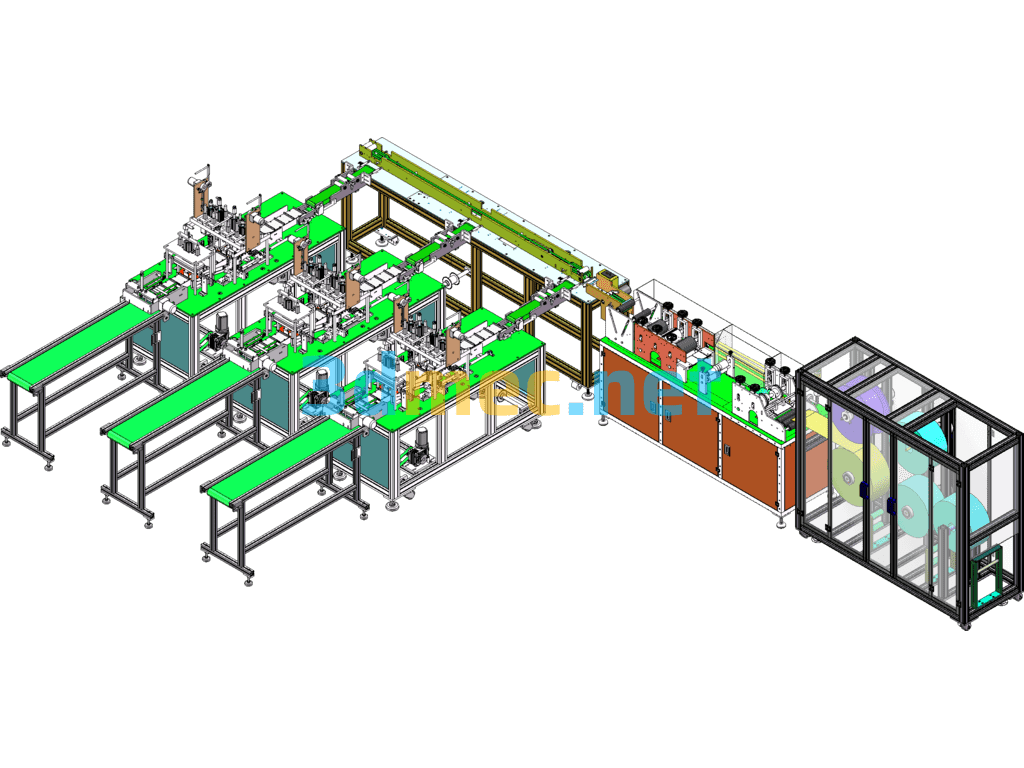

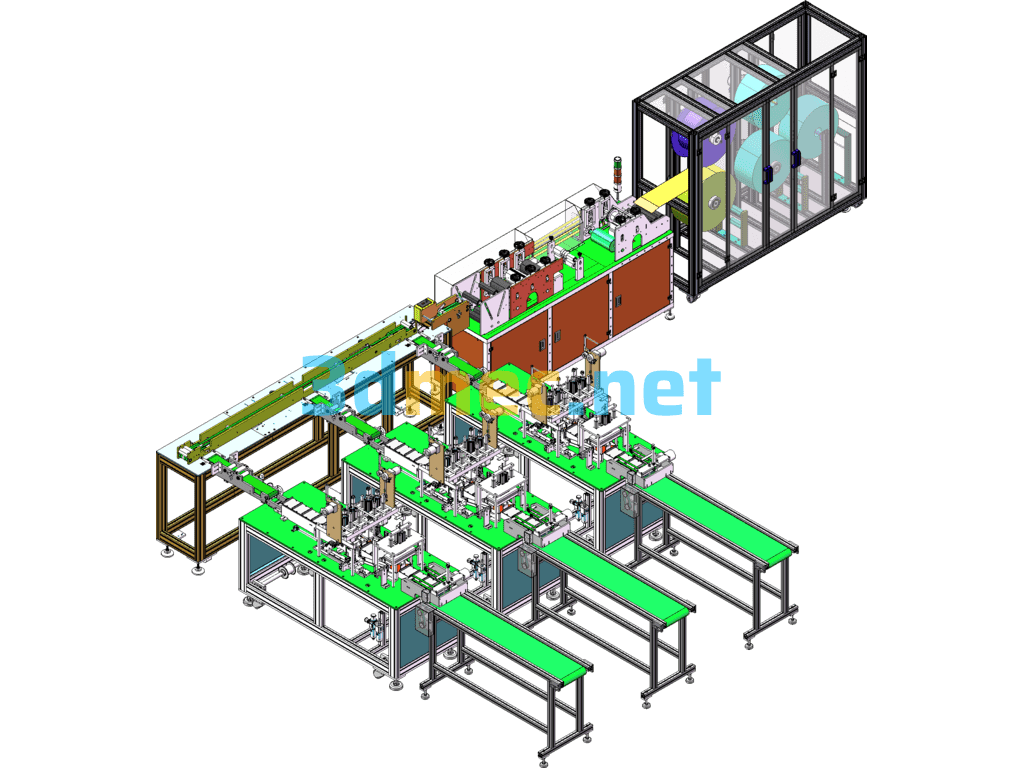

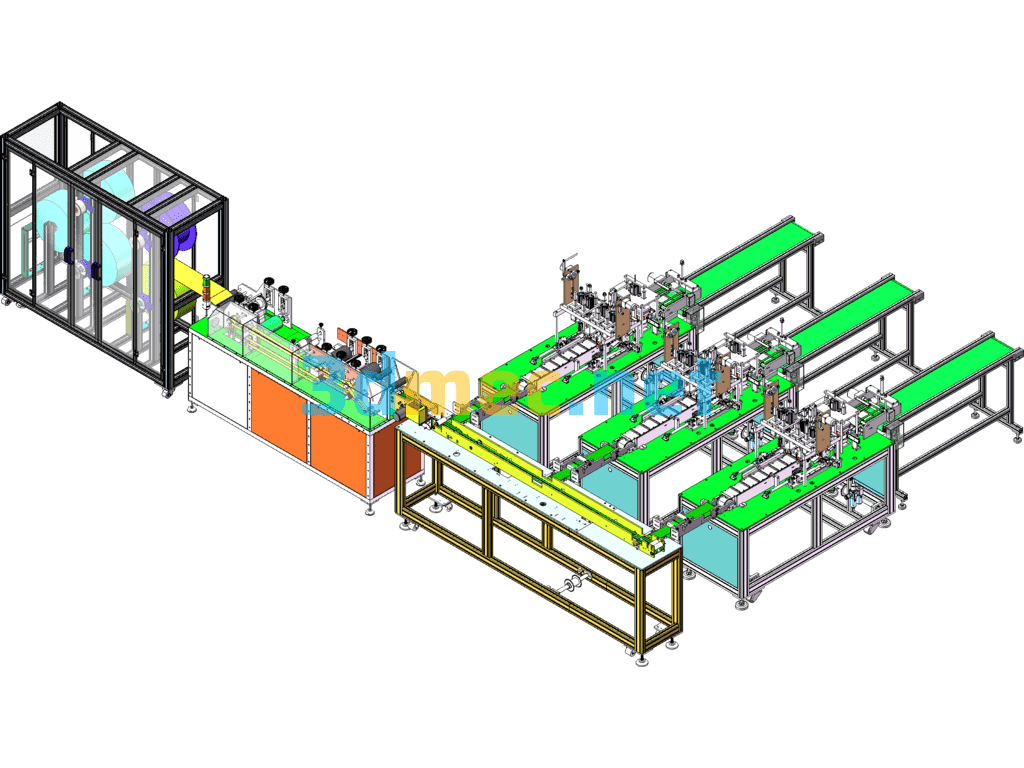

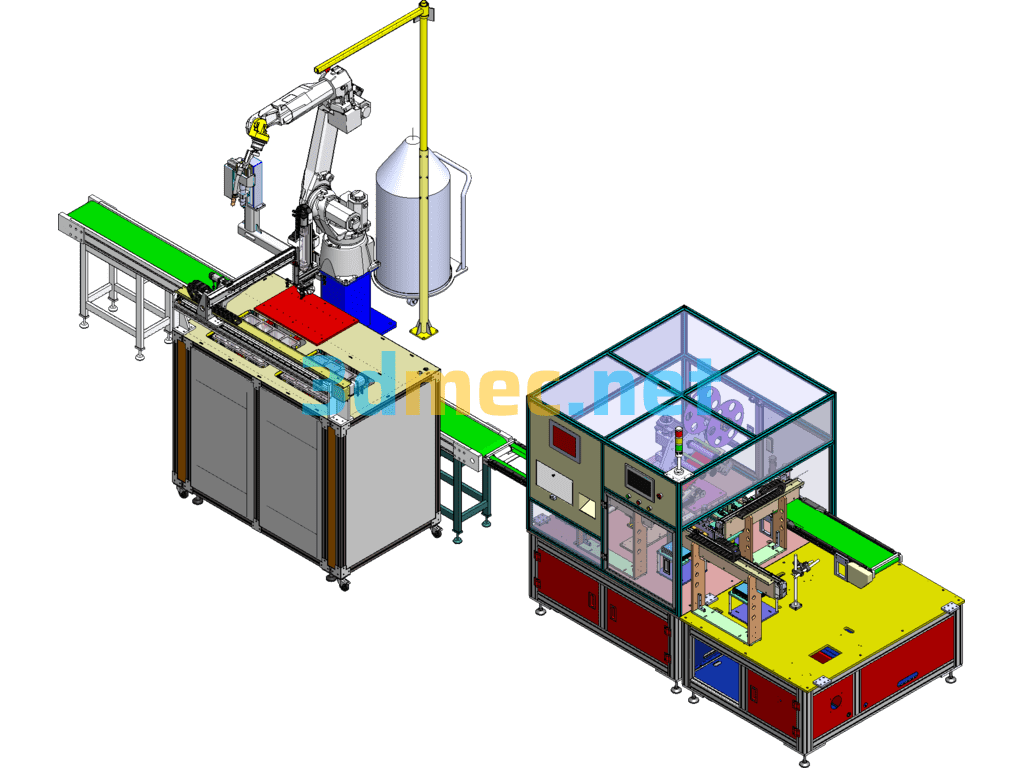

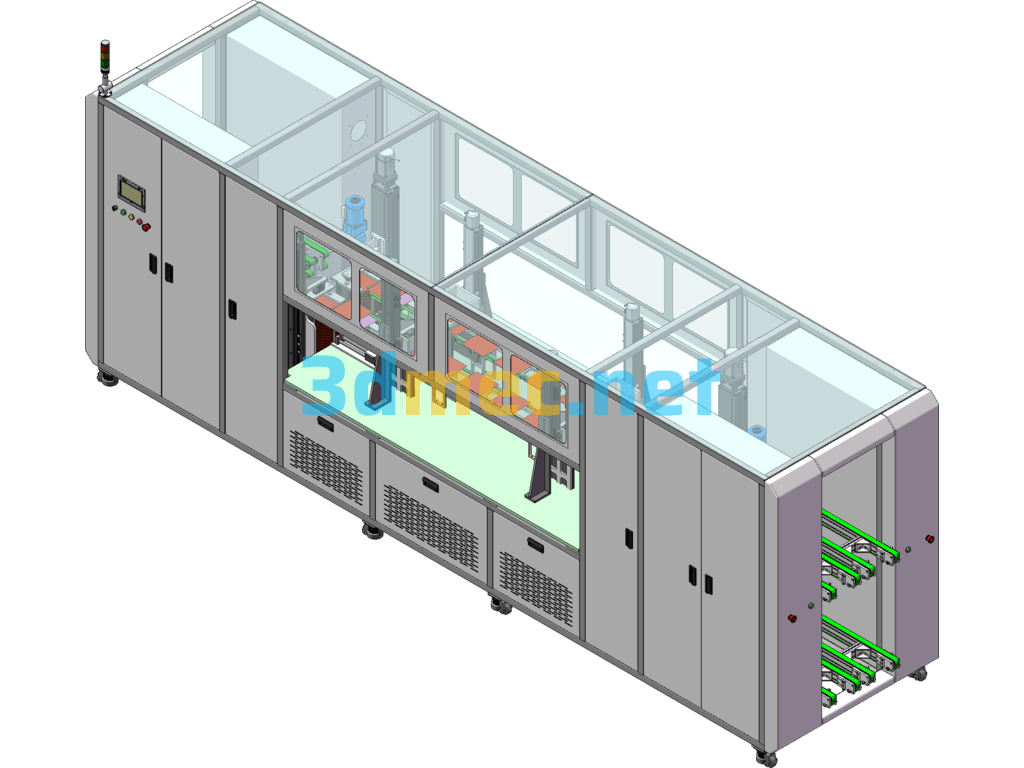

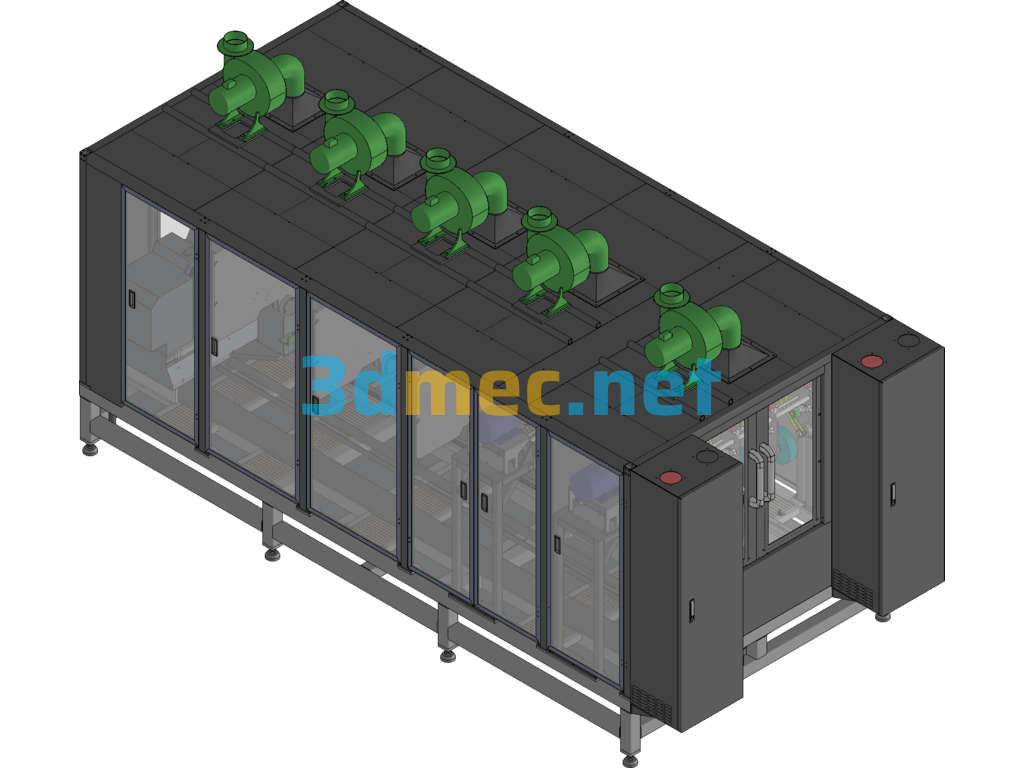

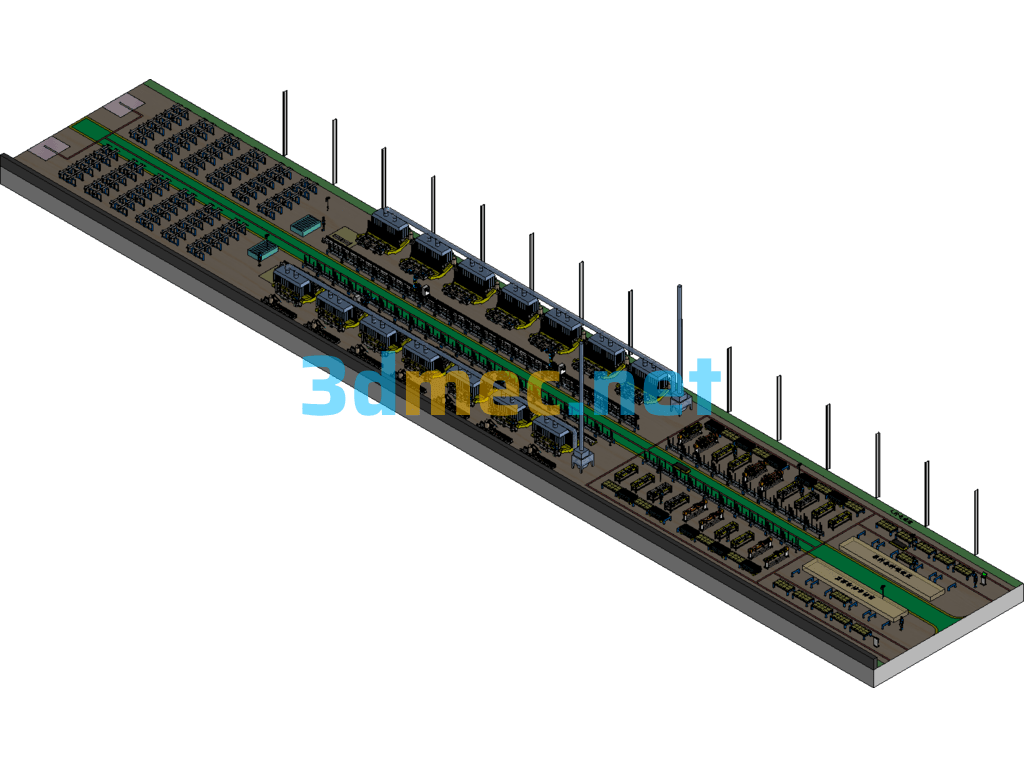

The fully automatic mask production line, also known as the one-to-three mask production line, consists of a mask body machine and three ear strap welding machines. It can produce 160-180 complete flat masks per minute. The mask specifications are: 175 X 95 mm three-layer non-woven flat filter mask. Compared with a single independent mask making machine, an automatic conveyor belt and connection port are added. This unique design not only improves production efficiency and reduces labor costs, but also minimizes manual participation and reduces the risk of masks being contaminated during the production process. risk.

This production line is a fully automatic one-to-three mask machine, with one main body machine driving three ear loop machines. After the main body machine outputs the mask body, the conveyor belt structure transports the mask body pieces to the flipping mechanism. The flipping mechanism flips the mask plate onto the conveyor belt connected to the ear-banding machine, and then transports the mask pieces to the ear-banding machine through the conveyor belt. Above the first mask disk on the front, the mask piece is finally placed into the mask disk of the ear strap machine through the downward pressure of the cylinder. Subsequently, the ear strap machine completes the ear strap welding, hemming and other actions of the mask, thereby completing an ear strap mask. Production of products.

Specification: One-To-Three Mask Production Line/Fully Automatic Flat Mask Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “One-To-Three Mask Production Line/Fully Automatic Flat Mask Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.