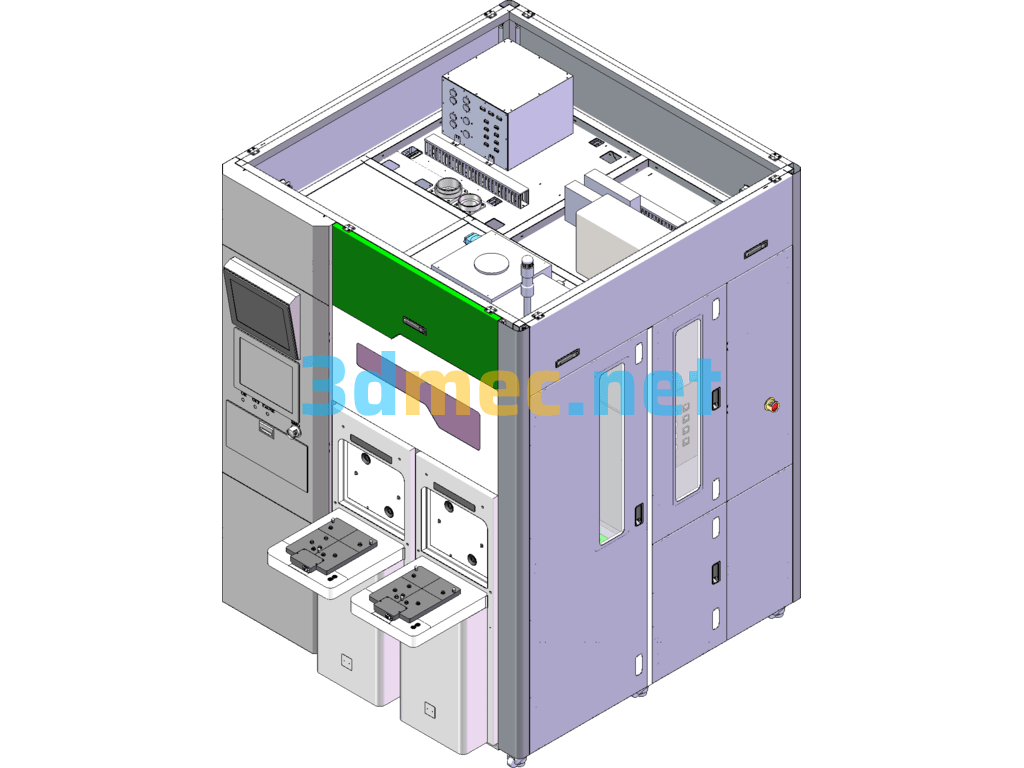

Technical requirements for electric card dispensing and pressing equipment

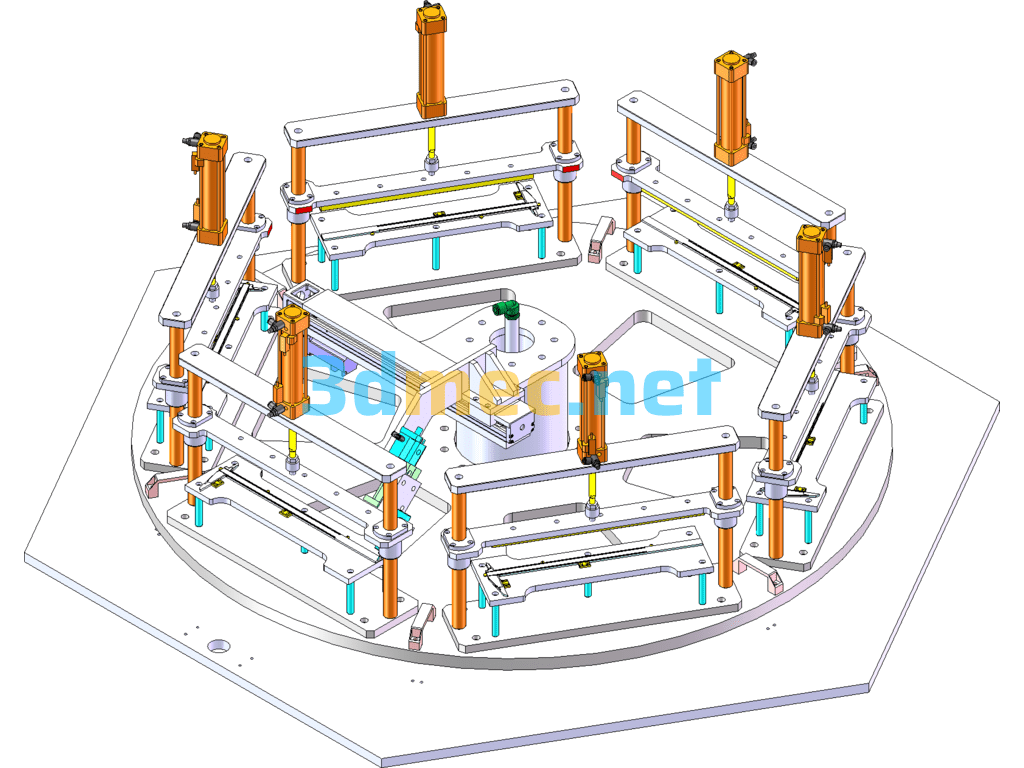

