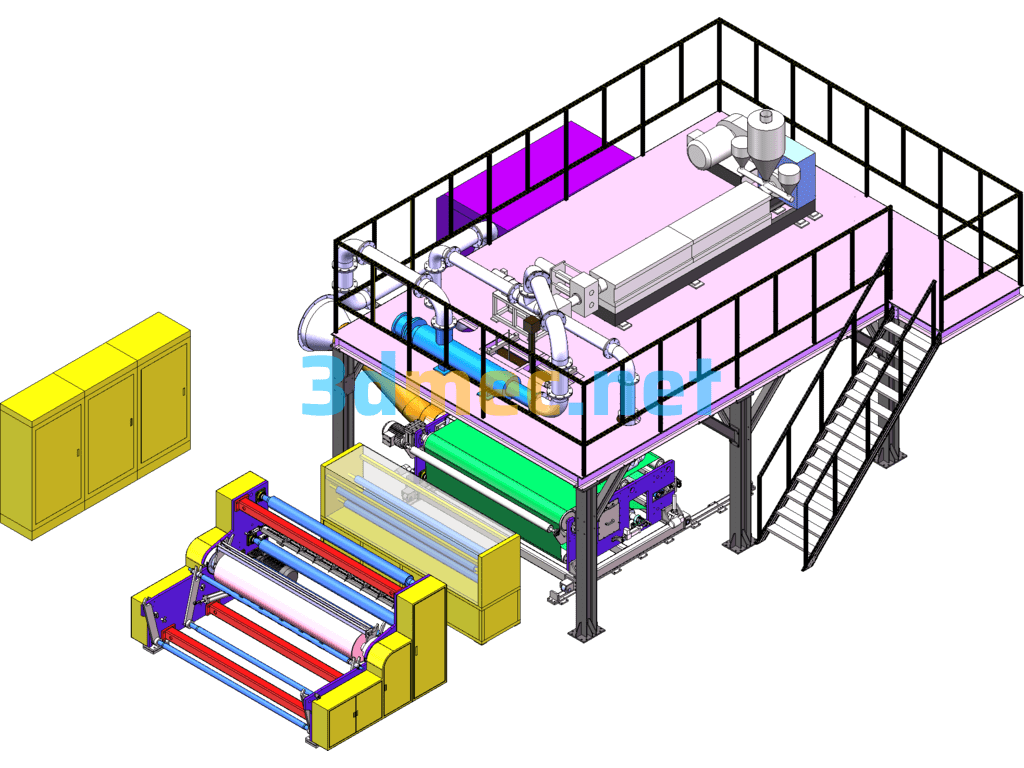

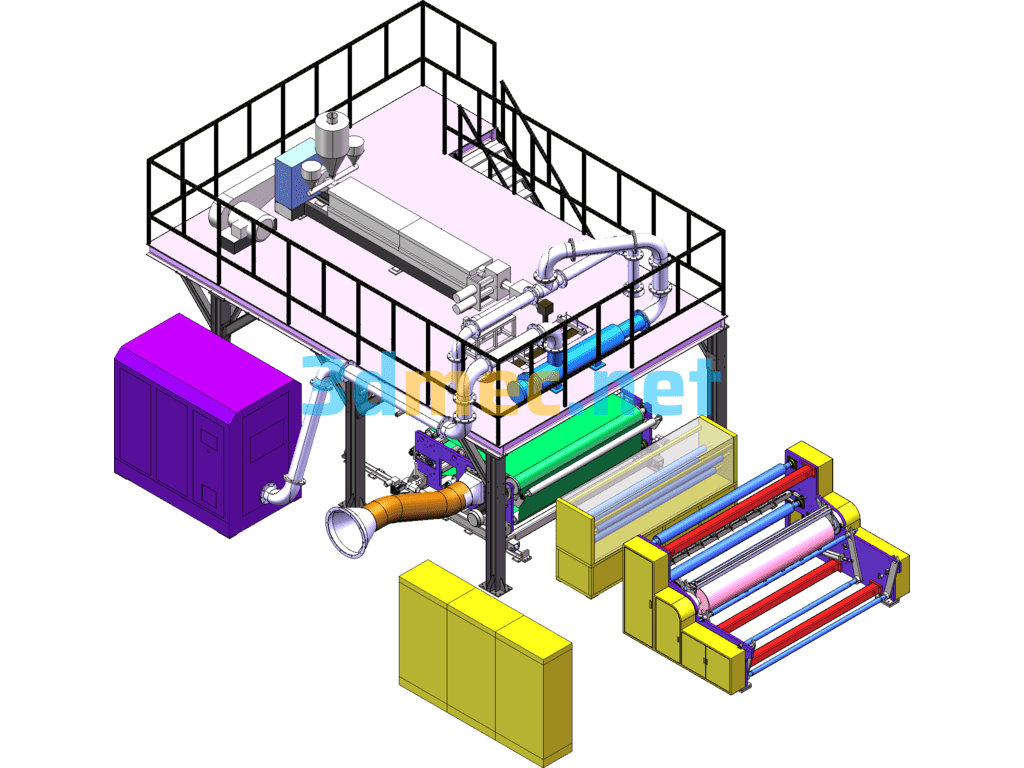

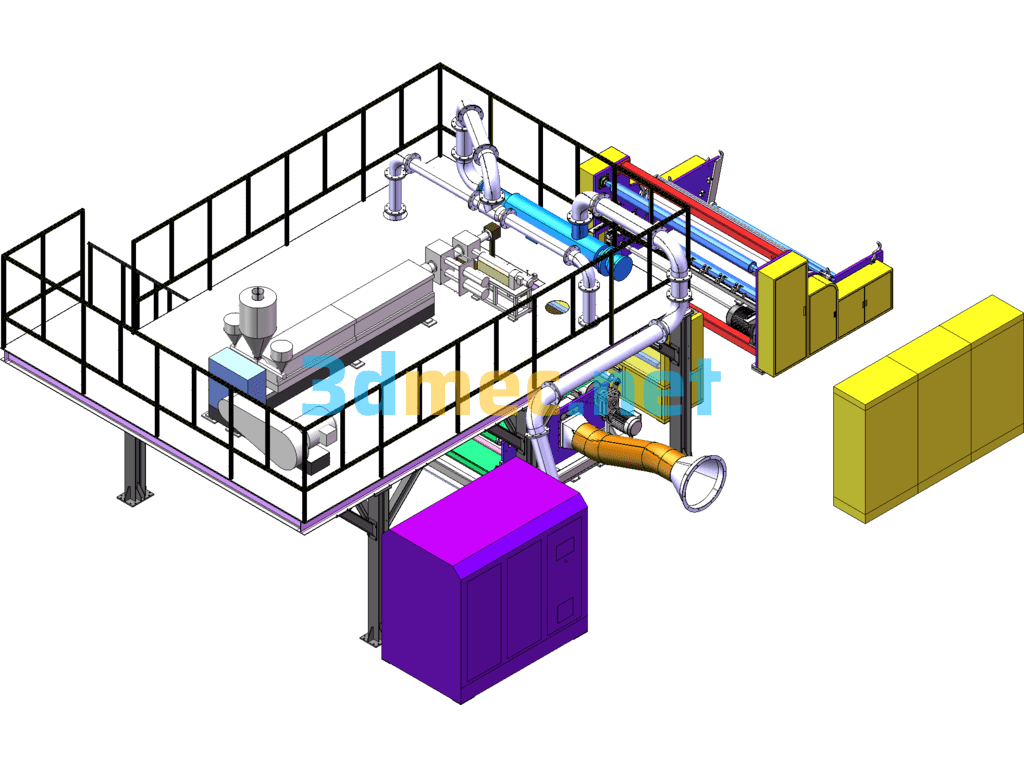

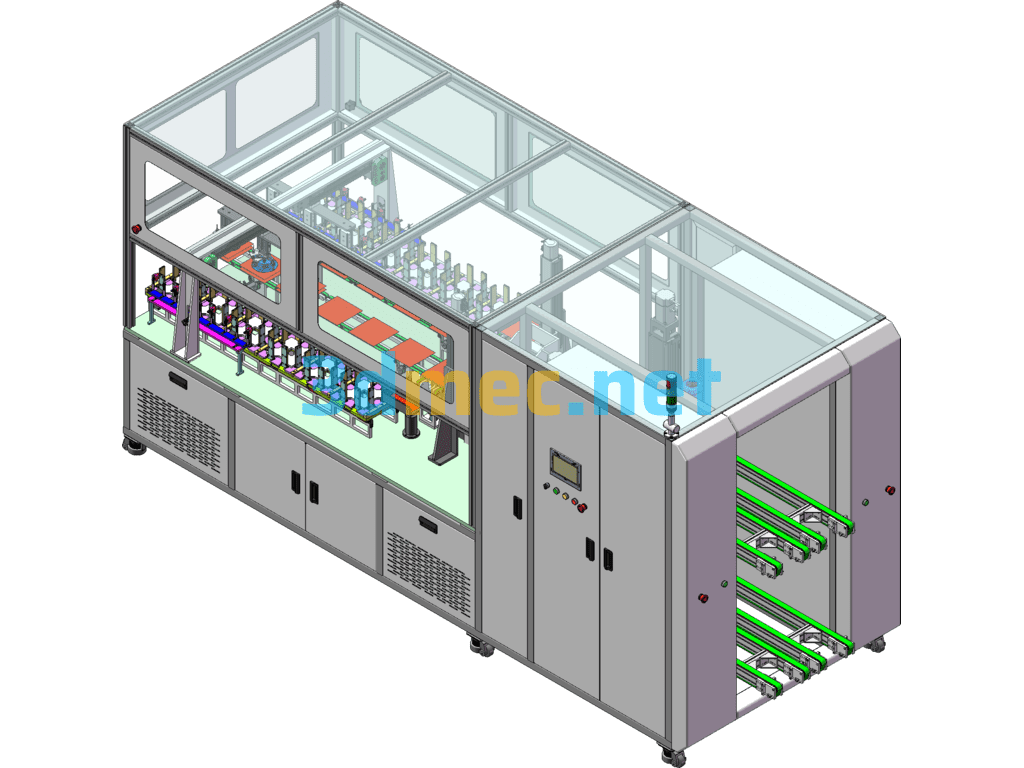

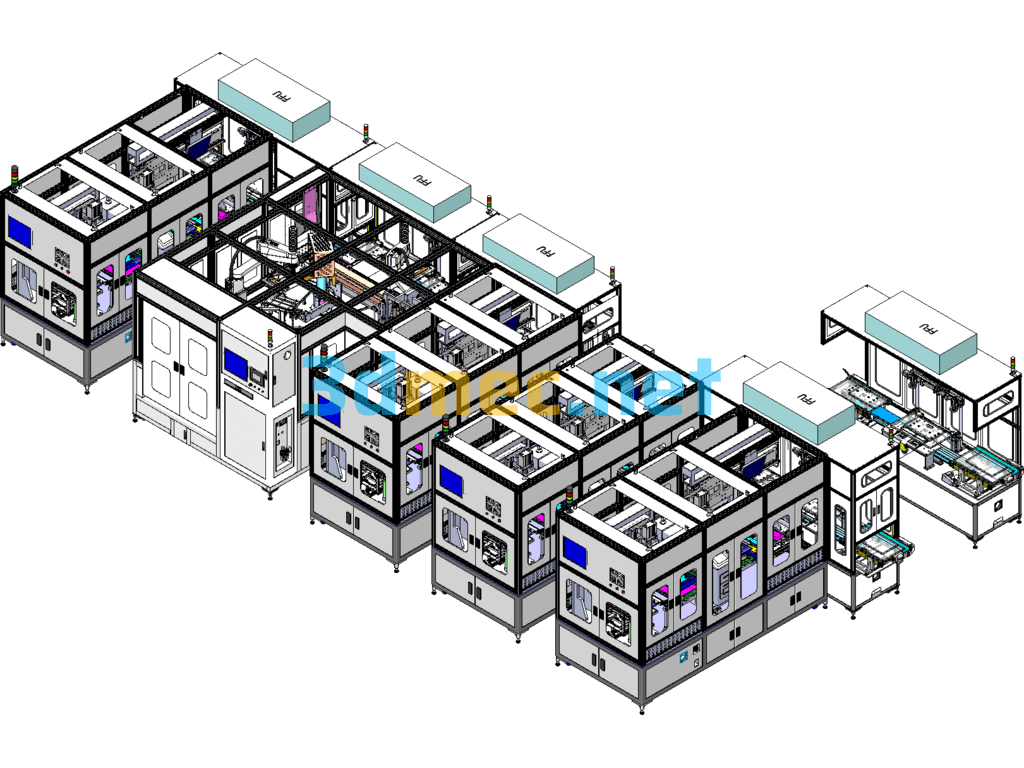

2400 Melt Blown Cloth Production Equipment (Melt Blown Machine) 3D+Engineering Drawing+CAD+PDF – 3D Model SolidWorks

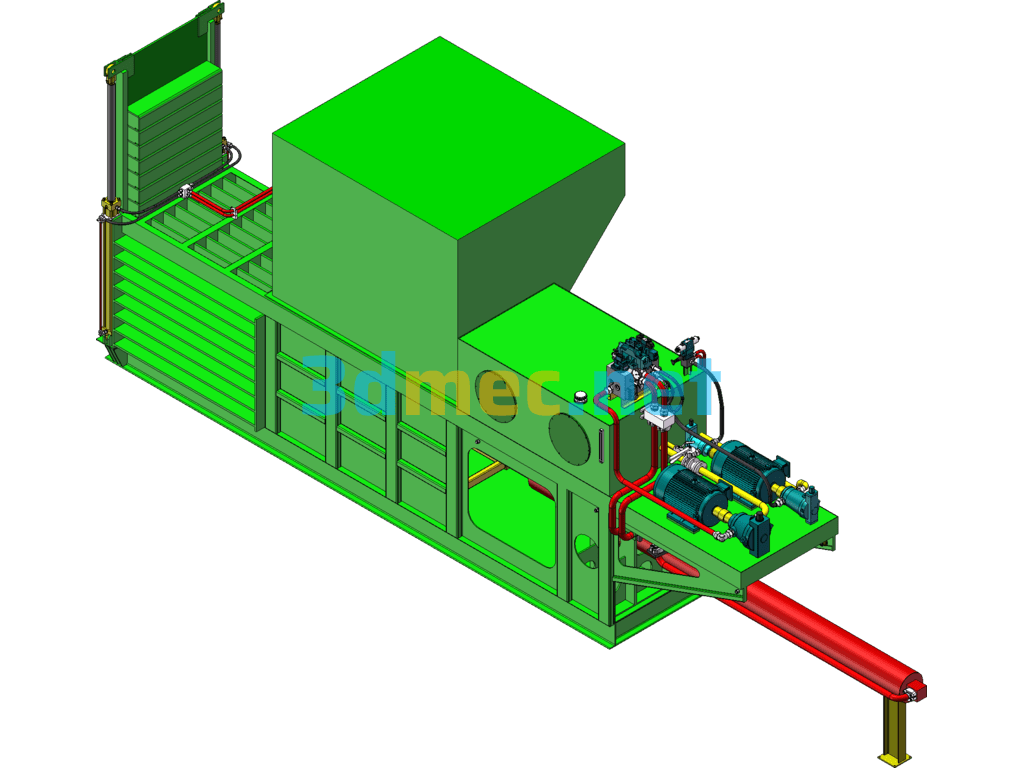

Equipment drawings of a 2400MM wide meltblown fabric production line worth millions of dollars. Meltblown fabric is the “heart” of the mask and is the core filter layer. It has excellent filtering, shielding, thermal insulation and oil absorption properties. The production process of meltblown non-woven fabrics is to dry the PP material and mix it with necessary additives (such as stabilizers, brighteners and masterbatches), then extrude the PP through a screw extruder, and stretch the melt stream through a meltblown die and other auxiliary equipment to form extremely fine fibers, which eventually become meltblown fiber nonwoven fabrics with different widths.

The main machine of the meltblown fabric extruder consists of a screw, a barrel, a transmission system, a barrel heating, a cooling system, a frame, a head connector, an electrical control box and other main parts.

The main uses of meltblown fabric extruder products: sanitary materials, masks, protective clothing, industrial filtration, sound-absorbing materials, automotive filtration, air filtration, liquid filtration, etc.

Specification: 2400 Melt Blown Cloth Production Equipment (Melt Blown Machine) 3D+Engineering Drawing+CAD+PDF – 3D Model SolidWorks

|

User Reviews

Be the first to review “2400 Melt Blown Cloth Production Equipment (Melt Blown Machine) 3D+Engineering Drawing+CAD+PDF – 3D Model SolidWorks”

You must be logged in to post a review.

There are no reviews yet.