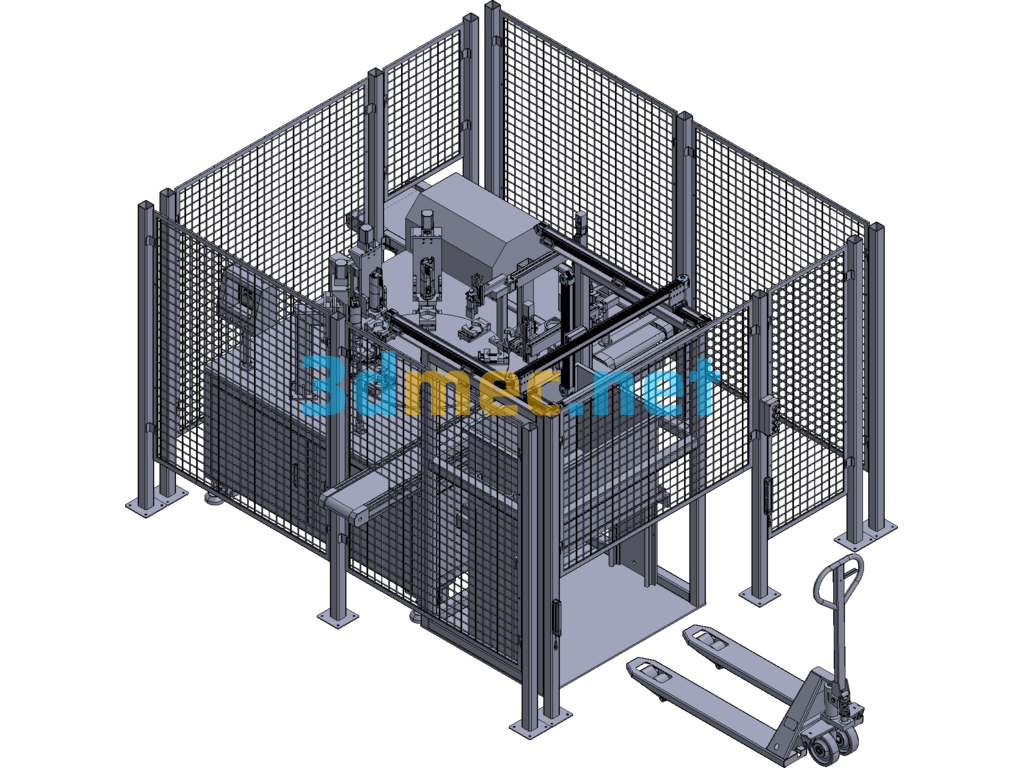

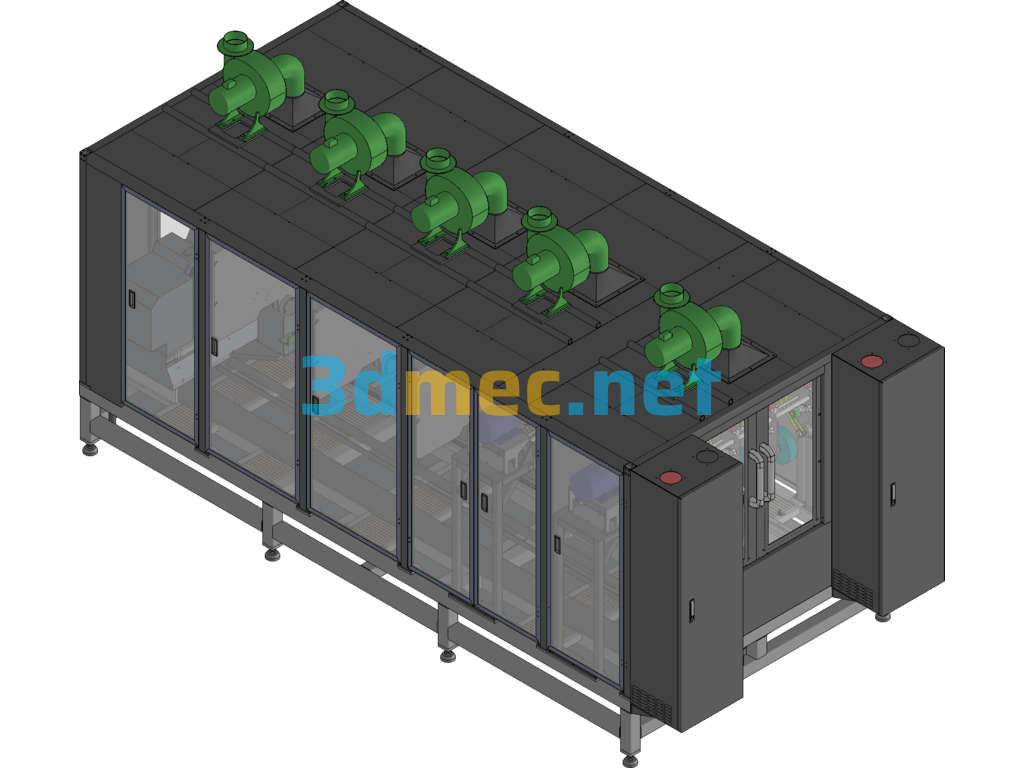

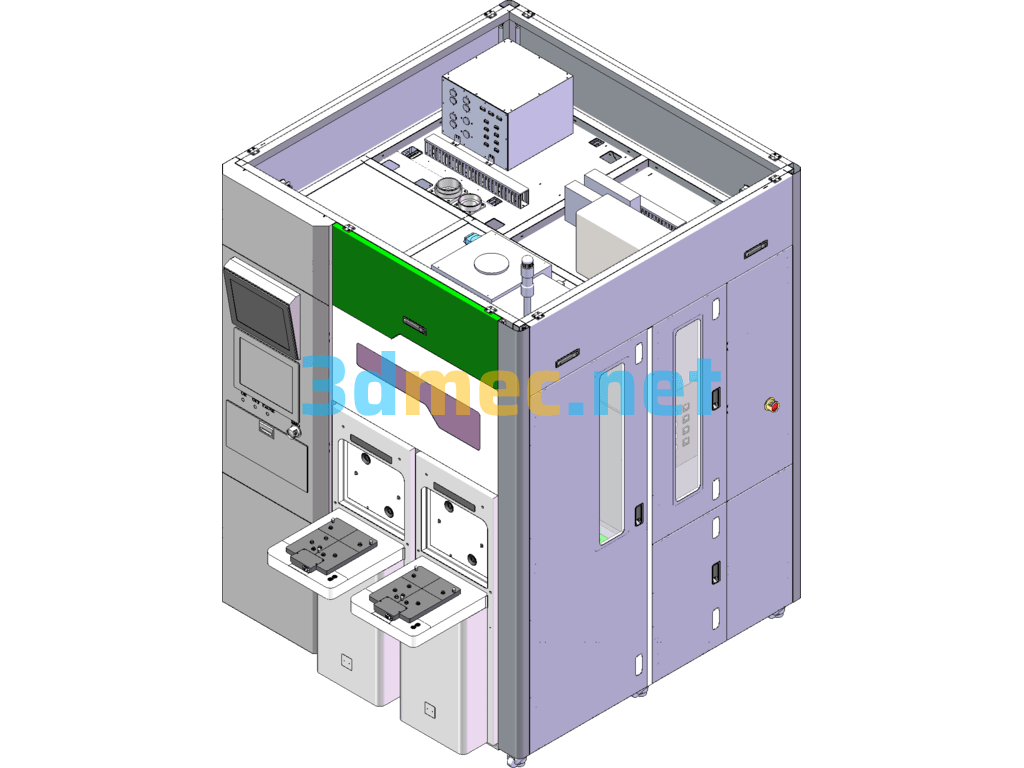

The equipment uses automatic riveting point leveling, and automatically stacks the leveled stators in the turnover basket. The requirements are: sorting the disordered rotors, separating the front and back sides → automatically riveting point leveling → automatic stacking; currently, there is no detailed internal attachment plan!

