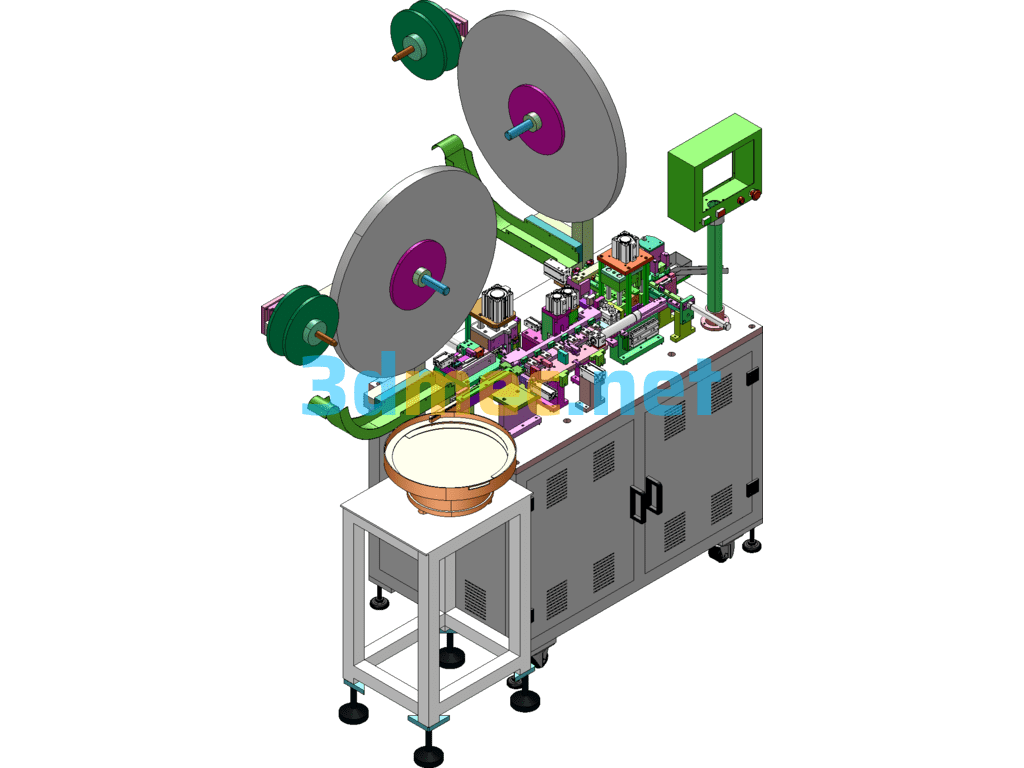

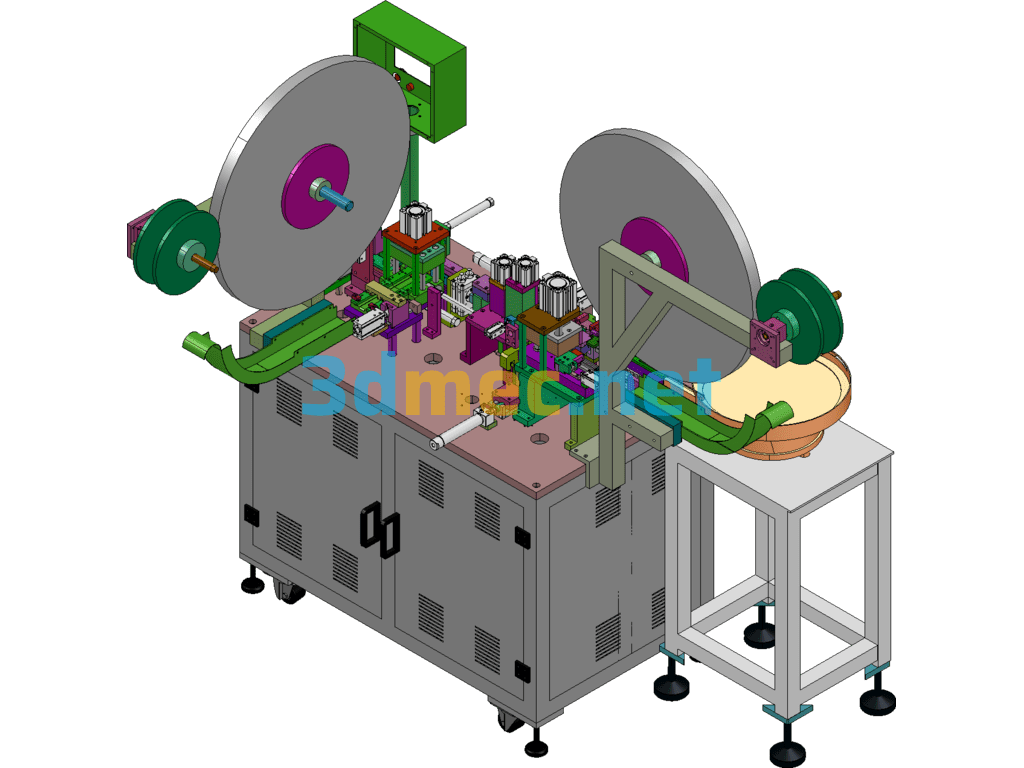

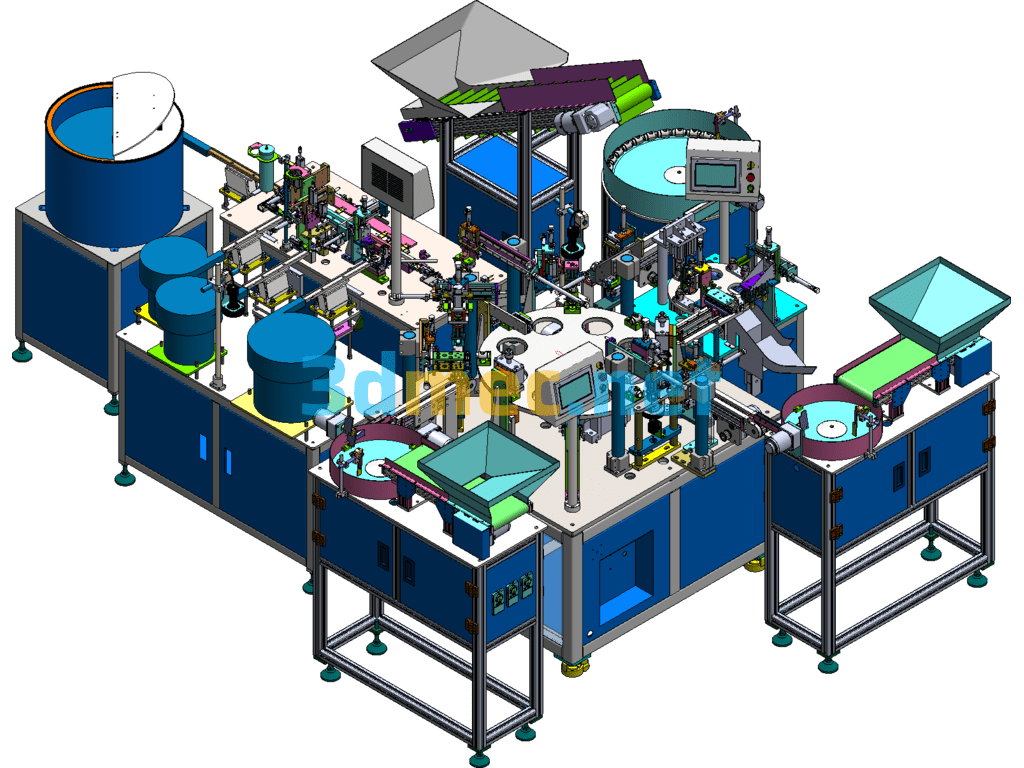

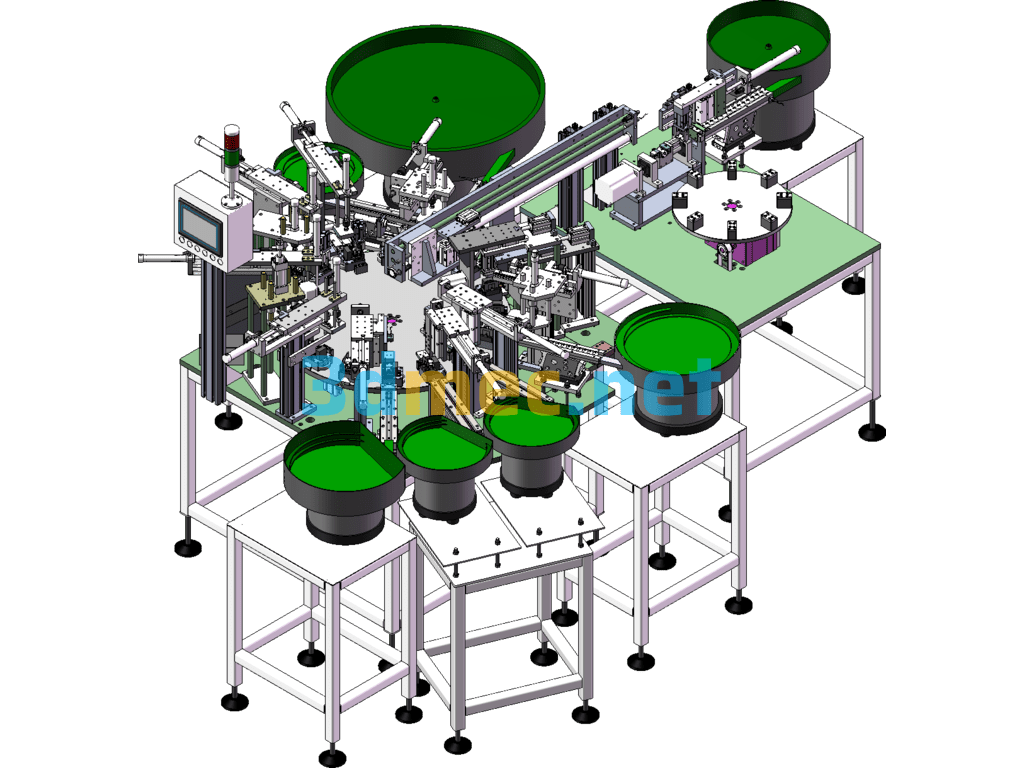

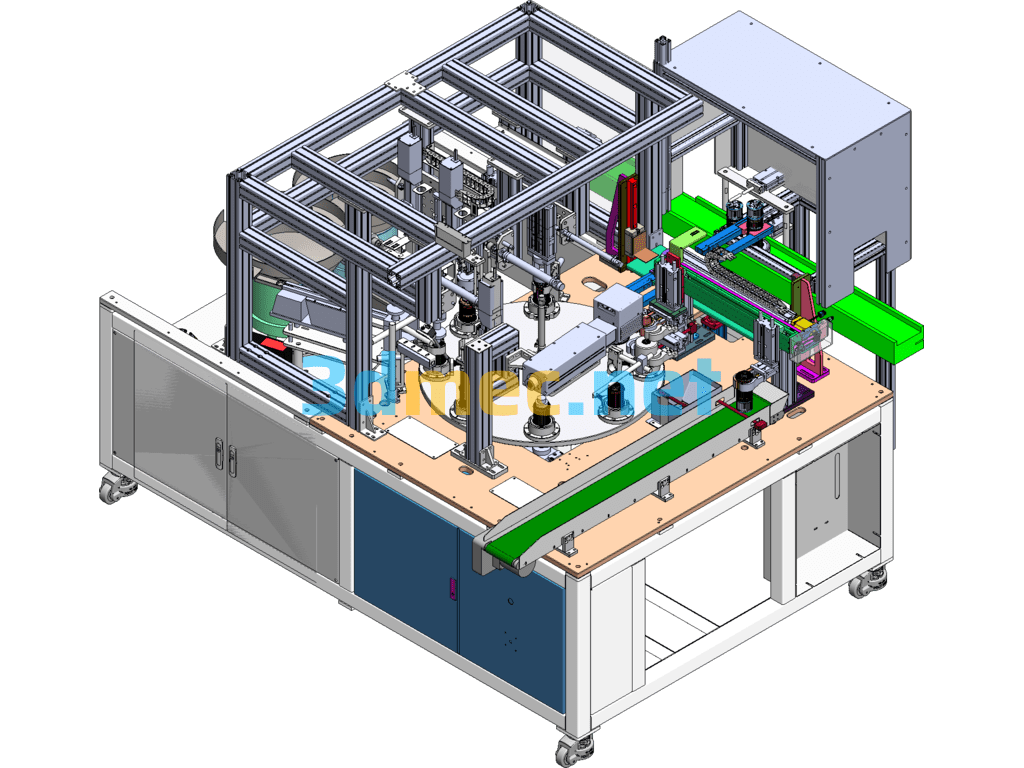

