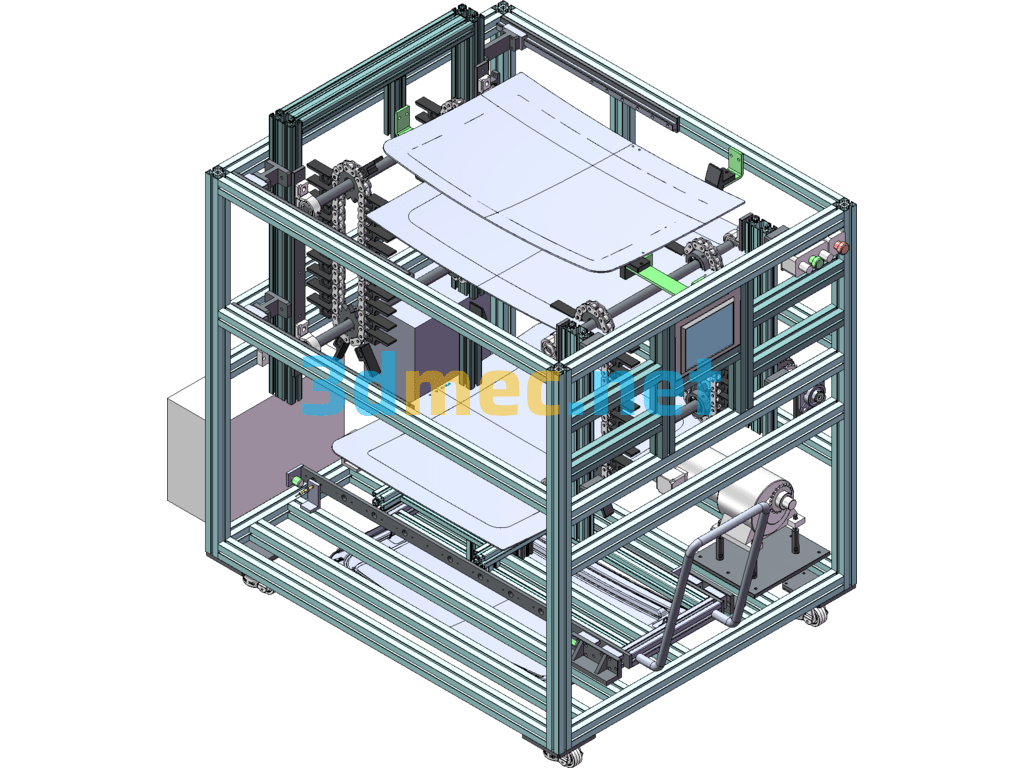

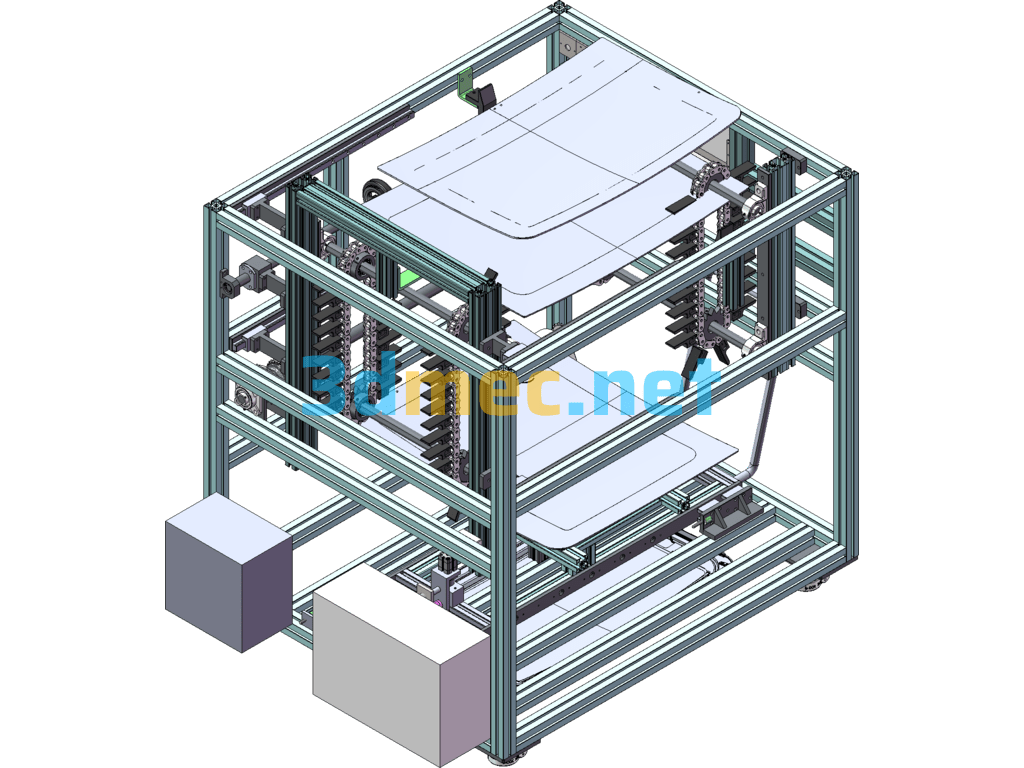

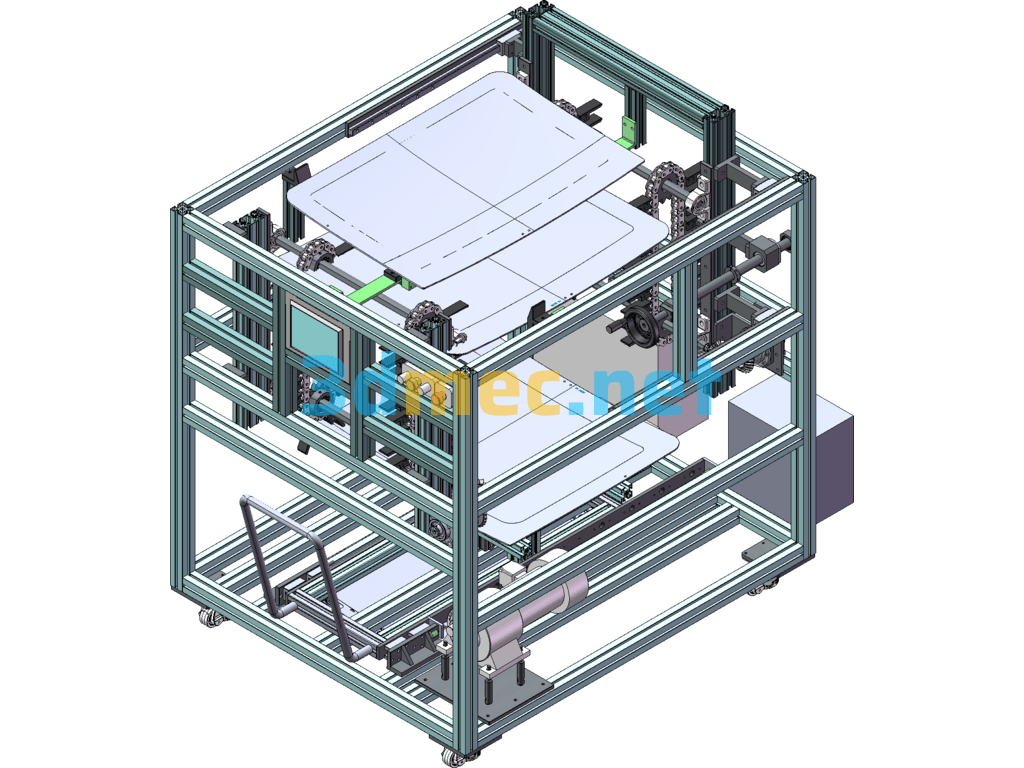

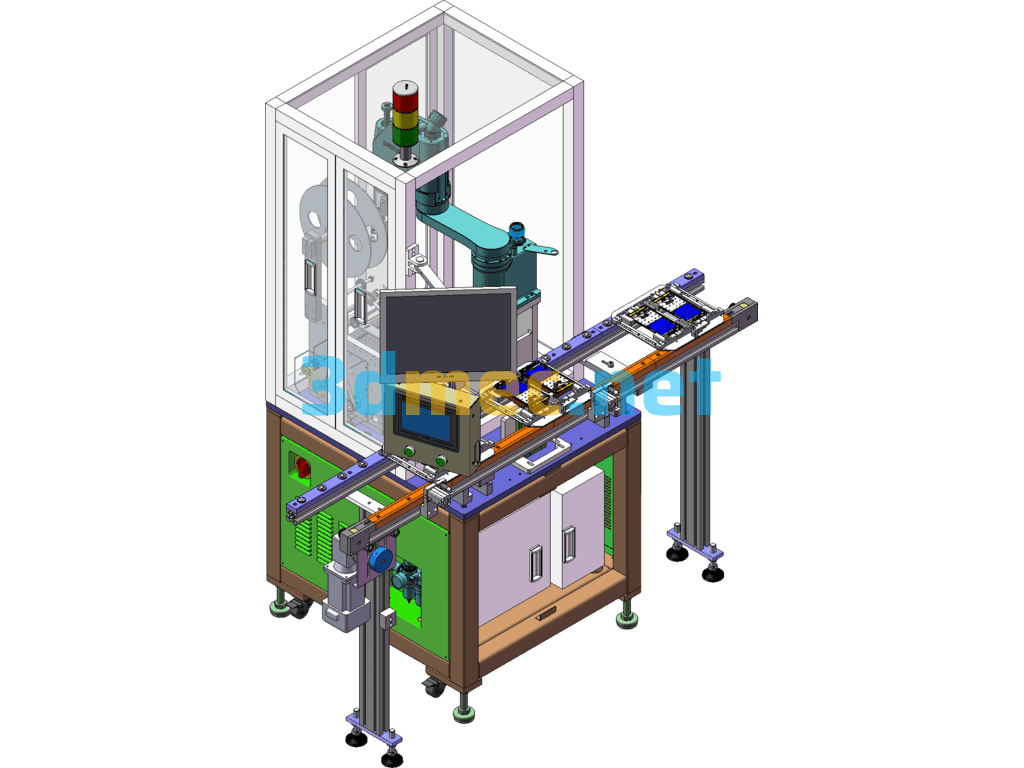

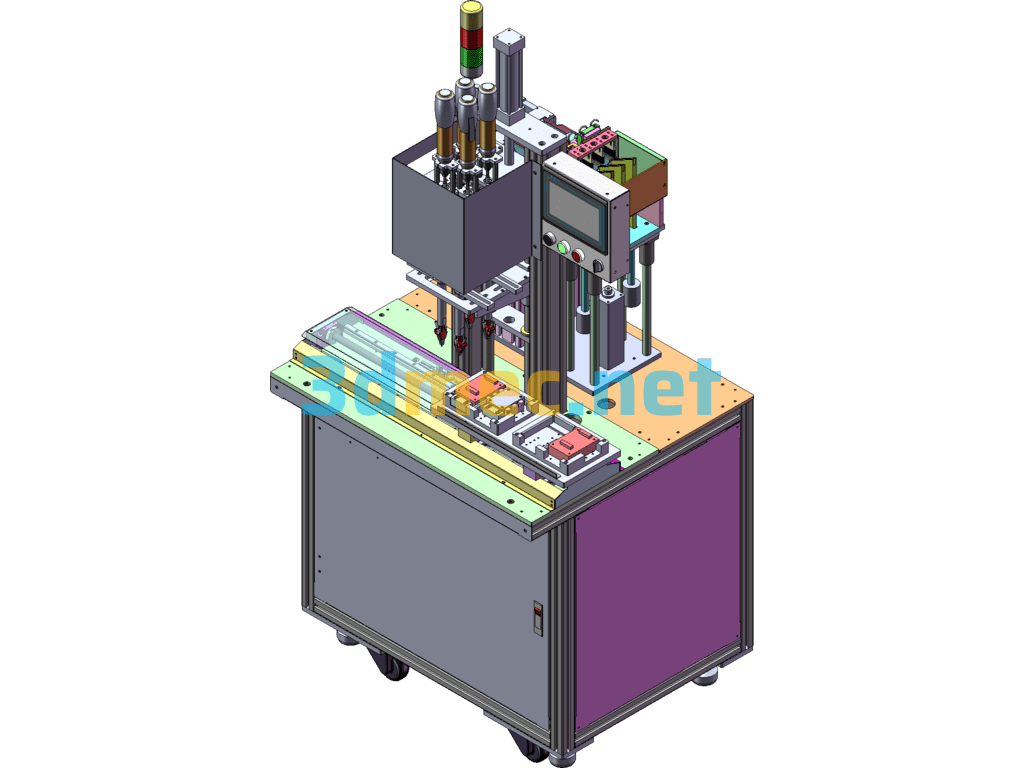

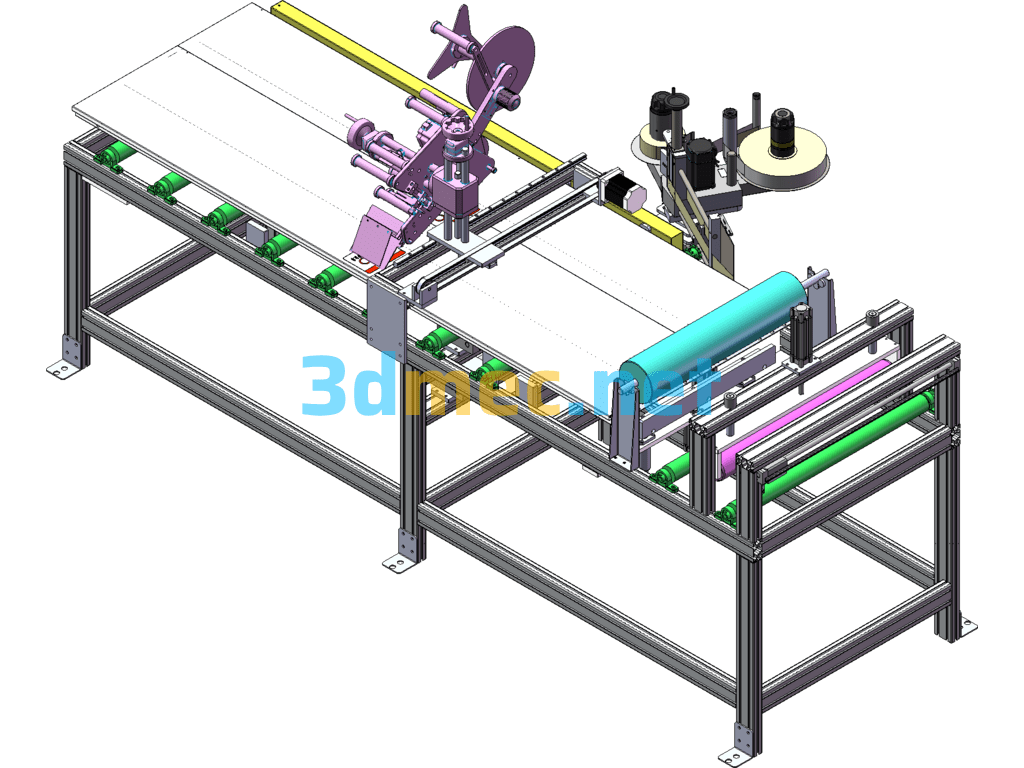

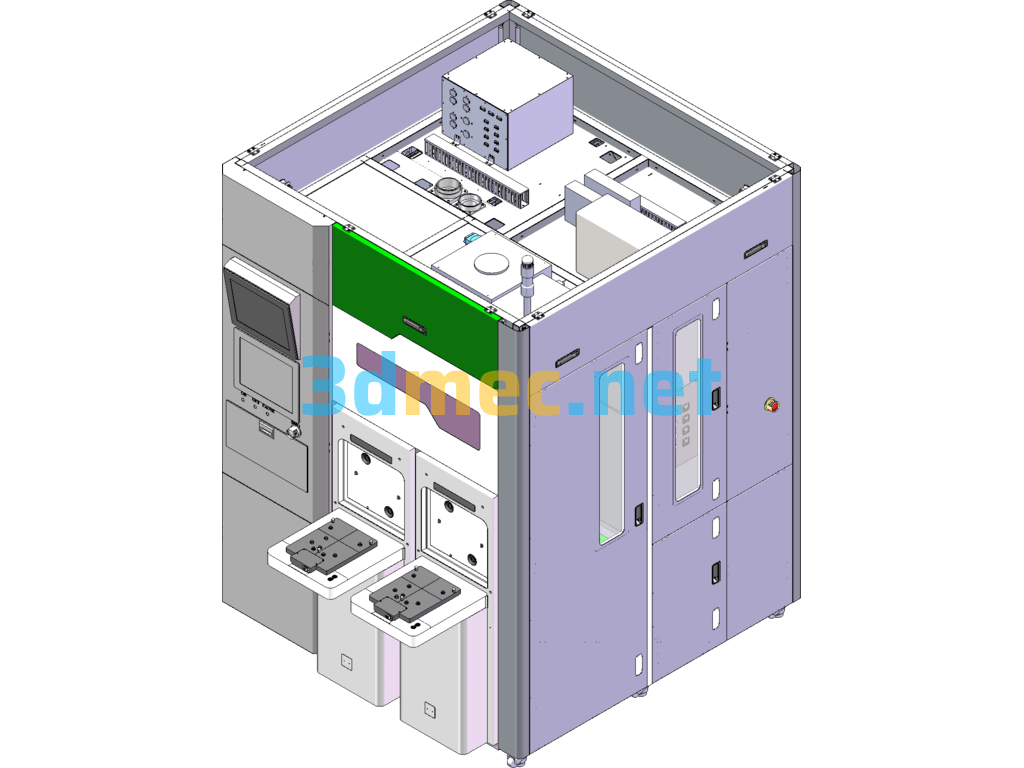

Function: Carrying primed glass, one-way drive in set time, easy to place and take out the glass, with exhaust/extraction interface n Error-proof function: 20min minimum drying time, first-in-first-out n Number of operators: 1 person n Continuous use time:24H/dayn Total cycle time:< 25 secn Manual operation time:< 25 secn Product switching tooling adjustment time:< 1 min (width adjustment, glass support position adjustment)n Noise level: 70dB or less from the noise generator to 1m awayn Technical description of structural components n - The material frame is made of 50*50 doctoral aluminum profile, external dimensions: W1500 × D1100 × H1500mm (maximum glass 800 × 1000). - The back side, left and right sides