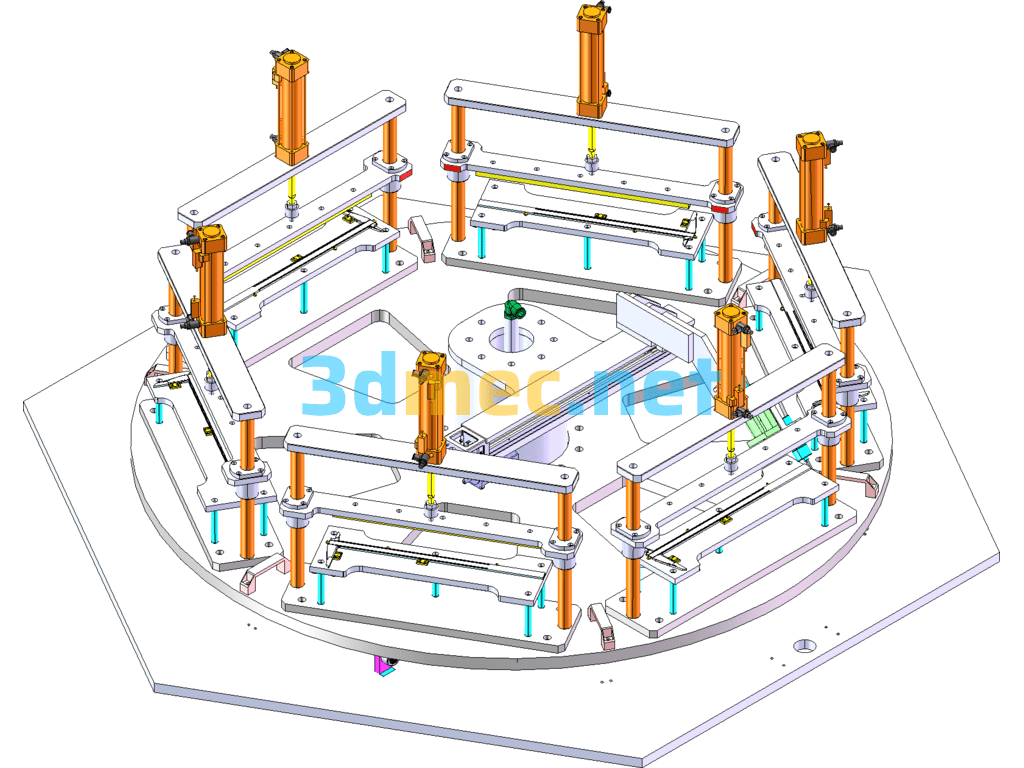

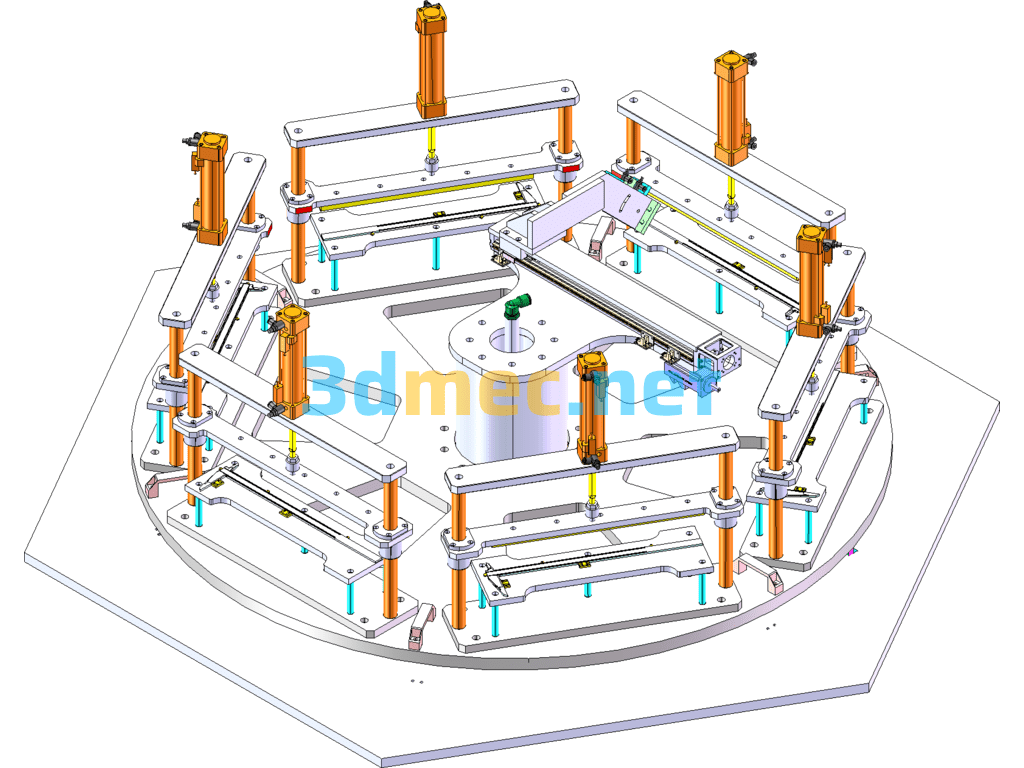

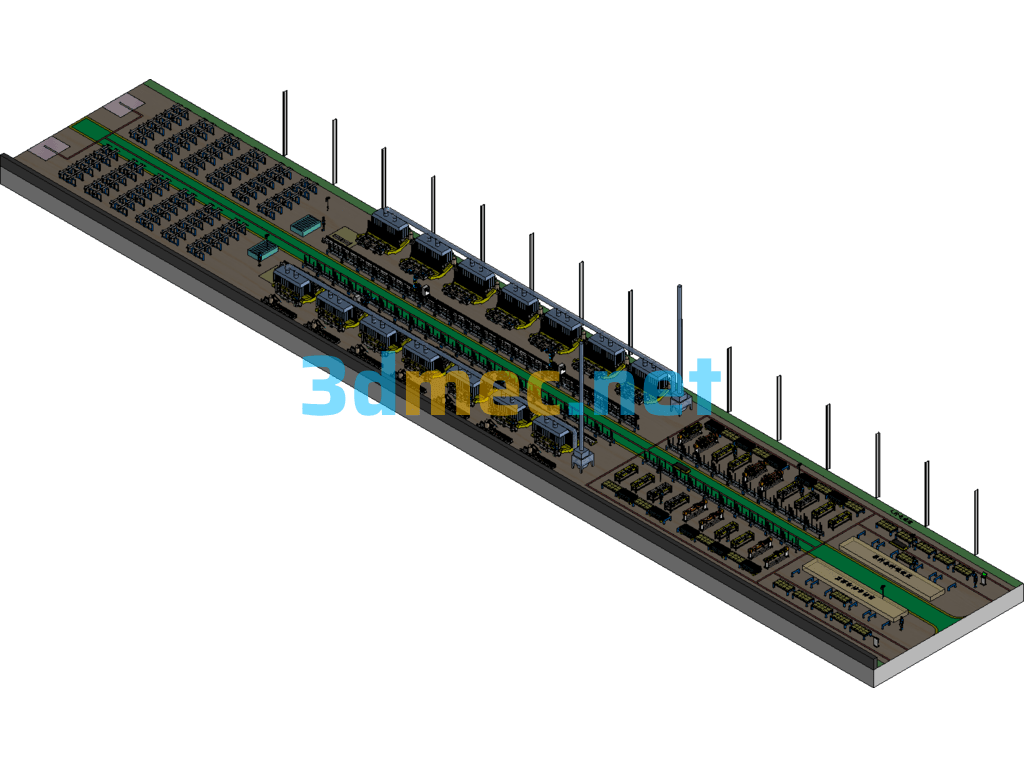

1. Workbench: a. The workbench of the dispensing and pressing equipment is disc-type, centrally positioned, and can rotate in a circle.

