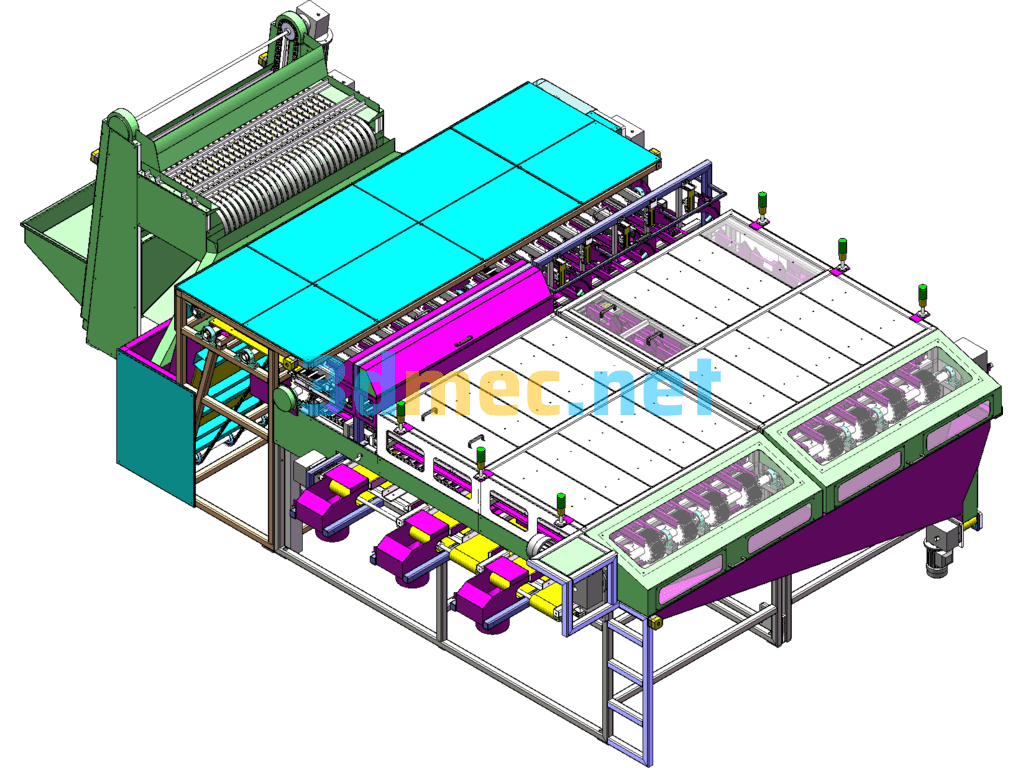

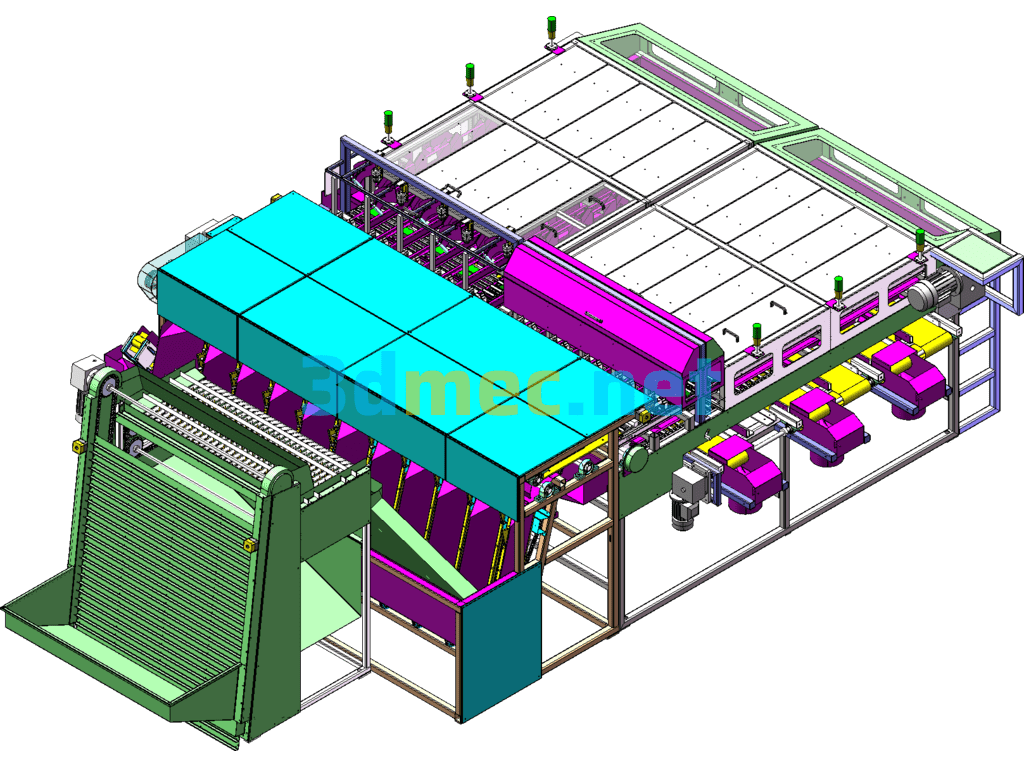

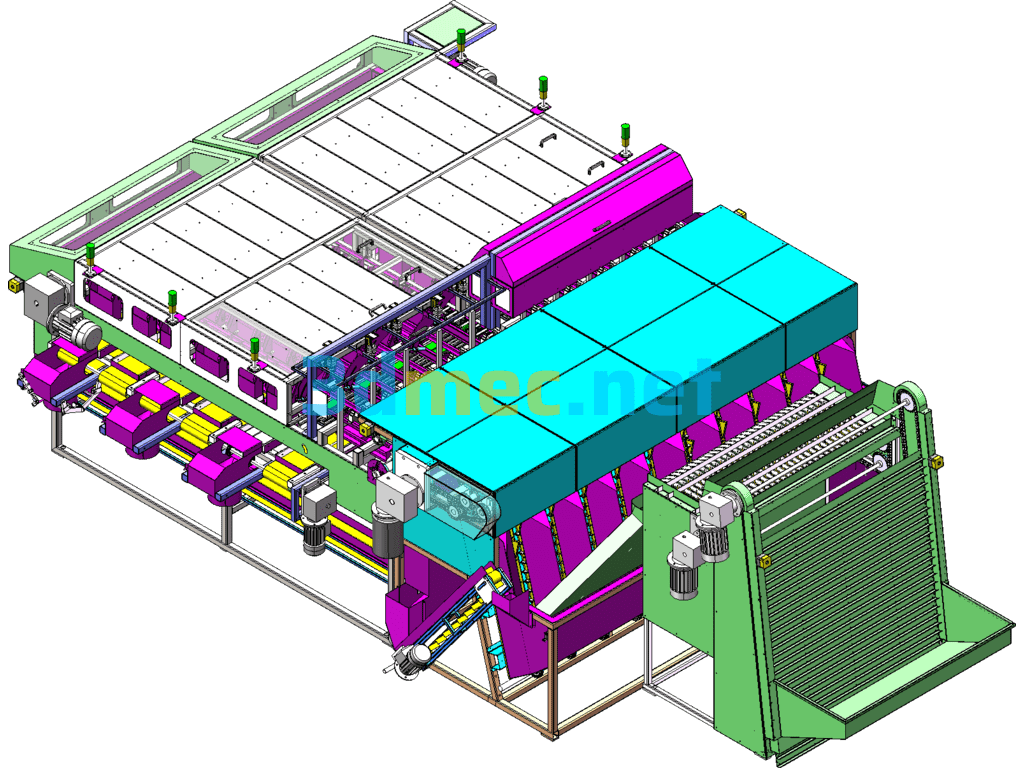

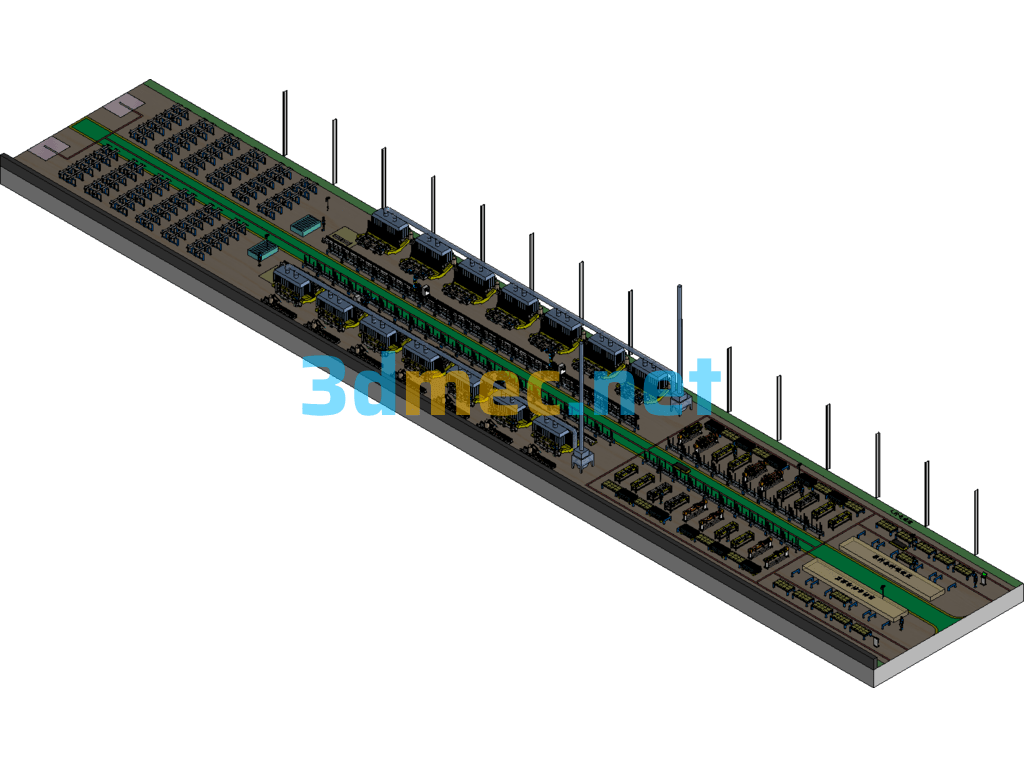

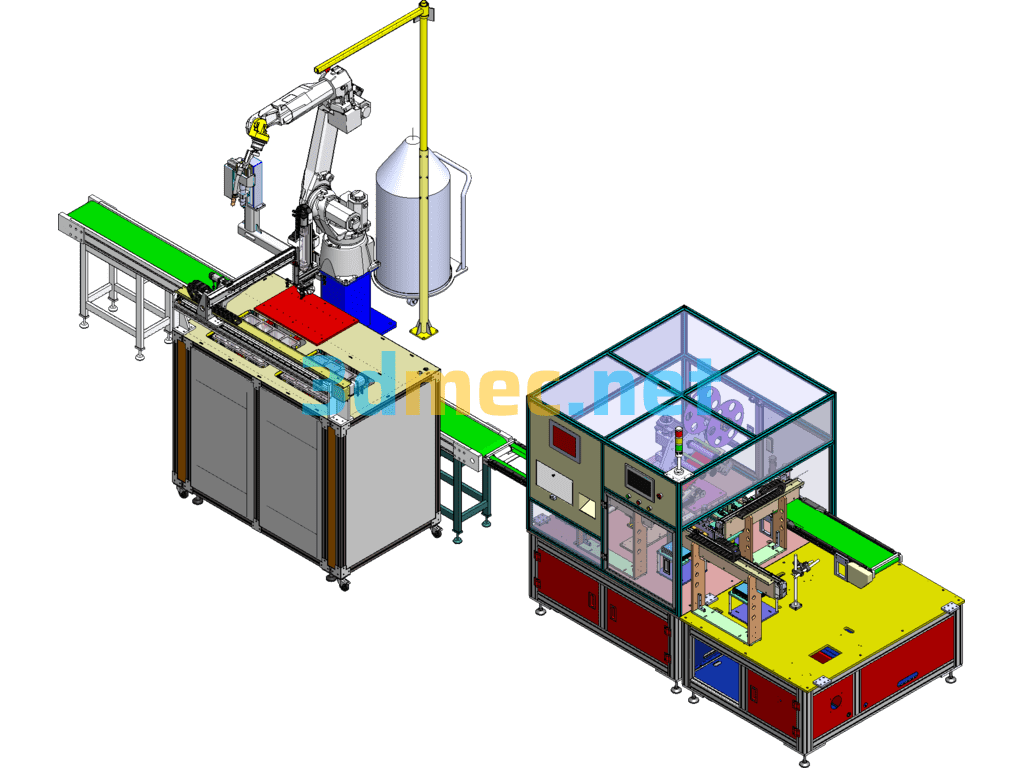

complete assembly design model of the betel nut production line includes the machine head and filter, machine head assembly, fuselage assembly, filter, material distribution conveyor belt assembly, upper wire chain module, diversion belt splicing, and other main structures

1. Stirring device: The overall dimensions of the digestion tube are enlarged, the overall height is reduced, and the distance between the magnetic stirrer is increased to enhance the stirring effect and solve the problem of uneven upper and lower stratification;