and front side of the table are equipped with plexiglass sealing boards; - The effective number of layers for glass drying is 12, with a spacing of 35~50mm, and the weight of the chain must not be less than 80kg (calculated according to the weight of the glass). - The support of the glass is made of black nylon (flat) and black felt wool is applied to avoid scratching of the glass. The support length is 65mm. - Conveyor pallet: The pallet frame is I-shaped (350X450), with cylinders installed on the lower side (with adjustable running speed) for front and back transportation of glass. 4 suction cups (FESTO brand, Φ80) are installed on the pallet, and the position can be adjusted manually. When the button is pressed manually, the conveyor frame extends with a piece of glass, the glass extends and the lifting device is activated to lift up the glass (the height is not lower than 600), then tilts it inward (about 30 degrees), the lifting device automatically drops and retracts after the glass is taken away and the chain drops down by one frame; - the left side of the chain is fixed and the right side is adjustable with an adjustable range of 300mm; - The control display is mounted in the upper left corner of the front side (the top is mounted on the profile), with a Plexiglas shield outside the screen. - Transmission mechanism. It is composed of inverter + transmission motor + reducer. - The cable between the cabinet and the outside world is connected with a quick connector, and the control cabinet is placed at the bottom of the lower left side, which can be pushed and pulled out for easy maintenance. - The transmission mechanism is required to have chain tension adjustment (to prevent loosening in the transmission process), and adjustable in the axial direction. Adjustable range 0-30MM. n - PLC control system: production starts: the glass with primer coating is put into the top layer of the time-delayed material rack from the top end, the top sensor senses the glass and presses the button