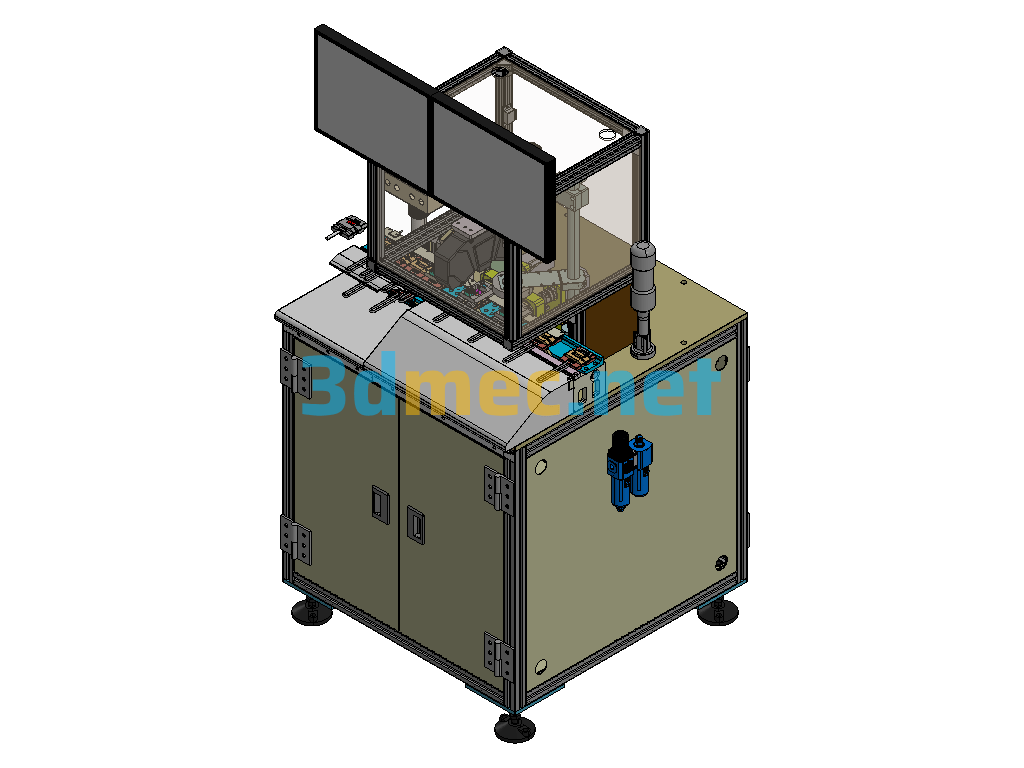

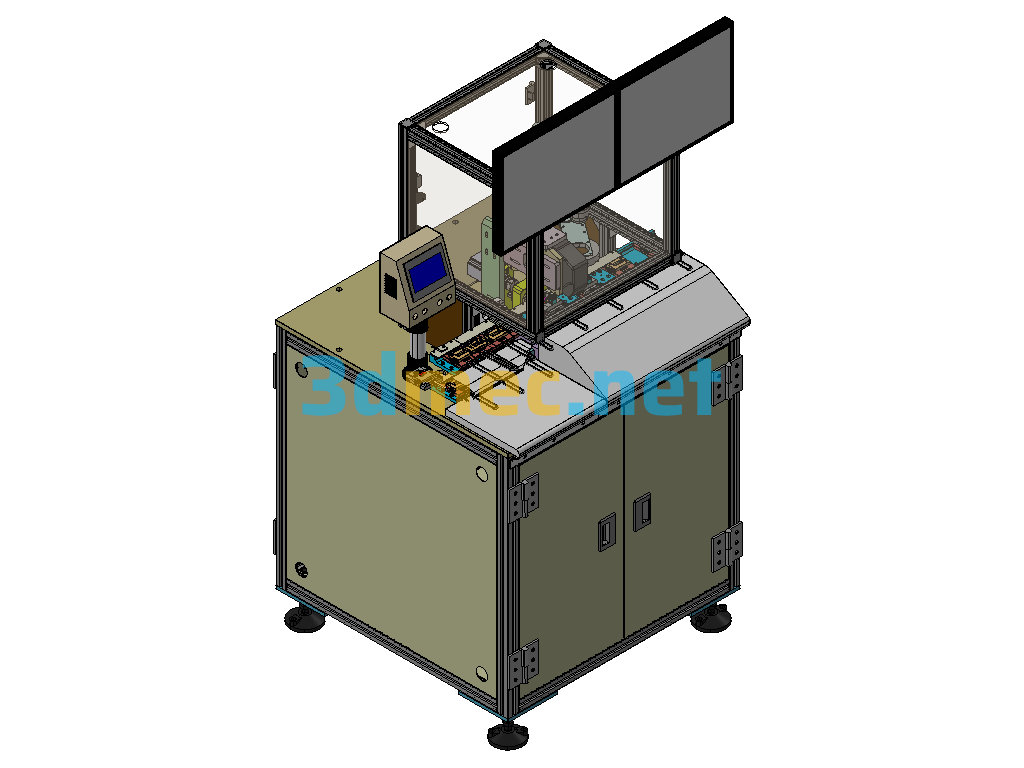

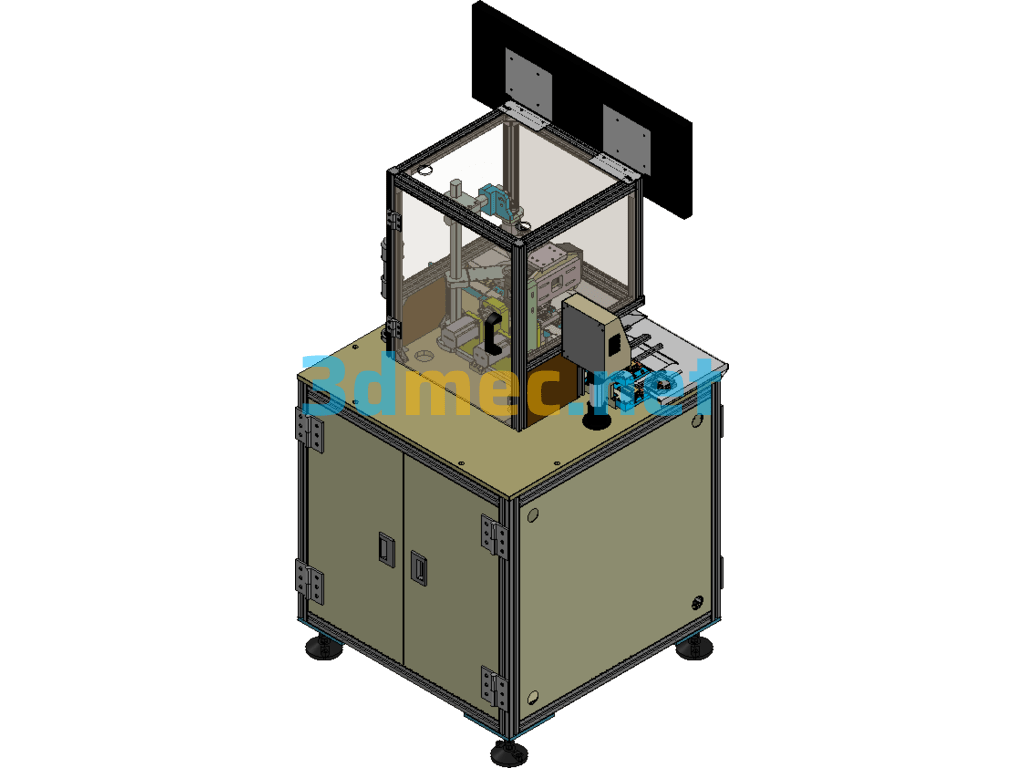

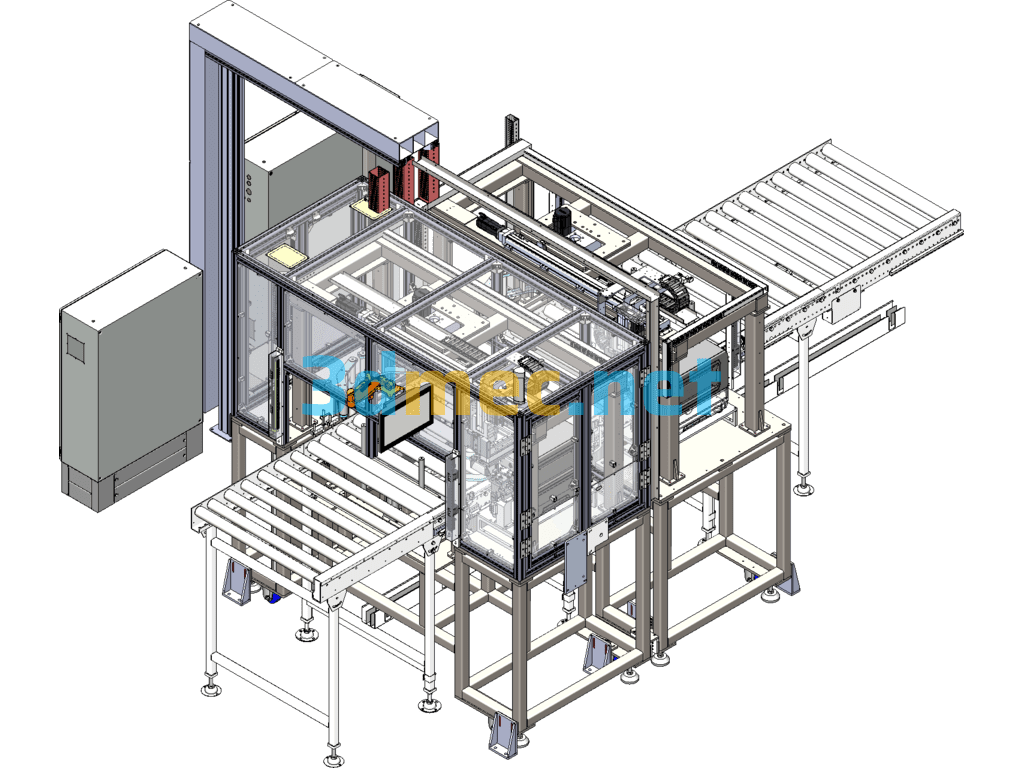

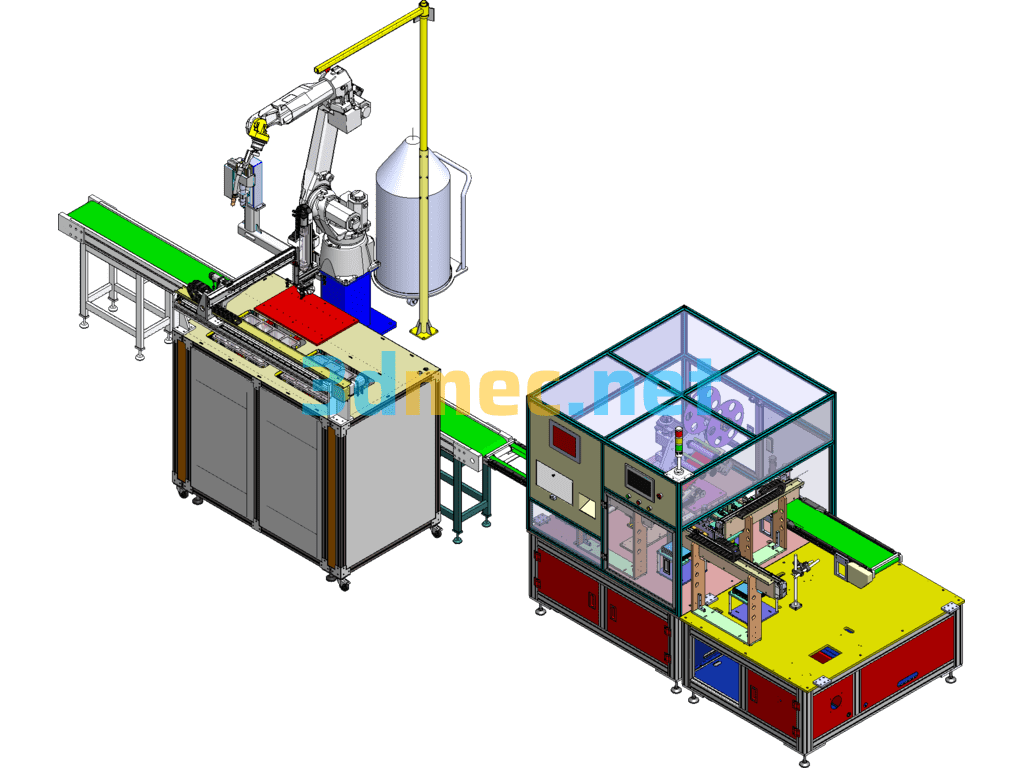

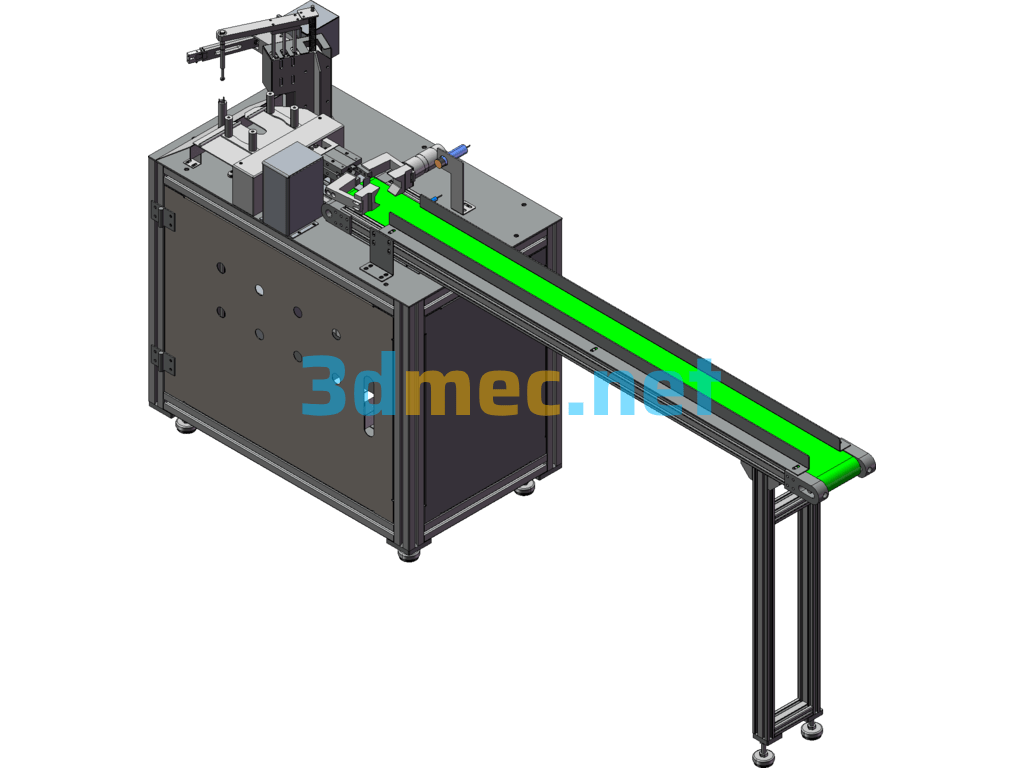

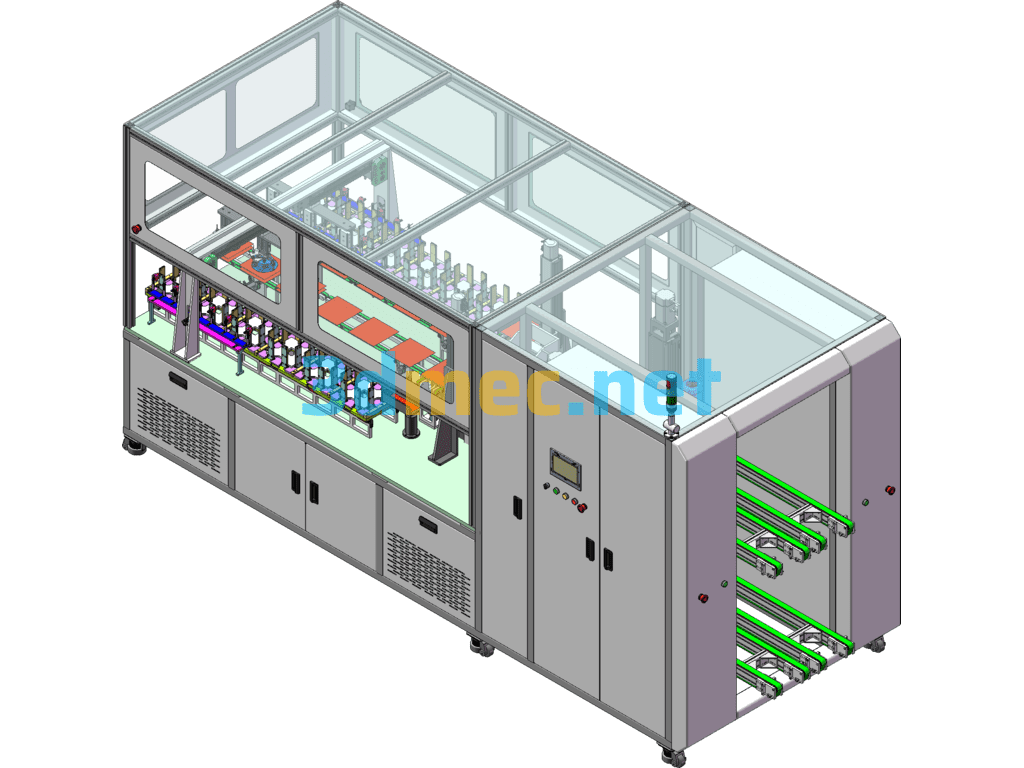

After the wire solder joints are welded, the machine is placed (the jig for automatic welding and the jig for solder joint detection are common), and the machine automatically starts to detect the wire barcode. After the detection is completed, it moves to start 2D solder joint welding offset detection (left and right offset and solder joint tin pulling and solder position lack of tin) and 3D detection of solder joint welding volume and height. Using Keyence PLC and imaging system, after the detection is completed, the detection data and results can be uploaded to the MES system (factory work system).

PTC CoCreat 17.0

Specification: Fully Automatic Wire Solder Joint Inspection Machine – 3D Model Exported

|

User Reviews

Be the first to review “Fully Automatic Wire Solder Joint Inspection Machine – 3D Model Exported”

You must be logged in to post a review.

There are no reviews yet.