b. Six pressing fixtures are evenly arranged around the disc workbench (for 6-station operation). The workbench can be automatically locked every 60

degrees of rotation, and the stop state is maintained. The opening and locking are manually controlled.

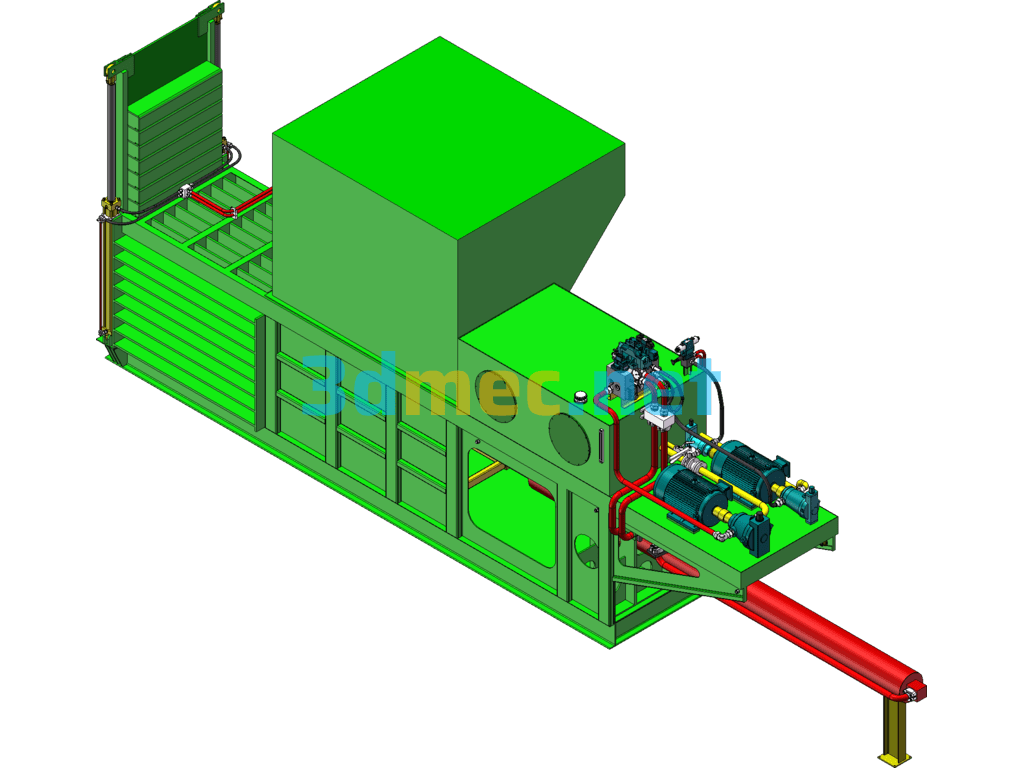

2. Caliper dispensing machine, automatic dispensing fixture: The pressing surface of the fixture is slightly soft rubber, and the longitudinal section of the rubber is a semi-circular arc of the pressing surface to ensure that the flexible surface is pressed

and the glue can be spread from the middle to both sides.

3. Glue dispensing valve: The glue valve is suitable for instant glue (Loctite 480), the glue output is adjustable, and the needle should not be blocked within 2 hours after the glue valve is sprayed

A small liquid container is fixed on the workbench. After the glue valve is stopped, the needle can be inserted into the container liquid

The body keeps the glue in the needle from solidifying.

Electronic vernier caliper glue dispensing machine

Specification: Electronic Display Vernier Caliper Dispensing Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Electronic Display Vernier Caliper Dispensing Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.