of "drop one frame", the chain will drop one frame; then after the glass is put into the chain, the chain will drop down automatically; take out the glass: when the glass drops down to the tray and reaches the set time, press the button of "drop one frame", the chain will drop down one frame. Remove glass: when the glass falls down to the tray and reaches the set time, press the "In/Out" button, the tray holds the bottom glass and extends out; in the process of extending out, the code scanner will scan the bar code information, if it is not read, the red light will be on to alarm, and it is not until the bar code is scanned that the reset button is available to reset it; the operator can remove the glass from the tray (the ejector will automatically fall down and retract); - Glass removal: the glass is removed from the tray by pressing the "In/Out" button. The operator can remove the glass from the pallet (the ejector automatically drops down and retracts); - The glass removal buttons ① are mounted on the top of the left and right sides (2), with the button box flush with the side of the profile and the buttons extended. - The buttons on the control panel (from left to right) are: Mode knob ②, Control button ③, Down one frame ④, Reset ⑤, Emergency stop button ⑥, the models are shown in the table below. - Three-color light is installed on the right profile (near the rear 1500-high profile). - Electrical control cabinet is placed at the left rear bottom side, size of the cabinet is 400x600). - The rear and side of the cabinet need to be limited (the material is black nylon sheet, two at the rear and one at the side), and the front of the glass for safety protection;

Specification: 3D Model + BOM + Design Specification For Automotive Glass Delay Shelf Equipment SolidWorks 3D Model

|

User Reviews

Be the first to review “3D Model + BOM + Design Specification For Automotive Glass Delay Shelf Equipment SolidWorks 3D Model”

You must be logged in to post a review.

There are no reviews yet.