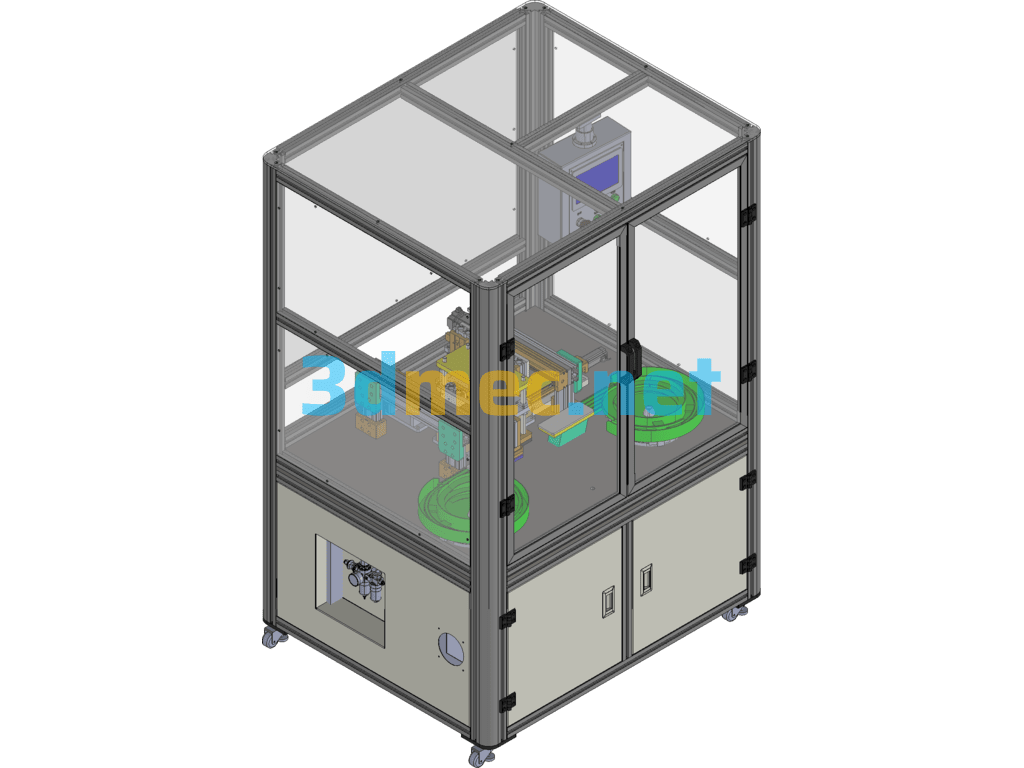

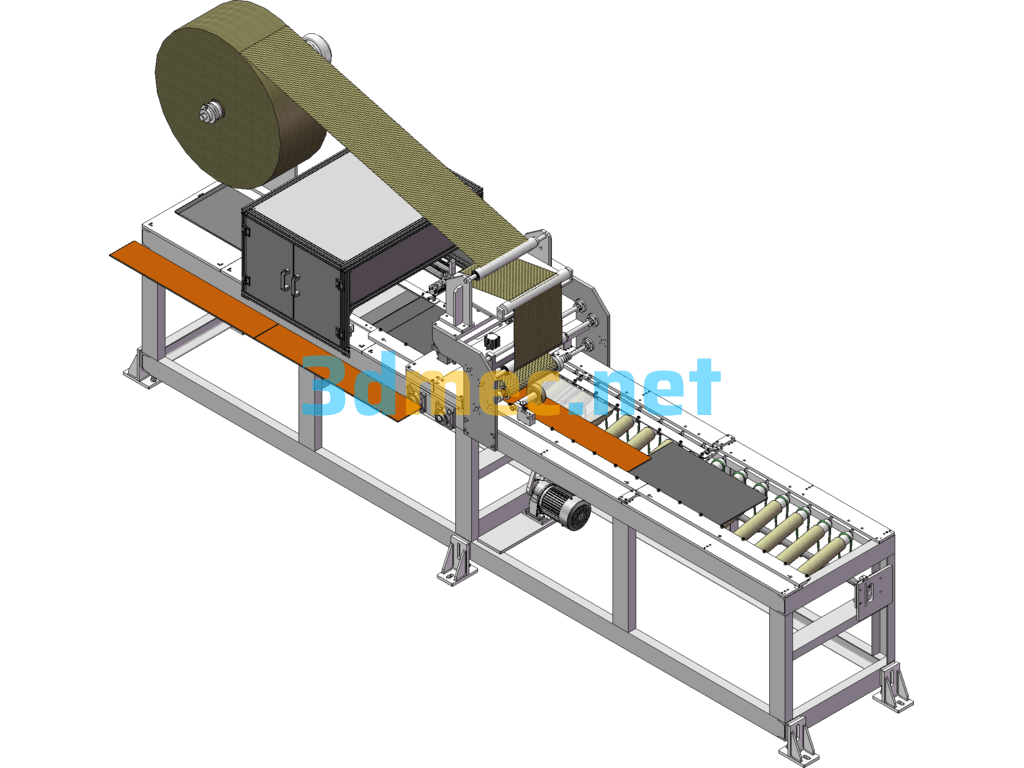

Function introduction of automatic feeding magnetizing machine:

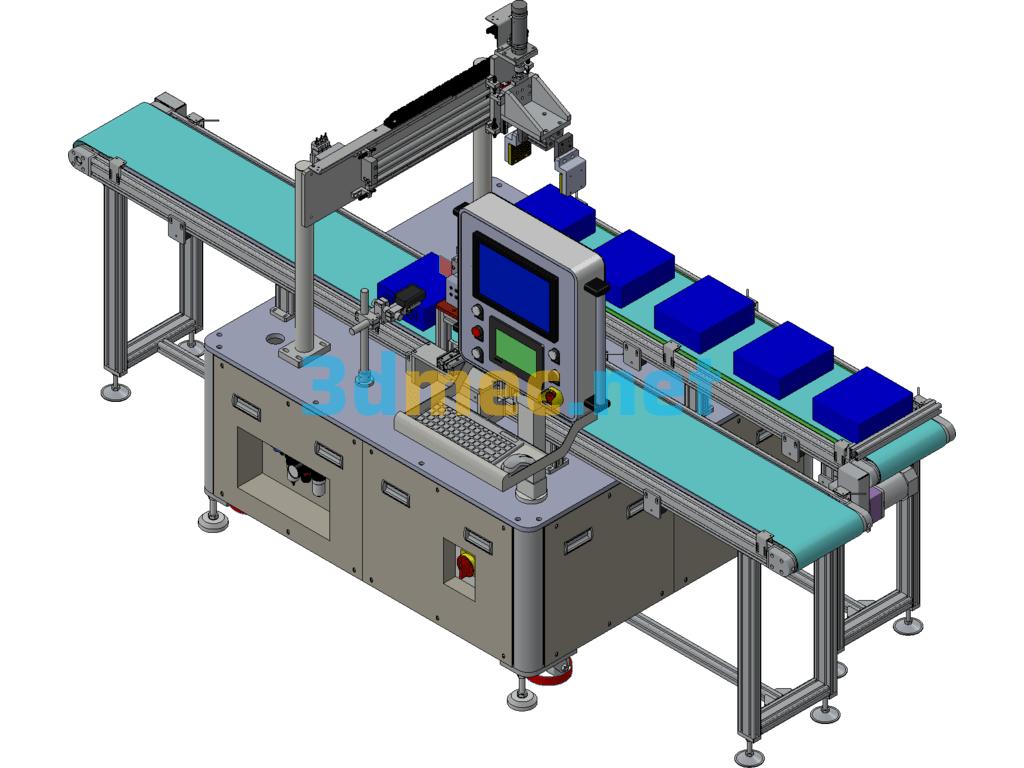

Feeding by vibration plate, grabbing by shifting the vertical module, cooperating with the shifting of the horizontal module, realizing alternating loading and unloading of products at both ends, improving production efficiency

Scope of application:

It can adapt to a variety of products by replacing the vibration plate, material channel and material suction head

