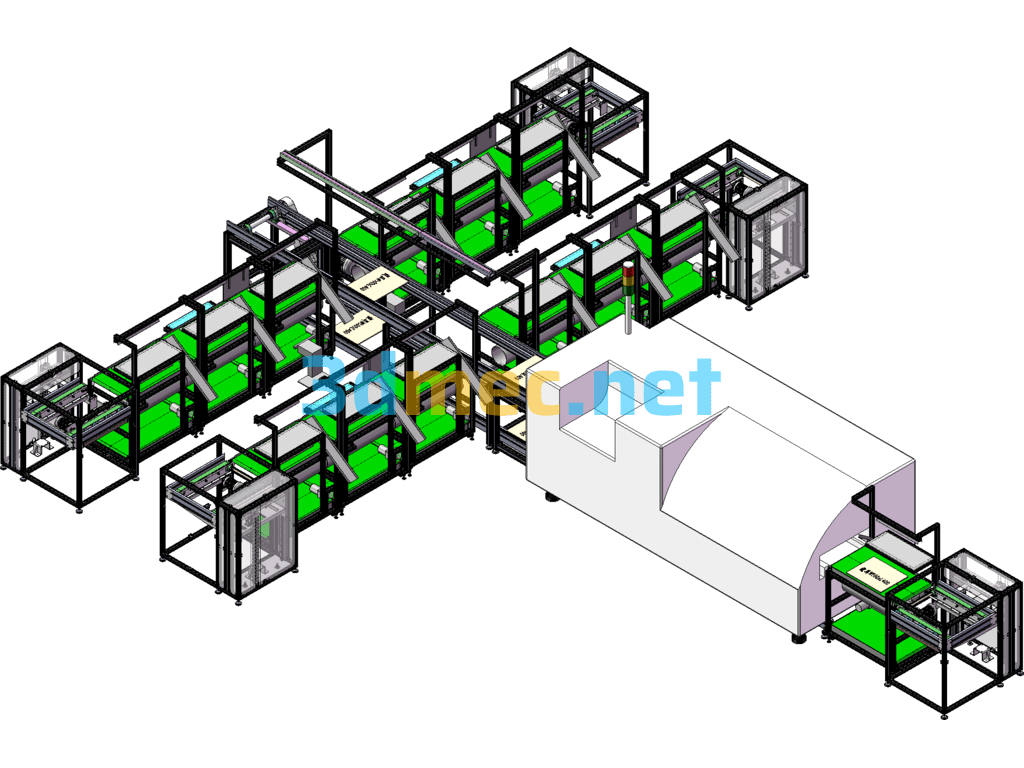

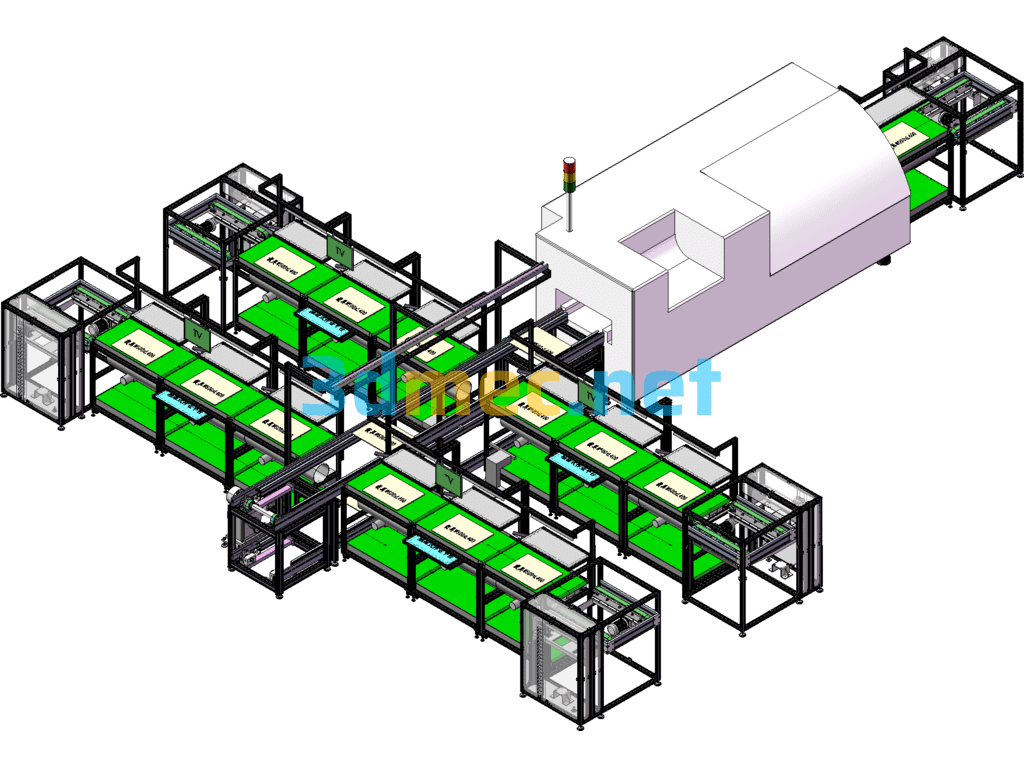

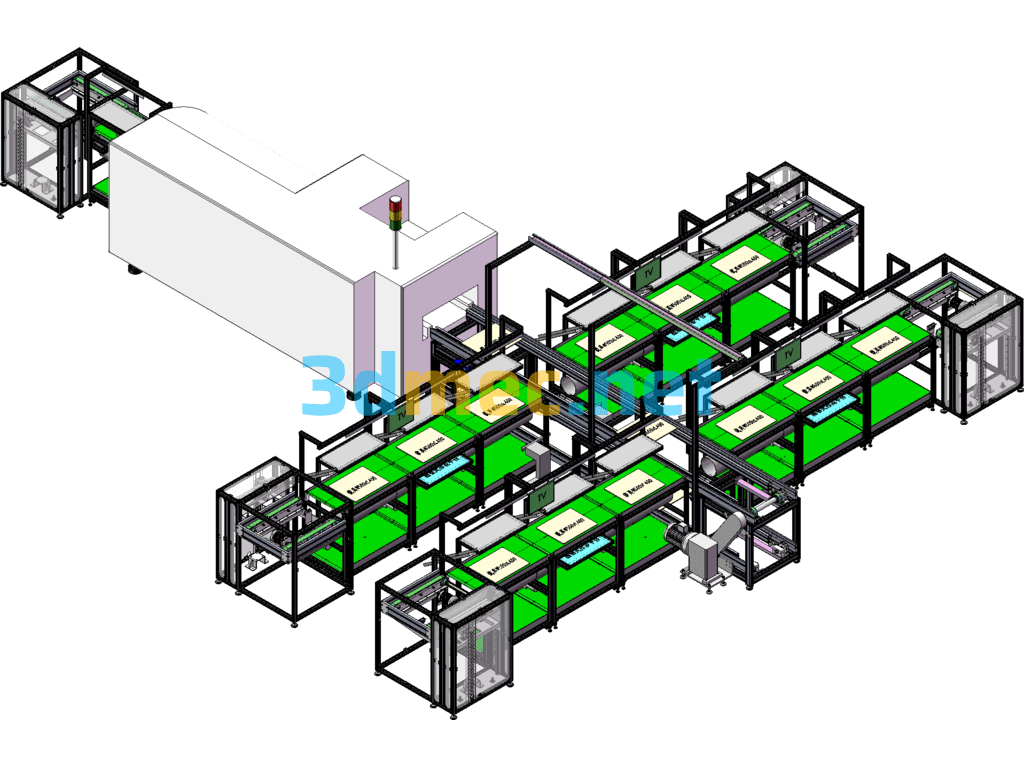

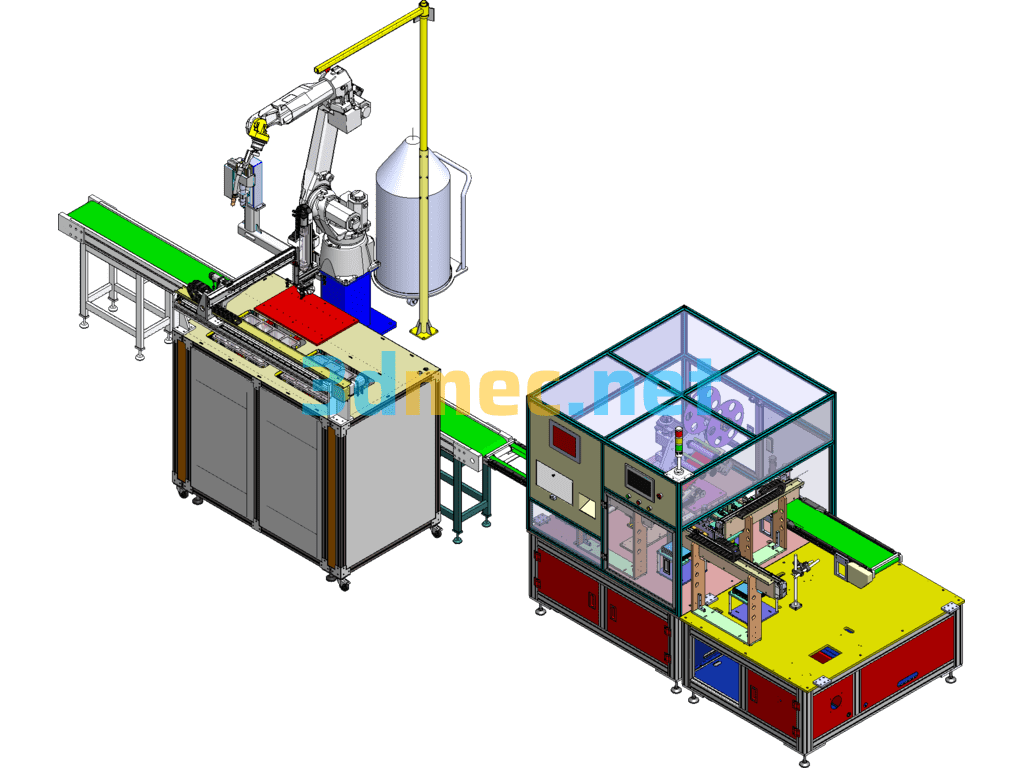

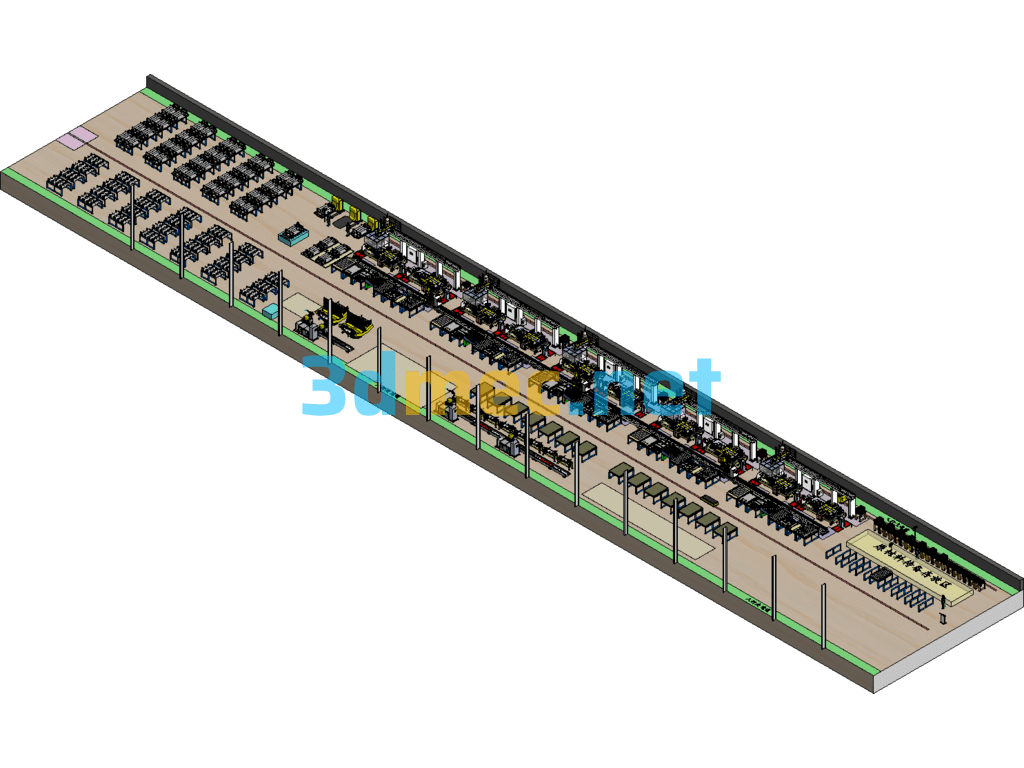

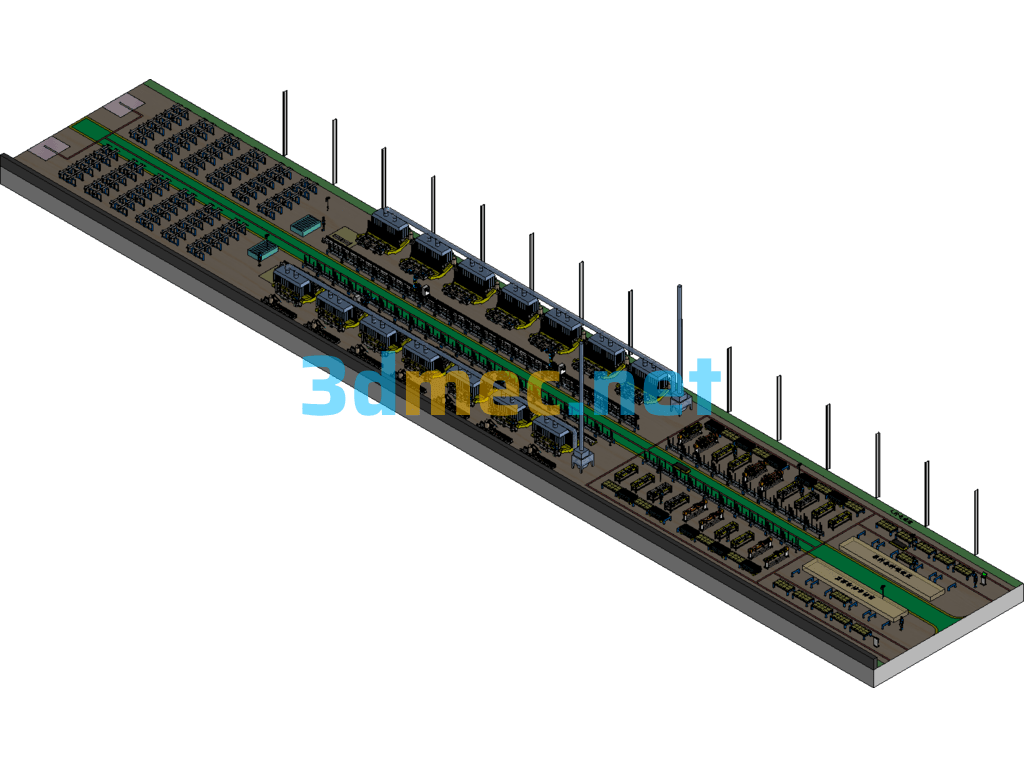

Plug-in welding production line

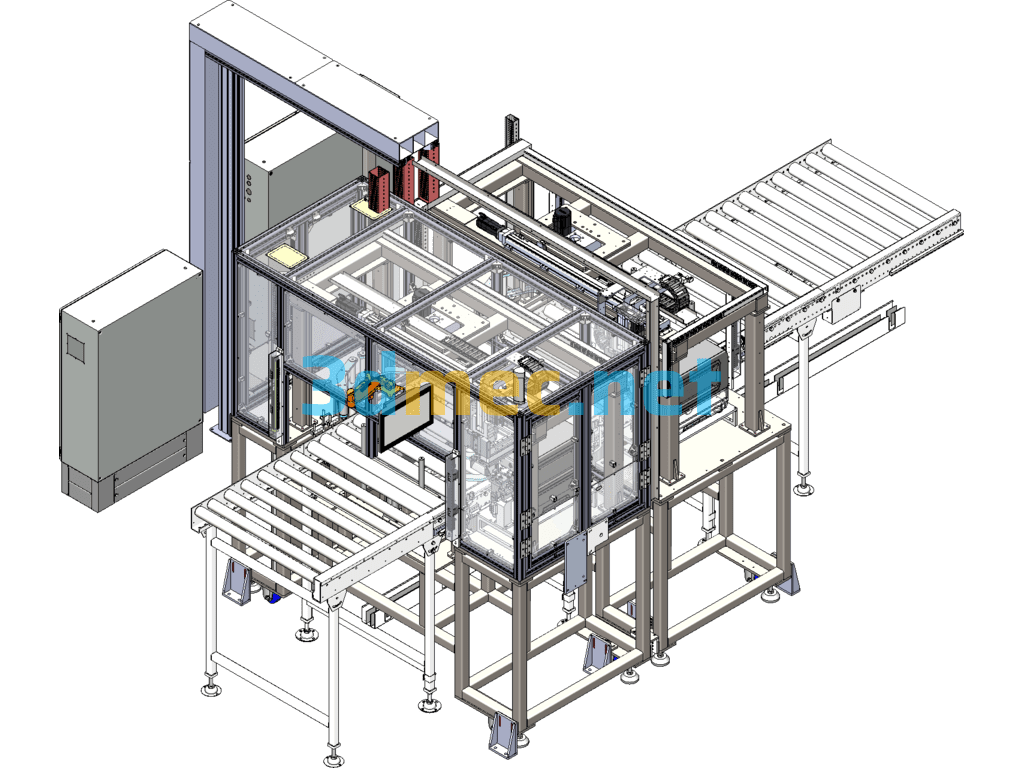