Analysis of each part;

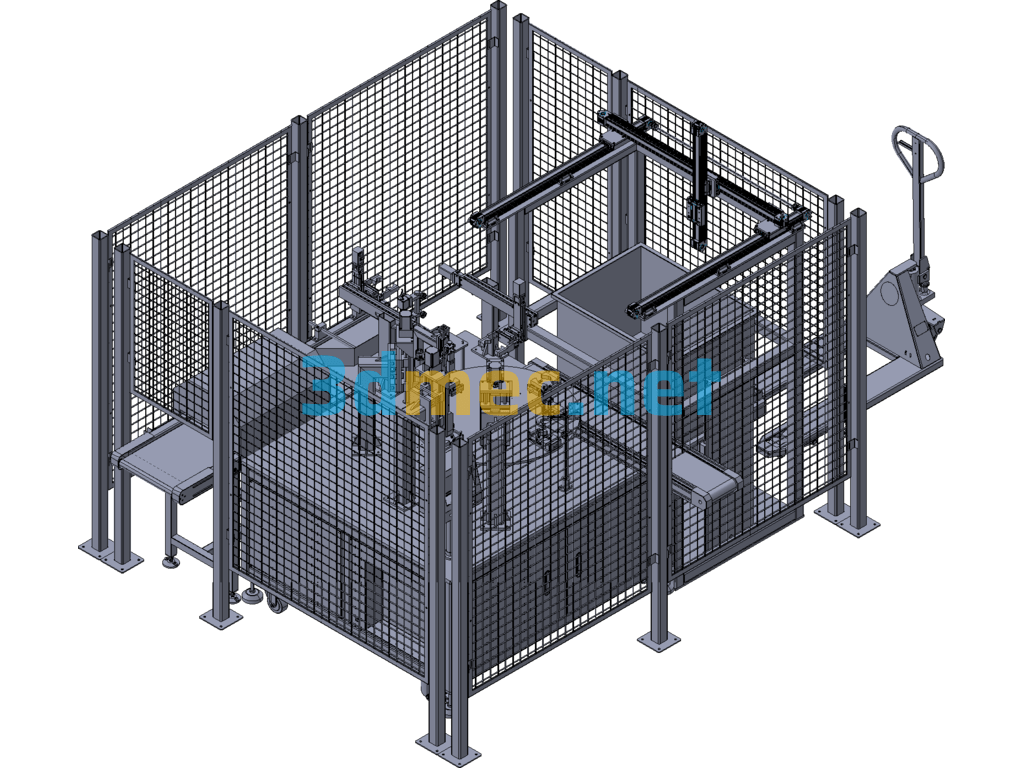

Feeding robot 01: This robot is equipped with a 180-degree rotating air gripper, which clamps the outer ring of the product. After grabbing the product, it will determine whether it needs to be turned over based on the orientation of the product detected by the CCD visual inspection in front, and then place the product on the positioning transfer position, clamping the outer ring of the product for easy rotation;

Positioning transfer position: This position has the function of rotating direction positioning, and can position products with directional requirements;

Feeding robot 02: The function of this robot is to grab and place the product from the transfer station to the turntable feeding station;

Pre-pressing station: This position pre-presses the product in a flat line to ensure that the product can be placed parallel to the tooling panel;

