Brief introduction to working principle

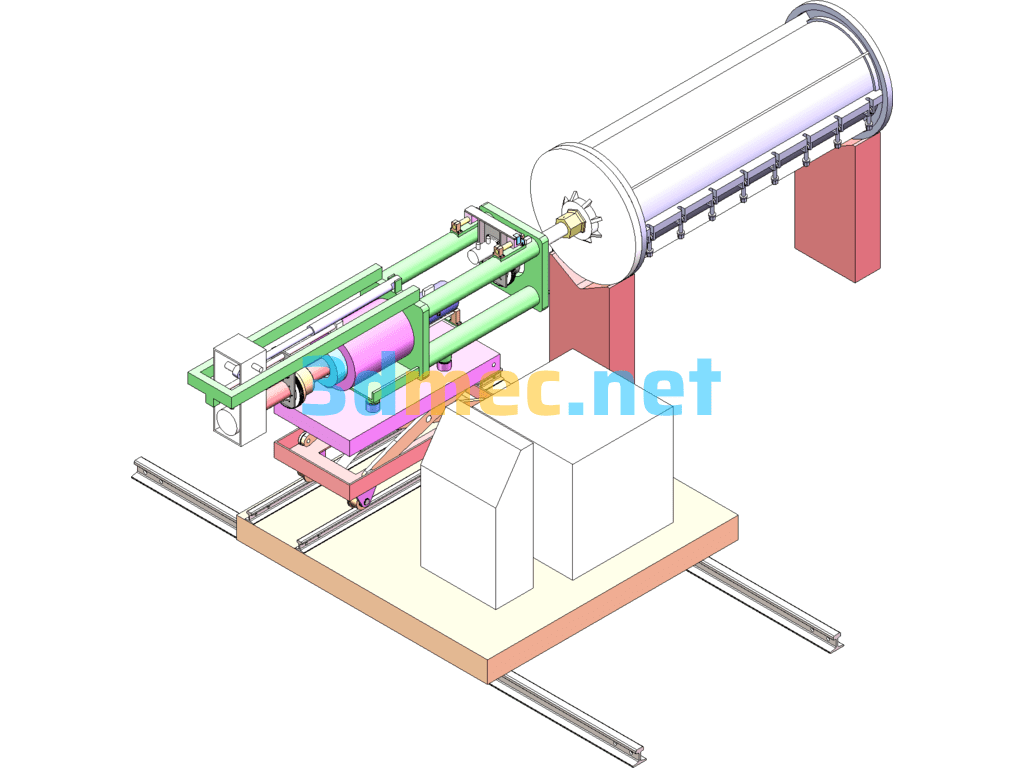

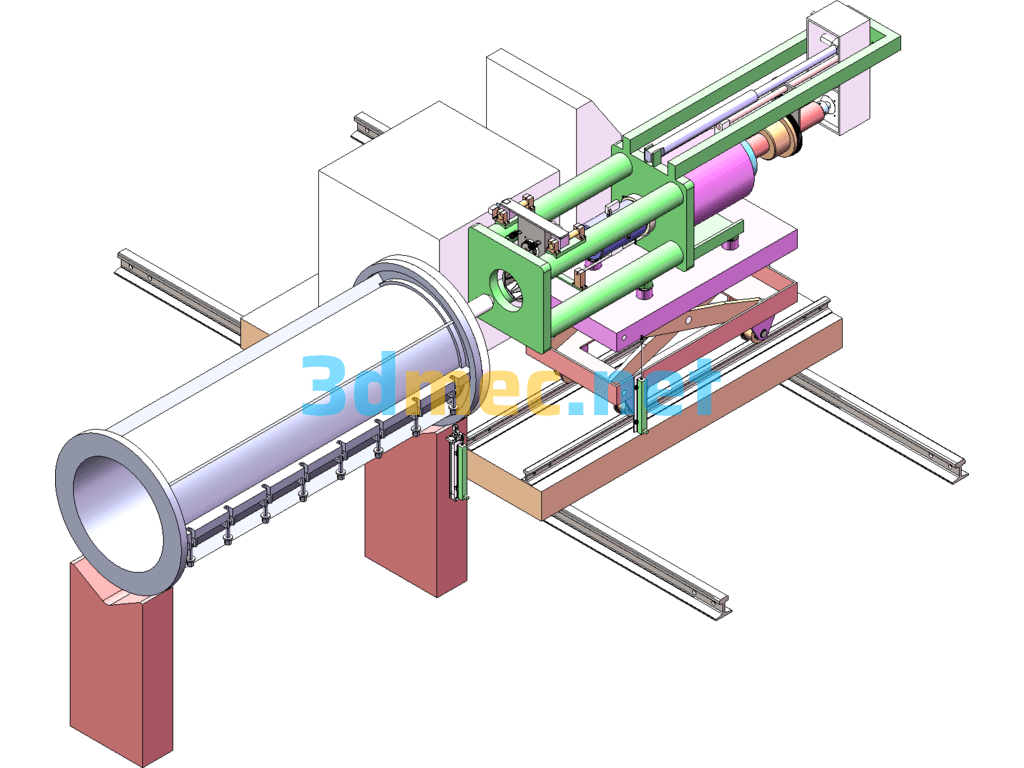

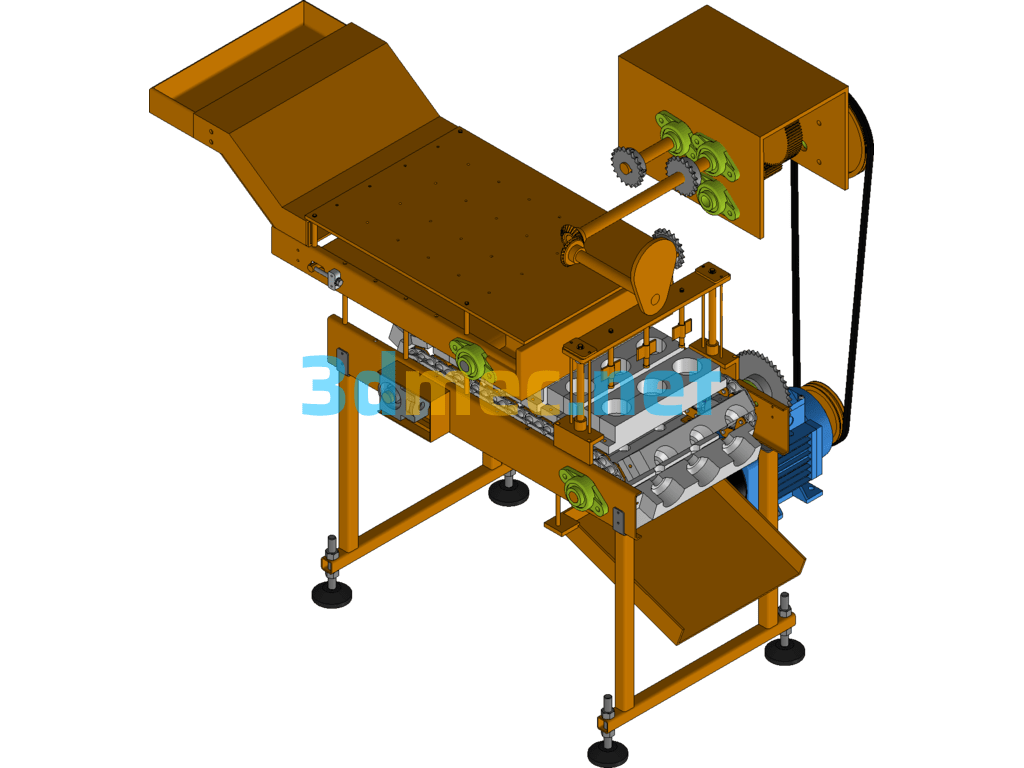

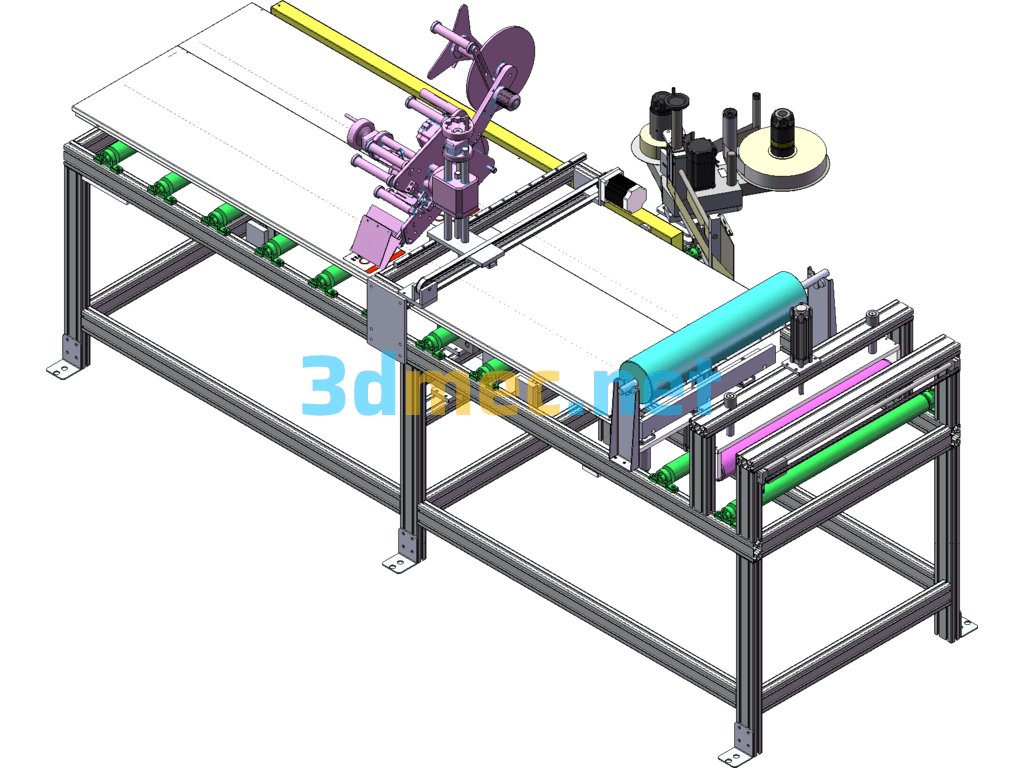

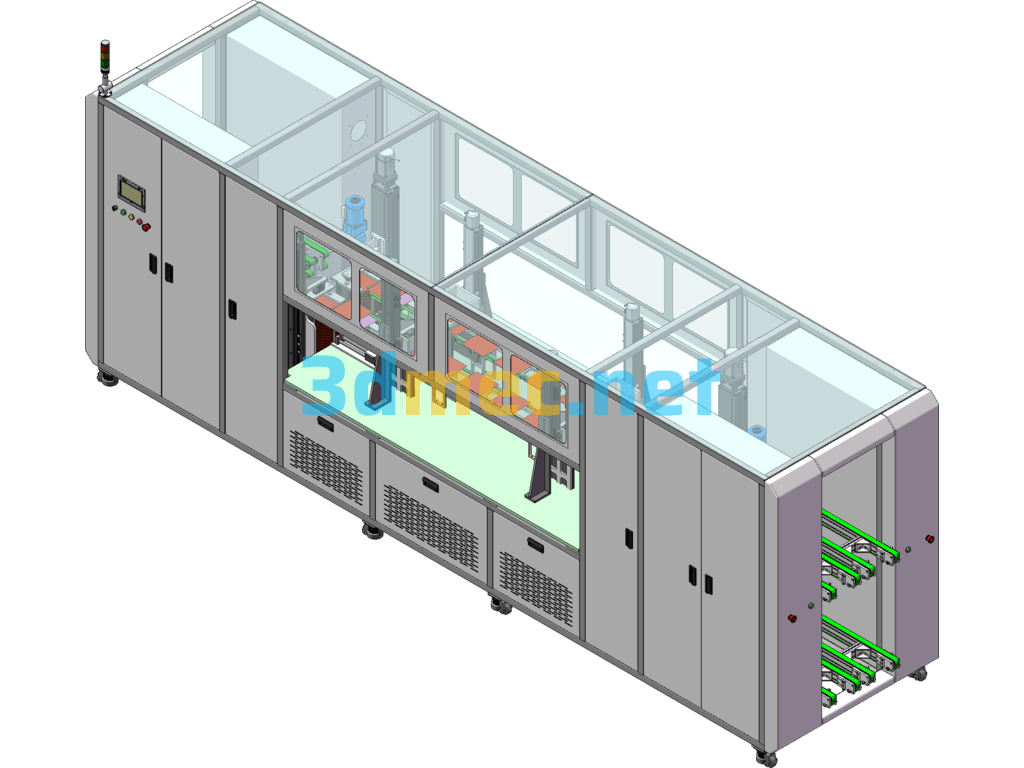

The horizontal prestressed pipe pile automatic tensioning machine includes a pipe pile mold assembly, a tensioning device and a three-dimensional mobile platform, a pipe diameter detection device, a displacement sensor device, and the tensioning device includes a docking locking device, a tightening locking device, a jack hydraulic cylinder and a nut locking device. The three-dimensional mobile platform adjusts the alignment of the tensioning device and the pipe pile mold assembly by moving in the three directions of X, Y and Z. The tensioning screw of the pipe pile mold head plate is docked with the docking locking