2. Heating device: Determine the shape of the heating plate, add tetrafluoroethylene insulation support at the bottom, improve the installation position of the temperature sensor and the safety protection of the heating power cord, and consider the distance between the magnetic stirrer and the bottom of the digestion tube to prevent the magnetism from being too weak to affect the stirring;

3. Cooling fan: First consider the upper and lower cooling separation, use a separate wind curtain or blower at the bottom, and use a wind curtain or four large axial flow fans for cooling at the upper part. If the effect is not ideal, electronic refrigeration can be considered;

4. Condenser box: remake the sheet metal according to the new cooling fan and condenser tube size, and consider the weight that the condenser box docking robot can bear;

5. Condenser tube: use jacket circulating water cooling or add a water storage jacket device to the upper end of the condenser tube for cooling;

6. Dosing device: determine whether the required dosing peristaltic pump uses a high-precision peristaltic pump or an ordinary peristaltic pump based on the dosing accuracy, and whether to use a plunger pump or other dosing methods can also be demonstrated;

7. Determine the layout of all liquid pipelines and electrical circuits of the machine;

8. Determine the installation and wiring layout of the internal electrical appliances of the control box, and conduct relevant tests and configurations on the industrial computer, display and other hardware;

Specification: Non-Standard Automated Betel Nut Production Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “Non-Standard Automated Betel Nut Production Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.