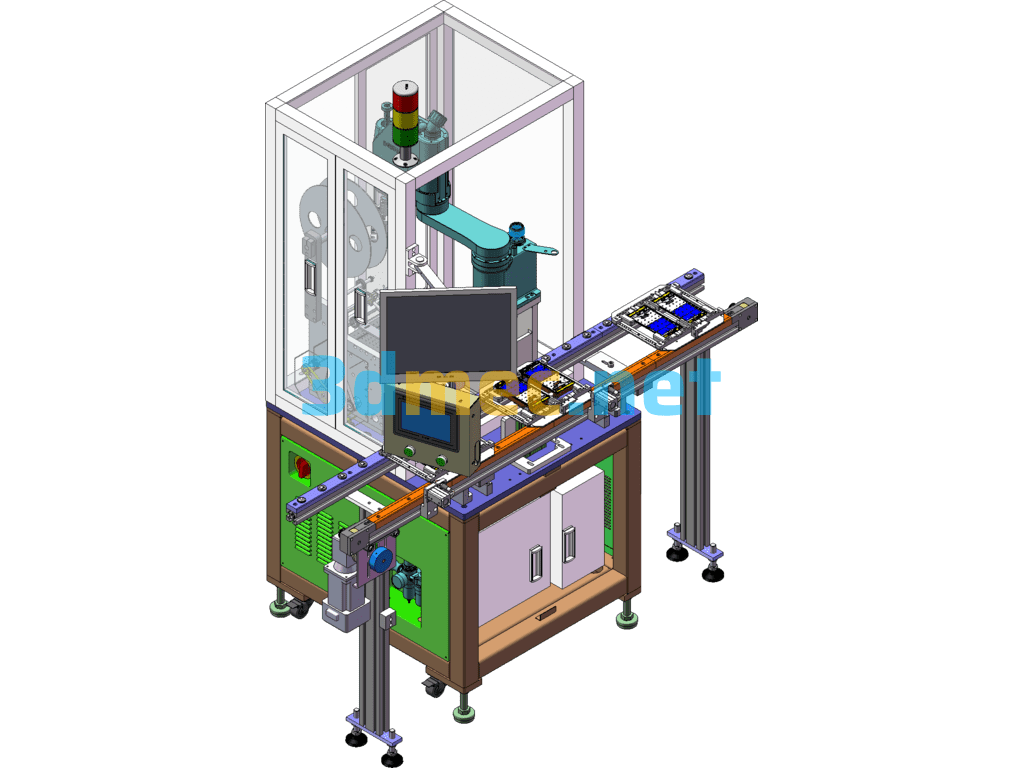

Multifunctional Solar Cell Laser Scribing Machine SW2016 (In Mass Production) – 3D Model SolidWorks