1.Using the tin furnace method, multiple PCBs of different styles can be passed through the furnace at the same time.

2.Using the up and down board type.

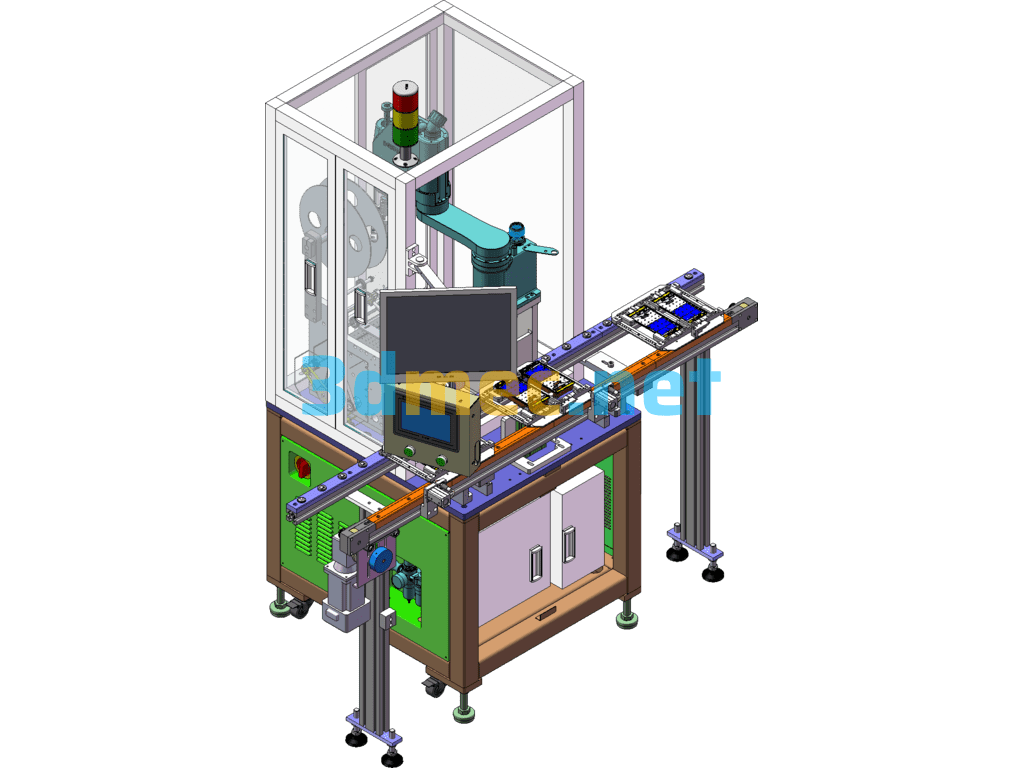

3.After the product is soldered, the fixture automatically returns to the corresponding position according to the barcode type when returning to the board.

4.There is no handling action after the plug-in is completed, and the plug-in direction is 90 degrees to the furnace direction.

5.The line body is modular, that is, each branch line can be combined at will without site restrictions.

6.The operating foot position has a fixture protection cover to prevent the fixture from being damaged.

7.The plug-in material rack adopts a double-layer design, and the plug-in material box has a recycling function.

8.The lighting adopts an integral lampshade type lighting.

9.Add an exhaust duct and integrate it into the line body, and use a splicable duct.

10. One of the workbenches in each plug-in line has a concealed work surface, which can realize the dual functions of plug-in/tinning.

11. Each plug-in station has a display to show the indicator card.

Specification: Selective Soldering Production Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “Selective Soldering Production Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.