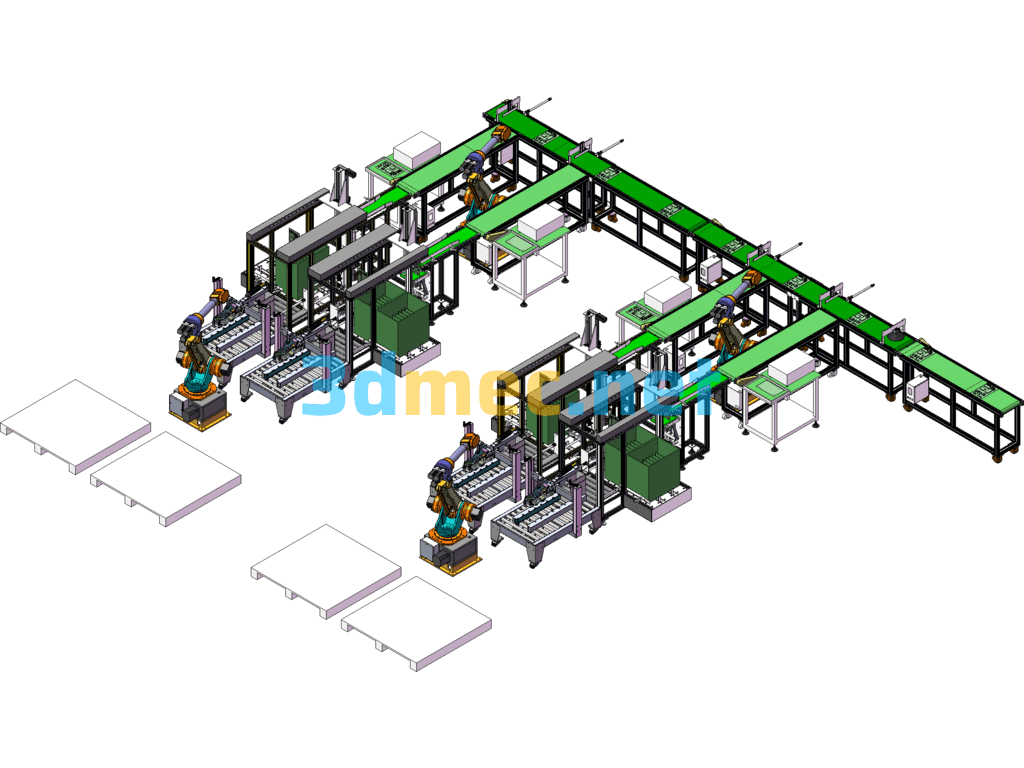

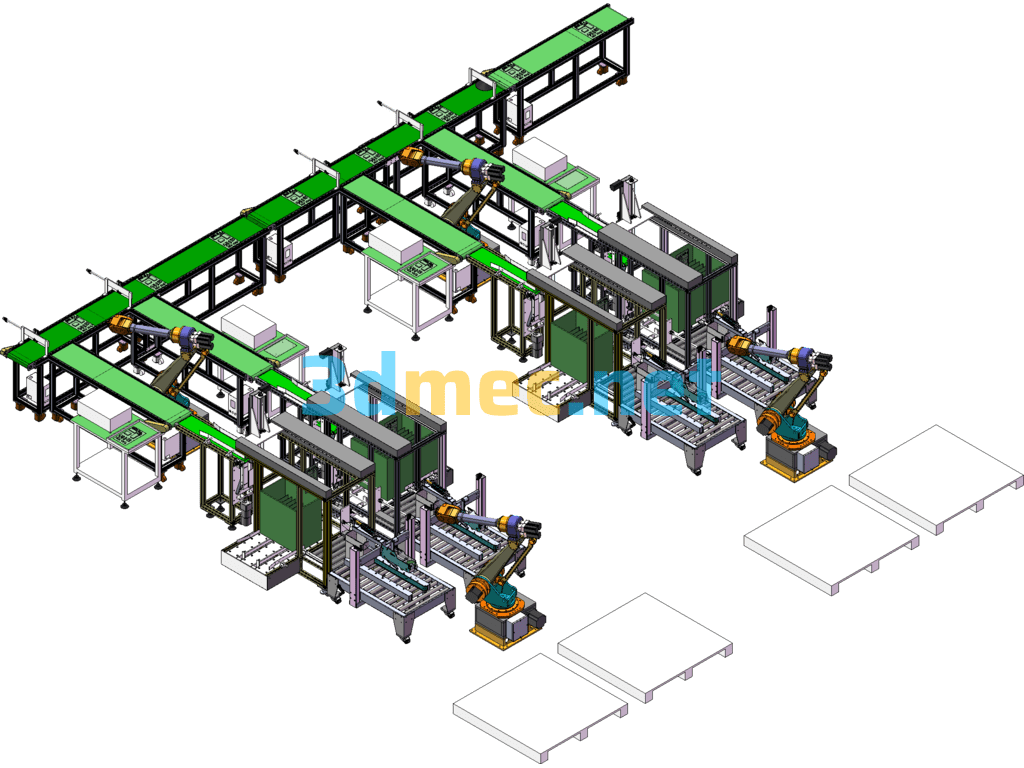

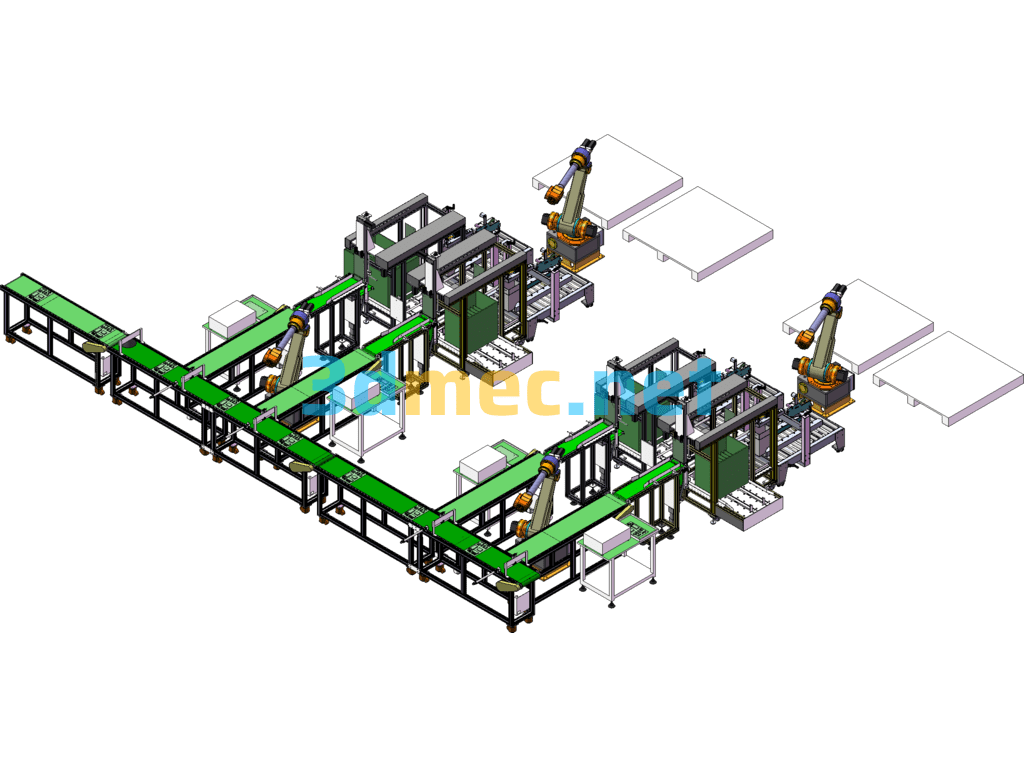

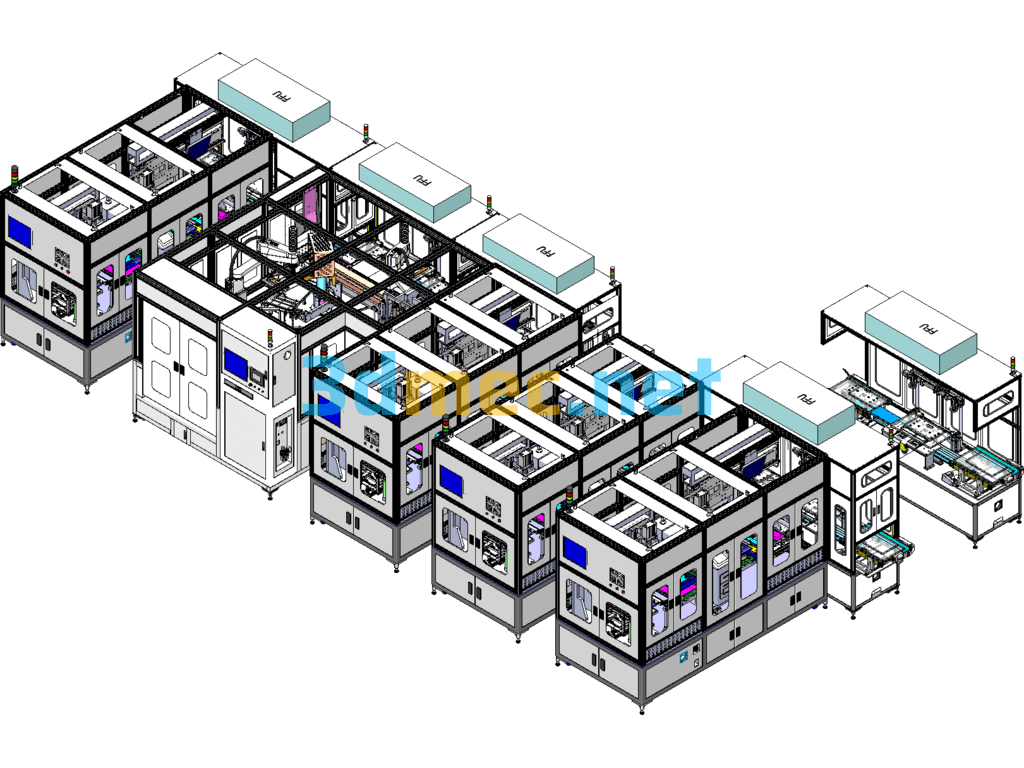

Automatic packaging line

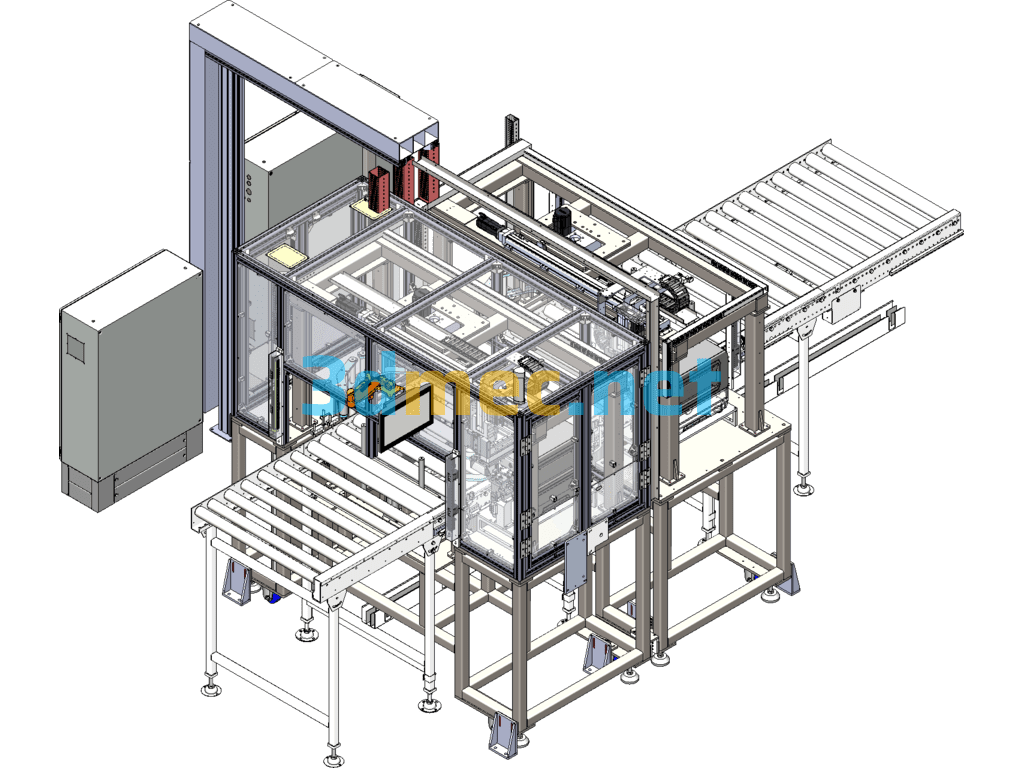

1. PCB boards are placed manually and evenly placed; CCD camera recognition is used to reach the designated material distribution position and enter the small line body; then the robot arm is clamped for inspection. After the inspection is completed, NG products are placed in the box and manually