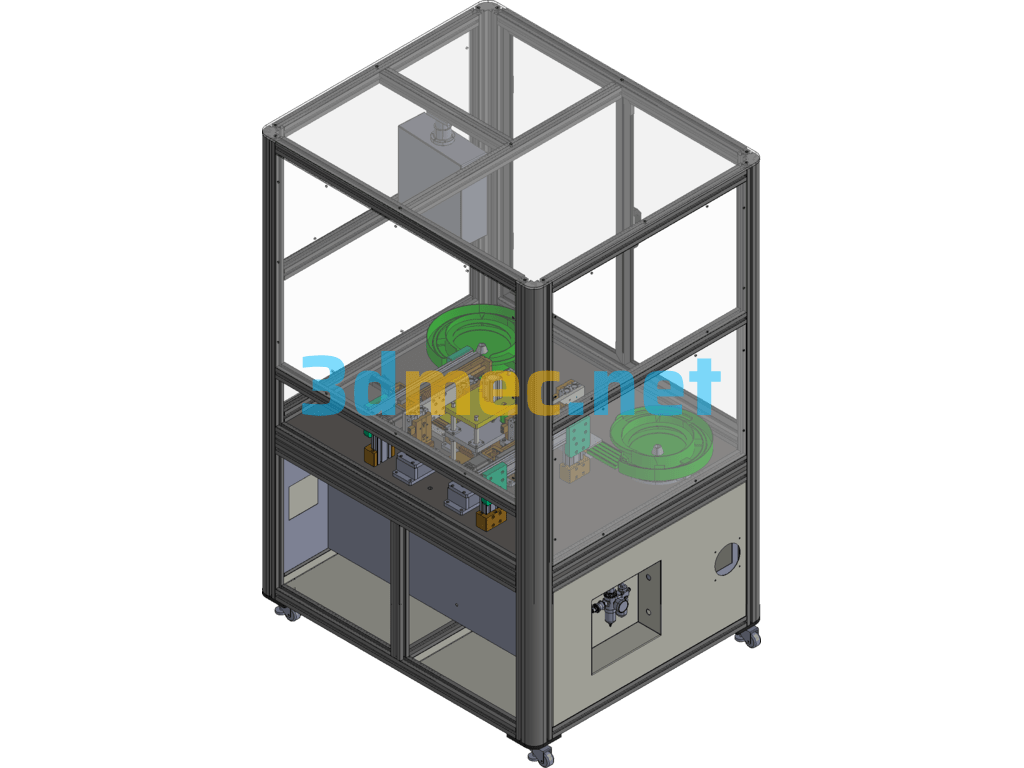

Structural composition:

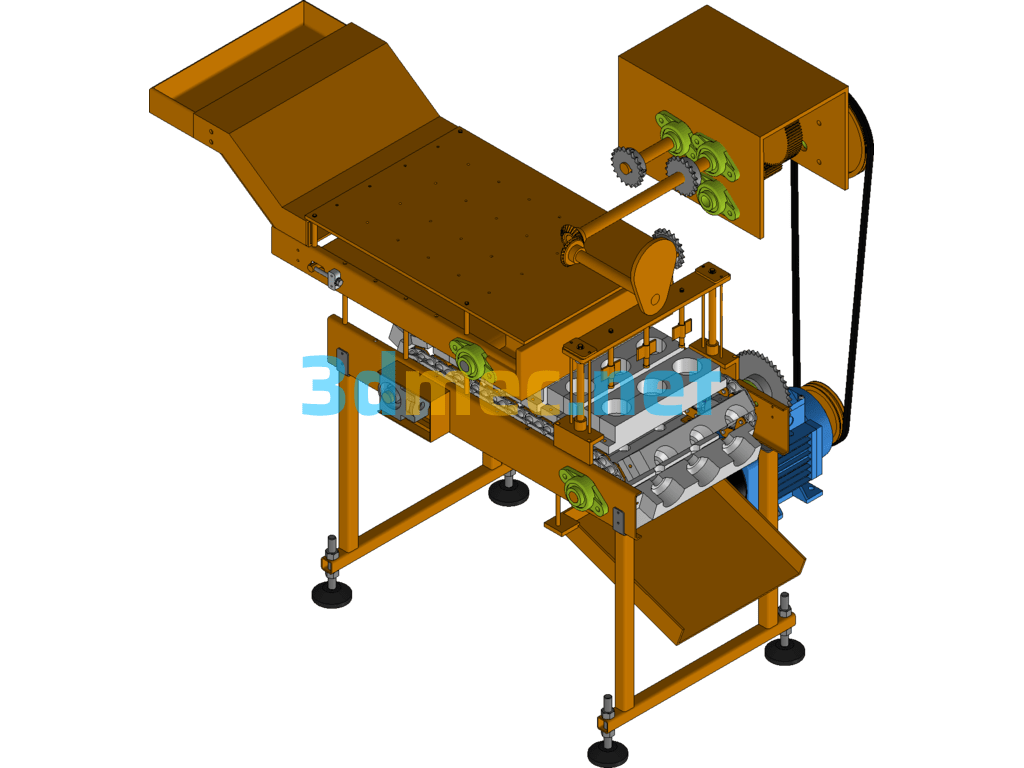

1. Vibration plate feeding mechanism: The function of loading on both sides is achieved through two vibration plates

2. Carrier handling mechanism: The module drives the two cylinders to move to achieve the loading and unloading of the product

3. Grabbing mechanism: The lower baffle is recovered by the downward movement of the cylinder to make the magnetic column close to the product to achieve the loading effect. When unloading, the baffle opens to achieve the unloading effect

4. Direct vibration feeding mechanism: The direct vibration mechanism is connected to the back of the vibration plate, so as to achieve the function of material storage buffer and linear long-distance feeding.

