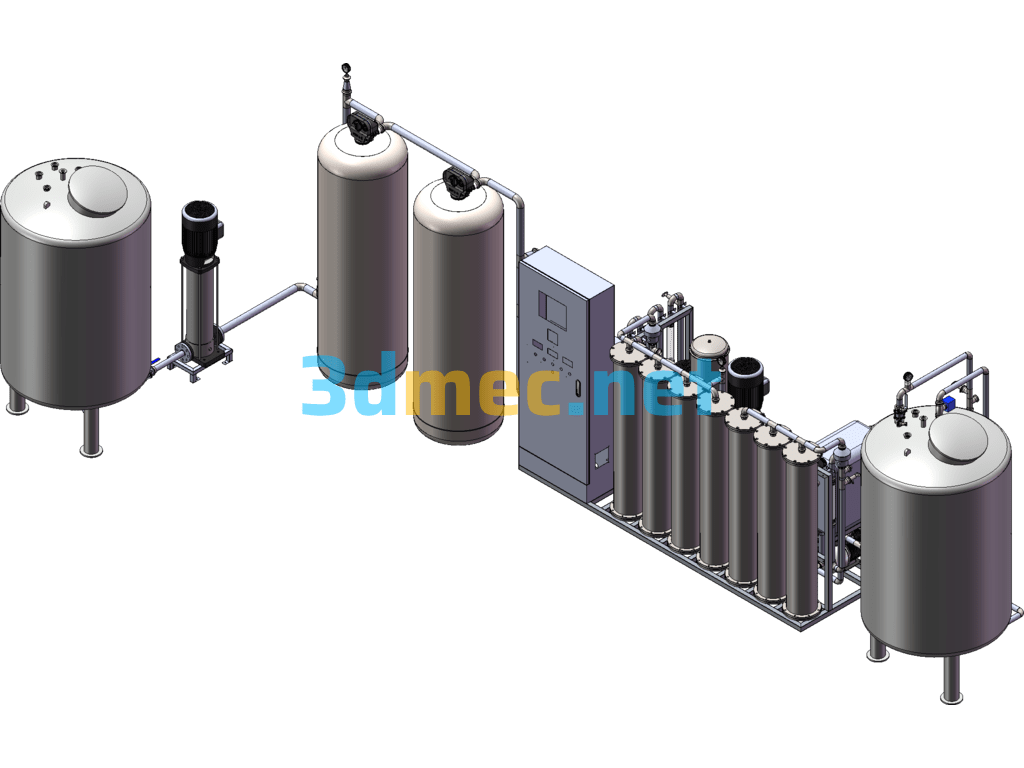

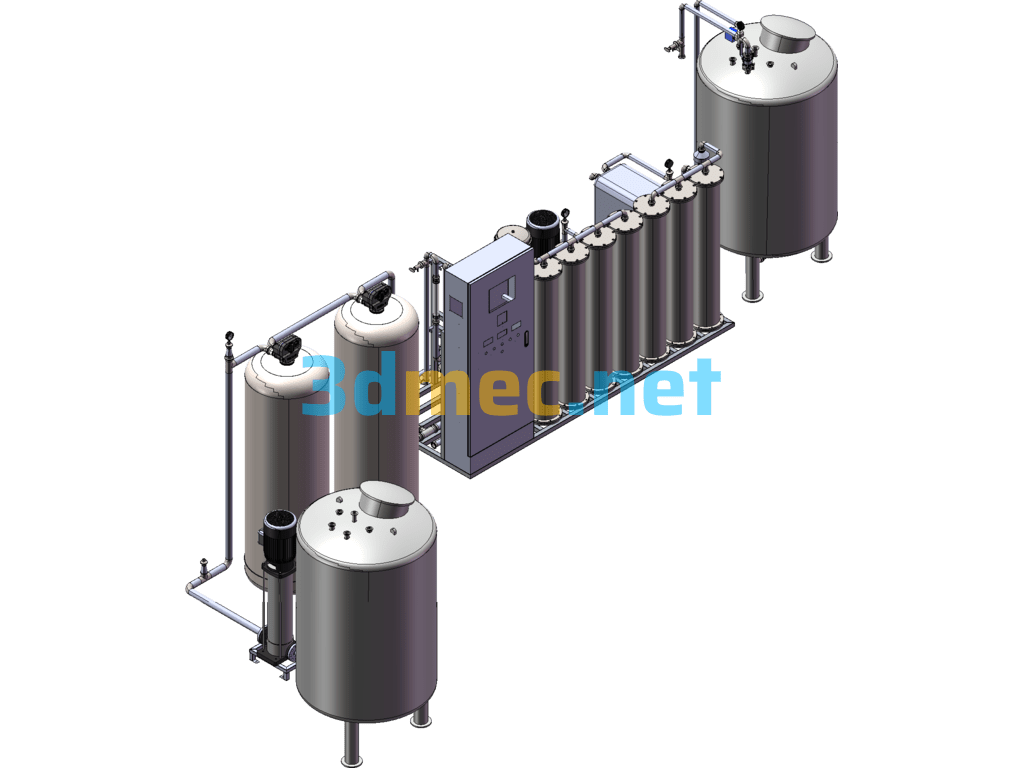

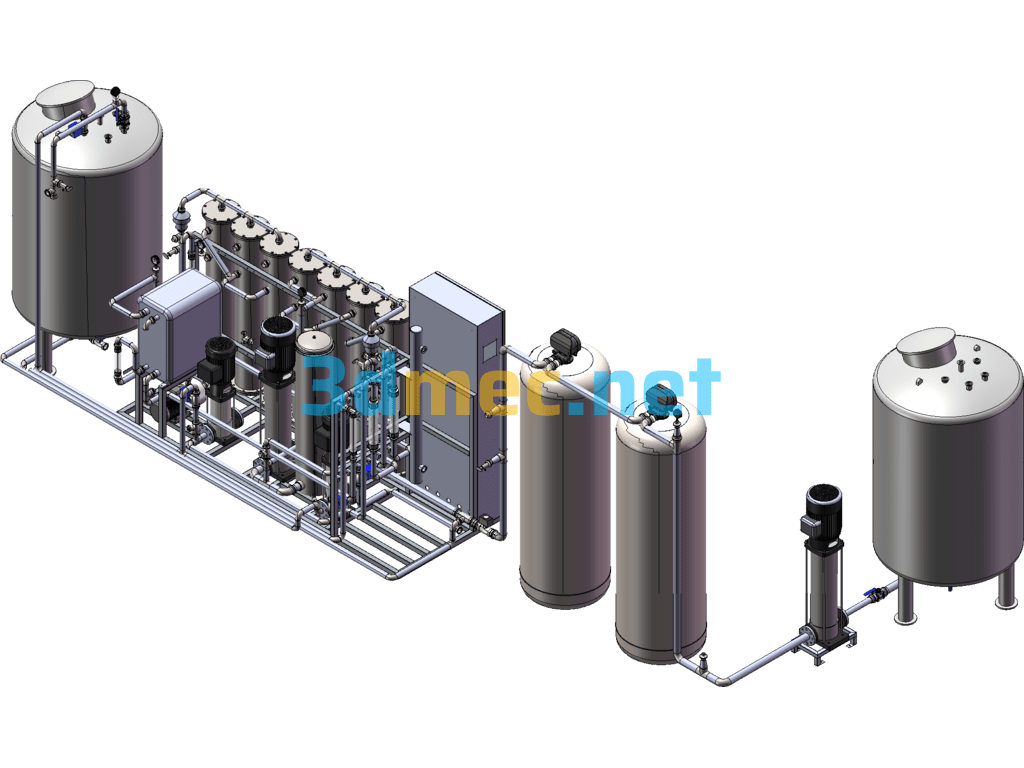

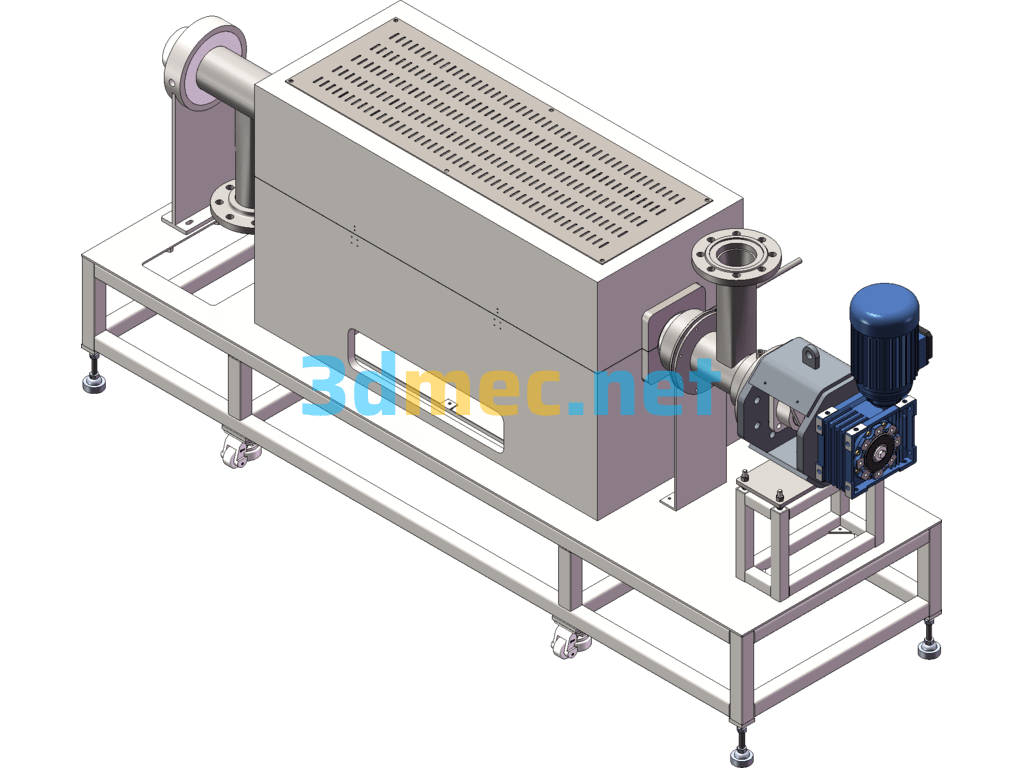

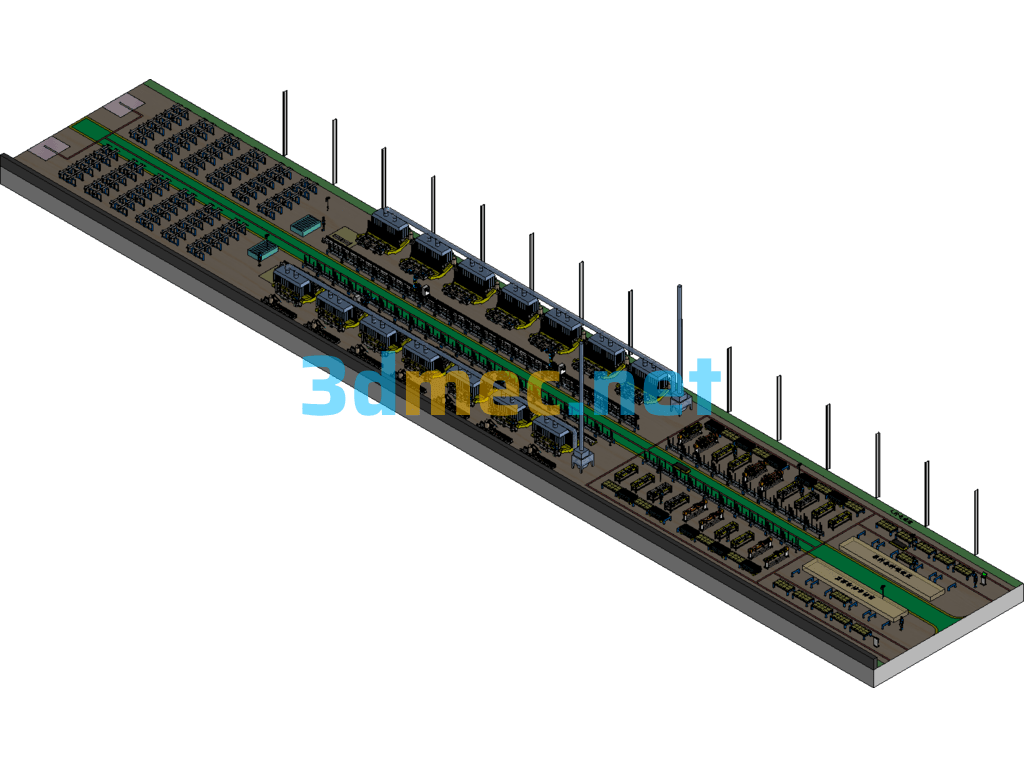

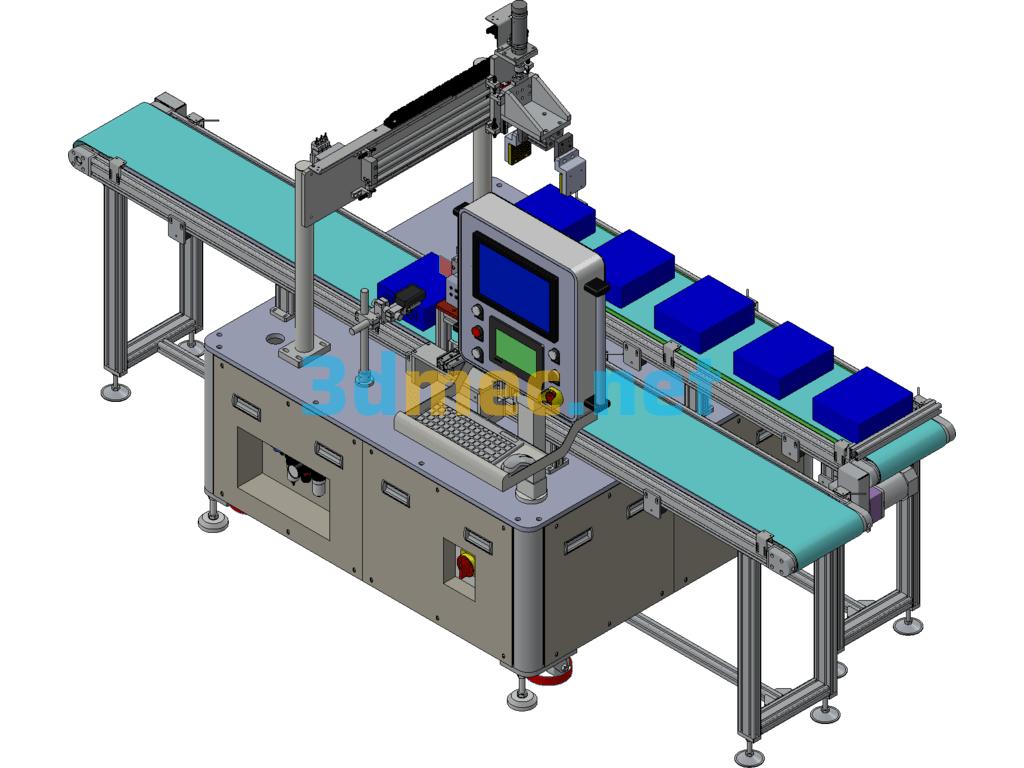

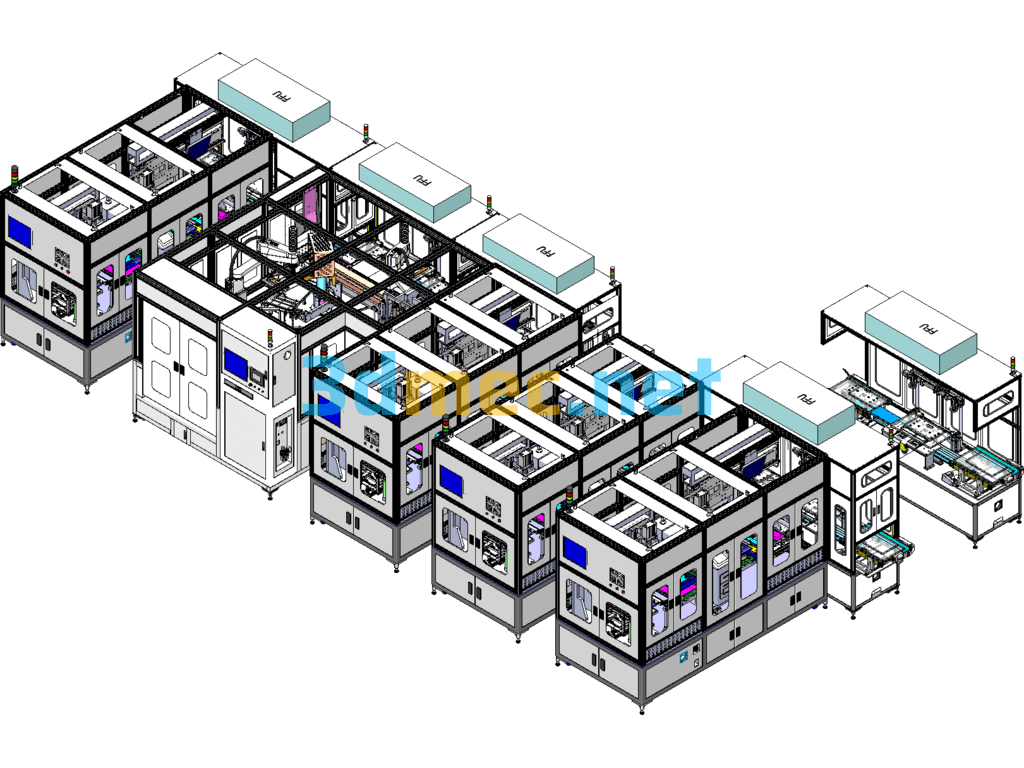

4000 Pure Water Preparation Water Treatment Equipment – 3D Model SolidWorks

The RO-I+MB pure water preparation system consists of pretreatment, reverse osmosis desalination, ion exchange and fine treatment. The system is designed according to the requirements of the water treatment system in the GMP specification of the pharmaceutical industry and is now widely used in the pharmaceutical industry.