processed. OK products are placed on the flip line body for flipping operation; after flipping, they are clamped by the cylinder and transported to the packing position and placed in cartons in turn; after packing, the packaging machine is used to specify the packaging and sealing; finally, the robot arm classifies and stacks the packed cartons on the pallet.

2. The use of six-axis manipulators has greatly improved work efficiency, and the compact structure saves space.

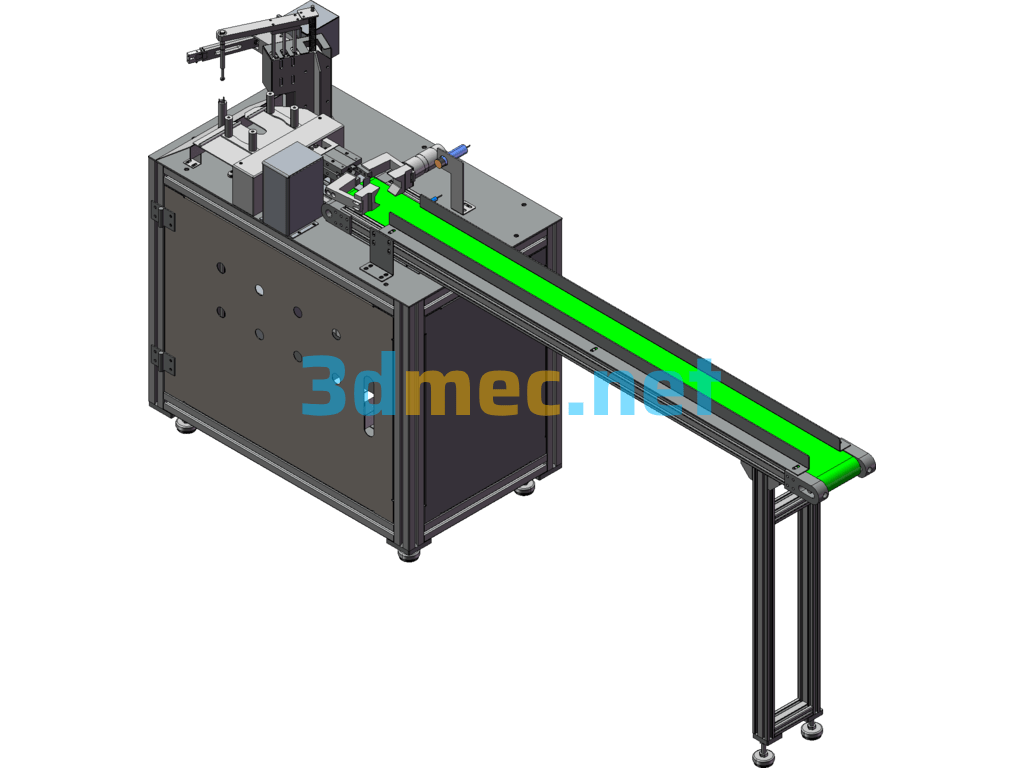

After the PCB board is flipped 90°, it is clamped by the material-taking claws, and the PCB board is taken out from the flipping line and transported horizontally to the packing position. Before packing, the opening module opens the knife card, and then the opening module is removed and the board is inserted; 1-2 packaging boxes can be placed on the sliding platform. The packaging box is first blocked by the middle blocking cylinder, and the first row of PCB boards is inserted. Then the middle blocking cylinder descends, and the motor pushes the packaging box to the rear limit block position to install the second row of PCB boards. After insertion, the box pushing cylinder pushes the full packaging box to the roller conveyor line to send the packaging box out for the next packaging process.

Specification: Automatic Packaging Line – Packaging, Sorting And Stacking Equipment Line – 3D Model SolidWorks

|

User Reviews

Be the first to review “Automatic Packaging Line – Packaging, Sorting And Stacking Equipment Line – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.