5. Material receiving mechanism: Through the groove, the magnetized finished material is clamped.

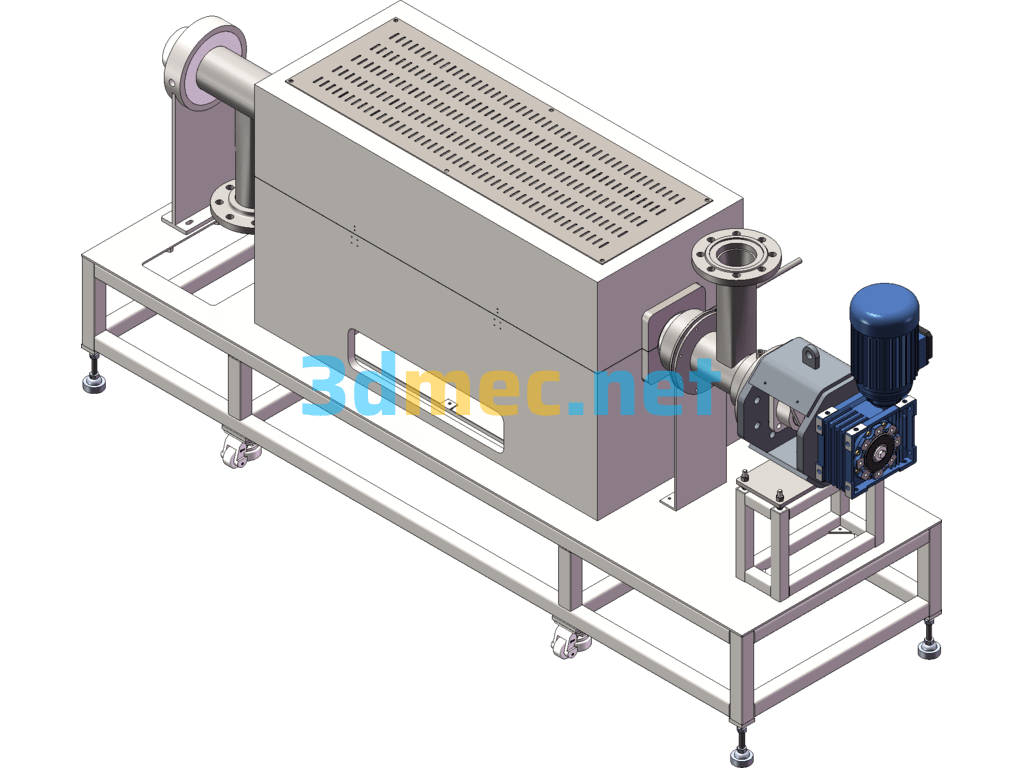

6. Downward pressure magnetization mechanism: The cylinder drives the pressure head to press the product and energize to complete the magnetization.

7. Horizontal transport mechanism: The module drives the product to complete the left and right materials and transport them to the magnetization position.

Process flow:

Step 1: Loading through the vibration plate and the straight vibration mechanism

Step 2: The right carrier transport mechanism moves to the top of the straight material channel, and the cylinder moves down and the block moves up to take the material

Step 3: The carrier transport mechanism moves to the top of the horizontal transport mechanism, and the unmagnetized material is placed on the carrier by moving the cylinder down and the block down

Step 4: The horizontal transport mechanism moves to the left to transport the material to the bottom of the downward pressure magnetizer

Step 5: Downward pressure magnetization The machine uses the cylinder to press the material and energize it to complete the magnetization

Step 6: At the same time as step 5, the previously magnetized products are pushed to the bottom of the left carrier handling mechanism

Step 7: The left carrier handling mechanism loads the left material and unloads the magnetized products

Step 8: The horizontal handling mechanism moves the magnetized products to the right to the bottom of the right carrier handling mechanism

Step 9: The carrier handling mechanism transports the magnetized materials to the receiving device and loads the unmagnetized materials at the same time.

Specification: Automatic Feeding Magnetizing Equipment – 3D Model Creo.Parametric

|

User Reviews

Be the first to review “Automatic Feeding Magnetizing Equipment – 3D Model Creo.Parametric”

You must be logged in to post a review.

There are no reviews yet.