device, and it is tightened with the hydraulic cylinder body through the tightening nut device. The pipe pile mold is tensioned through the tensioning device and the locking nut is locked through the nut locking device. The pipe diameter of the pipe pile mold is detected by the pipe diameter detection device, and the lifting value of the three-dimensional mobile platform is detected by the displacement sensor device.

1-Pile mold assembly, 101-Pile mold, 102-Head plate, 103-Locking nut, 104-Head plate tensioning screw, 105-Transport support, 2-Tensioning device, 201-Docking locking device, 20101-Docking nut, 20102-Limit switch, 20103-Docking nut stop rod, 20104-Docking motor, 20105-Docking bracket, 20106-Docking guide rail, 20107-Pull rod auxiliary hydraulic cylinder, 20108-Tightening nut limit guide rod, 20109-Tail guide rod bracket, 20110-Light rod guide rail, 20111-Light rod guide rail support, 20112-Slip ring, 20113-Slip ring bracket, 20114-Displacement sensor, 20115-Coupling, 20116-Travel switch, 20117- Travel switch bracket, 202-tightening locking device, 20201-tightening motor, 20202-tightening support plate, 20203-transmission gear, 20204-turntable bearing, 20205-tightening nut, 20206-driven gear, 203-jack hydraulic cylinder, 20301-jack pull rod, 20302-piston rod, 20303-cylinder body, 204-nut locking device, 20401-turntable bearing, 20402-locking head, 20403-conical tooth line, 20404-transmission gear, 20405-passive tension spring, 20406-locking base, 20407-locking switch bracket, 20408-locking switch, 20409-locking switch block, 20410-cylindrical guide support, 20411-cylindrical guide, 20412-linear cylindrical slider, 20413-locking motor, 20414-driven gear, 205-tensioning bracket, 2051-front plate, 2052-rear plate, 2053-support rod, 3-three-dimensional mobile platform, 301-control console, 302-hydraulic station, 303-lifting trolley, 304- Mobile base slide rail, 305-mobile base, 306-ground slide rail, 30301-steel wheel, 30302-steel wheel support, 30303-lifting trolley base, 30304-cross bracket, 30305-lifting hydraulic cylinder, 30306-center support shaft, 30307-lifting trolley top plate, 30308-buffer spring, 30309-bracket, 4-pipe diameter detection device, 401-top pulley, 402-displacement sensor touch rod, 403-pipe diameter detection sleeve, 404-displacement sensor, 405-sensor fixing card, 406-slide rod, 5-linear displacement sensor.

Specification: Horizontal Prestressed Pipe Pile Automatic Tensioning Machine – 3D Model SolidWorks

|

User Reviews

Be the first to review “Horizontal Prestressed Pipe Pile Automatic Tensioning Machine – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.