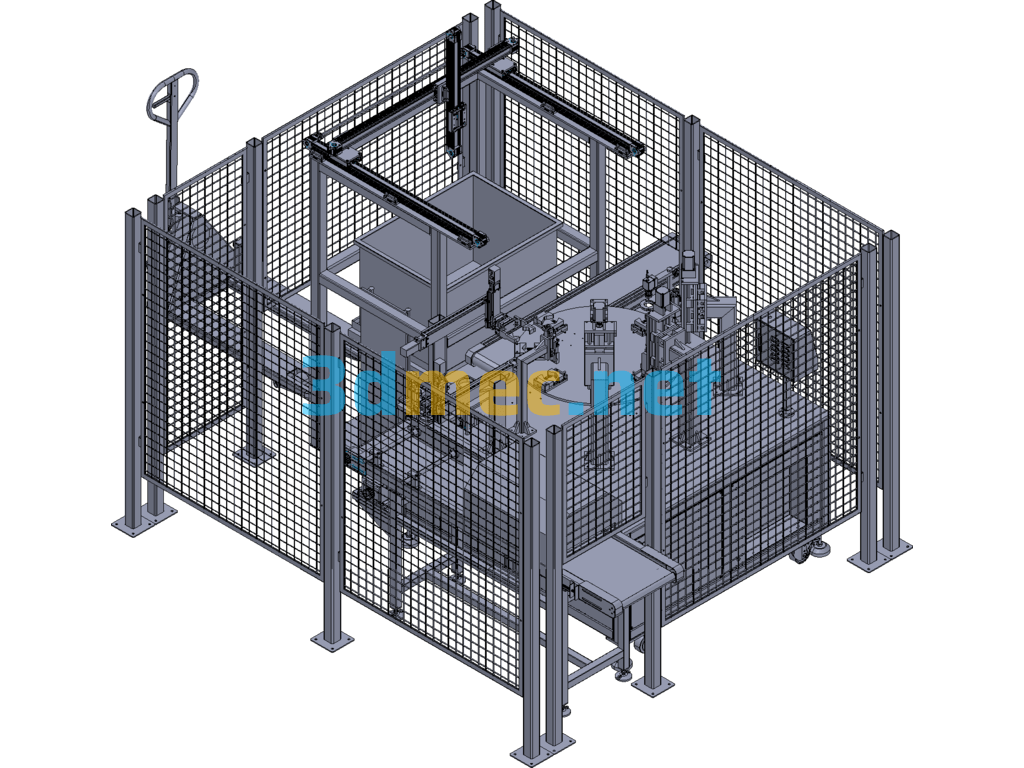

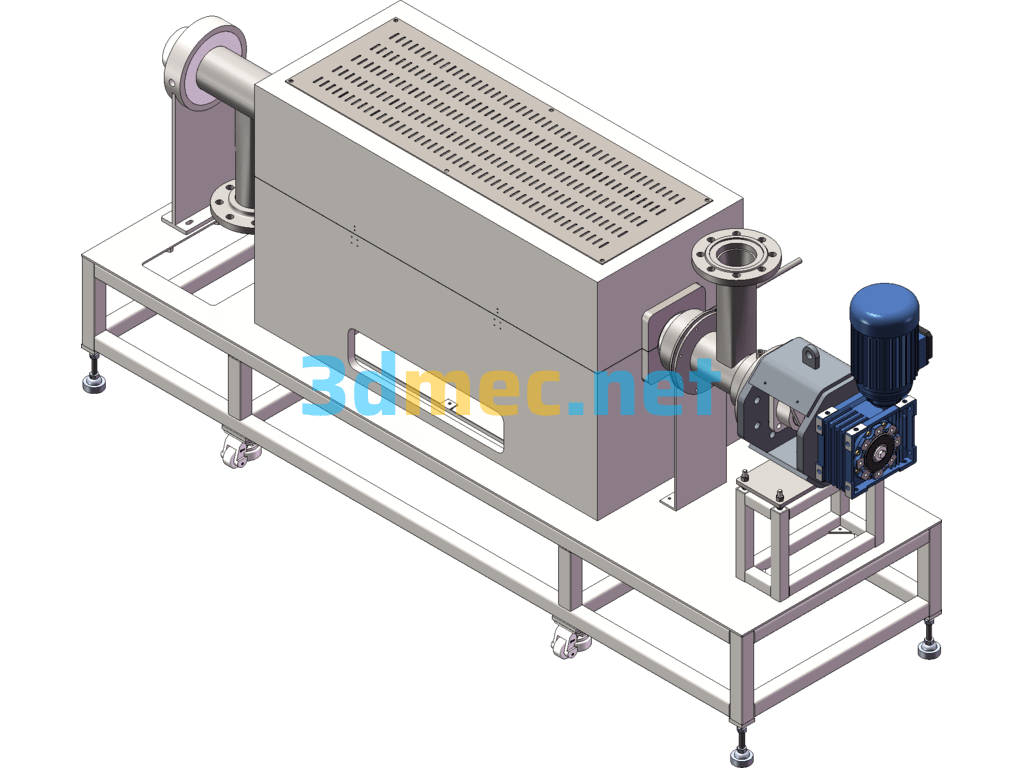

Leveling station 01: Roughing, rough processing, one knife flies off most of the rivet points that need to be leveled, leaving a margin;