The pretreatment part of the system is mainly composed of metered dosing, multi-media filter, activated carbon adsorber (or softener), and fine filtration. In general, because surface water contains residual chlorine, activated carbon is used to adsorb and remove it to protect the reverse osmosis membrane from oxidation; groundwater is generally hard, so a softener is used to soften it to prevent the deposition of CaCO3 and CaSO4 on the concentrated water side of the membrane. Because the surface water source has a high turbidity, 5μ and 1μ two fine filtrations are used for treatment.

The reverse osmosis part uses low-pressure and ultra-low-pressure large-flux composite membranes, and is equipped with stainless steel multi-stage pumps. The desalination rate of the device reaches ≥97~98% of the international advanced level of the same period, and can remove most of the organic matter, bacteria and pyrogenic substances in the water.

For the ion exchange part, the surface water source has a low salt content. After 97~98% of the ions are removed by reverse osmosis, there are not many ions left, so only a mixed bed is used. If the salt content of the groundwater source is below 500PPM, a mixed bed can also be used. If it is above 500PPM, it is recommended to use cation, anion, and mixed processes. For water sources with higher HCO3-, in order to extend the service life of the anion bed, a degassing tower device can be considered.

For the fine treatment part, ultraviolet sterilization and 0.22μ microporous membrane filtration are generally used. The original imported ultraviolet sterilizer is used to ensure the sterilization effect.

RO-II type two-stage reverse osmosis system is an advanced treatment process. It is based on the reverse osmosis effluent and then enters the reverse osmosis again. When the inlet water is ≤500PPM, the conductivity of the secondary reverse osmosis effluent can be ≤2μs·cm-1, which meets the water requirements of the pharmaceutical industry. The biggest advantage of this process is that it completely eliminates the acid and alkali treatment in the ion exchange regeneration process. The disadvantage is that the one-time investment is relatively high. Therefore, this process is more suitable for users such as hospitals and high-tech enterprises that require no waste acid and alkali discharge.

Specification: 4000 Pure Water Preparation Water Treatment Equipment – 3D Model SolidWorks

|

User Reviews

Be the first to review “4000 Pure Water Preparation Water Treatment Equipment – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.