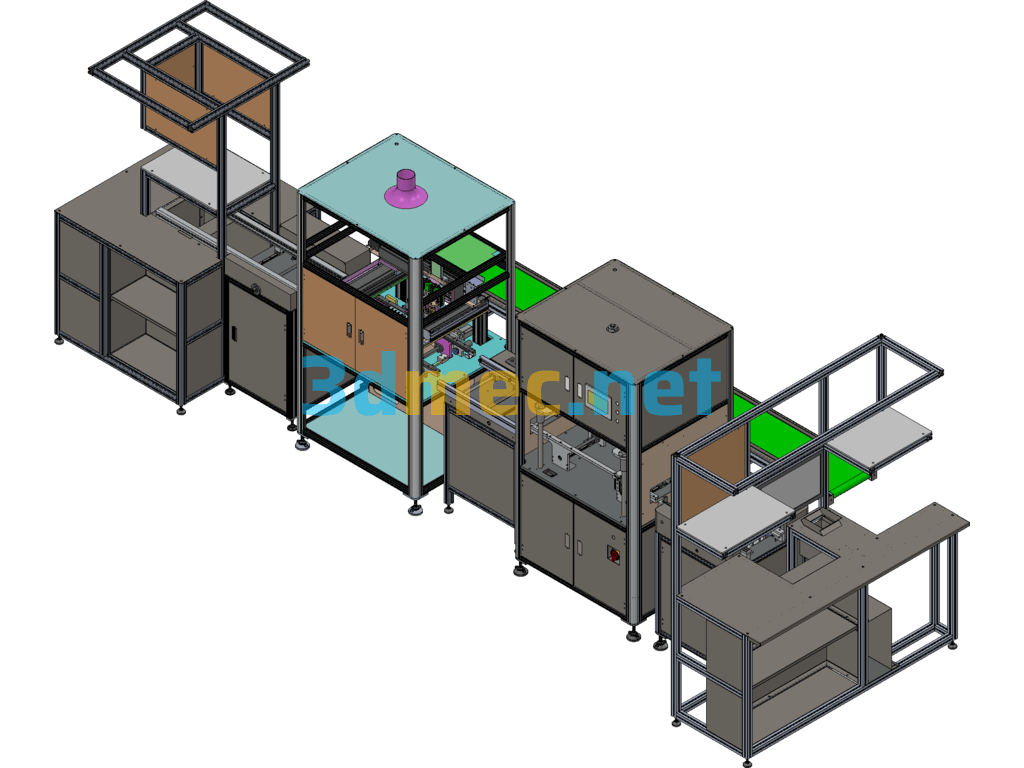

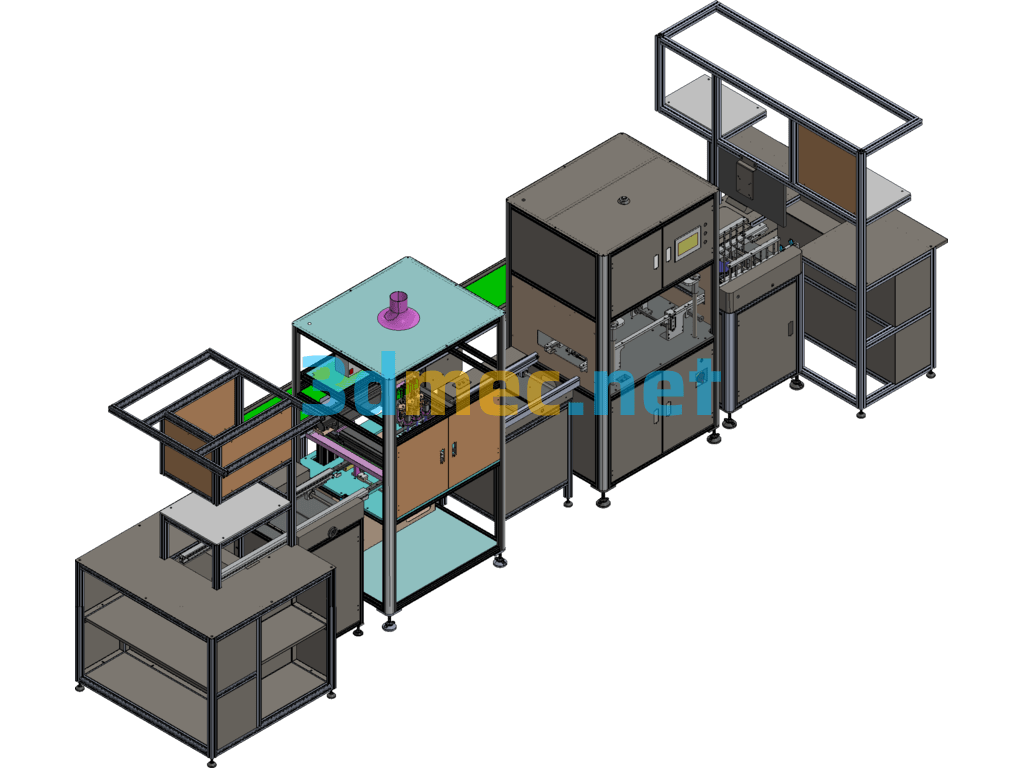

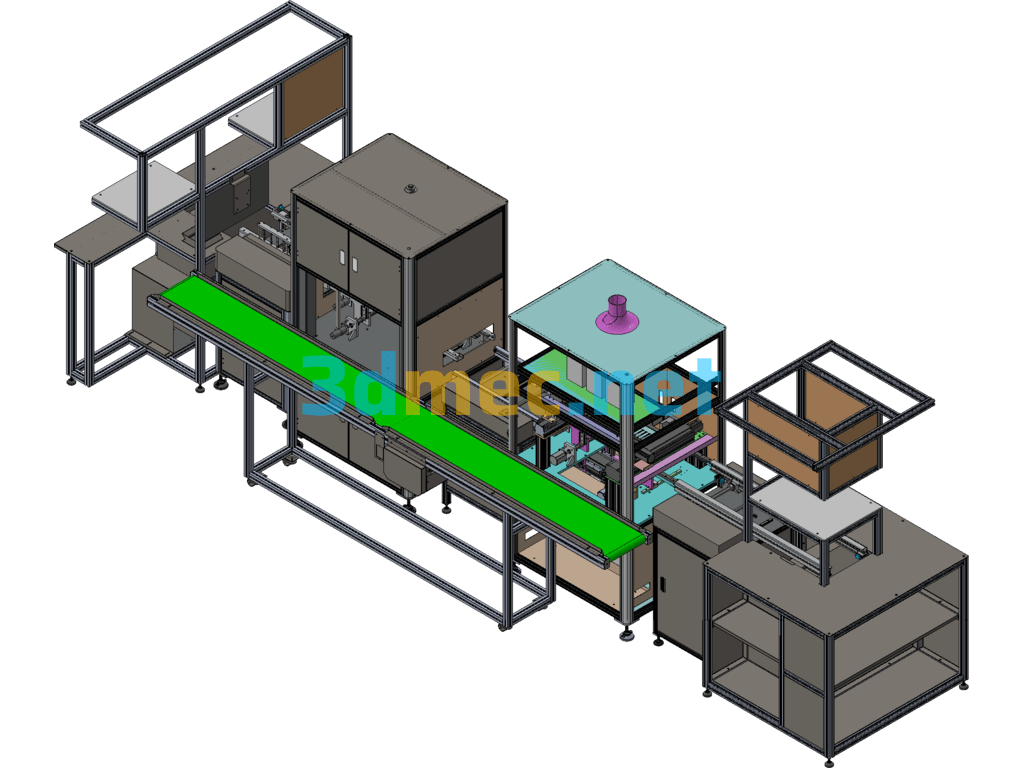

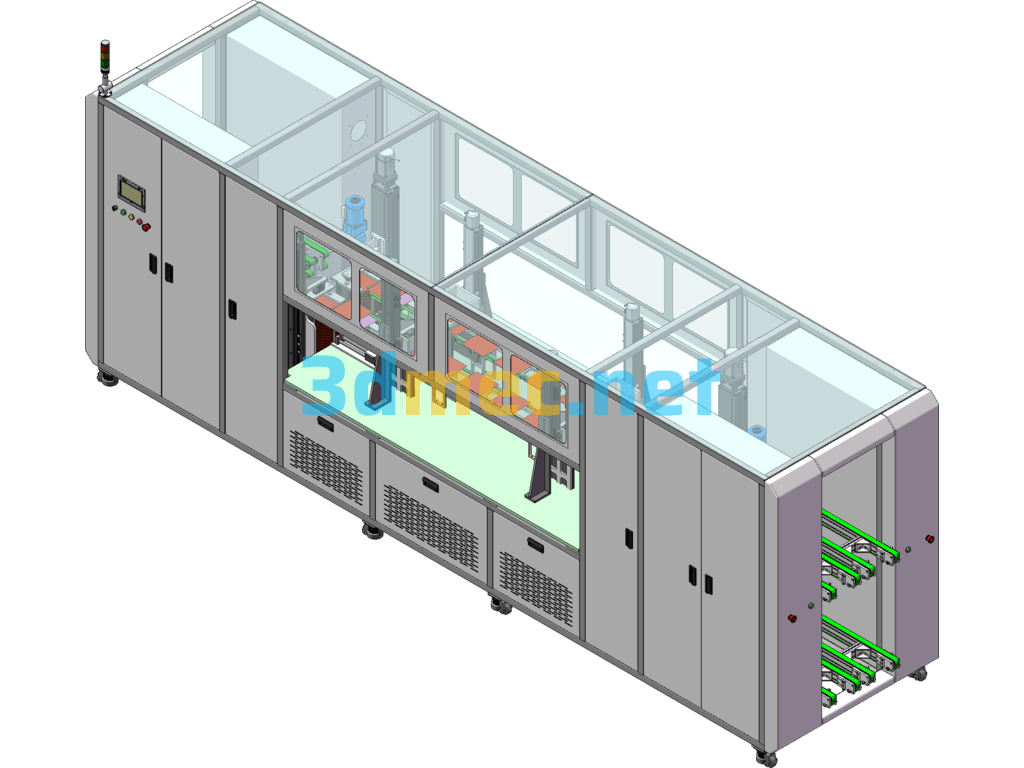

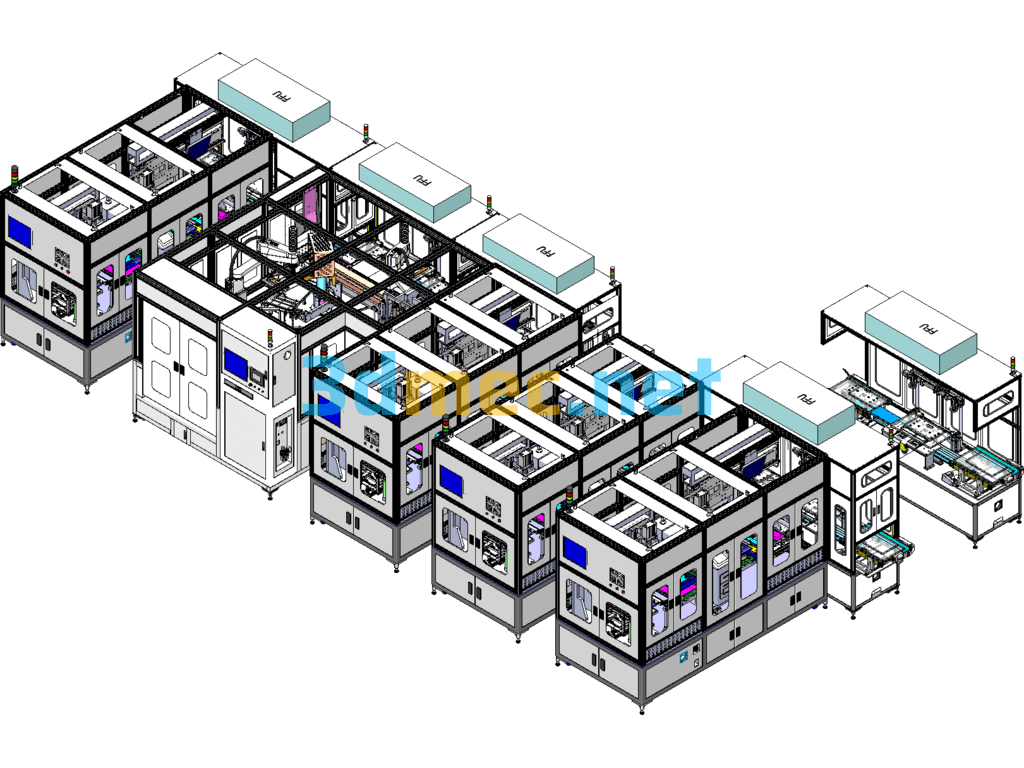

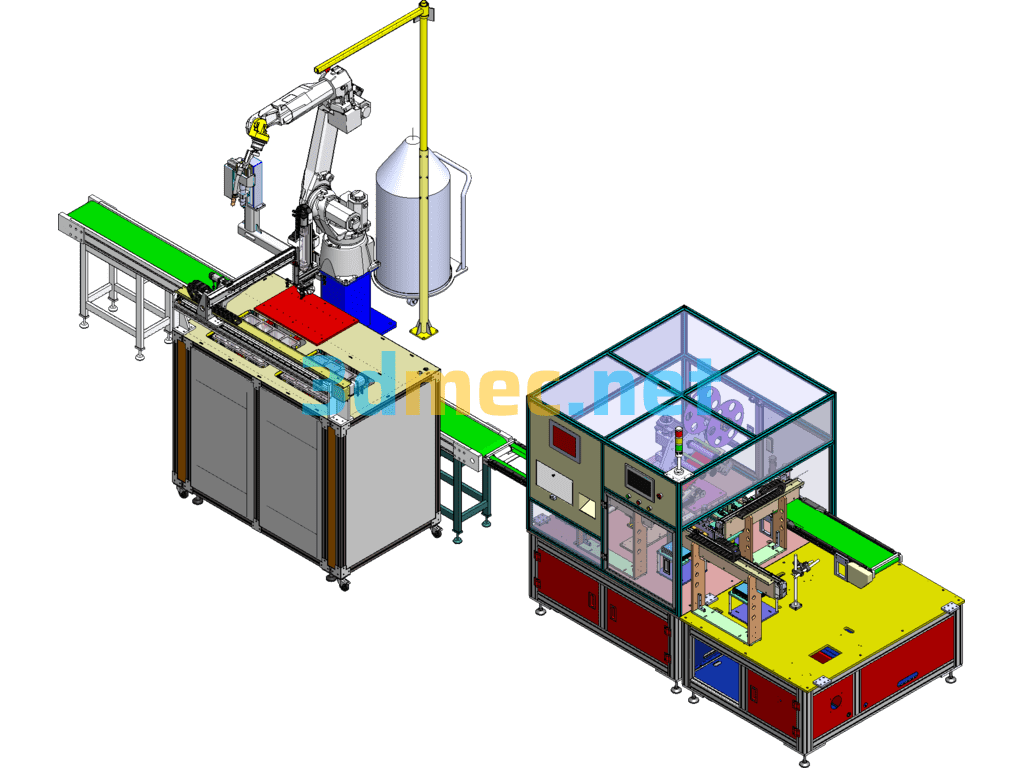

The PCBA plug-in welding test and packaging production line includes a loading workbench, a docking station, an automatic soldering machine, a docking station, an LED light test, an NG sorting machine, a material unloading and packaging station, a recycling belt line, etc. The line body plug-in is manually inserted, the material unloading and packaging are manual, and the soldering and testing are all automated.

The project is used for the PCBA board welding test of the dimming motor system for automotive front lighting, which effectively reduces manual work, improves pcba welding efficiency, test efficiency and accuracy, and avoids interference from human factors; reduces circuit board inspection and debugging personnel and their training, saving expenses for enterprises; can optimize the chaotic test links on the production line, simplify quality control processes and methods; greatly reduce after-sales service costs and improve corporate reputation.

Specification: PCBA Insertion, Welding, Testing And Packaging Production Line – 3D Model Exported

|

User Reviews

Be the first to review “PCBA Insertion, Welding, Testing And Packaging Production Line – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.