Leveling station 02: finishing, fine processing, less removal, avoid one-cut, uneven surface and many burrs;

Inspection part composition: use laser torque measurement to test whether the rivet point is within the appropriate range after leveling to determine whether it is qualified or defective;

Chamfering station: chamfer and deburr the flat product;

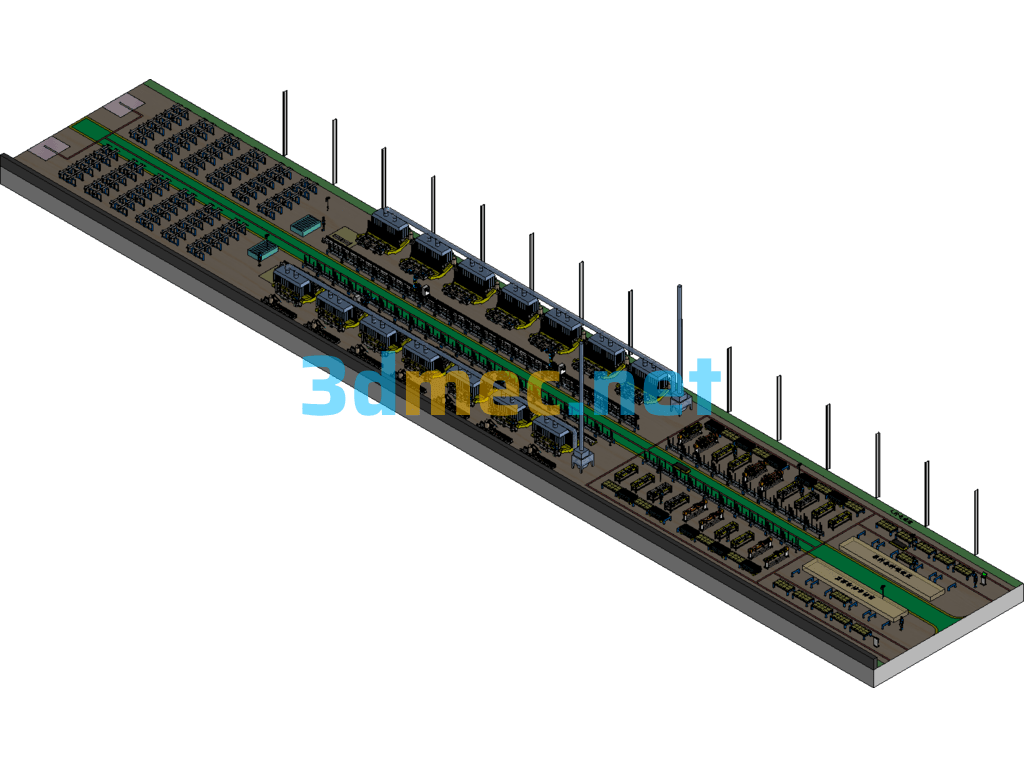

Discharging station: after the inspection is completed, transfer the station and wait for the assembly robot to sort the materials;

NG line: the robot automatically puts the qualified products into the turnover box, and the unqualified products are caught on the NG line. The NG line will cache a certain amount of defective products. When the amount is reached, the alarm prompts the workers to take them away.

Send to the palletizer and put them into the defective product turnover box;

Turntable assembly: a heavy-duty bearing support is installed at the bottom of the turntable, which plays a supporting role without affecting the rotation of the turntable;

Specification: Cast Aluminum Rotor Shaping Stacker 3D Model + PPT Equipment Analysis – 3D Model Exported

|

User Reviews

Be the first to review “Cast Aluminum Rotor Shaping Stacker 3D Model + PPT Equipment Analysis – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.