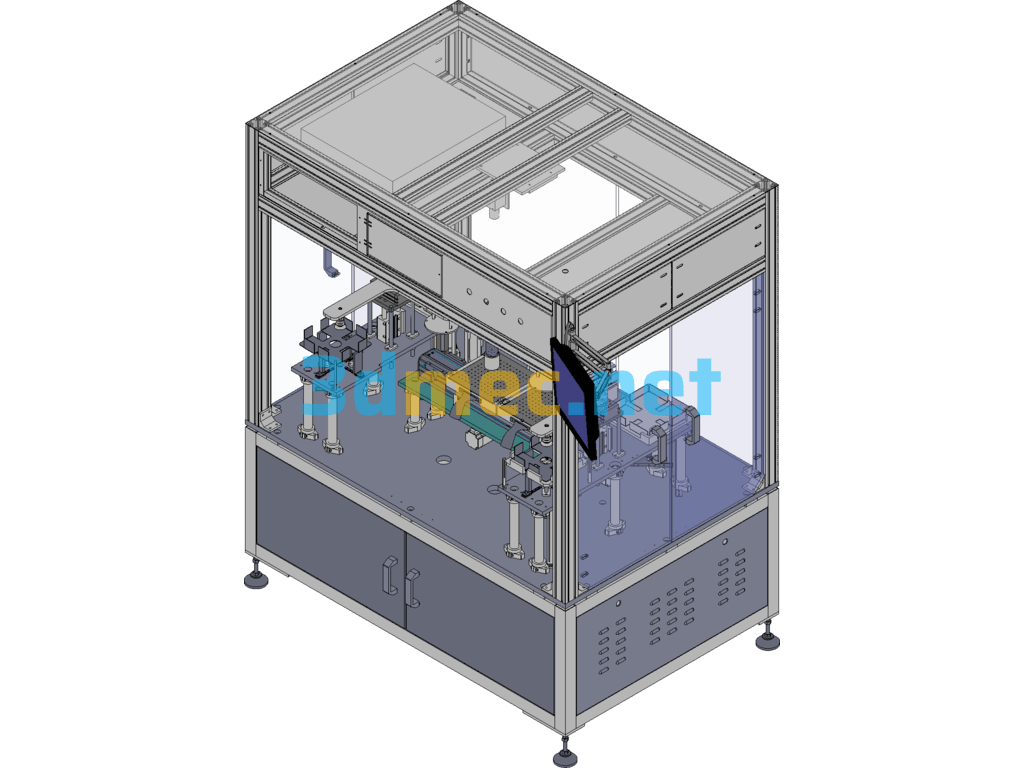

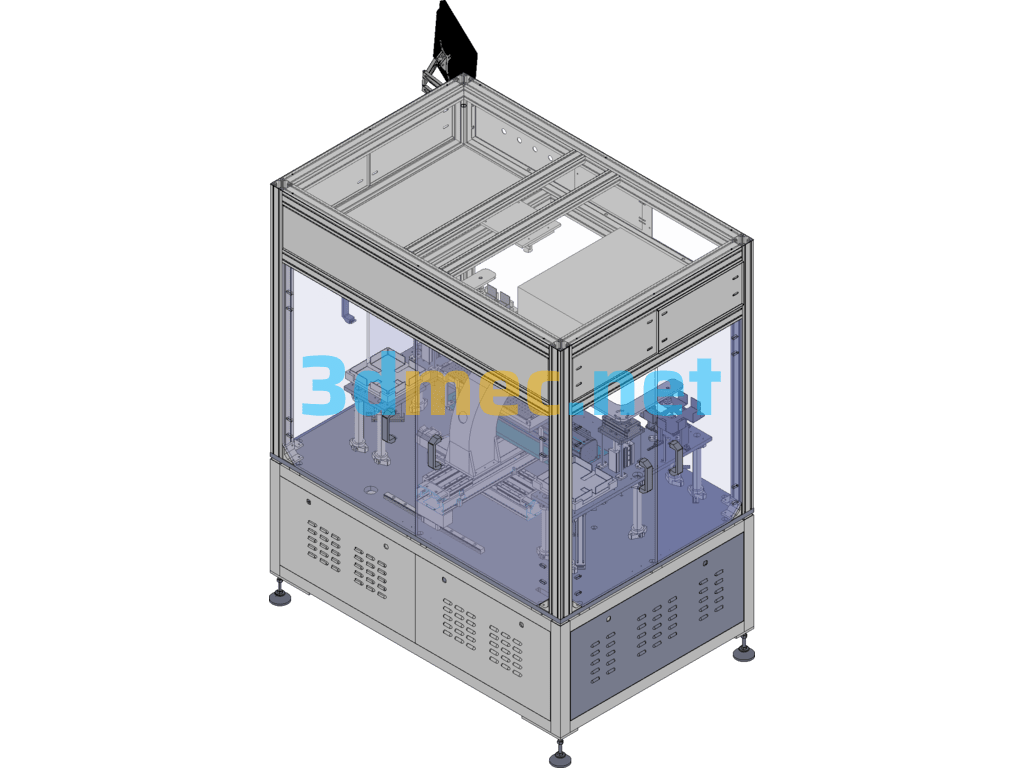

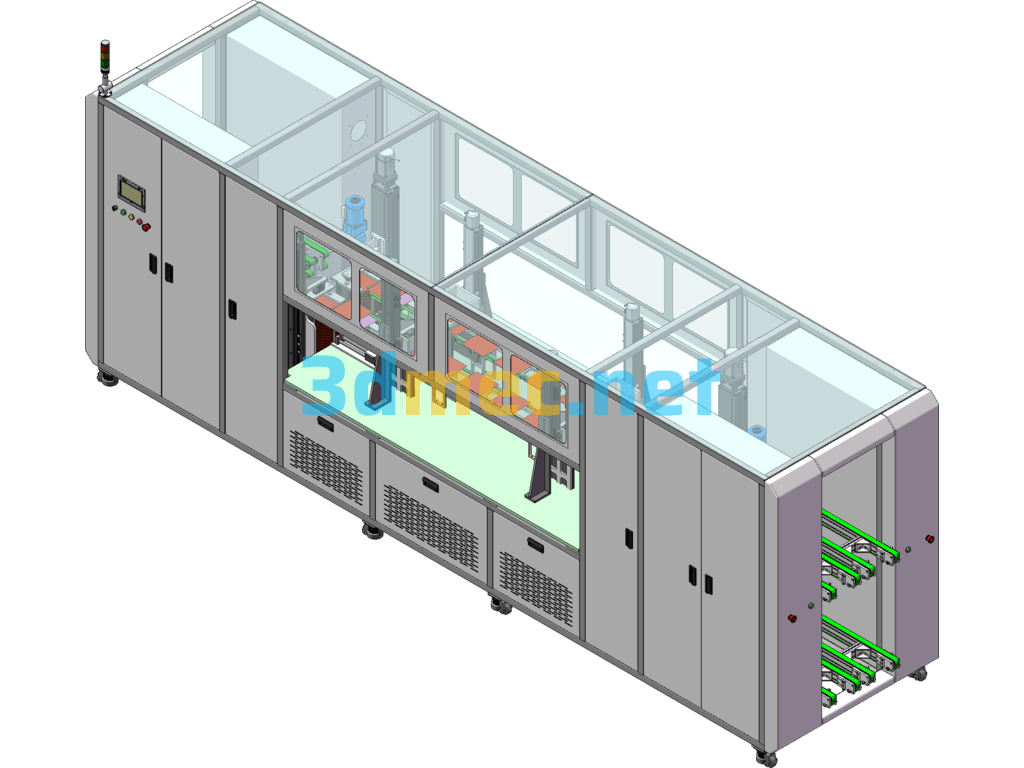

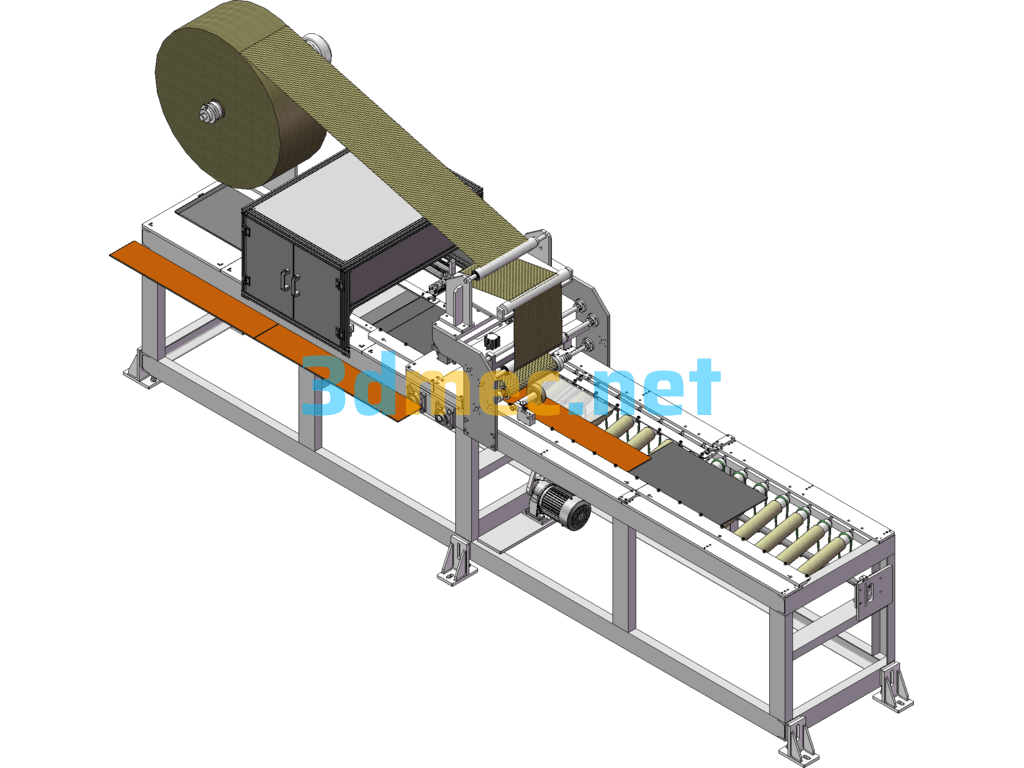

The multifunctional solar cell laser scribing machine uses machine vision servo to control the laser to re-cut the damaged silicon wafers into usable silicon wafers, thereby improving the utilization rate of the damaged silicon wafers. It includes a rack, a loading and unloading device, an intermediate workbench device, a laser cutting device, a detection device and an industrial computer; there are two loading and unloading devices, which are respectively arranged at both ends of the middle plate of the rack. The loading and unloading device includes a loading and unloading platform, a loading device, a rotating arm device and a unloading device. The intermediate workbench device includes an intermediate working platform, a vacuum fixture fixing plate device and a single-axis robot. The vacuum fixture fixing plate device can be driven by the single-axis robot to move back and forth between the two loading and unloading devices. The loading and unloading device moves the solar cell in the loading device to the vacuum fixture fixing plate device through rotation and the suction cup arranged thereon to complete the loading. After loading and detection by the detection device, the industrial computer plans the path and controls the laser cutting device to complete the cutting. Finally, the cut solar cell is moved to the unloading device through the rotating arm device. It has a simple structure, is stable and reliable, and has high efficiency.