The equipment’s action process is to feed the terminal disc with the cylinder, bend it, and cut it. The feeding method for the plastic part body is to move the grabbing cylinder to the assembly position to insert the PIN. The second station is for cutting the material strip, the grabbing cylinder is shifted twice, and the PIN is inserted and cut. The last station is for conduction testing and good products are discharged.

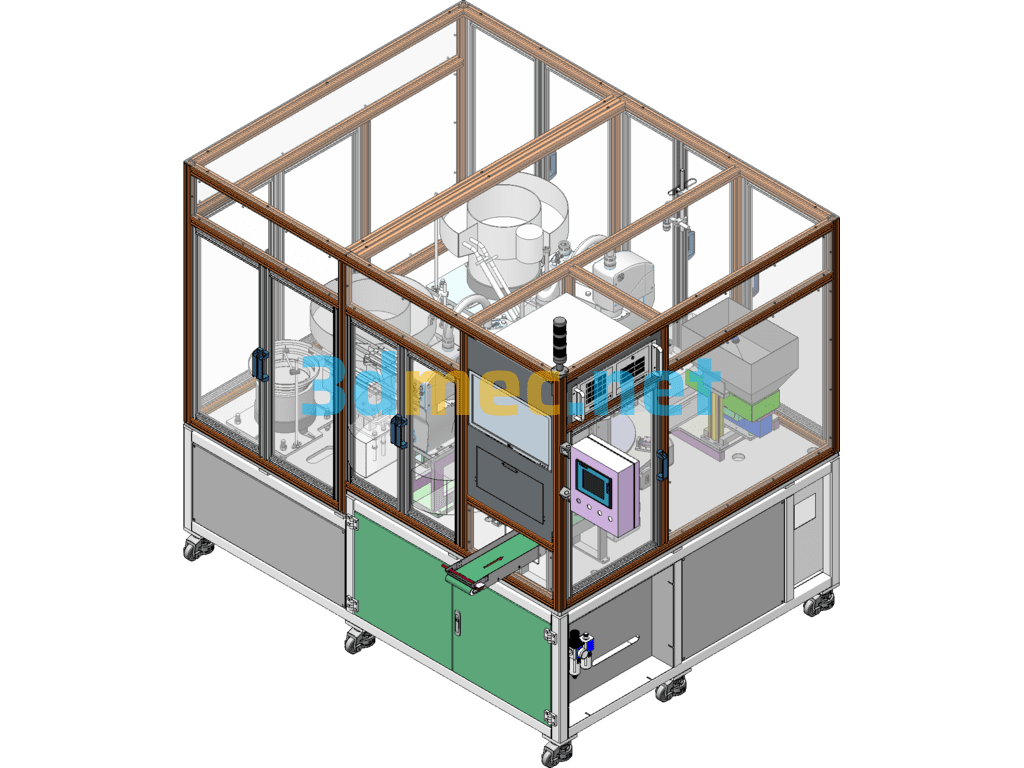

Specification: USB High Speed Automatic PIN Assembly Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “USB High Speed Automatic PIN Assembly Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.