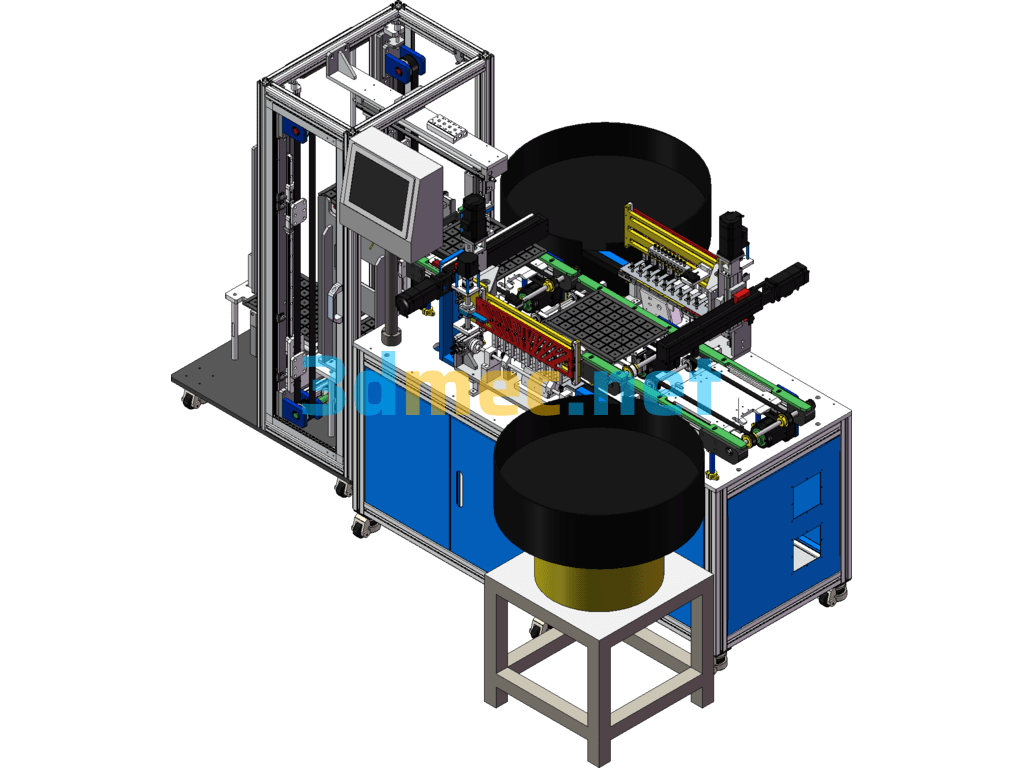

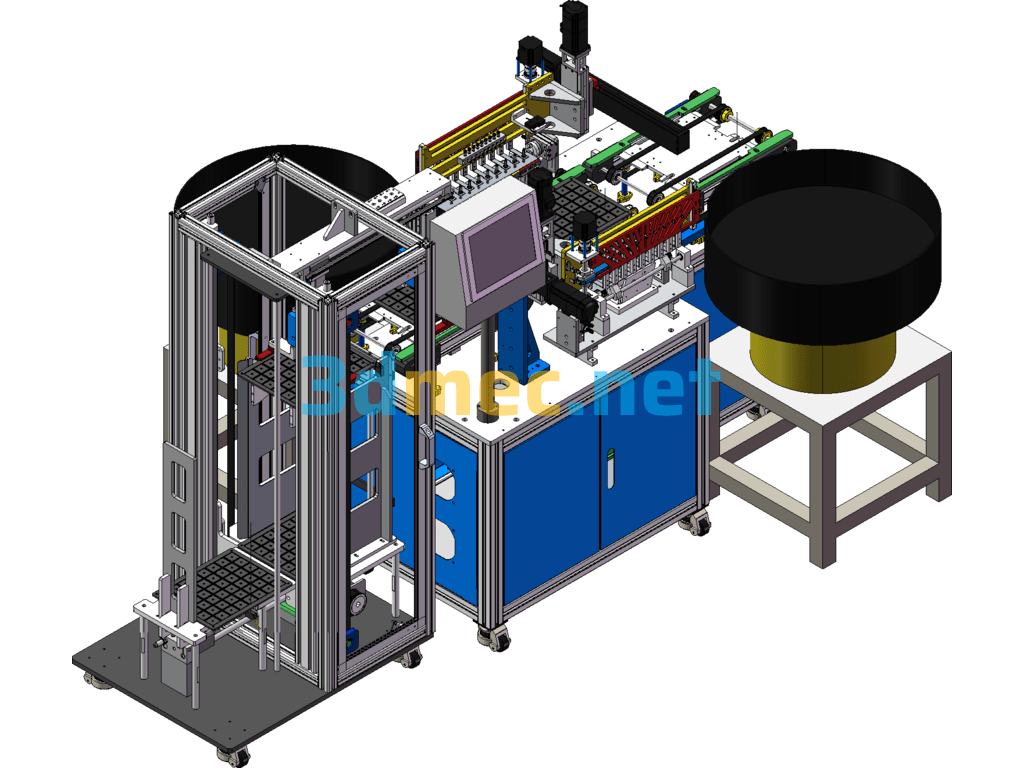

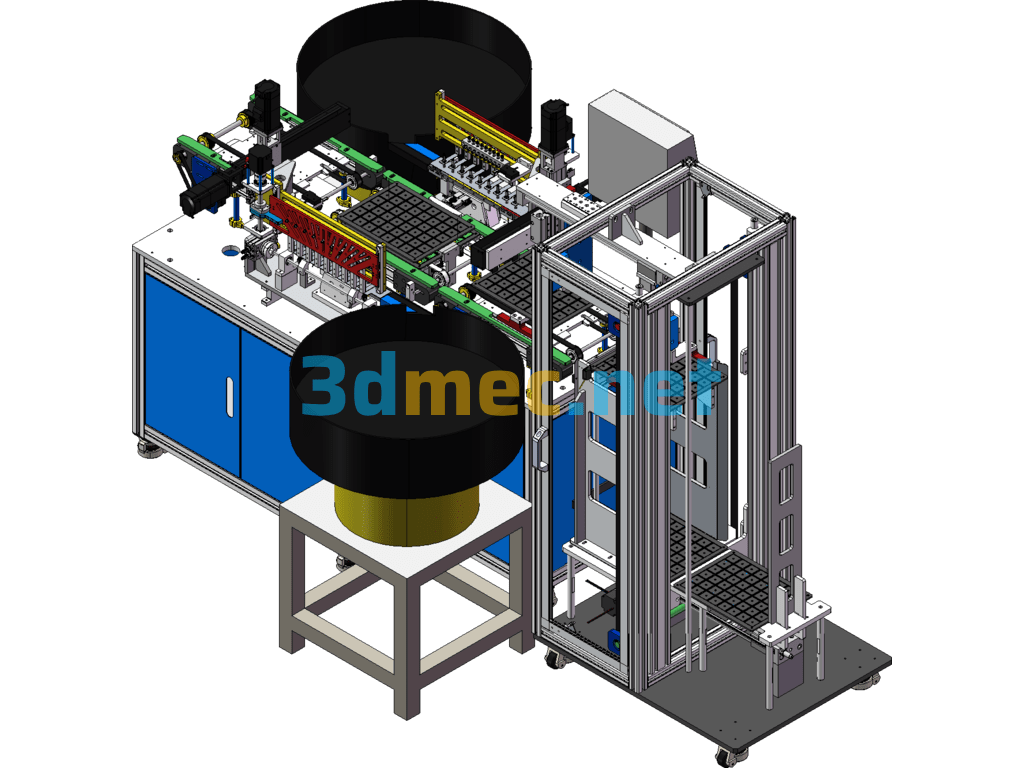

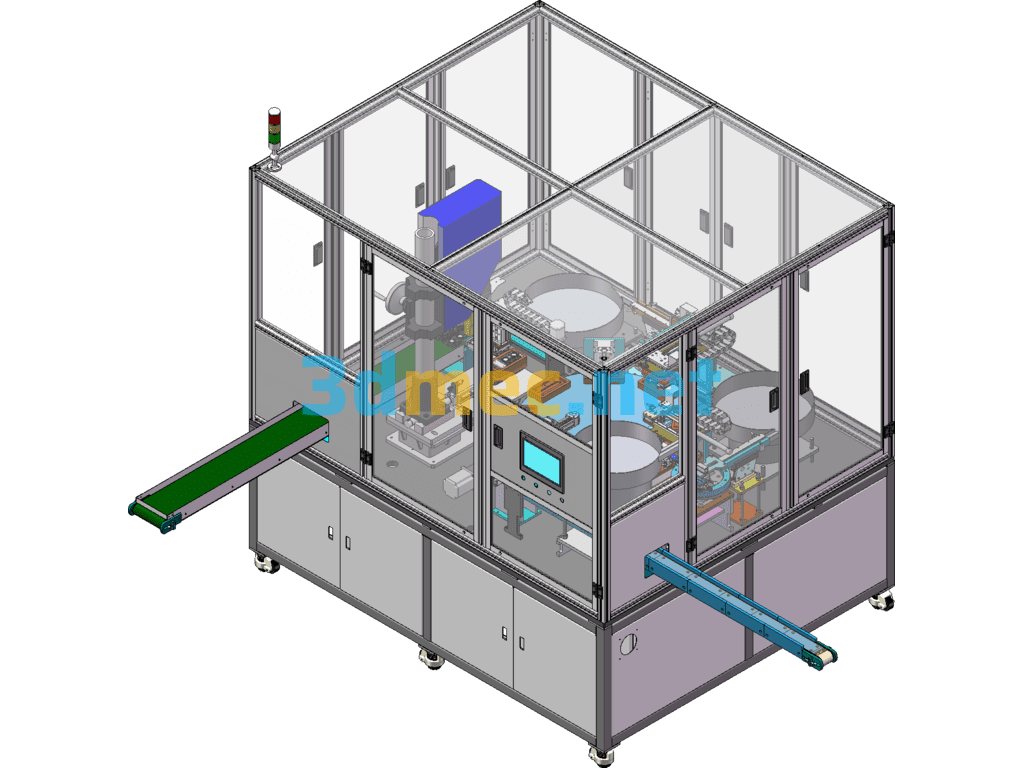

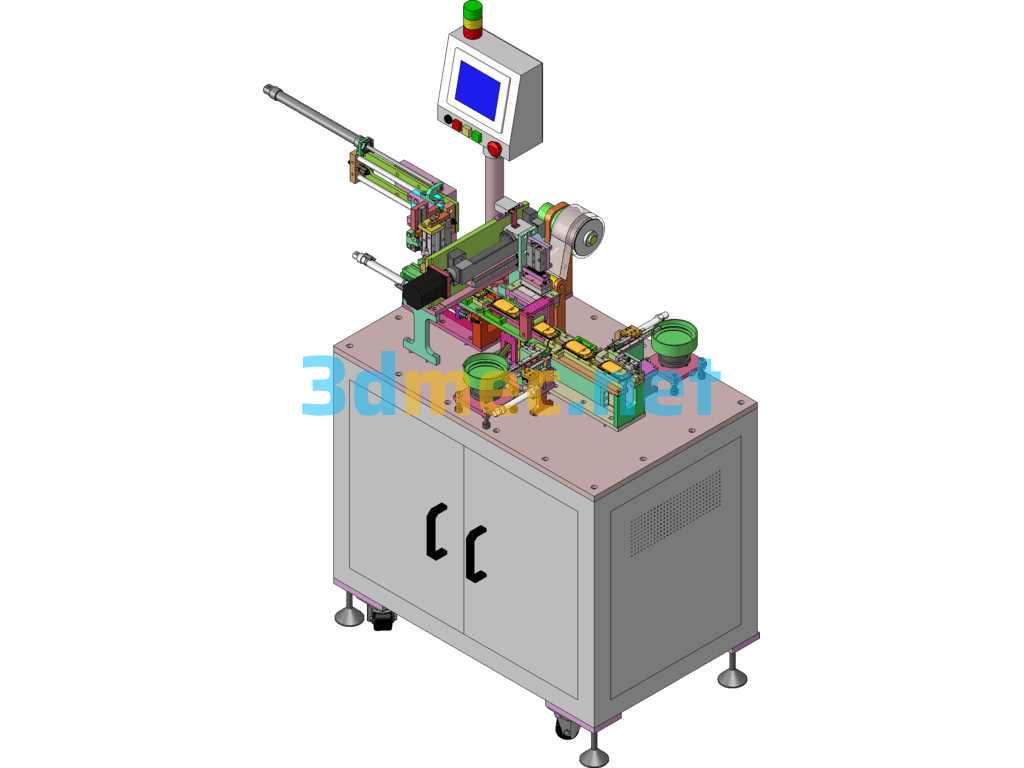

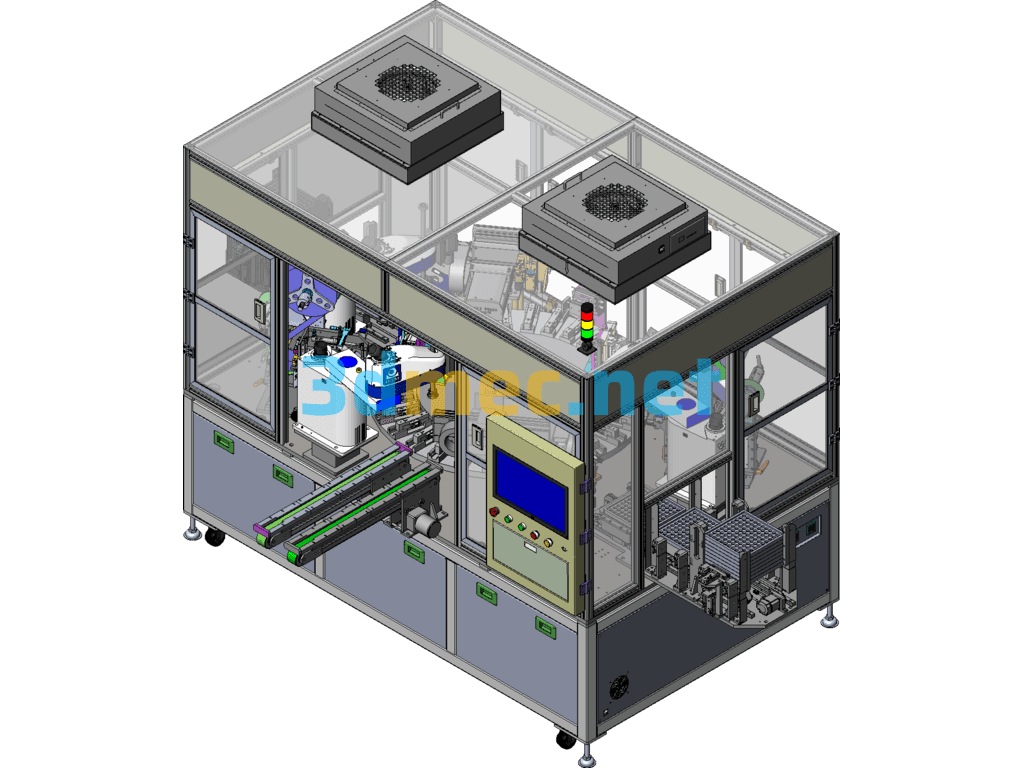

The fully automatic assembly transfer machine includes a drive motor, a reversing cylinder, a cylinder bracket, a transmission shaft, a main frame, a mounting shaft, a transmission belt, a conveyor roller, a roller rotating bracket, a connecting plate, a transmission sprocket, a spherical bearing and a reversing hinge. The drive motor is installed at the bottom of the main frame. The front end of the reversing cylinder is connected to the reversing hinge on the upper side through a spherical bearing, and the rear end is fixed on the cylinder bracket. The cylinder bracket is connected to the main frame. The transmission shaft is fixed to the main frame through a bearing. The transmission sprocket and nylon roller are connected to the transmission shaft. The conveyor roller is installed on the roller rotating bracket through the mounting shaft. The roller rotating bracket is installed on the connecting plate, and the connecting plate is connected to the main frame. The structure is simple and reasonable, and the effect is excellent in actual use. No other complex mechanisms and components are required. The mechanical performance is stable, the production cost is low, the transfer speed is fast, and multi-channel sorting and transfer can be completed.

Specification: Fully Automatic Alignment And Assembly Transfer Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Fully Automatic Alignment And Assembly Transfer Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.