1-upper frame,2-middle plate,3-square steel frame,4-square steel frame front door,5-upper frame front door,6-upper frame front cover plate,7-upper frame side cover plate,8-upper frame side door,9-square steel frame side door,10-door handle,11-hinge 1,12-square steel frame side door 1, 13-oil-water separator installation box shield,14-upper frame rear cover plate,15-square steel frame rear plate,16-laser cutting device,17-loading and unloading device,18-hinge 2, 19-handle,20-middle workbench device,21-drag chain,22-dust suction fixing frame, 23-upper frame top plate,24-upper frame interlayer,25-upper frame interlayer plate,26-support foot,27-oil-water separator installation box,28-square steel frame middle bottom plate,29-square steel frame left and right bottom plates,30-servo hanging plate, 31-pad, 32-air circuit hanging plate, 33-PLC hanging plate, 34-foot cup, 35-foot cup fixing plate, 36-camera fixing frame, 37-camera horizontal bracket, 38-camera fine-tuning platform fixing block, 39-camera fine-tuning platform, 40-industrial camera, 41-camera fixture 1, 42-camera fixture 2, 43-loading and unloading platform, 44-rotating arm device, 45-loading device, 46-unloading device, 47-upper guide plate, 48-light rod 1, 49-telescopic cylinder, 50-support column, 51-sensor bracket, 52-light shielding plate, 53-lower guide plate, 54-linear bearing, 55-blowing device, 56-movable stopper, 57-loading box, 58-loading bin, 59-optical rod 2, 60-lower fixed block, 61-stepping motor lead screw, 62-through stepping motor, 63-upper fixed block, 64-unloading box, 65-unloading bin, 66-rotating arm, 67-unloading suction cup support column, 68-unloading suction cup, 69-unloading suction cup sealing plate, 70-rotating cylinder, 71-loading suction nozzle, 72-blowing block, 73-blowing block base, 74-linear guide 1, 75-stopper, 76-laser head support, 77-focusing lens adapter, 78-focusing lens, 79-laser head fine-tuning mechanism, 80-laser welding frame, 81-linear guide connection block, 82-linear guide 2, 83-Y-axis robot, 84-X-axis robot, 85-intermediate working platform, 86-vacuum fixture fixing plate device, 87- workbench blowing rack, 88- single-axis robot, 89- light shield 1, 90- vacuum fixture fixing plate, 91- vacuum fixture sealing plate, 92- vacuum fixture suction plate, 93- tablet pressing, 94- vacuum fixture, 95- opposite-beam sensor bracket, 96- laser head.

SolidWorks2016 and CAD engineering drawings

Specification: Multifunctional Solar Cell Laser Scribing Machine SW2016 (In Mass Production) – 3D Model SolidWorks

|

User Reviews

Be the first to review “Multifunctional Solar Cell Laser Scribing Machine SW2016 (In Mass Production) – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.